Types of Heat Treating

- Hardening. In this process, the metal is heated to a temperature which causes the elements in the metal to switch to being a solution.

- Anealing. In the annealing process, various metals such as aluminum, steel, copper, brass or silver are heated to a set temperature and held there for a certain amount of time ...

- Case Hardening. This process allows the surface of the metal to be hardened while keeping the interior soft. Low carbon iron and steel has to have carbon-infused into the surface.

- Tempering. Tempering is a process by which heat treating is used to increase resilience in iron-based alloys such as steel.

- Normalizing. This is a type of annealing process for steel which heats it to 150-200°F higher than in typical annealing.

What is heat treatment of metals?

Mar 19, 2021 · Generally, heat treatment of steel involves the heating and cooling of the material. The metal or alloy is heated to a specific temperature. Then, cooling occurs to harden the heated material. The process aims towards changing the microstructure of the metal. Also, it helps to bring out desired mechanical, chemical, and physical characteristics.

What are the different types of heat treatment steel?

Dec 08, 2017 · It is estimated that over 80% of all industrial heat treatment processes are performed on steel, however a number of other ferrous and non-ferrous metals are also heated and cooled for similar purposes. Ferrous heat-treated metals often include cast iron, alloys, stainless steel and tool steel, whereas some heat-treated non-ferrous metals include …

What is heat treatment used for in manufacturing?

Jul 14, 2020 · Normalizing only applies to ferrous metals like steel. But there’s another key difference in the heat treatment process: when normalizing, after the metal is heated to a higher temperature, it is air-cooled after removal from the furnace. Normalized steel is …

Can non ferrous metals be heat treated?

The heat treatment process can be applied to ferrous metals such as cast-iron, AHSS, stainless steel and other alloy steels, as well as non-ferrous metals such as aluminium, magnesium, titanium, copper, or brass [2].

What metals are suitable for heat-treating?

What is heat treatment materials?

What are the four types of heat treatment?

- Annealing. Annealing is a heat treatment process used to modify the microstructure of a metal to improve its ductility while reducing internal stress and overall hardness. ...

- Hardening. ...

- Quenching. ...

- Stress Relieving.

What is heat treatment process of metals?

Why heat treatment of steel is done?

What is heat treatment of carbon steel?

Can you heat treat stainless steel?

Austenitic stainless steels cannot harden via heat treatment. Instead, these steels work harden (they attain hardness during their manufacture and formation). Annealing these stainless steels softens them, adds ductility and imparts improved corrosion resistance.Feb 9, 2018

What is metal annealing?

What is case hardened steel?

What are the three types of heat treatment?

- Heat Treatment Steel: Annealing.

- Heat Treatment Steel: Normalizing.

- Heat Treatment Steel: Hardening.

- Heat Treatment Steel: Tempering.

What is the most important heat treatment for hardening steels?

What are the three stages of heat treatment?

- Heating: Heating is the first stage in a heat-treating process. ...

- Soaking: Soaking is the stage at which the complete part of the heated metal completely changes in its structure. ...

- Cooling: The third stage of heat treatment is cooling.

What is heat treating metal?

Heat treating metal consists of systematically heating the material to a critical temperature and then cooling it to modify the material’s physical state or mechanical properties. The high-temperature target, how long it remains at that temperature, and then how rapidly, or gradually, the item is cooled is what determines ...

What is secondary heat treatment?

A secondary heat treatment process requires heating the material to a temperature lower than the critical temperature used in the methods above, and then slowly cooling the part. This process is referred to as stress relieving.

What is the process of annealing?

The annealing process changes the physical structure of the material , making it softer and more malleable.

What is a quenching material?

Typical quenching materials include water and oil, however, gases, polymers, or salts are sometimes used depending upon the final desired mechanical properties of the part.

How to cryogenically treat a part?

Cryogenic treating. Components can also be cryogenically treated by slowly lowering the temperature of a part in liquid nitrogen, leaving it in that state for a defined period, and then putting the part through a more standard heat treatment process. This cryogenic treating results in a more corrosion resistant piece.

What is a retort furnace?

Retort furnaces are optimal for the continuous heat treating of small parts. Cryogenic, air and vacuum processing are often used for stress relief. When used for stress relief, these processes do not change the material’s mechanical or chemical properties.

What are the advances in metalworking?

These advances continually offer manufacturers improved opportunities in terms of component accuracy, material strength, forming options, surface finishes, and pricing of materials. Advances that yield better components while maintaining competitive pricing.

What is heat treated metal?

Heat Treated Metals and Their Uses. The process of heat-treating metals on the industrial scale primarily serves to improve the overall properties of the metals required for their future use. Such metal properties can include toughness, hardness, ductility, machinability, refined grain structure, removal of residual stresses ...

Why is tempered metal used?

