What is a digester in a wastewater treatment plant?

Wastewater Digester. In large wastewater treatment plants, anaerobic digestion is often used to break down organic waste. The process produces digester gas from the decomposition of sewage sludge from primary or secondary clarifiers. Wastewater digester gas is a methane-rich byproduct that can be an energy source.

How is material removed from the digester?

This often includes a third party who is qualified to handle the cleaning and removal of solids out of the digester. This approach employs the mechanical use of hydraulic pumps to mix and remove the contents. The material is extracted to approved transport equipment to haul the materials out of the wwtp.

What can be processed in a food waste digester?

However, digesters built to process food waste can also co-digest other organic materials, such as yard waste, manures and wastewater solids. Demand for stand-alone digesters is increasing to address the increase of diversion of food waste from landfills.

What are the benefits of digesters for agriculture?

Digesters can help farmers manage nutrients, reduce odors, and generate additional farm revenue. Dairy, swine and poultry are the primary animal types for farms with digesters. On-farm digesters can also accept outside food waste as a feedstock.

What is a digester in wastewater treatment?

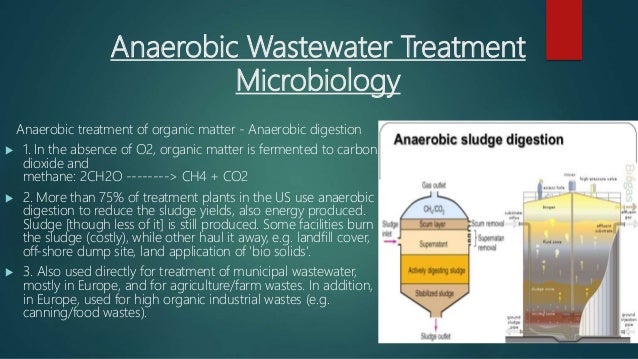

Anaerobic wastewater digester systems are a collection of processes by which microorganisms break down biodegradable material in the absence of oxygen.

Which process occurs in the biogas digester?

Anaerobic digestion is a process through which bacteria break down organic matter—such as animal manure, wastewater biosolids, and food wastes—in the absence of oxygen.

What is the purpose of a digester?

Digesters can help farmers manage nutrients, reduce odors, and generate additional farm revenue. Dairy, swine and poultry are the primary animal types for farms with digesters. On-farm digesters can also accept outside food waste as a feedstock.

What is a digester and how does it work?

Digesters enlist the help of anaerobic bacteria, which exist in environments deprived of oxygen. As the bacteria feed on organic matter, they release methane gas. When this process occurs in an open system, like a landfill or a manure slurry pit, the methane is released into the atmosphere as a greenhouse gas.

What is an anaerobic process?

Anaerobic processes occur in the absence of free or combined oxygen, and result in sulfate reduction and methanogenesis. They usually produce biogas, a mixture of mostly methane and carbon dioxide, as a useful by-product and tend to generate lower amounts of biosolids (sludge) as by-product.

What is the process of biogas?

Biogas is produced when bacteria digest organic matter (biomass) in the absence of oxygen. This process is called anaerobic digestion. It occurs naturally anywhere from the within the digestive system to the depth of effluent ponds and can be reproduced artificially in engineered containers called digesters.

What is a digester chemical?

A digester (alternative: digestor) is a huge vessel where chemical or biological reactions are carried out. These are used in different types of process industries.

What is digester and its types?

Digesters can be classified as passive (covered lagoons), low rate (complete mix, plug flow, mixed plug flow), and high rate (contact stabilization, fixed film, suspended media, and sequencing batch). All reactors perform the same basic function, but each type operates at an optimal manure consistency.

Which methods uses anaerobic digestion?

The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

What is the role of digesters in anaerobic digestion?

Anaerobic digesters are simply an enclosed structure where anaerobic break down of manure organic matter takes place. The anaerobic microorganisms convert the organic matter into biogas, which then can be captured and utilized for energy as a flammable gas.

What does the anaerobic digester do?

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels.

What is the function of a digester when the sludge is brought there?

The sludge then enters the secondary digester. Anaerobic digestion is a biological process which breaks down a significant amount of organic solids in the sludge and at the same time produces methane gas that is used as a boiler fuel for plant heating. Consequently, the volume of final sludge is significantly reduced.

What are digesters used for?

Anaerobic digesters are commonly used in various industrial applications to produce biogas, including: 1 Farms use digesters to exercise manure management for an energy source and co-generation 2 Brewers use digesters in wastewater treatment for pollution prevention and create biogas for use in their boilers reducing natural gas consumption 3 Distillers use digesters to convert their waste to energy and control pollution

Why do farmers use digesters?

Farms use digesters to exercise manure management for an energy source and co-generation. Brewers use digesters in wastewater treatment for pollution prevention and create biogas for use in their boilers reducing natural gas consumption. Distillers use digesters to convert their waste to energy and control pollution.

What is the gas produced by anaerobic digestion?

Anaerobic digestion at WW treatment plants produces wastewater digester gas, which is a methane-rich byproduct that can be an energy source. Digester gas is a form of biogas. The composition of wastewater digester gas varies, though the primary constituents are methane (CH4) and carbon dioxide (CO2). Trace amounts of nitrogen gas (N2), oxygen gas ...

What is an easy in-situ calibration method?

Easy in-situ calibration verification method to verify the accuracy and operation of the sensor and transmitter

Can biogas be used to heat a digester tank?

The biogas can (burned in engines) create electricity or even heat the digester tank to speed up the decomposition. Additionally, the digester gas, at times, can be supplemented with natural gas, can heat the facility. Digester gas is also dirty and wet and often condenses, causing a build-up in the pipe and probes inside the piping.

