Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Both ferrous, as well as non-ferrous metals, undergo heat treatment before putting them to use. Over time, a lot of different methods have been developed.

What is heat treatment?

What is heat treatment? Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness, ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

What is heat treatment in glass?

Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening,...

What is metal heat treatment and how does it work?

Metal heat treatment is an important process in mechanical manufacturing. It refers to a metal thermal processing to get the desired structure and properties via heating, warming, cooling method. It is an essential part of the manufacturing process.

What is chemical heat treatment?

The way of chemical heat treatment is to heat the material in a medium (gas, liquid, solid) containing carbon, nitrogen or other alloying elements for a long time. To make the carbon, nitrogen, boron and chromium elements get into its surface layer.

What is heat treatment simple definition?

Simply stated, heat treatment is the process of using heat at various, staged levels to change the physical properties (microstructure) of a material; most often metals (i.e. steel or aluminum).

What is heat treatment and why is it done?

Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat treatment is sometimes done inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming.

What is heat treatment examples?

For example, aluminum alloy automotive castings are heat treated to improve hardness and strength; brass and bronze items are heat treated to increase strength and prevent cracking; titanium alloy structures are heat treated to improve strength at high temperatures.

What is types of heat treatment?

What are the 4 Types of Heat Treating Processes? Common types of heat treating methods include annealing, hardening, quenching, and stress relieving, each of which has its own unique process to produce different results.

What are the principles of heat treatment?

Heat treating changes metal properties by heating the metal to a specific temperature, holding it at that temperature for a certain length of time, and then using one of several methods to control the cooling of the metal. A metal's properties are determined by the shape and alignment of its atoms.

What are the advantages of heat treatment?

WHAT ARE THE BENEFITS OF HEAT TREATMENT?It can change a material's physical (mechanical) properties and it aids in other manufacturing steps.It relieves stresses, making the part easier to machine or weld.Increases strength, making the material ductile or more flexible.More items...•

What are the objectives of heat treatment?

The main objectives of heat treatment as follows: to increase strength, hardness and wear resistance (bulk hardening, surface hardening) to increase ductility and softness (tempering, re-crystallization annealing) to increase toughness (tempering, re-crystallization annealing)

Where is heat treatment used?

Heat treatment can be used at different stages in the manufacturing process to change certain properties of that metal or alloy. For example, you might use heat treatment to make it stronger, harder, more durable, or more ductile, depending on what the material needs in order to perform properly.

What materials are used for heat treatment?

Ferrous heat-treated metals often include cast iron, alloys, stainless steel and tool steel, whereas some heat-treated non-ferrous metals include aluminum, copper, brass and titanium.

What are the 3 stages of heat treatment process?

Three stages of heat treatment The stages of the heat treatment process include heating, soaking, and cooling.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

Why is heat treatment important?

Heat treatment is an essential process in the material science industry to improve metal properties for commercial purposes. It is one of the key processes that help gain the desired mechanical and chemical properties of metals.

How does heat treatment help metals?

Heat treatment assist in improving the ductility of metal in the annealing process. Heat treatment helps in hardening metals. Case hardening helps in hardening only the outer surface of the metal piece keeping the rest of the portion soft and ductile. Machinability of metals gets improved.

How is annealing done?