Tempering. Metals are often tempered to improve their overall hardness and toughness following other heat treatment processes such as neutral hardening and other hardening processes to achieve a desired hardness/toughness ratio of the metal’s final product.

What are the properties of metals?

Such metal properties can include toughness, hardness, ductility, machinability, refined grain structure, removal of residual stresses and an overall improvement in the wear resistance. The specific techniques used to both heat and cool metals are not only specific to the metal of interest, but also the applied industry.

What is annealing metal?

To soften metals in an effort to improve their overall ductility, annealing is a form of heat treatment that heats metals past their temperature to ultimately change their microstructure. Following such high heat exposure, metals are then slowly cooled to allow for further processing while eliminating any potential for cracking of the metal.

What metals are annealed?

While steels are most often annealed, other metals to undergo this process can include copper, aluminum and brass.

What temperature is used to temper steel?

300-500°C: Most often used to temper spring steels or similar applications. > 500 °C: High temperature tempering; used to quench and temper steels that will be applied for hot working tool and/or high-speed steels. Quenching.

What is neutral hardening?

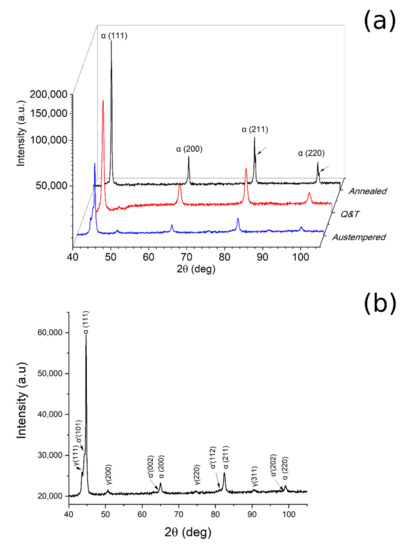

Neutral Hardening: Typically performed on steel, this heat treatment process initially involves quenching and tempering of the metal to retain a final martensite or bainite microstructure. Neutral hardening of steel can improve the heavy loading potential of the metal while simultaneously improving its strength, ...

What metals can be heat treated?

A huge majority of heat-treated metals consist of steel, including cast iron, stainless steel, and some alloys. However, non-ferrous metals such as aluminum, titanium, copper, and brass can also be heat treated.

What is the process of heat treating metal?

Listed below are some of the most common heat treatment techniques, how they are done, and the resulting changes they make on the metal. 1. Annealing. Annealing is a process where the metal is heated to a specific temperature, then cooled very slowly.

What is annealing metal?

Annealing. Annealing is a process where the metal is heated to a specific temperature, then cooled very slowly. This results in changes in the metal’s microstructure, often influencing its ductility, machinability, and electrical conductivity. Steel is the most common material to which annealing is done, but it’s also possible to anneal non-ferrous ...

What happens when a metal is heated?

Normalizing occurs when a metal is heated beyond its upper critical temperature. At this point, the recrystallization of the particles in the metal becomes possible, resulting in a more ordered microstructure. This eliminates the hardness that the metal may have as a result of cold working.

Why do we temper metal?

Tempering is typically done after quenching to also help relieve any internal stresses built up in the metal because of the quenching process.

What is heat treating?

Heat treating refers to a set of metalworking techniques designed to alter the physical and chemical properties of metals. These properties may include a metal’s hardness, ductility, malleability, toughness, grain structure, and resistance to wear and tear. Heat treating is an important industrial process that is done for about 90% ...

How does tempering work?

Tempering is done by heating the metal to below its critical temperature and allowing it to be air-cooled. The temperature to which the metal is heated determines how much hardness is removed. The chemical composition of the metal also plays a role in its optimal tempering temperature.

How to anneal ferrous metals?

To anneal steels and other ferrous metals to produce the highest level of ductility, you must heat the metal slowly to the appropriate temperature, soak it, and then allow it to cool slowly by either burying it in some sort of insulating material or by simply turning off the furnace and letting both the furnace and the part cool slowly together.

How to harden steel?

To harden most steels, you would use the first two stages of heat treatment (slow temperature heat followed by soaking by a specified time to a uniform temperature), the third stage is different. When you harden metals, you rapidly cool them by plunging them into water, oil, or brine.

What is the purpose of annealing steel?

Heat Treatment Steel: Annealing. The purpose of annealing is to do the opposite of hardening. You anneal metals to relieve stress, soften the metal, increase ductility, and improve their grain structures. Without an appropriate preheating stage, welding can lead to a metal with uneven temperatures, even molten areas next to areas ...

Why is steel normalized?

The purpose of normalizing is to remove any internal stresses from heat treatment, machining, forging, forming, welding, or casting. Metal failure can result from uncontrolled stress, so normalizing steel before any hardening can help ensure the success of projects.

