Five Reasons Fluid Short-Circuiting is a Problem

- It can reduce the effects of any chemicals reacting with the fluids being treated.

- It can increase the amounts of chemicals being added to the system far beyond what should be added.

- It may create dead-zones in the system where no desired reactions are taking place.

- It may cause excessive particle and solids precipitation in certain system zones.

What is a short circuit in a tank?

Jun 30, 2021 · With short-circuiting, the fluid or solids mixture takes the shortest route from the inlet to the outlet because gravity and hydraulics try to push the liquids in the shortest possible way to any outlet. This also means that not all the solids may be pumped out, but some may be left sitting against the tank or vessel walls.

What is short-circuiting in a drainage system?

short-circuiting A condition that occurs when water flows along a nearly direct pathway from the inlet to the outlet of a tank or basin, often resulting in shorter contact, reaction, or settling times in comparison with the calculated or presumed detention times.

What causes a short circuit in a hydrological system?

Dec 09, 2014 · Simply put, wastewater lagoon short-circuiting is when wastewater “short circuits” or takes a short-cut through the lagoon, bypassing the treatment process. Retention time is key to wastewater treatment—if wastewater doesn’t have enough contact with digesting microbes, it doesn’t get treated, and you get high TSS and BOD in your effluent.

What is process short-circuiting?

A short circuit is the flowing of incoming water through the tank, without proper stratification of the water in the basin. Short circuits are generally caused by the stratification of the water in the basin and are common during summer and winter. There should be a proper mixing and baffling of the influent with the water in the basin.

What causes short-circuiting in sedimentation tank?

Another major cause of inefficiency in the sedimentation basin is short-circuiting, which occurs when water bypasses the normal flow path through the basin and reaches the outlet in less than the normal detention time.

Why is short-circuiting a problem in ecological water treatment systems?

Five Reasons Fluid Short-Circuiting is a Problem It can increase the amounts of chemicals being added to the system far beyond what should be added. It may create dead-zones in the system where no desired reactions are taking place. It may cause excessive particle and solids precipitation in certain system zones.Jun 30, 2021

What is short-circuiting in sedimentation tank How do you avoid this?

The normal design includes baffles that gently spread the flow across the total inlet of the tank and prevent short circuiting in the tank. (Short circuiting is the term used for a situation in which part of the influent water exits the tank too quickly, by flowing across the top or along the bottom of the tank.)

What do you mean by short circuit?

short circuit. noun. a faulty or accidental connection between two points of different potential in an electric circuit, bypassing the load and establishing a path of low resistance through which an excessive current can flow. It can cause damage to the components if the circuit is not protected by a fuse.

What is short circuiting in a lagoon?

Simply put, wastewater lagoon short-circuiting is when wastewater “short circuits” or takes a short-cut through the lagoon, bypassing the treatment process.

Does water cause short circuit?

Water can cause electrical outlets to short-circuit and even ignite, presenting considerable risk.Jul 1, 2020

What is done to stop short circuiting of flow through a clarifier?

“Short-circuiting” occurs when influent is drawn directly into the underflow through leaky seals. This can be prevented by replacing the seals as they become worn. Suction clarifiers are also susceptible to plugging. Riser pipe valves can plug if the flow rate is low.

Why are sediments important?

Sediment is important because it often enriches the soil with nutrients. Areas rich in sediments are often also rich in biodiversity. Sedimentary soil is usually better for farming. Deltas and river banks, where much sediment is deposited, are often the most fertile agricultural areas in a region.Jun 4, 2011

What are the 4 types of sedimentation process?

Type 1 – Dilutes, non-flocculent, free-settling (every particle settles independently.) Type 2 – Dilute, flocculent (particles can flocculate as they settle). Type 3 – Concentrated suspensions, zone settling, hindered settling (sludge thickening). Type 4 – Concentrated suspensions, compression (sludge thickening).

What is short circuiting class 10th?

Short circuiting: It occurs sometimes that the live and neutral wires come in contact with each other, and this result is called short circuiting. In such instances, the resistance of a circuit decreases to an extremely small value. The decreasing of resistance results into the increase in the current.

How does the short circuit form?

