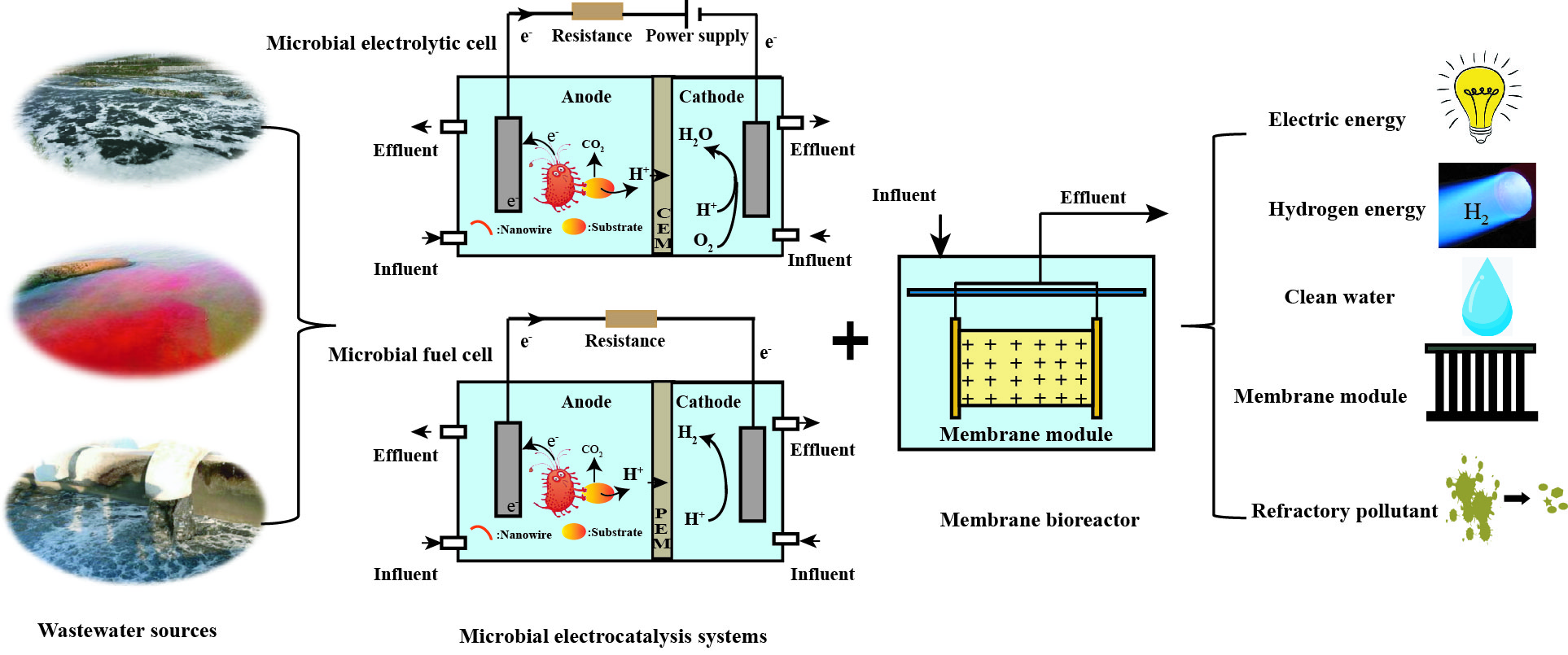

Membrane bioreactor

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor, and is now widely used for municipal and industrial wastewater treatment with plant sizes up to 80,000 population equivalent (i.e. 48 million liters per day).

Can microaerobic membrane bioreactors be used to treat wastewater?

Wastewater Management Fact Sheet . 1 . Membrane Bioreactors . INTRODUCTION The technologies most commonly used for per-forming secondary treatment of municipal wastewater rely on microorganisms suspended in the wastewater to treat it. Although these tech-nologies work well in many situations, they have several drawbacks, including the …

What type of bioreactor is used for wastewater treatment?

Apr 15, 2022 · A Membrane BioReactor (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial WasteWater Treatment Plants (WWTPs). 1) Bioreactor:

What is the role of adsorbent in membrane bioreactors (MBR)?

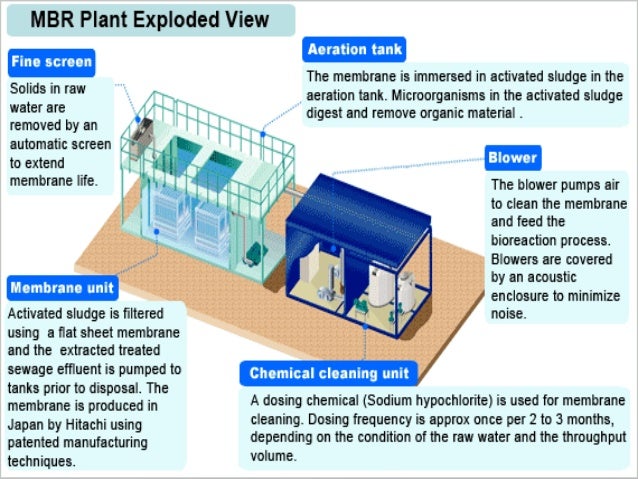

Jun 15, 2016 · The membrane bioreactor (MBR) has emerged as an efficient compact technology for municipal and industrial wastewater treatment. The major drawback impeding wider application of MBRs is membrane fouling, which significantly reduces membrane performance and lifespan, resulting in a significant increase in maintenance and operating costs.