Why is normalizing steel important?

The purpose of normalizing is to remove any internal stresses from heat treatment, machining, forging, forming, welding, or casting. Metal failure can result from uncontrolled stress, so normalizing steel before any hardening can help ensure the success of projects.

Is normalized steel stronger than annealed steel?

Normalized steel is stronger than annealed steel. With both high strength and high ductility, it is tougher than annealed steel. If the metal part needs to withstand impact or have maximum toughness to resist external stresses, it is usually recommended that it is normalized rather than annealed.

Does hardening steel make it stronger?

The intent of hardening is not just to harden the steel, but also to make it stronger. Unfortunately, there aren’t just plusses to hardening. While hardening does increase strength, it also decreases ductility, making the metal more brittle.

What metals can be treated with heat treatment?

The heat treatment process can be applied to ferrous metals such as cast-iron, AHSS, stainless steel and other alloy steels, as well as non-ferrous metals such as aluminium, magnesium, titanium, copper, or brass [2].

How to heat treat a sandpaper?

Heat treatment processes require the following three main steps [2]: 1 Heating the material to a specific temperature (in the range of up to 2400 °F / 1316 °C) 2 Soaking, or maintaining the specific temperature for a certain amount of time (varying from seconds to more than 60 hours) 3 Cooling at a suitable rate following prescribed methods. The material can be cooled rapidly, slowly (in the furnace), or can be quenched (using water, brine, oils, polymer solutions, salts, or gases).

What is case hardening?

This is also known as case hardening. It includes over a dozen treatments in which the surface of the material is hardened creating a hard ‘case’ while the core remains tough or soft. This provides improved wear resistance for parts such as gears, cams and sleeves. This process is one of the most common for steel and iron.

What is the process of quenching?

This rapid cooling process is known as quenching and is generally applied to stainless and high-alloy steels, primarily to produce controlled amounts of martensite in the microstructure and obtain increased hardness [2]. Hardening is often used in cast-irons and steels alloyed with metals such as nickel and magnesium.

Why do metals need heat treatment?

The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance. Common techniques for heat treatment include the following: Annealing is a form of heat treatment that brings a metal closer to its equilibrium state.

How does heat affect metal?

Effects of Heat on Metal. Subjecting metal to extreme heat causes it to expand in addition to impacting its structure, electrical resistance, and magnetism. Thermal expansion is pretty self-explanatory. Metals expand when subjected to specific temperatures, which vary depending on the metal.

Why does metal expand?

Subjecting metal to extreme heat causes it to expand in addition to impacting its structure, electrical resistance, and magnetism. Thermal expansion is pretty self-explanatory. Metals expand when subjected to specific temperatures, which vary depending on the metal. The actual structure of metal also changes with heat.

What is annealing metal?

Annealing is a form of heat treatment that brings a metal closer to its equilibrium state. It softens metal, making it more workable and providing for greater ductility. In this process, the metal is heated above its upper critical temperature to change its microstructure. Afterward, the metal is slow-cooled.

What is the process of quenching metal?

The quenching process stops the cooling process from altering the metal's microstructure.

How does normalizing metal work?

After this process, the metal is then slowly cooled. Normalizing is a form of heat treatment that eliminates impurities and improves strength and hardness by altering the grain size to be more uniform throughout the metal. This is achieved by cooling the metal by air after it has been heated to a precise temperature.

What happens to metals when they are heated?

The actual structure of metal also changes with heat. Referred to as allotropic phase transformation, heat typically makes metals softer, weaker, and more ductile. Ductility is the ability to stretch metal into a wire or something similar. Heat also can impact the electrical resistance of metal.

How does heat treatment affect metal?

Heat treating can affect a number of different aspects of the metal including strength, hardness, toughness, machinability, formability, ductility, and elasticity. It can also affect the physical and mechanical properties of metal to change the use of the metal or alter future work on the metal.

What is heat treating?

Heat treating is a pre and post-manufacturing process which is used to change a number of properties of metals and their alloys. The primary use of heat treating is to make the metal suitable for a particular application.

What is the process of annealing?

Anealing. In the annealing process, various metals such as aluminum, steel, copper, brass or silver are heated to a set temperature and held there for a certain amount of time so that a transformation occurs, it is then air-cooled.

What metals are annealed?

In the annealing process, various metals such as aluminum, steel, copper, brass or silver are heated to a set temperature and held there for a certain amount of time so that a transformation occurs, it is then air-cooled.

What is case hardening?

Low carbon iron and steel has to have carbon-infused into the surface. Case hardening is used as a final step after the part has been machined. The process itself used high heat in combination with various elements and chemicals to achieve the hardened layer.

What is the process of tempered metal?

