How does methane come out of a sewage treatment plant?

Gaseous methane formed in rising mains may come out of solution where there is a pressure drop and will most likely be vented to atmosphere via downstream gas release valves. Similarly, dissolved methane will almost certainly be stripped from the sewage when it is discharged to a wastewater treatment plant (WWTP) and aerated.

Does methane production in sewers influence sulphide production and management?

Further, methane production in sewers influences sulphide production and its management due to the competition between methanogens and sulphate-reducing bacteria for potentially the same electron donors. The potential interactions between sulphate-reducing and methanogenic bacteria in sewer networks are discussed. 1. Introduction

What are the sources of methane emissions from wastewater treatment facilities?

The wastewater treatment facilities which handle human faecal matter and urine are an underappreciated source of methane emissions.

What are the activities that release methane?

Fossil fuel production, rice cultivation, biomass burning, and waste management are some of the activities that release methane. In case of organic waste, it is produced from microbial decomposition of organic matter in the absence of oxygen (Anaerobic decomposition).

See more

How is methane produces in wastewater treatment?

When organic waste decomposes in an oxygen-free environment—such as deep in a landfill —it releases methane gas. This methane can be captured and used to produce energy, instead of being released into the atmosphere. Sewage treatment systems begin treating wastewater by collecting the solid sludge.

Where is methane gas produced?

Methane (CH4): Methane is emitted during the production and transport of coal, natural gas, and oil. Methane emissions also result from livestock and other agricultural practices, land use and by the decay of organic waste in municipal solid waste landfills.

Does sewage treatment produce methane?

Municipal wastewater treatment plants emit methane. Since methane is a potent greenhouse gas that contributes to climate change, the abatement of the emission is necessary to achieve a more sustainable urban water management.

Which sewage treatment process produces methane as a byproduct?

Anaerobic digestionAnaerobic digestion reduces the volume of the waste, produces methane for use, and provides a by-product that can be used as fertilizer. In addition to animal waste, plant waste from agriculture can be processed by anaerobic digestion.

How is methane gas produced?

Methane is produced by the breakdown or decay of organic material and can be introduced into the atmosphere by either natural processes – such as the decay of plant material in wetlands, the seepage of gas from underground deposits or the digestion of food by cattle – or human activities – such as oil and gas ...

What is the main source of methane?

Methane emissions get produced wherever there are fossil fuels. It gets released whenever fossil fuels get extracted from the earth. Whether it is natural gas (which is in most part methane), coal or petroleum.

Which decomposition process produces carbon dioxide and methane?

Anaerobic DigestionThe anaerobic digestion process produces gas composed of methane (CH4) and carbon dioxide (CO2), known as biogas.

Which among the following is the best source for methane production?

Water hyacinthWhich among the following is the best source for methane production? Explanation: Water hyacinth is the best source for methane production in the given options.

What gases are produced in anaerobic sludge digesters?

Gases produced in anaerobic sludge digesters are methane, hydrogen sulphide and carbon dioxide.

Where are biomasses collected?

Biomasses (Biowastes) are collected at the biogas plant and the slurry is fed. Biomasses are rich in organic matter. Some of the bacteria can grow anaerobically inside the biogas plant. These bacteria can digest the biomasses which are present in the slurry and sewage.