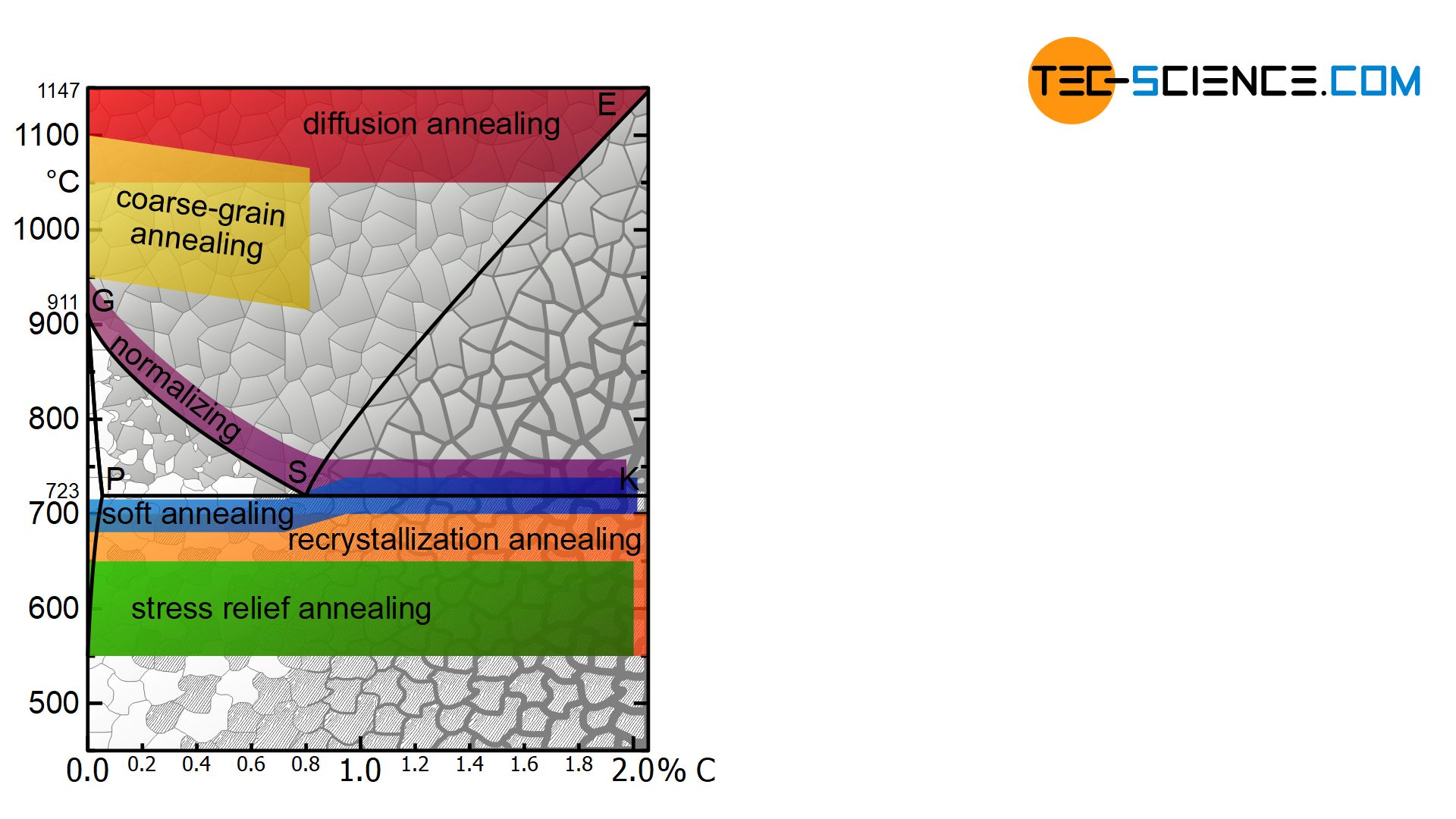

Annealing is done by heating the metals at the above critical temperature , hold them there for some time and then cool it at a very slow rate in the furnace itself. Annealing is usually done on ferrous and non-ferrous metals to reduce hardness after the cold working process.

What is annealing in metals?

Annealing. Annealing is a heat treatment process that is used to soften the metal. In other words, annealing helps to improve ductility, machinability, and toughness. On the flip side, the hardness of metals gets reduced. Annealing does this by changing the microstructure of metals.

What is the process of increasing the hardness of a metal?

Curborization. In carburization, the hardness of the metal piece is increased by increasing the carbon content. The metal piece is heated below the melting point with high carbon materials such as charcoal. The heated metal piece then absorbs carbons to make it more hard and brittle.

What is case hardening?

Case hardening or surface hardening is a hardening heat-treatment process. In the case of hardening, the complete metal piece is heated. But in the case of case hardening, only the outer surface is heat-treated to make it hardened. The inner metal is still soft and ductile.

What is heat treatment?

Simply stated, heat treatment is the process of using heat at various, staged levels to change the physical properties (microstructure) of a material; most often metals (i.e. steel or aluminum). Heating is carried out in large-scale, industrial “furnaces” (extremely different from a house-hold furnace, capable of reaching temperatures ...

What industries use heat treatment?

Making this more remarkable is the fact that heat treatment affects nearly all aspects of modern life: construction, automotive, aerospace, oil & gas, and military are just some industries that rely on heat treatment as part of their product pipeline. Everyday items, such as: steel plates, pipes, engine blocks, pistons, springs, ...

What is the process of shaping metals?

Process of shaping metals by hammering or pressing. Heat treating allows for a metal’s shape to be changed, more than if it were cold, without adding unnecessary strain in the metal

Why is heat treatment important?

It is very important manufacturing process that can not only help the manufacturing process but can also improve the product, its performance, and its characteristics in many ways. By Heat Treatment process, Example: The plain carbon steel. The following changes may be achieved: The hardness of Steel may be increased or decreased.

What is the purpose of hardening steel?

Hardening is carried to accomplish the following: To reduce the grain size. Obtain maximum hardness.

What is nitriding used for?

Nitriding is generally employed to Steel parts which are moving like engine parts such a cylinder, crankshaft, etc. 6. Cyaniding: Cyaniding is also a surface hardening process in which the heated parts to be surface hardened are immersed in a bath of molten sodium or potassium cyanide.

