What is flocculation in water treatment?

What is flocculation water treatment? Flocculation is a water treatment process where solids form larger clusters, or flocs, to be removed from water. This process can happen spontaneously, or with the help of chemical agents. It is a common method of stormwater treatment, wastewater treatment, and in the purification of drinking water.

How can flocculants be used to clean up contaminated water?

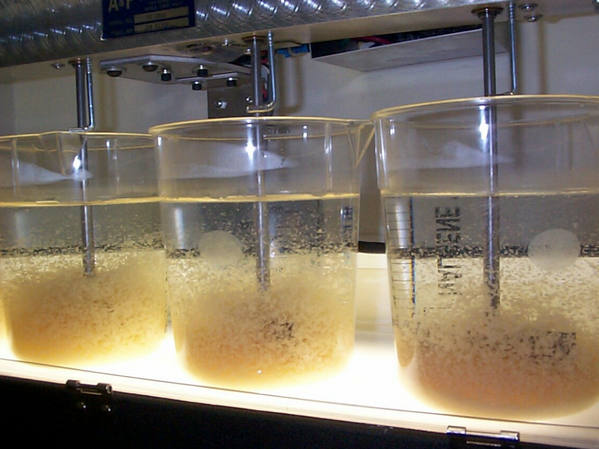

Positively charge flocculants can be added to contaminated water and will cause negatively charged particles to clump together and their increased weight will allow them to settle more quickly in the water. Figure 2.

How are coagulants mixed in water treatment?

rapid mixing to disperse coagulant chemicals by violent agitation into the water being treated, and flocculation to agglomerate (join together) small particles into well-defined floc by gentle agitation for a much longer time.

Can you use alum as a flocculant in a water treatment plant?

Alum is just one flocculant that is used in a drinking water treatment plant. Test if other types of flocculants, such as polymer flocculants, which can be found in some pool water clarifiers work as well as alum. After adding the alum solution, you stirred the solutions for 2 minutes.

What is added to water for flocculation?

Chemicals (coagulants) are added to the water to bring the nonsettling particles together into larger, heavier masses of solids called floc. Aluminum sulfate (alum) is the most common coagulant used for water purification. Other chemicals, such as ferric sulfate or sodium aluminate, may also be used.

How do you promote flocculation?

Water Treatment 101: 6 Tips for Improving Coagulation, Flocculation and ClarificationUse the correct polymer or coagulating chemicals. ... Keep injection point close. ... Slow mixing is good mixing. ... Velocity gradient is important. ... Keep an eye on temperature. ... Balance the velocity.

What is used in flocculation?

Basically, coagulation is a process of addition of coagulant to destabilize a stabilized charged particle. Meanwhile, flocculation is a mixing technique that promotes agglomeration and assists in the settling of particles. The most common used coagulant is alum, Al2(SO4)3·14H2O.

What step is flocculation in water treatment?

Coagulation-flocculation is a chemical water treatment technique typically applied prior to sedimentation and filtration (e.g. rapid sand filtration) to enhance the ability of a treatment process to remove particles.

What is flocculant made of?

The aluminum-based flocculants include aluminum sulfate, aluminum chloride, sodium aluminate, aluminum chlorohydrate, and polyaluminum chloride. The iron-based flocculants include ferric chloride, ferric sulfate, ferrous sulfate, and ferric chloride sulfate [15, 69].

Which of the following chemical is usually added in the process of coagulation and flocculation?

Answer: Chemicals (coagulants) are added to the water to bring the nonsettling particles together into larger, heavier masses of solids called floc. Aluminum sulfate (alum) is the most common coagulant used for water purification.

Why are flocculants used in water treatment?

Used in a wide range of industries and applications, flocculants help to remove suspended solids from wastewater by aggregating contaminants into flakes or “flocs” that float to the surface of the water or settle at the bottom. They can also be used for lime softening, sludge thickening, and solids dehydration.

Which chemicals are added in sewage treatment plant for the process of flocculation?

Ferric Chloride works as a flocculant and coagulant. It is versatile in the water treatment industry and is an alternative to ferric sulfate.

How do you make a flocculant?

2:055:34Flocculation - YouTubeYouTubeStart of suggested clipEnd of suggested clipBecause they work well with high turbidity fluid mixtures. Now let's demonstrate how flocculationMoreBecause they work well with high turbidity fluid mixtures. Now let's demonstrate how flocculation works first we'll need to go out and collect some muddy water from the Charles. River.

Which of the following step is considered as flocculation?

Transport step is known as flocculation whereas coagulation is the overall process involving destabilization and transport.

What is alum used for in water treatment?

ALUMINIUM SULFATE OR ALUM IS USED AS A FLOCCULANT TO REMOVE UNWANTED COLOUR AND TURBIDITY FROM WATER SUPPLIES. IT HAS BEEN USED SINCE ANCIENT TIMES FOR THIS PURPOSE AND ITS USE TOGETHER WITH FILTRATION IS STANDARD PRACTICE IN CONVENTIONAL WATER TREATMENT PROCESSES AROUND THE WORLD.

What is flocculant and coagulant?

Coagulation: Particles that aggregate with themselves e.g. by the influence of a change in pH. Flocculation: Particles that aggregate by the use of polymers that binds them together. Coagulation and flocculation are well-known techniques within wastewater treatment.

What is the purpose of flocculation and clarification?

The general purpose of this sequence is to remove solids and turbidity from the water to produce clear product water and meet turbidity standards, expressed as NTUs (nephelometric turbidity units). Coagulation, flocculation and clarification can ...