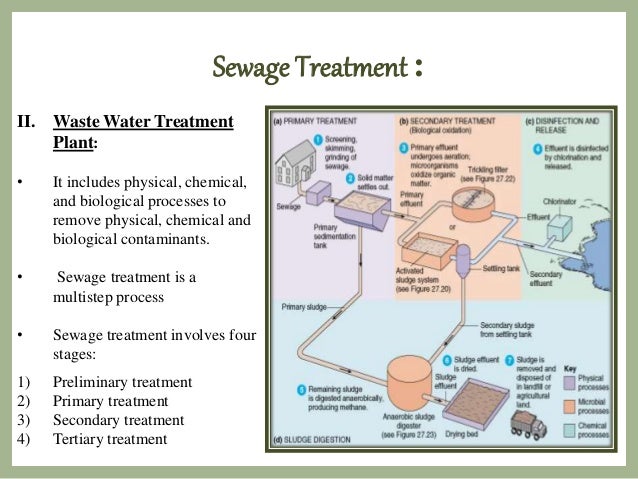

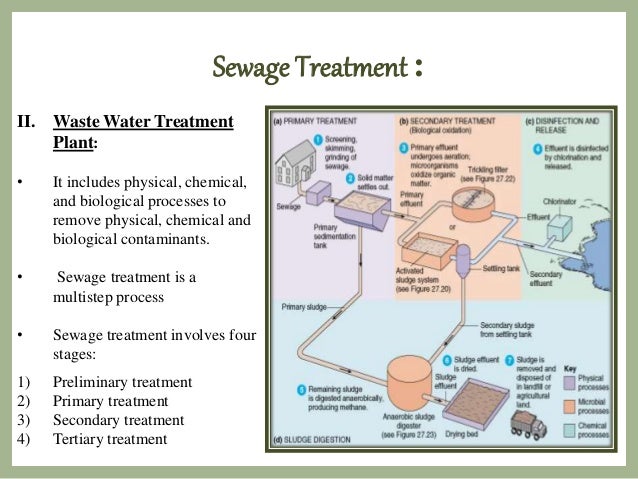

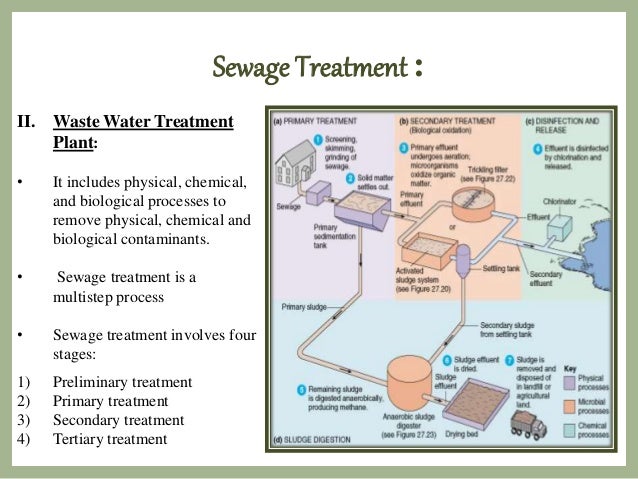

What is biological treatment of sewage?

Biological Treatment: Aerobic microorganisms are inoculated into the sewage treatment plant. These microbes utilize the organic components of the sewage and reduce the toxicity. This can be measured by BOD (Biological oxygen demand). After the biological treatment, the sludge is pumped from the treatment plant into a large tank.

How are biogas and microbial fuel cells used?

Biogas is removed from the biogas plant through a separate outlet. Microbial fuel cells are also used to generate electricity from wastewater. Microbial fuel cells utilize the organic matter from the wastewater treatment plant. During digestion, organic matters are converted into the simple molecule and release the carbon dioxide and electrons.

What is the role of sewage treatment plant?

Hence, Sewage treatment plant design and sewage management play a crucial role in the maintenance of human welfare.

Why is sewage treatment important?

Sewage treatment is necessary to reduce the toxicity of sewage and maintain a safe and healthy environment, as well as promote human welfare.

What happens to organic matter during digestion?

During digestion, organic matters are converted into the simple molecule and release the carbon dioxide and electrons. Those electrons are absorbed by the electrode and used as the source of electricity. To learn more about sewage treatment and energy generation, login to BYJU’S. Test your Knowledge on Sewage Treatment!

What are some activities that release methane?

Fossil fuel production, rice cultivation, biomass burning, and waste management are some of the activities that release methane. In the case of organic waste, it is produced from microbial decomposition of organic matter in the absence of oxygen (Anaerobic decomposition).

What is methane emitted from?

Methane emission from waste water treatment plants can earn carbon revenue. Methane (CH 4) is emitted from both anthropogenic and natural sources. Fossil fuel production, rice cultivation, biomass burning, and waste management are some of the activities that release methane. In the case of organic waste, it is produced from microbial decomposition ...

How can methane be avoided?

Methane emissions can be avoided, however, by treating the wastewater and the associated sludge under aerobic conditions or by capturing methane released under anaerobic conditions. Projects with technology that can capture methane from ...

Where is wastewater treated?

Wastewater from domestic (municipal sewage) and industrial sources are treated in municipal sewage treatment facilities and private effluent treatment plants (ETPs). If the wastewater contains loads of organic constituents (with high Chemical Oxygen Demand- COD) then it is treated anaerobically.

How wastewater produces methane

In the developed world, most wastewater treatment plants function via an aerobic treatment system, which collects and processes all types of human waste efficiently and effectively.

Benefits of methane capture

While many people only associate negative connotations with methane, it’s important to recall that it’s a valuable source of energy. As the principal component of natural gas – responsible for as much as 85% of its composition – methane can be captured and harvested as a fuel.

How can methane be captured from wastewater?

The first step to optimising methane capture and reuse is implementing a robust monitoring system, which takes advantage of all of the latest methane monitoring techniques. In this way, site managers can keep tabs on the performance of their facility and track how much methane is produced – and how much is captured.

Why do municipal wastewater plants emit methane?

Municipal wastewater treatment plants emit methane. Since methane is a potent greenhouse gas that contributes to climate change, the abatement of the emission is necessary to achieve a more sustainable urban water management. This requires thorough knowledge of the amount of methane that is emitted ….

What is the effect of methane on wastewater?

Municipal wastewater treatment plants emit methane. Since methane is a potent greenhouse gas that contributes to climate change, the abatement of the emission is necessary to achieve a more sustainable urban water management. This requires thorough knowledge of the amount of methane that is emitted from a plant, ...

