What are the best metals for conducting heat?

Jul 14, 2020 · Normalizing only applies to ferrous metals like steel. But there’s another key difference in the heat treatment process: when normalizing, after the metal is heated to a higher temperature, it is air-cooled after removal from the furnace. Normalized steel is …

What is the most heat resistant steel?

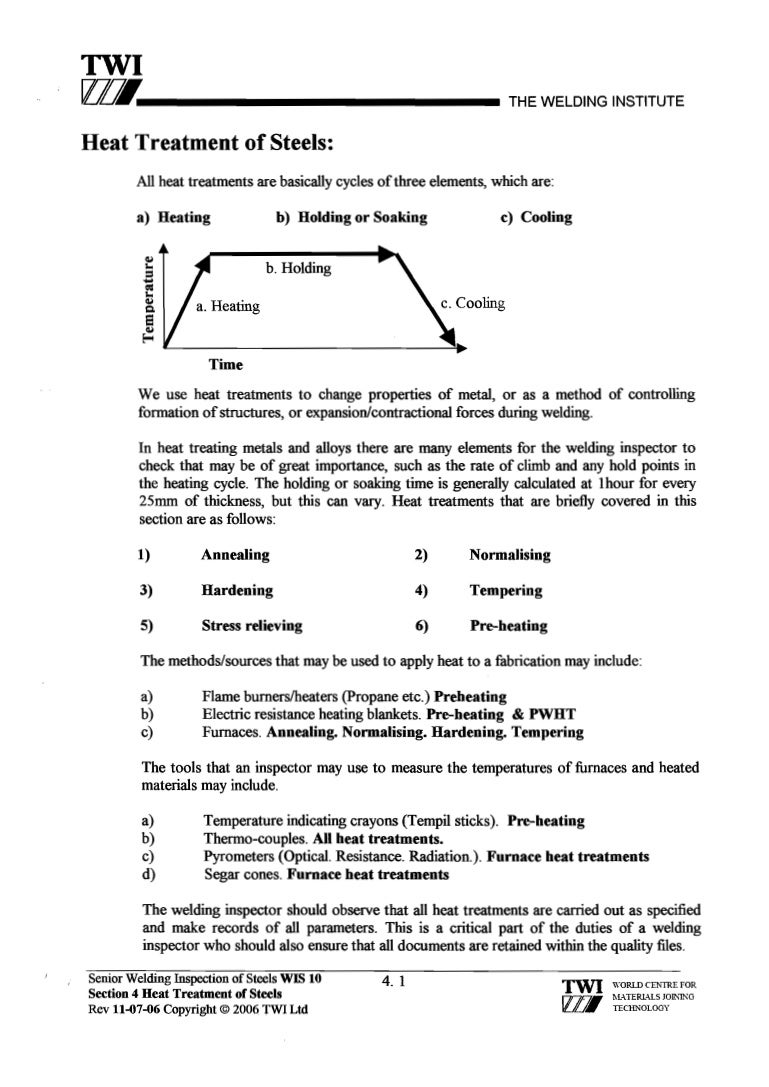

Aug 16, 2021 · Heat treatment is a process of heating that is used on different materials to achieve varying goals depending on the treatment and material. In steel manufacturing, the rate of heating and afterwards cooling can achieve different mechanical properties on the end result material. Heat treatment to steel has been an ongoing process for several decades and has …

What is the best heat insulation metal?

Heat treatment of martensitic stainless steel Compared with ferritic stainless steel, austenitic stainless steel and duplex stainless steel, the most prominent feature of martensitic stainless steel is that the mechanical properties can be adjusted in a wide range through heat treatment methods to meet the needs of different use conditions.

Is steel good conductor of heat?

Jul 27, 2019 · Supports various materials for metal heat treating service, includes: iron, carbon steel, stainless steel, alloy steel, aluminum (alloy), copper (alloy), magnesium (alloy), titanium (alloy) and other alloys.