Headworks (Pretreatment)

In the pretreatment process, large bar screens remove rags, sticks, rocks, and other debris that could otherwise clog machinery. Grit chambers remove heavier objects like sand and gravel.

Primary Treatment

This 24-hour physical process removes about 50 percent of wastewater contaminants. In large tanks, the flow is slowed to allow gravity to separate large particles. This process mimics the natural processes of creeks and rivers, where sediments settle to the bottom.

Digesters

The pollutants and solid material removed during the three treatment steps are put in digester tanks.

Secondary Treatment

Aeration: Aeration tanks pump air into the wastewater to nurture the growth of naturally occurring aerobic bacteria that remove organic pollutants in the wastewater

Tertiary Treatment

Tertiary treatment is the third and final process. During tertiary treatment, wastewater flows through several filter beds composed of gravel, sand and anthracite coal to remove small suspended solids.

Outfall Channel

After tertiary treatment, about 80% of the treated water is piped to the outfall channel. From here, it flows to Artesian Slough, through Coyote Creek, and eventually into the South San Francisco Bay. Many birds and fish are found at the outfall channel, including stripers, black bass, and salmon.

Valuable outputs from Biogas Digester: Biogas and Digestate

Biogas consists of a relatively high percentage (50-75%) of methane (CH4), the main component of natural gas, as well as carbon dioxide (CO2), hydrogen sulfide (H2S), water vapor, and traces of other gases. Like natural gas, the energy contained in biogas can be used to generate heat and electricity.

Biogas Digester as Problem Solver

The increasing substitution of fossil fuels, such as natural gas, by biogas, would dramatically improve the climate balance. Biomass is probably the most underestimated natural and never-ending resource in the world.

Dry Anaerobic Digestion Technology

Dry Anaerobic Digestion with a Biogas Digester has proven to be the optimal technology for the utilization of these organic residues and wastes, which are predominantly available worldwide in a solid and stable form. This is regarded as the new generation of biogas technology.

Biogas Digester Technology for a Renewable World

Our lighthouse project in Sundern, Germany, is a prime example of sustainability and closed cycles with worldwide impact. At the Hellefelder Höhe composting plant near Sundern, Germany, 20,000 tonnes of biowaste from surrounding communities are recycled annually.

Renergon Simultaneous Digestion (RSD)

The Renergon process is the anaerobic degradation of organic matter for biogas production by percolation. The organic matter is mainly solid, rich in structure, and stackable. This process is called Solid-State Fermentation – other terms can be: Dry Fermentation, High Solids Anaerobic Digestion (HSAD) or Solid-State-Anaerobic Digestion (SSAD).

What is the term for the combination of multiple organic materials in one digester?

Multiple organic materials can be combined in one digester, a practice called co-digestion. Co-digested materials include manure; food waste (i.e., processing, distribution and consumer generated materials); energy crops; crop residues; and fats, oils, and greases (FOG) from restaurant grease traps, and many other sources.

What is digestestate in biology?

Digestate is the residual material left after the digestion process. It is composed of liquid and solid portions. These are often separated and handled independently, as each have value that can be realized with varying degrees of post processing.

What are the two outputs of anaerobic digestion?

Anaerobic digestion produces two valuable outputs: biogas and digestate.

What is Agstar project development?

AgSTAR Project Development Handbook. Compilation of the latest knowledge in the industry on best practices for AD/ biogas systems. Contains information about AD applications and processes, benefits, challenges, feedstocks, products, economic and financial factors, and more.

What is anaerobic digestion?

Anaerobic digestion is a process through which bacteria break down organic matter—such as animal manure, wastewater biosolids, and food wastes—in the absence of oxygen. Anaerobic digestion for biogas production takes place in a sealed vessel called a reactor, which is designed and constructed in various shapes and sizes specific to ...

How does co-digestion increase biogas production?

Co-digestion can increase biogas production from low-yielding or difficult-to-digest organic waste. The following figure illustrates the flow of feedstocks through the AD system to produce biogas and digestate.

How is biogas used?

The energy in biogas can be used like natural gas to provide heat, generate electricity, and power cooling systems, among other uses. Biogas can also be purified by removing the inert or low-value constituents (CO2, water, H2S, etc.) to generate renewable natural gas (RNG).

What happens in a second stage digestor?

In the second stage digestor, which may be heated, or unheated, separation of supernatants accompanied with a reduction in the volume of sludge due to gravi ty thickening takes place, and digestion is completed.

How is compressed gas injected into digesting sludge?

Compressed gas is injected into the digesting sludge by a network of small diameter pipes suspended from the cover.

What is the name given to the process when all three steps are followed?

To summarise, if the first two processes are used in the sludge digestion system, it is known as Aerobic Sludge Digestion. Anaerobic Sludge Digestion is the name given to the process when all three steps are followed.

Why is aerobic sludge digested?

When comparing the two processes, the aerobic procedure helps to minimize impurity concentrations, If we digest sludge aerobically, contaminants will be increased, resulting in more sludge, which is harder to handle and expensive.

How is sludge mixed in a high rate digester?

In a high-rate digester, the sludge is more or less continuously added and vigorously mixed either mechanically or by recirculating a portion of digestion gases through a compressor.

How many stages of anaerobic digestion?

If we consider only anaerobic sludge digestion then there are 3 stages.

Where is digested sludge drawn from?

The digested sludge is withdrawn from the tank bottom. The supernatant is drawn from the digestor through any one of the series of pipes extending out of the tank wall (See in the figure).