Wastewater Collection

What are the four stages of wastewater treatment?

- Screening and Pumping.

- Grit Removal.

- Primary Settling.

- Aeration / Activated Sludge.

- Secondary Settling.

- Filtration.

- Disinfection.

- Oxygen Uptake.

Primary Treatment

What are the main treatment steps in a water treatment plant to treat river water?

- Coagulation.

- Coagulation-Flocculation.

- Flocculation.

Sludge Treatment

What does a wastewater treatment system typically remove?

- Biochemical oxygen demand. Biochemical oxygen demand, or BOD, refers to the amount of dissolved oxygen needed by aerobic biological organisms to break down organic matter into smaller molecules.

- Nitrates and phosphates. ...

- Pathogens. ...

- Metals. ...

- Total suspended solids. ...

- Total dissolved solids. ...

- Synthetic chemicals. ...

Odor Control

Process of Treating Wastewater

- Pre-treatment. It is the very first step just before the actual treatment. ...

- Primary Treatment. The wastewater at this point is devoid of solid materials and grit but has dissolved organic and inorganic solids which are treated at this stage.

- Secondary Treatment. In this stage, there are two ways to go about it. ...

- Tertiary Treatment. ...

- Sludge Treatment. ...

Screening

What are the stages of wastewater treatment?

What are the steps in the water treatment process?

How does wastewater treatment worksthe basics?

What is sewage water and its treatment process?

What are the treatment processes for wastewater?

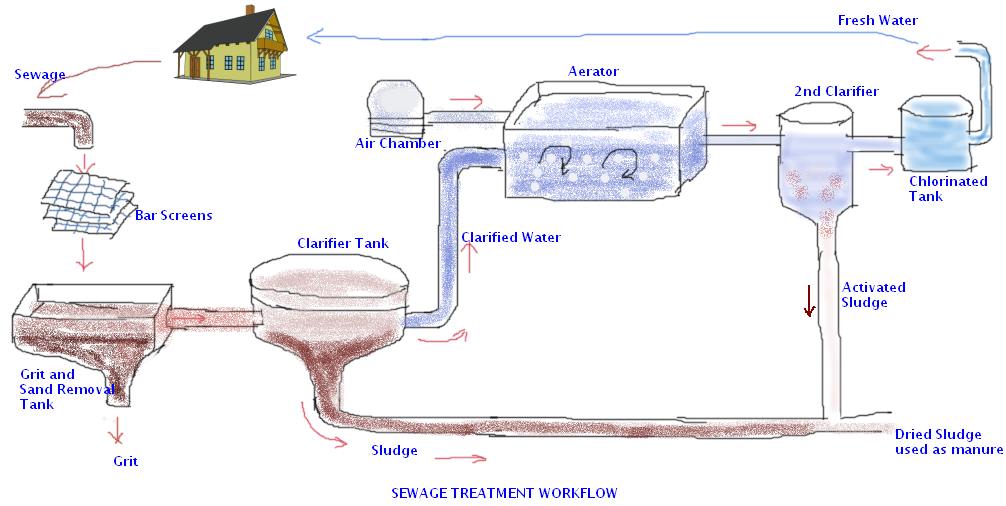

The Wastewater Treatment ProcessStage One — Bar Screening. ... Stage Two — Screening. ... Stage Three — Primary Clarifier. ... Stage Four — Aeration. ... Stage Five — Secondary Clarifier. ... Stage Six — Chlorination (Disinfection) ... Stage Seven — Water Analysis & Testing. ... Stage Eight — Effluent Disposal.

What are the 3 steps to wastewater treatment?

There are three main stages of the wastewater treatment process, aptly known as primary, secondary and tertiary water treatment. In some applications, more advanced treatment is required, known as quaternary water treatment.

What are the 4 stages of wastewater treatment?

4-Step Wastewater Sludge Treatment ProcessStep 1 – Sludge Thickening. The first step in the sewage sludge treatment plan is called thickening. ... Step 2 – Sludge Digestion. After amassing all the solids from the sewage sludge begins the sludge digestion process. ... Step 3 – Dewatering. ... Step 4 – Disposal.

What is the order of water treatment?

These include: (1) Collection ; (2) Screening and Straining ; (3) Chemical Addition ; (4) Coagulation and Flocculation ; (5) Sedimentation and Clarification ; (6) Filtration ; (7) Disinfection ; (8) Storage ; (9) and finally Distribution.

What are the 7 steps in wastewater treatment?

The Wastewater Treatment ProcessStage One — Bar Screening. ... Stage Two — Screening. ... Stage Three — Primary Clarifier. ... Stage Four — Aeration. ... Stage Five — Secondary Clarifier. ... Stage Six — Chlorination (Disinfection) ... Stage Seven — Water Analysis & Testing. ... Stage Eight — Effluent Disposal.

What is the process of removing large items from the influent?