Which steel is best suited for heat treatment?

The plain medium-carbon steels have low hardenabilities and can successively heat treated only in thin sections and with very rapid quenching rates. High Carbon steel have carbon contents between 0.6-1.4 wt%.

Can all steels be heat treated?

All steel has to be treated in order to be used in commercial products. The heat treatment of steel generally always involves annealing, quenching, and tempering.

Which steels are heat treatable?

A: The most commonly welded heat-treatable steels are 4130, 4340, and 8630. However, any steel prefaced with a 41, 43, or 86 is considered heat-treatable. When a weldment is heat treated, it is put into a furnace at a predetermined temperature and cooling rate.

What is the best steel for hardening?

Carbon is the most important hardening element in steel or cast iron.1045 carbon steel (0.45%carbon). ... 4140/709M alloy steel (0.40%carbon). ... 4340 alloy steel (0.40%carbon). ... EN25 alloy steel (0.30%carbon). ... EN26 alloy steel (0.40%carbon). ... XK1340 carbon steel (0.40%carbon). ... K245 tool steel (0.65% carbon).More items...•Jul 19, 2020

What are the four types of steel?

Authorities grade and categorize steel types into four groups—Carbon, Alloy, Stainless, and Tool.Nov 3, 2021

How do you harden and temper steel?

Steels are heated to their appropriate hardening temperature {usually between 800-900°C), held at temperature, then "quenched" (rapidly cooled), often in oil or water. This is followed by tempering (a soak at a lower temperature) which develops the final mechanical properties and relieves stresses.

Can you heat treat stainless steel?

Types of stainless steel Austenitic stainless steels cannot harden via heat treatment. Instead, these steels work harden (they attain hardness during their manufacture and formation). Annealing these stainless steels softens them, adds ductility and imparts improved corrosion resistance.Feb 9, 2018

How many times can steel be heat treated?

Normalizing at least twice and maybe three times will reduce the grain size of the steel so that you can get the most from a single heat treat. What ever way you want to go about it is up to you.Jul 4, 2004

What materials should be heat treated?

The Basics of Heat Treating Although iron and steel account for the vast majority of heat treated materials, alloys of aluminum, copper, magnesium, nickel and titanium may also be heat treated.

What type of steel is suitable for hardening and tempering?

Steels for quenching and tempering – EN 10083, EN 10132-3StandardAnnealed to spheroidized cementite1.70035045 50461581.721841301581.722041351671.7225414017113 more rows

What steels can be flame hardened?

Flame hardening is a surface hardening process used on medium carbon mild or alloy steels (such as 1045, 4140, 4340), or cast irons, to produce a hard wear resistant surface (case) on the part.

What is W2 steel?

W2 steel is water hardenable high carbon low alloy steel with a carbon percentage above 1%. This steel is most commonly used in knives, cutting tools, and large blades due to an excellent combination of high hardness, optimum toughness, and refined grain size.Sep 11, 2021

What are the elements that are added to stainless steel?

In addition, alloying elements such as Mo, Cu, Nb, N and W are added, and the C content is controlled very low. Depending on the proportion of alloying elements, some ferrite, some are mainly austenite, constituting two duplex stainless steels that exist simultaneously.

What is the C content of stainless steel?

It has a low C content (generally ≤0.09%), a higher Cr content (generally ≥14% or more), plus Mo, Cu and other elements, which makes it have higher corrosion resistance that is equivalent to Austenitic stainless steel.

What is the main alloying element in stainless steel?

1. Ferritic stainless steel. The main alloying element is Cr, or to add a small amount of stable ferrite elements, such as Al, Mo, etc., and the structure is ferrite. Strength is not high, which can not use heat treatment methods to adjust the performance, there is a certain plasticity and large brittleness.

Is ferritic stainless steel corrosion resistant?

Among the stainless steels that appeared earlier, ferritic stainless steels and austenitic stainless steels have good corrosion resistance, but the mechanical properties cannot be adjusted by heat treatment methods, which limits their effects.