Short circuit occurs when naked live and neutral wires touch each other. In such situations, the resistance of the circuit becomes very less. Now, according to Ohm's law, current is inversely proportional to resistance. Thus, the decrease in value of resistance of the circuit raises the current to a significant amount.

What is open and short circuit?

The open circuit voltage is the voltage difference measured between two terminals when no current is drawn or supplied. The short circuit current is the current that flows when the terminals are forced to have zero voltage difference.

What is a wastewater lagoon short circuit?

Simply put, wastewater lagoon short-circuiting is when wastewater “short circuits” or takes a short-cut through the lagoon, bypassing the treatment process. Retention time is key to wastewater treatment—if wastewater doesn’t have enough contact with digesting microbes, it doesn’t get treated, and you get high TSS and BOD in your effluent.

What causes a lagoon to short circuit?

1. Flaws in lagoon design: Lagoon design, such as the placement of influent and effluent pipes, can contribute to the likelihood of short-circuiting. A single influent pipe can forcefully push wastewater toward the effluent side of the pond. A lagoon oriented in such a way that it’s affected by wind is also subject to short circuit.

Problems lagoon short circuit can cause

The lack of treatment that short-circuiting causes is due to insufficient retention time. Retention time is key to wastewater treatment: Digesting microbes need time and good DO levels to remove BOD and pathogens. Wastewater that short circuits through the system can have effluent BOD and TSS levels as high as the influent.

What are the steps of water treatment?

The water treatment process to deliver safe and wholesome water to customers includes many steps. Coagulation, flocculation, sedimentation, filtration, and disinfection are the water treatment processes that make up a conventional surface water treatment plant. These water treatment processes ensure that the water consumers receive is safe to drink and aesthetically pleasing.

How does surface water treatment work?

In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to settle out of solution via gravity during sedimentation. Any remaining particles and pathogens will be removed during the filtration treatment process. Finally, the water is disinfected to inactivate any remaining pathogens prior to entering the water system’s distribution system.

Why do flocculation basins have baffles?

Flocculation basins are normally designed with baffles to decrease the chance of short-circuiting. Short circuiting occurs when water is able to flow almost directly from the inlet to the outlet of a tank or treatment process without receiving adequate contact, settling, or reaction times . The baffles usually separate the flocculation basin into a few distinct compartments. These compartments make it easier for operators to control the amount of residence time and mixing energy the water receives.

How do clarifiers work?

The large flocs will settle out of suspension via gravity. Clarifiers can remove a very large percentage of the suspended materials in water. In some plants, clarifiers remove as much as 90% of the suspended solids load. Particles that do not settle will be removed by filtration in the next treatment step.

When do you need to ripen a water filter?

A filter must be ripened when it is first placed into service or following a backwash. If the filter media is too clean, and the pore spaces between the sand grains and the anthracite coal too large, there are chances for particulates to pass right through the filter. The pore spaces decrease and the filter is better at removing the particulates as more water is filtered and more particles are captured. Until the filter is ripened, the water produced by it may not meet the necessary turbidity requirements. Systems must be equipped with the ability to pump this non compliant water to waste without it entering the distribution system.

What is the purpose of the Surface Water Treatment Rule?

The goal of the SWTR is to reduce illnesses related to pathogens in drinking water. These pathogens include coliform, Giardia, and Cryptosporidium .

How does contact time work in water treatment?

In order for systems to be sure that they are properly disinfecting the filtered water, the Surface Water Treatment Rule requires systems to provide enough contact time. Contact time (CT) is a function of the known disinfection concentration and the amount of time that the disinfectant is in contact with the water. Contact time is expressed in terms of mg/L-min. The EPA has published tables that show how much CT credit water systems will receive. In order to use these tables you use the concentration of chlorine, time, water temperature and pH.

What happens to the water after the floc is mixed?

After raw water and chemicals have been mixed and the floc formed, the water containing the floc (because it has a higher specific gravity than water) flows to the sedimentation or settling basin.

How long does it take to fill a water tank?

Detention time (the time it takes to fill the tank) ranges from 1 to 6 hours, depending on the design of the basin. A short circuit is the flowing of incoming water through the tank, without proper stratification of the water in the basin.

What are the factors that affect sedimentation?