Tempering. Tempering is a process by which heat treating is used to increase resilience in iron-based alloys such as steel. The natural properties of iron-based metals make them very hard but also brittle, in fact, they may be too brittle for the most common uses.

What is tempering metal?

Tempering is a process by which heat treating is used to increase resilience in iron-based alloys such as steel. The natural properties of iron-based metals make them very hard but also brittle, in fact, they may be too brittle for the most common uses. By tempering the metal, it’s hardness, ductility and strength can be changed to make it easier to machine.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

How to increase hardness of metal?

Hardening. As the name suggests, hardening is used to increase the hardness of a metal. This is usually done by heating the metal above normalization temperature, keeping it at normalization temperature, and then rapidly quenching ( Cooling) it in water, oil, or brine solution. The heat required depends on the size and the required mechanical ...

What is process annealing?

Process annealing is done when metal is heated below the critical temperature, keep it for a suitable time, and then cool it slowly. This process is suitable for low carbon steel like sheet metal and wires. No phase transformation occurs during process annealing, and it’s considerably cheaper than full annealing.

What is the process of hardening metal?

After that, the metal piece is cooled into lime water so that cyanide salt is sticking to the outer surface of the metal. This cyanide salt is responsible for hardening the outer surface of the metal.

What is the process of cooling a metal piece quickly after it is heated?

Quenching is a process of cooling a metal piece quickly after it was heated. Quenching helps metals to become harder or softer depending upon whether it’s a ferrous or non-ferrous alloy. In the case of ferrous alloy, quenching helps to make it harder, but it becomes softer in the case of non-ferrous.

What is the first step in heat treatment?

The first step in the heat treatment process is heating the metal. The temperature depends on the types of metal and the technique used. Sometimes you need to heat the outer surfaces of the metal, and sometimes you need to heat the whole body. That depends on what kind of alteration you want in the mechanical structure.

What happens after holding a furnace?

After the holding process, cooling starts. The cooling must be done in a prescribed manner. During cooling, there are some structural changes occur. Different media such as water, oil, or forced air is used to aid in cooling. You can also use furnaces for cooling purposes as the control environments help inefficient cooling.

What is heat treatment?

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating ...

What is a heat treating furnace?

Heat treating furnace at 1,800 °F (980 °C) Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass.

What is the difference between alpha and gamma iron?

The alpha iron has no spaces for carbon atoms to reside , while the gamma iron is open to the free movement of small carbon atoms.

What happens when an alloy is cooled to an insoluble state?

If the alloy is cooled to an insoluble state, the atoms of the dissolved constituents (solutes) may migrate out of the solution. This type of diffusion, called precipitation, leads to nucleation, where the migrating atoms group together at the grain-boundaries.

What is the temperature of steel?

For instance, steel that has been heated above the austenizing temperature (red to orange-hot, or around 1,500 °F (820 °C) to 1,600 °F (870 °C) depending on carbon content), and then cooled slowly, forms a laminated structure composed of alternating layers of ferrite and cementite, becoming soft pearlite.

What is the melting point of a hypoeutectic alloy?

A hypoeutectic alloy has two separate melting points. Both are above the eutectic melting point for the system but are below the melting points of any constituent forming the system. Between these two melting points, the alloy will exist as part solid and part liquid. The constituent with the lower melting point will solidify first. When completely solidified, a hypoeutectic alloy will often be in a solid solution.

What is annealing in metals?

Annealing consists of heating a metal to a specific temperature and then cooling at a rate that will produce a refined microstructure, either fully or partially separating the constituents. The rate of cooling is generally slow. Annealing is most often used to soften a metal for cold working, to improve machinability, or to enhance properties like electrical conductivity .

What Is Heat Treating?

Types of Heat Treating

- There are many heat treatment types, and one or more of these processes can be applied to any given component. The desired mechanical, magnetic, or electrical properties of the final part will define which steps to include.

Heat Treating Processes

- Each of the types of heat treating listed above can be achieved through one or more different processes. Annealing is one of the most common heat treatments and is achieved through retort, air, or vacuum processing. Retort furnaces are optimal for the continuous heat treating of small parts. Cryogenic, air and vacuum processing are often used for stress relief. When used for stre…

Benefits of Heat Treating Metal

- Hardening is a typical desired outcome of the heat treatment process. Selectively applying that process to a limited section of a component allows for localized hardening. Creating a specific finish on just the surface of a piece is another example of selective heat treating. An additional reason to incorporate heat treatments is to upgrade a particular characteristic of the metal or all…

Manufacturers and Heat Treatment

- The history of metalworking is impressive, and modern technology in metalworking continues to break new ground. These advances continually offer manufacturers improved opportunities in terms of component accuracy, material strength, forming options, surface finishes, and pricing of materials. Advances that yield better components while maintaining competitive pricing. The ind…