What is recrystallization in steel?

This causes complete recrystallization in steel to form New grain structure. This will release the internal stresses previously the strip in the steel and improve the machinability.

What is annealing in metal?

Annealing is carried out for accomplishing one or more of the following: Softening of a metal or alloy. This may be done due to improving machinability. Relieving internal residual stresses caused by the various manufacturing process. Refining the grain size of the metal or alloy.

What is normalizing steel?

Normalizing is a heat treatment process similar to annealing in which the Steel is heated to about 50 degree Celsius above the upper critical temperature followed by air cooling. This results in a softer state which will be lesser soft than that produced by annealing.

What temperature does annealing take place?

Annealing consists of heating of steel parts to a temperature at or near the critical temperature 900 degree Celsius hold it at that temperature for a suitable time and when allowed to cool slowly in the Furnace itself. The heating done during annealing affects the metal in two stages of recovery and recrystallization.

What is Heat Treatment?

Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Both ferrous, as well as non-ferrous metals, undergo heat treatment before putting them to use.

Heat Treatment Process Steps

In simple terms, heat treatment is the process of heating the metal, holding it at that temperature, and then cooling it back. During the process, the metal part will undergo changes in its mechanical properties. This is because the high temperature alters the microstructure of the metal.

Heat Treatment Methods

There are quite a few heat treatment techniques to choose from. Every one of them brings along certain qualities.

What Metals Are Suitable for Heat Treating?

Although ferrous metals account for the majority of heat-treated materials, alloys of copper, magnesium, aluminum, nickel, brass, and titanium may also be heat treated.

Why is heat treatment called an arrest?

This temperature is referred to as an "arrest" because at the A temperature the metal experiences a period of hysteresis.

What is the process of heating something to alter it?

Process of heating something to alter it. Heat treating furnace at 1,800 °F (980 °C) Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the ...

How much carbon is in hypoeutectoid steel?

A hypoeutectoid steel contains less than 0.77% carbon. Upon cooling a hypoeutectoid steel from the austenite transformation temperature, small islands of proeutectoid-ferrite will form. These will continue to grow and the carbon will recede until the eutectoid concentration in the rest of the steel is reached.

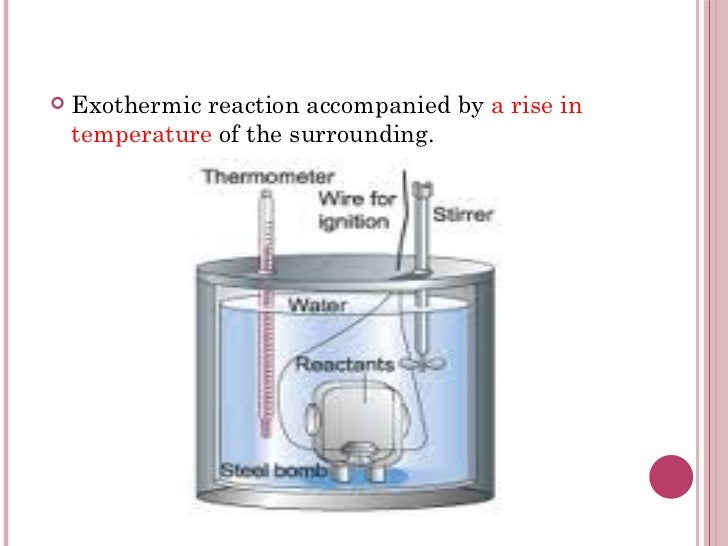

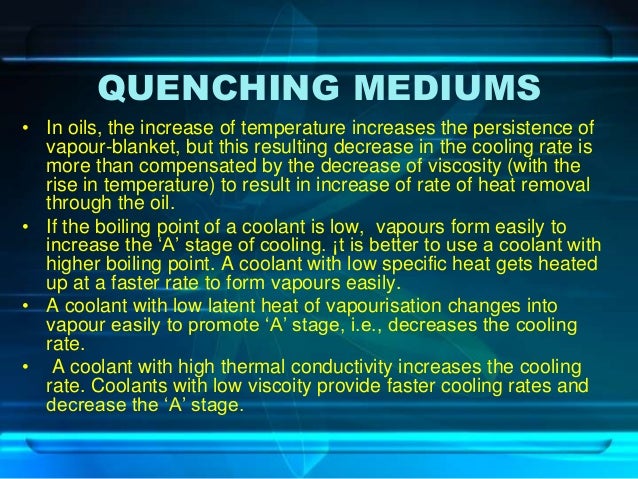

Why are liquids used in chemistry?

Liquids may be used, due to their better thermal conductivity, such as oil, water, a polymer dissolved in water, or a brine. Upon being rapidly cooled, a portion of austenite (dependent on alloy composition) will transform to martensite, a hard, brittle crystalline structure.