What are the two types of membranes used in wastewater treatment?

Membrane Bioreactor (MBR) is a modern, cost-effective and most efficient wastewater treatment process, which combines a filtration membrane technology for solid-liquid separation together with traditional activated sludge process. With an MBR system, microorganisms are completely trapped in the bioreactor, achieving complete separation between Hydraulic …

What is wastewater membrane bioreactor?

Membrane bioreactor (MBR) is a combination of membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment.

What is membrane bioreactor system?

Membrane Bioreactors combine conventional biological treatment (e.g. activated sludge) processes with membrane filtration to provide an advanced level of organic and suspended solids removal. When designed accordingly, these systems can also provide an advanced level of nutrient removal.Jun 3, 2019

How does membrane reactor work?

Membrane reactors combine reaction with separation to increase conversion. One of the products of a given reaction is removed from the reactor through the membrane, thus forcing the equilibrium of the reaction 'to the right' (according to Le Chatelier's principle), so that more of that product is generated.

What are the advantages of membrane bioreactor?

The MBR technology provides the following advantages over ASP: High-quality effluent, higher volumetric loading rates, shorter hydraulic retention times (HRT), longer solid retention times (SRT), less sludge production, and potential for simultaneous nitrification/denitrification in long SRTs [2,5,13,14,15,16].Jun 15, 2016

What is an MBR in wastewater treatment?

'Membrane bioreactor' (MBR) is generally a term used to define wastewater treatment processes where a perm-selective membrane, eg microfiltration or ultrafiltration, is integrated with a biological process − specifically a suspended growth bioreactor.Jan 16, 2018

What is membrane bioreactor made of?

Membrane Bioreactors (MBRs) consist of a biological reactor with suspended biomass and solids removal by ultra- and microfiltration membranes. These can be used for municipal or industrial wastewaters.

What happens in a bioreactor?

Bioreactors are vessels that have been designed and produced to provide an effective environment for enzymes or whole cells to transform biochemicals into products. In some cases, inactivation of cells or sterilization is carried out in the bioreactor such as in water treatment.

What causes membrane fouling?

Membrane fouling in almost all membrane processes is normally caused by precipitation and deposition of molecules or particulates on the membrane surface or membrane pores. The consequences of membrane fouling are increased membrane separation resistances, reduced productivity, and/or altered membrane selectivity.

What are the advantages and disadvantages of MBR?

Specific advantages and disadvantagesAdvantagesDisadvantagesHigh effluent qualityStress on sludge in external MBRHigh volumetric load possibleMembrane pollutionHigh rate of degradationCost pricePossible to convert from existing conventional active sludge purification1 more row

What are the significant advantages of MBR compared with conventional treatment process?

Compared to the traditional activated sludge process, the membrane bioreactor (MBR) has several advantages such as the production of high-quality effluent, generation of low excess sludge, smaller footprint requirements, and ease of automatic control of processes.

What are the factors that affect MBR?

Membrane composition, membrane module, mixed liquor, sludge, and feed water characteristics, as well as the operational conditions have been among the most prominent factors affecting the membrane performance in terms of fouling.

How does filtration work?

The filtration reduces virus and bacteria by 99.9999%. Filter surfaces are continuously aerated through bubble diffusers to keep them clean. The membranes don’t need regular chemical cleaning except one or two maintenance clearings per year.

What is MENA water?

MENA-Water is developing compact package plants for MBR systems so that more than 1000 m³/day can be filtered in one 40-feet ISO container. The inside tanks are made of stainless steel sheets. Due to the standardized ISO container design the plants can be easily transported and quality testing at factory enables Plug & Play solutions at site.

What is membrane bioreactor?

First things first, let’s define it. A Membrane Bioreactor (MBR) is the combination of a biological reaction stage and a membrane barrier. But to better understand where it comes from, and what it can achieve, let’s go back to the roots of MBRs.

When were membranes invented?

Although membranes had been around since 1748, and the discovery of Osmosis by Jean-Antoine Nollet, their large-scale adoption in the water industry has taken quite a while. The reason is shared by Graeme Pearce in his podcast interview:

What is the primary material used in MBRs?

Depending on the manufacturer ( as for the MABRs ), membranes used in MBRs might be flat sheet or hollow fiber. And their primary material historically was PVDF, but could as well become ceramics.