How do you know when to backwash your filter?

0:596:02How Often Should You BACKWASH A POOL FILTER? | Swim UniversityYouTubeStart of suggested clipEnd of suggested clipNormal if your pressure gauge is 10 psi or pounds per square inch over your normal operating.MoreNormal if your pressure gauge is 10 psi or pounds per square inch over your normal operating. Pressure it's time to backwash. A high pressure reading means that your filter has accumulated.

How often should I backwash my water filter?

In most cases, the cleaning time is set in the early morning when everyone is asleep. Every 4 to 7 days, the backwashing system gets activated and completes the cleaning process by itself. You do not need to manage the backwashing system personally.

How do you backwash a water treatment plant?

Backwashing involves shutting down filtration and reversing the flow of water to run backwards through the filter at a higher velocity, which dislodges particle build up. Airflow is sometimes used to amplify the cleaning process, either before or during backwashing with water.Nov 27, 2013

Why backwashing of filter is needed?

When the filter's pores become clogged, they need to be cleaned. One of the best ways to clean a drinking water system's filter is to backwash it, meaning reversing the flow and increasing the velocity at which water passes back through the filter. This, in effect, blasts the clogged particles off of the filter.

How long do you rinse after backwash?

Turn the lever to RINSE, start the pump and rinse for about 15-30 seconds. Stop the pump and turn the lever to FILTER. This is the normal operating position. Close the drain outlet valve and start the pump.

How long should a backwash last?

Set the sand filter valve handle to the BACKWASH pool position and ensure the handle locks in place. Turn on the pump and backwash for 2 minutes or until the water in the sight glass (located on the filter) is running clear.

How do you backwash a filter?

This is a pretty straightforward process.Attach the backwash hose to the waste or backwash port.Turn the filter system off.Turn the multiport valve to Backwash.Turn the filter system back on.Let the water run out of the backwash port and through the backwash hose for about a minute, or until the water runs clear.More items...•Mar 10, 2022

What is the rate of backwash water?

Backwashing is the reversal of flow through the filters at a higher rate to remove clogged particles from the filters. Backwash run times can be anywhere from 5–20 minutes with rates ranging from 8 to 25 gallons per minute per square foot of filter bed area, depending on the quality of the pre-filtered water.Nov 22, 2020

Where does the backwash water go?

Backwash pools directly into the private sewer cleanout on your property instead of into the storm gutter. If you are on septic and don't have sufficient area to discharge onto your property, try the following: Hire a contractor to pump the pool water into a truck to be hauled offsite.May 29, 2018

How often should I backwash my carbon filter?

Catalytic carbon backwash filters typically need media changed every 4-6 years. A water softener resin bed normally lasts 5 to 10 years.Oct 19, 2018

How often should you backwash iron filter?

or twice a weekIron filters take this clear iron and transform it to rust or ferric iron in the process known as oxidation in an aerobic environment. These trapped particles are periodically and automatically backwashed out with the flush or backwash of the filter, usually once or twice a week.Jan 16, 2017

What is backwash process?

Backwashing is a process that is used in water and wastewater treatment to pump water backward through filter media, which includes anything placed in a filter that changes the quality of water flowing through it.

How long does a backwash last?

In a standard residential filter, a typical backwash lasts about ten minutes. After the backwash, the control valve initiates a “rinse” of the bed during which water flows downward through the medium, up through the riser tube, and out the drain.

How does backwash work?

The backwash is accomplished by sending water down the riser tube from which it enters the filter tank at the bottom. The force of the water is such that it actually lifts the media bed, swirling and tossing the granular medium.

What is backwashing in water?

Backwashing consists of reversing the flow of water so that it enters from the bottom of the filter bed, lifts and rinses the bed, then exits through the top of the filter tank. The filter bed itself is a granular substance that is usually referred to as the filter medium. Media (media is plural, medium is singular) are numerous and varied.

What is a mineral tank?

Tanks. Called “mineral tanks,” most are made of polypropylene and/or polyethylene with fiberglass reinforcement. Mineral tanks are very strong and usually guaranteed for up to ten years by the manufacturer. Control Valves.

What is the best filter media for iron and manganese?