Several factors affect sedimentation, including: 1 Detention time. An adequate detention time is important for complete sedimentation. The shorter the detention time, the less the settling, higher the turbidity, and vice versa. 2 Velocity. Higher velocities cause the scouring (resuspension) of the settled floc, which may rise to the surface and cause high effluent turbidity. Very low velocity would not distribute the solids in the basin properly. 3 Surface turbulence. The greater the turbulence, the less is the rate of sedimentation, and vice versa. 4 Short circuits. Short-circuiting causes a short detention time, which results in an inefficient sedimentation. 5 Temperature. The higher the temperature, the faster is the sedimentation, and vice versa. At higher temperatures water is lighter, and settling is faster. 6 Dimensions. Proper dimensions of the basins are also important, particularly depth, which is generally 15 feet or more. 7 Inlets and outlets. Inlets and outlets of the horizontal flow basins should be properly located to allow proper mixing of the water to prevent short circuits. 8 Chemical feed points. Feed points of the chemicals should be carefully located for proper reaction of each chemical with its target substance, i.e. alum should always be applied before lime. 9 Sludge withdrawal. A proper withdrawal of the sludge is important to control the effective volume of the basin, the sludge decomposition, and the sludge scouring. Denser sludge settles readily and must be removed at a higher rate when compared to a ligher fluffy or flakey sludge.

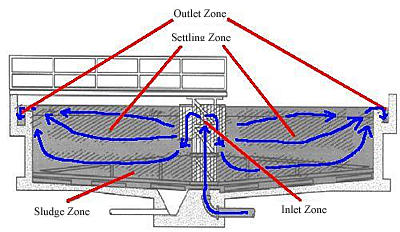

Where is the sludge zone in a tank?

The sludge zone is found across the bottom of the sedimentation basin where the sludge collects temporarily. Velocity in this zone should be very slow to prevent resuspension of sludge. A drain at the bottom of the basin allows the sludge to be easily removed from the tank.

What is the purpose of sedimentation basins?

Sedimentation basins are designed to provide idle conditions, such as a uniform low velocity, proper detention time, no short circuits, and no surface turbulence to the flocculated water for an effective sedimentation. Velocity varies from 1 to 3 ft/minute.

How deep is a basin?

Conventional basins are rectangular or circular. Generally, they are 15 to 20 feet deep to allow proper sedimentation by keeping sludge, light floc (above the sludge), and clear water on the top well separated. Thus, carryover of the floc into the effluent is prevented. Detention time of water in these basins is 4 to 6 hours.

What is a high rate basin?

High rate basins are designed for a better treatment with high load and less detention time. They are compact units. Detention time is generally 1 to 2 hours, as compared to 4 to 6 hours in the conventional basins. These basins consist of tube settler basins, plate settler basins, and solid contact basins.

What is the sludge in a sedimentation tank?

The sludge which is found in the bottom of a sedimentation tank is primarily composed of water. The solids in the sludge are mainly excess coagulant, such as alum. Alum sludge has a solids concentration of only about 1% when automatically removed from the basin, or about 2% if manually removed. (The greater solids concentration of manually removed sludge is due to a small amount of gravity thickening.)

What happens after a floc settles?

After passing through the inlet zone, water enters the settling zone where water velocity is greatly reduced. This is where the bulk of floc settling occurs and this zone will make up the largest volume of the sedimentation basin. For optimal performance, the settling zone requires a slow, even flow of water.

What is sedimentation process?

Sedimentation is a treatment process in which the velocity of the water is lowered below the suspension velocity and the suspended particles settle out of the water due to gravity. The process is also known as settling or clarification.

How many zones are there in a sedimentation basin?

All sedimentation basins have four zones - the inlet zone, the settling zone, the sludge zone, and the outlet zone. Each zone should provide a smooth transition between the zone before and the zone after. In addition, each zone has its own unique purpose.

Where is the sludge zone?

The sludge zone is found across the bottom of the sedimentation basin where the sludge collects temporarily. Velocity in this zone should be very slow to prevent resuspension of sludge.

What is the purpose of the inlet zone?

The two primary purposes of the inlet zone of a sedimentation basin are to distribute the water and to control the water's velocity as it enters the basin. In addition, inlet devices act to prevent turbulence of the water.

What is an outlet zone?