What is the purpose of ferritic stainless steel?

The main purpose is to reduce brittleness and improve resistance to intergranular corrosion. ① σ phase brittleness. Ferritic stainless steel is very easy to generate σ phase, which is a kind of Cr-rich metal compound with hard and brittle characteristics.

What temperature should annealing be used?

In order to eliminateσ phase, brittleness at 475°C and brittleness at high temperature, annealing treatment can be used. It needs to heat and hold at 780~830°C, and then to use air cooling or furnace cooling.

Does ferritic stainless steel need heating?

Ferritic stainless steel under normal circumstances is a stable single ferrite tissue heating, cooling does not occur phase change, so it can not use heat treatment to adjust the mechanical properties.

Why do metals need heat treatment?

The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance.

How long does it take to heat treat a metal?

It can take anywhere from an hour to four hours to carry out the process. The length of time typically depends on the thickness of the metal and similar factors. Tempering:- Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys.

How does heat affect metals?

How Does Heat Affect Metal 1 Thermal Expansion – Heating metal can increase its volume, length and surface area, as the heat displaces atoms from their usual position which alters the structure. 2 Magnetism – Iron, cobalt and nickel are all naturally magnetic materials, or ferromagnetic materials. When heat is applied to them it can reduce their natural magnetic properties to a point so low that it is completely gone. 3 Resistance – Some metals are able to effectively reduce, or halt, the flow of an electric current. This is known as resistance and how resistant a metal is depends on how quickly electrons are able to pass through it.

What is normalizing steel?

Normalizing:- Normalizing involves heating steel, and then keeping it at that temperature for a period of time, and then cooling it in air. The resulting microstructure is a mixture of ferrite and cementite which has a higher strength and hardness, but lower ductility.

What are creep resistant steels?

The creep resistant steels for various applications like tubing, boiler drum, main steam pipe, rotors and turbine blades, castings etc. can be put in three categories based on the microstructure: ferritic, bainitic and martensitic.

What is hardening metal?

Hardening:- Hardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal.

How does tempered metal work?

Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

What does higher hardness mean?

Higher hardness means better resistance to rolling, particularly in thin edges . Learn about the importance of strength in thin edges in this article on edge stability. There are some exceptions to this general rule, where a measure of strength called “yield strength” is not perfectly correlated with hardness.

Why use thin geometry?

Using thin geometry also means better ease in sharpening because there is less material to remove. However, steel choice and heat treatment also affects ease in sharpening. Higher hardness means more wear resistance so material removal takes more time. However, low hardness steel does not reach the same level of sharpness due to an increase in edge roughness. Low hardness steel and steel with excessive retained austenite is prone to burr formation, particularly in thin edges. Hard steel is less likely to form large burrs, though if the steel is brittle micro-chipping can be a problem when sharpening thin edges.

What is steel heat treating?

Steel Heat treating is a process which involves cooling and heating of a metal substance at usually high temperature and conditions. It is useful for softening, hardening, and changing physical properties. Moreover, you can manufacture various metal structures like glass by passing it through different thermal techniques.

What is the process of hardening steel called?

Quenching heat treatment. The third process of heat treatment of steel is named as Quenching. This process is also called hardening due to the characteristics of metals. In this technique, the solid metal is first heated above the conditions and then quickly allowed to cool down.

What is the process of annealing?

The first process through which metal passes through is termed as Annealing. The procedure involves both cooling and heating processes. As a result, the microstructure increases, thus ensuring a change in electrical and mechanical properties. This steel heat-treating process heats the metal at a critical temperature.

What is case hardening?

In this technique, the heat treatment involves the absorption of iron and steel. The carbon layer formed in Case hardening is absorbed with the iron alloy’s help for making the metal more durable. This process is also known as Case hardening and should be performed under the same conditions and temperatures.

What is nitriding in metal?