Granular carbon is the preferred treatment for many chemical contaminants. It is perhaps the most versatile and universal of filter media. Birm. For reduction of iron and manganese, under the right conditions. As iron media go, Birm is relatively light in weight and hence easy to backwash.

What is calcite in water?

Calcite is a sacrificial medium that dissolves as it works and has to be replaced. Centaur Catalytic Carbon. Reduction of chlorine, chloramine, hydrogen sulfide, and iron. A relatively expensive grade of specially prepared carbon, Centaur is a favorite for chloramine removal on city water systems.

What is carbon used for?

Carbon can also remove sediment and even iron if the iron is pretreated properly. It is the most commonly used medium for hydrogen sulfide reduction. Granular carbon is the preferred treatment for many chemical contaminants.

Terminology

Operation

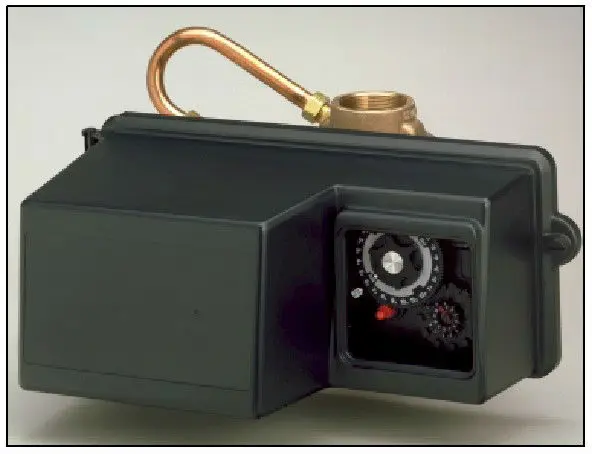

- The picture at right shows the filter in service position. This is how it works when it is doing the job it is designed to do. The unfiltered water enters from the left and is routed by the control valve into the filter tank. The water then filters slowly through the medium until it reaches the bottom of the tank where it is collected through a specially-designed sieved basket at the bottom of the ce…

Example

- Note that there's a drain line in the picture, but no water goes through it during the filter's service function.

Use

- The backwash is an intense rinsing and tossing of the medium that lasts for several minutes. In a standard residential filter, a typical backwash lasts about ten minutes. Centaur Catalytic Carbon. Reduction of chlorine, chloramine, hydrogen sulfide, and iron. A relatively expensive grade of specially prepared carbon, Centaur is a favorite for chlor...

Types

- Tanks. Called mineral tanks, most are made of polypropylene and/or polyethylene with fiberglass reinforcement. Mineral tanks are very strong and usually guaranteed for up to ten years by the manufacturer.

Cost

- Birm. For reduction of iron and manganese, under the right conditions. As iron media go, Birm is relatively light in weight and hence easy to backwash. It is also low in cost, so it's a popular iron medium although it has some drawbacks. A pH of at least 6.8 is normally required for Birm to remove iron.

Purpose

- Calcite. To increase the pH of acidic water. Calcite is a sacrificial medium that dissolves as it works and has to be replaced.

Introduction

- Multi-Media, consisting of layers of such natural elements as garnet, sand, and anthracite: Used for the reduction of sediment and oxidized iron, multi-media filters are slowly being replaced by newer granular zeolite media.

Applications

- Filter Ag, Zeolite, Micro Z. These are all common sediment media. They reduce particles in water down to 20 to 5 microns. These are usually natural zeolite products.

Industry

- Filox. A natural mined mineral, Filox is known for high level iron removal and reduction of hydrogen sulfide odors. It is very dense and requires frequent and intense backwashing.

Details

- Backwash Rate. Backwash flow rates differ significantly from filter to filter.The correct backflow rate is essential to proper operation of a backwashing filter.The correct backwash flow rate is determined by considering the square footage of the surface of the media bed and the density of the media. The filter must have a flow control installed in the drain line to allow a backwash flo…

Advantages

- Service Flow. Service flow of the filter is limited by the size of the tank and the nature of the medium. Some media require longer to work than others. Media are rated according to the service flow they can support by a measurement called empty bed contact time in filter-maker jargon. When the recommended contact time for the medium is violated by excess service flow, the filte…