The outlet zone controls the water flowing out of the sedimentation basin - both the amount of water leaving the basin and the location in the basin from which the outflowing water is drawn. Like the inlet zone, the outlet zone is designed to prevent short-circuiting of water in the basin. In addition, a good outlet will ensure that only well-settled water leaves the basin and enters the filter. The outlet can also be used to control the water level in the basin.

Where is the sludge zone in a tank?

The sludge zone, located at the bottom of the tank , provides a storage area for the sludge before it is removed for additional treatment or disposal. Basin inlets should be designed to minimize high flow velocities near the bottom of the tank. If high flow velocities are allowed to enter the sludge zone, the sludge could be swept up and out of the tank. Sludge is removed for further treatment from the sludge zone by scraper or vacuum devices which move along the bottom.

What is a solids contact unit?

solids contact unit combines coagulation, flocculation, and sedimentation in one unit. These units are also called upflow clarifiers or sludge-blanket clarifiers. These units are used primarily with lime-soda ash to settle floc formed during water softening. Flow is usually in an upward direction through a sludge blanket or slurry of flocculated suspended solids.

What is sedimentation in water?

Sedimentation, or clarification, is the processes of letting suspended material settle by gravity. Suspended material may be particles, such as clay or silts, originally present in the source water. Suspended material or floc is typically created from materials in the water and chemicals used in coagulation or, in other treatment processes, such as lime softening (see Lime Softening chapter).

How does a basin outlet work?

The basin outlet zone (or launder) should provide a smooth transition from the sedimentation zone to the outlet from the tank. This area of the tank also controls the depth of water in the basin. Weirs set at the end of the tank control the overflow rate and prevent the solids from rising to the weirs and leaving the tank before they settle out. The tank needs enough weir length to control the overflow rate, which should not exceed 20,000 gallons per day per foot of weir.

What is an influent zone?

The inlet or influent zone should distribute flow uniformly across the inlet to the tank. The normal design includes baffles that gently spread the flow across the total inlet of the tank and prevent short circuiting in the tank. (Short circuiting is the term used for a situation in which part of the influent water exits the tank too quickly, by flowing across the top or along the bottom of the tank.) The baffle is sometimes designed as a wall across the inlet, with holes perforated across the width of the tank.

What is a circular basin?

Circular basins are often referred to as clarifiers. These basins share some of the performance advantages of the rectangular basins, but are generally more prone to short circuiting and particle removal problems. For square tanks the design engineer must be certain that some type of sludge removal equipment for the corners is installed.

What is a high rate tube settlers?

High rate tube settlers are designed to improve the characteristics of the rectangular basin and to increase flow through the tank. The tube settlers consist of a series of tubes that are installed at a 60 degree angle to the surface of the tank. The flow is directed up through the settlers. Particles have a tendency to flow at an angle different than the water and to contact the tube at some point before reaching the top of the tube. After particles have been removed from the flow and collected on the tubes, they tend to slide down the tube and back into the sludge zone.

Coagulation

Flocculation

- Following the coagulant chemical addition and the rapid mix processes, the raw water will continue on to a flocculation basin. The goal of the flocculation treatment process is to increase the size of the flocs in order to increase their ability to settle out.

Sedimentation

- The water continues on to the sedimentationbasin, or clarifier, after the flocs have been formed. The goal of this stage of the treatment process is to reduce the amount of solids in the water before the water is filtered in the next treatment step. The large flocs will settle out of suspension via gravity. Clarifiers can remove a very large percentage of the suspended materials in water. I…

Filtration

- The final water treatment process in removing particulates is filtration. The sedimentation process will have already removed a large percentage of the suspended solids. Sedimentation is unable to remove many small particles in water though. Filtration will remove these microorganisms and other suspended material that did not settle out previously.

Disinfection

- As discussed previously, the surface water treatment rule requires both the filtration and disinfection of surface water sources. The water must be disinfected now that it has been filtered.

Chlorination Operations

- Chlorination was one of the first drinking water disinfection methods. It is still the most commonly used disinfection method used today. The filtered water is injected with either liquid sodium hypochlorite, gaseous chlorine, or solid calcium hypochlorite. Chlorine is a strong oxidant. It is used to both disinfect and also to remove color, taste and odor compounds, iron and manganes…

Conclusion

- In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to se…