Why should biogas be treated?

Raw biogas should be treated to prevent corrosionof installed equipment or to achieve adequatequality standards for use as a natural gas substitu-te or transport fuel. An overview of available tech-niques for biogas treatment is provided in Table 6.

How do fuel cells work?

Fuel cells make use of direct electrochemical con-version of the fuel with oxygen to generate elec-tricity and heat with near-zero emissions. The fuel(methane in the case of biogas) is converted tohydrogen by the action of a catalyst or high tem-perature steam reforming. The H2is then electro-chemically converted to electricity and heat.Water and CO2are the main by-products. Thepotential electrical efficiency is > 50% while thethermal efficiency is approx. 35%. For utilisationof biogas two fuel cell types are most relevant forthe near future. Phosphoric acid fuel cells (PAFC)are at present applied in a number of 200 kW to2 MW power plants operating on natural gas witha practical electrical efficiency of 41% [46]. ThePAFC operates at approx. 200 ºC which allowsusable heat recovery. Utilisation of biogas in aPAFC requires near-complete removal of sulphi-des and halogenated compounds [46], [50]. InJapan a 200 kWe PAFC is used in a brewery forconversion of biogas from wastewater effluent[51]. Before entering the fuel cell the biogas ispurified in a pre-treatment section composed of adesulphuriser, an ammonia/salt removing unit, abuffer tank and a gas analyser. Impurities are ade-quately removed while at the same time CO2isremoved from the gas. The overall conversion effi-ciency (electricity + heat) is 80% [51]. SolidOxide Fuel Cells (SOFC) operate at temperatures> 900 ºC. The SOFC has a relatively high toleran-ce for impurities, although it also requires near-complete removal of sulphides and halogens. Thehigh operating temperature allows direct methaneconversion and recovery of high temperatureheat. The attainable electrical efficiency on naturalgas is > 40%. In The Netherlands the utilisation ofbiogas from animal manure in an SOFC system iscurrently being explored at farm scale [52]. The utilisation of biogas in fuel cells is an impor-tant strategy to enhance the efficiency of electrici-ty generation. A substantial cost reduction of fuelcells is however required for large-scale applica-tion. The conversion of fermentation gases in fuelcells is being explored in ‘BFCNet’: ‘Network onBiomass Fermentation Towards Usage in FuelCells’ [53]. The objectives of BFCNet includeR&D and demonstration, and the development ofstandards on EU level.

What is anaerobic digestion?

Anaerobic digestion is an established technology for the treatment of wastes and wastewater. The finalproduct is biogas: a mixture of methane (55-75 vol%) and carbon dioxide (25-45 vol%) that can be usedfor heating, upgrading to natural gas quality or co-generation of electricity and heat. Digestion installa-tions are technologically simple with low energy and space requirements. Anaerobic treatment systemsare divided into 'high-rate' systems involving biomass retention and 'low-rate' systems without biomassretention. High-rate systems are characterised by a relatively short hydraulic retention time but longsludge retention time and can be used to treat many types of wastewater. Low-rate systems are general-ly used to digest slurries and solid wastes and are characterised by a long hydraulic retention time, equalto the sludge retention time. The biogas yield varies with the type and concentration of the feedstockand process conditions. For the organic fraction of municipal solid waste and animal manure biogasyields of 80-200 m3per tonne and 2-45 m3 per m3are reported, respectively. Co-digestion is an impor-tant factor for improving reactor efficiency and economic feasibility. In The Netherlands co-digestion isonly allowed for a limited range of substrates, due to legislation on the use of digested substrate in agri-culture. Maximising the sale of all usable co-products will improve the economic merits of anaerobictreatment. Furthermore, financial incentives for renewable energy production will enhance the compe-titiveness of anaerobic digestion versus aerobic composting. Anaerobic digestion systems currently ope-rational in Europe have a total capacity of 1,500 MW, while the potential deployment in 2010 is esti-mated at 5,300-6,300 MW. Worldwide a capacity up to 20,000 MW could be realised by 2010.Environmental pressures to improve waste management and production of sustainable energy as well asimproving the technology’s economics will contribute to broader application.

Is industrial wastewater heterogeneous?

Industrial wastewater is heterogeneous, both incomposition and volume. Effluents from the Food& Beverage (F&B) industry contain the highestconcentration of organic compounds [41].Anaerobic wastewater treatment is widely appliedin this branch of industry as in the Pulp and Paperindustry, as is shown in Table 3 and Figure 14.

Is anaerobic digestion a technique?

Anaerobic digestion is a proven technique and atpresent applied to a variety of waste (water) streams but world wide application is still limitedand a large potential energy source is being ne-glected. Moreover some potential sources, whichare now treated otherwise, are an excellent sub-strate for anaerobic treatment and could contribu-te to renewable energy production rather thanconsuming energy during treatment.