Nitriding. Nitriding is the sixth process of heat treatment of steels. As Carburizing uses carbon alloy to make the metal hard, this Nitriding process diffuses nitrogen gas on the surface of the solid metal substance. The nitrogen gas absorbs on the surface of the metal and makes it sturdy and more robust.

How long does annealing take?

This whole process of heating, cooling, and then repeating is continuously performed for 4 to 8 hours.

What are the four types of heat treatment?

Four basic types of heat treatment are used today. They are annealing, normalizing, hardening, and tempering . The techniques used in each process and how they relate to steelworkers are given in the following paragraphs.

How does hardening steel work?

Hardening of steels is done to increase the strength and wear properties. If there is sufficient Carbon content then the steel can be directly hardened. The hardening treatment for most steels consists of heating the steel to a set temperature and then cooling it rapidly by plunging it into oil, water, or brine. Most steels require rapid cooling (quenching) for hardening but a few can be air-cooled with the same results. Hardening increases the hardness and strength of the steel, but makes it less ductile. To remove some of the brittleness, you should temper the steel after hardening.

What is heat treatment?

Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat treatment is sometimes done inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming.

Is cast iron hard?

Cast iron has limited capabilities for hardening. When you cool cast iron rapidly, it forms white iron, which is hard and brittle. In plain carbon steel, the maximum hardness ob-tained by heat treatment depends almost entirely on the carbon content of the steel.

What is carburizing steel?

Carburizing is a case-harden-ing process by which carbon is added to the surface of low-carbon steel. This results in a carburized steel that has a high-carbon surface and a low-carbon interior. When the carburized steel is heat-treated, the case be-comes hardened and the core remains soft and tough.

What is soft annealing?

Soft annealing is carried out at a temperature of just under Ac1*, sometimes also over Ac1 or by fluctuating around Ac1 with subsequent slow cooling to achieve a soft condition (DIN 17022 part 1-5). Through this heat treatment, the cementite lamination of the perlite is transformed to a spherical form - known as granular cementite. This type of microstructure provides the best workability for steels with a C-content of more than approx. 0.5%. Granular cementite provides the condition for best workability for any type of cold working e.g. for cold-heading, drawing, or cold extrusion.

What is case hardening?

Case hardening is ideal for parts that require a wear-resistant surface and must be tough enough internally to withstand heavy loading. The steels best suited for case hardening are the low-carbon and low-alloy series. When high-carbon steels are case-hardened, the hardness penetrates the core and causes brittleness.

How does heat treatment help metals?

Heat treatment assist in improving the ductility of metal in the annealing process. Heat treatment helps in hardening metals. Case hardening helps in hardening only the outer surface of the metal piece keeping the rest of the portion soft and ductile. Machinability of metals gets improved.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

Why is heat treatment important?

Heat treatment is an essential process in the material science industry to improve metal properties for commercial purposes. It is one of the key processes that help gain the desired mechanical and chemical properties of metals.

How is annealing done?

Annealing is done by heating the metals at the above critical temperature , hold them there for some time and then cool it at a very slow rate in the furnace itself. Annealing is usually done on ferrous and non-ferrous metals to reduce hardness after the cold working process.

What is the first step in heat treatment?

The first step in the heat treatment process is heating the metal. The temperature depends on the types of metal and the technique used. Sometimes you need to heat the outer surfaces of the metal, and sometimes you need to heat the whole body. That depends on what kind of alteration you want in the mechanical structure.

What happens after holding a furnace?

After the holding process, cooling starts. The cooling must be done in a prescribed manner. During cooling, there are some structural changes occur. Different media such as water, oil, or forced air is used to aid in cooling. You can also use furnaces for cooling purposes as the control environments help inefficient cooling.

What is annealing in metals?

Annealing. Annealing is a heat treatment process that is used to soften the metal. In other words, annealing helps to improve ductility, machinability, and toughness. On the flip side, the hardness of metals gets reduced. Annealing does this by changing the microstructure of metals.