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment .#N#The process of treating and reclaiming water from wastewater (any water that has been used in homes, such as flushing toilets, washing dishes, or bathing, and some water from industrial use and storm sewers) starts with the expectation that after it is treated it will be clean enough to reenter the environment.#N#The quality of the water is dictated by the Environmental Protection Agency (EPA) and the Clean Water Act, and wastewater facilities operate to specified permits by National Pollutant Discharge Elimination System (NPDES). According to the EPA, The Clean Water Act (CWA) establishes the basic structure for regulating discharges of pollutants into the waters of the United States and regulating quality standards for surface waters. Under the CWA, EPA sets wastewater standards for industry. The EPA has also developed national water quality criteria recommendations for pollutants in surface waters. EPA's National Pollutant Discharge Elimination System (NPDES) permit program controls discharges.#N#As an example of expected standards, the Biochemical Oxygen Demand (BOD) of average wastewater effluent is 200 mg/L and the effluent after treatment is expected to be >30 mg/L. It is crucial a wastewater facility meets these expectations or risk stiff penalty.#N#The physical process of wastewater treatment begins with screening out large items that have found their way into the sewer system, and if not removed, can damage pumps and impede water flow. A bar screen is usually used to remove large items from the influent and ultimately taken to a landfill.

What happens after a wastewater treatment plant meets all permit specifications?

After meeting all permit specifications, clean water is reintroduced into the environment. Although testing is continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications.

Why is wastewater pumped into a secondary clarifier?

Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow. As the influent exits the aeration process, it flows into a secondary clarifier where, like the primary clarifier, any very small solids (or fines) sink to the bottom of the tank.

What is activated sludge?

These small solids are called activated sludge and consist mostly of active bacteria. Part of this activated sludge is returned to the aeration tank to increase the bacterial concentration, help in propagation, and accelerate the breakdown of organic material. The excess is discarded.

What is the function of an aeration tank?

The primary function of the aeration tank is to pump oxygen into the tank to encourage the breakdown of any organic material (and the growth of the bacteria), as well as ensure there is enough time for the organic material to be broken down.

Why is chlorine added to water?

Chlorine is added to kill any remaining bacteria in the contact chamber. With the enhanced concentration of bacteria as part of the aeration stage, there is a need to test the outgoing effluent for bacteria presence or absence and to disinfect the water.

What is a bar screen in wastewater treatment?

A bar screen is usually used to remove large items from ...

Stage 1: mechanical water treatment

In the first stage, the still completely untreated wastewater is mechanically treated; this removes about 20 - 30% of the contained solids. To achieve this, the wastewater is guided into a screening plant, where a screen or sieve drum filters out coarse impurities such as leaves, paper or textiles.

Stage 2: biological cleaning

In most wastewater treatment plants, the water pre-purified in the mechanical treatment stage now reaches what are known as aeration tanks, which are often designed as circulation tanks. This is where the biological cleaning takes place.

Stage 3: chemical wastewater treatment

In this stage of wastewater treatment, chemical processes are used for wastewater treatment. To this end, chemical compounds are used to achieve legally prescribed water standard values.

Stage One — Bar Screening

Stage Two — Screening

- Removal of grit by flowing the influent over/through a grit chamber. Fine grit that finds its way into the influent needs to be removed to prevent the damage of pumps and equipment downstream (or impact water flow). Too small to be screened out, this grit needs to be removed from the grit chamber. There are several types of grit chambers (horizontal, aerated or vortex) which control t…

Stage Three — Primary Clarifier

- Initial separation of solid organic matter from wastewater. Solids known as organics/sludge sink to the bottom of the tank and are pumped to a sludge digestor or sludge processing area, dried and hauled away. Proper settling rates are a key indicator for how well the clarifier is operating. Adjusting flow rate into the clarifier can help the operator adjust the settling rates and efficiency…

Stage Four — Aeration

- Air is pumped into the aeration tank/basin to encourage conversion of NH3 to NO3 and provide oxygen for bacteria to continue to propagate and grow. Once converted to NO3, the bacteria remove/strip oxygen molecules from the nitrate molecules and the nitrogen (N) is given off as N2↑ (nitrogen gas). At the heart of the wastewater treatment process is the encouragement and …

Stage Five — Secondary Clarifier

- Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow. As the influent exits the aeration process, it flows into a secondary clarifier where, like the primary clarifier, any very small solids (or fines) sink to the bottom of the tank. These small solids are called activated sludge and consist mostly of active …

Stage Six — Chlorination

- Chlorine is added to kill any remaining bacteria in the contact chamber. With the enhanced concentration of bacteria as part of the aeration stage, there is a need to test the outgoing effluent for bacteria presence or absence and to disinfect the water. This ensures that higher than specified concentrations of bacteria are not released into the environment. Chlorinationis the m…

Stage Seven — Water Analysis & Testing

- Testing for proper pH level, ammonia, nitrates, phosphates, dissolved oxygen, and residual chlorine levels to conform to the plant’s NPDES permit are critical to the plant’s performance. Although testingis continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the p…

Stage Eight — Effluent Disposal

- After meeting all permit specifications, clean water is reintroduced into the environment. Although testingis continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications. Plants that don`t meet permit discharge levels are subject to fines and po…