How does steel change carbon?

When steel is heated in an oxidizing environment, the oxygen combines with the iron to form an iron-oxide layer, which protects the steel from decarburization. When the steel turns to austenite, however, the oxygen combines with iron to form a slag, which provides no protection from decarburization. The formation of slag and scale actually increases decarburization, because the iron oxide keeps oxygen in contact with the decarburization zone even after the steel is moved into an oxygen-free environment, such as the coals of a forge. Thus, the carbon atoms begin combining with the surrounding scale and slag to form both carbon monoxide and carbon dioxide, which is released into the air.

What happens when an alloy is cooled to an insoluble state?

If the alloy is cooled to an insoluble state, the atoms of the dissolved constituents (solutes) may migrate out of the solution. This type of diffusion, called precipitation, leads to nucleation, where the migrating atoms group together at the grain-boundaries.

What is a semi continuous batch furnace?

These upgraded furnaces are a very commonly used piece of equipment for heat-treating.

What is heat treatment?

Definition - What does Heat Treatment mean? Heat treatment is a process that is used to alter the physical properties of a material in a beneficial way. During a heat treatment process, a material is typically heated to a target temperature at which its physical properties change. It is then cooled at a controlled rate.

Why is heat used in corrosion?

Corrosionpedia explains Heat Treatment. Heat treatment is used for several reasons: To anneal or normalize a metal. If a metal has been hardened due to work or heat, then annealing or normalizing may be employed to bring it back to a softer, more ductile state. During the annealing process, the metal is heated above its recrystallization ...

Is normalizing the same as annealing?

Normalizing is the same as annealing, except that the metal is air cooled rather than furnace cooled. The metal being heat-treated must be considered heat treatable for any effect to occur. To harden a material. For this process, a material is heated above a certain temperature.

What are the different types of metal heat treatment?

Metal heat treatment processes can be roughly divided into three categories: overall heat treatment, surface heat treatment and chemical heat treatment . Depending on the heating medium, heating temperature and cooling method. Each category can be divided into several different heat treatment processes. The same metal uses different heat treatment processes to obtain different microstructures and thus different properties. Steel is the most widely used metal in the industry. Its microstructure is also the most complex. Therefore, there are many kinds of steel heat treatment processes.

Why is a metal workpiece heated above the phase transition temperature?

However, it is generally heated above the phase transition temperature to obtain a high temperature structure. In addition, the transformation takes a certain time. Therefore, when the surface of the metal workpiece reaches the required heating temperature.

Is there a holding time for heat treatment?

When high-energy density heating and surface heat treatment are used, the heating rate is extremely fast. Generally, there is no holding time, and the heat treatment time of the chemical heat treatment tends to be long.

What is chemical heat treatment?

Chemical Heat Treatment. It is to change the chemical composition, structure, properties of steel material surface. It can change the chemical composition of the surface layer of the steel material. It is a big difference between chemical heat treatment and surface heat treatment. The way of chemical heat treatment is to heat ...

What is heat treatment?

Heat treatment is one of the most important processing for the production of machine fittings and mold base. It can control all kinds of properties of steel material. Such as wear resistance, corrosion resistance, magnetic properties and so on. Use the right heat treatment processing to the gear wheel, its useful life would longer than ...

How does heat treatment change the chemical composition of steel?

It is to change the chemical composition, structure, properties of steel material surface. It can change the chemical composition of the surface layer of the steel material. It is a big difference between chemical heat treatment and surface heat treatment. The way of chemical heat treatment is to heat the material in a medium (gas, liquid, solid) containing carbon, nitrogen or other alloying elements for a long time. To make the carbon, nitrogen, boron and chromium elements get into its surface layer. After that, also need other heat treatments sometimes, such as quenching and tempering. Carburizing, nitriding are the main methods of chemical heat treatment.

What are the two methods of surface heat treatment?

Make the surface of steel quickly get high temperature. The main methods of surface heat treat are flame quenching and induction heat treatment. The oxyacetylene, ethylene oxide and etc are the most useful heat sources.

What is thermomechanical treatment?

The way of thermomechanical treatment needs pressure processing deformation and heat treatment effectively combining. It will make the steel material get good hardness and toughness. The heat treatment performed in a vacuum atmosphere or in a vacuum is referred to as a vacuum heat treatment. It not only can prevent the alloy steel material ...

Why is steel heat treated?

The purpose of make steel been through heat treatment is to get the desired structure and properties.

How many types of steel heat treatment are there?

There are three types of steel heat treatment. Such as overall heat treatment, surface heat treatment, and chemical heat treatment. According to the mediator, temperature and the way of cooling of heat treatment, every classification can be divided into several different heat treatment process.