What is clarified water?

The clarified water passes on to downstream processes such as filtration and disinfection. Like most water treatment processes, coagulation, flocculation and clarification sound simple but are subject to many variables that affect the efficiency and success of the operation.

How to remove bacteria and color from water?

Coagulation, flocculation and clarification can also remove bacteria and color from the water. First, coagulating chemicals are mixed with water in a rapid-mix step for even distribution. The chemicals cause particles in the water to clump together. In the flocculation step, the water and chemicals are gently mixed, ...

Is slow mixing good for mixing?

“The further away the mixing is from the injection point, the less (effective) mixing you’re going to see,” Zurcher says. 3. Slow mixing is good mixing.

Why is chlorine added to water?

After the water has been filtered, a disinfectant (for example, chlorine, chloramine) may be added in order to kill any remaining parasites, bacteria, and viruses, and to protect the water from germs when it is piped to homes and businesses.

What are the steps of water treatment?

Today, the most common steps in water treatment used by community water systems (mainly surface water treatment) include: Coagulation and flocculation are often the first steps in water treatment. Chemicals with a positive charge are added to the water.

How does a water treatment unit work?

Even though EPA regulates and sets standards for public drinking water, many Americans use a home water treatment unit to: 1 Remove specific contaminants 2 Take extra precautions because a household member has a compromised immune system 3 Improve the taste of drinking water

What is the process of boiled water?

Distillation is a process in which impure water is boiled and the steam is collected and condensed in a separate container, leaving many of the solid contaminants behind. Disinfection. Disinfection is a physical or chemical process in which pathogenic microorganisms are deactivated or killed.

Why is surface water more contaminated than ground water?

Typically, surface water requires more treatment and filtration than ground water because lakes, rivers, and streams contain more sediment and pollutants and are more likely to be contaminated than ground water. Some water supplies may also contain disinfections by-products, inorganic chemicals, organic chemicals, and radionuclides.

What is a water softener?

Water Softeners. A water softener is a device that reduces the hardness of the water. A water softener typically uses sodium or potassium ions to replace calcium and magnesium ions, the ions that create “hardness.”. Distillation Systems.

What is the most common type of water treatment system?

The most common types of household water treatment systems consist of: Filtration Systems. A water filter is a device which removes impurities from water by means of a physical barrier, chemical, and/or biological process. Water Softeners. A water softener is a device that reduces the hardness of the water.

What is floculation in water?

Flocculation is a water treatment process where solids form larger clusters, or flocs, to be removed from water. This process can happen spontaneously, or with the help of chemical agents. It is a common method of stormwater treatment, wastewater treatment, and in the purification of drinking water. One of the requirements for treated water leaving ...

Why is high energy mixing required in wastewater?

The wastewater must be agitated with mixers. High energy mixing is required initially to ensure that the coagulant spreads throughout the water. When flocculation is in progress the mixing energy is reduced to prevent the mass of particles from separating again.

What is the charge of suspended solid particles in wastewater?

Suspended solid particles in wastewater are negatively charged. In the first stage of flocculation, a coagulant like aluminium sulphate is added to the wastewater. The positively charged coagulant molecules neutralize the negatively charged solid particles suspended in the water.

What is Cleanawater wastewater?

Cleanawater is an Australian company that specialises in wastewater treatment equipment and solutions. Our track record and experience over more than 20 years means that we have the expertise to help you solve your wastewater problems. Our technical experts can help you evaluate your application and advise you on the optimum solutions for your needs.

What is Cleanawater's solution?

Cleanawater offers a number of solutions for the wastewater industry to help keep wastewater within specification: Chemical dosing, in particular pH dosing, is a common method of wastewater treatment. Regulations require treated wastewater to be in a neutral pH range when discharged into the environment.

Where does phosphate enter wastewater?

Phosphate enters our wastewater systems from human and animal waste, detergents and food residues. Food and Beverage plants are therefore prime sources of phosphate in wastewater. Flocculation is a key method for the removal of phosphate from this wastewater, which can be done at the Food and Beverage plant itself before discharging wastewater ...

Why is Cleanawater important?

Cleanawater uses a chlorine-based system to achieve a high level of disinfection. This protects workers and the general public from potential health hazards associated with unwanted bacteria in the wastewater system. It is particularly important where water is recycled for use.

How long to flocculate cuvettes?

Put the full cuvettes to the side until measurement. Set your timer again for 13 minutes and start it. Observe the flocculation process in each cup. Prepare your third set of labeled cuvettes ("15") and after 13 minutes use your rinsed transfer pipettes again to take a sample of each cup.

How does water become clean?

To become clean and clear, the water has to undergo several treatment steps before it is safe to drink. This cleanup happens in a drinking water treatment plant. One of the first steps in a treatment plant is getting rid of the total suspended solids with a process called flocculation.

How does a turbidimeter work?

A turbidimeter works by measuring light that is reflected off particles suspended in water.

What does it mean when water has more particles?

More particles mean that more light will be scattered and the water is more turbid . For this reason, total suspended solids and turbidity are closely related, and turbidity changes often indicate a change in total suspended solid concentrations in the water.

Where does drinking water come from?

Drinking water all over the world originates from either surface waters such as lakes, reservoirs, and rivers or from underground sources such as groundwater. In the United States, 68% of the population that gets water delivered from community water systems receive their drinking water from surface waters.

What is the device that measures turbidity?

The device for measuring turbidity is called a turbidimeter or nephelometer and measures light scattering. In light scattering, the incoming light bounces off of small, suspended particles, and is thus redirected away from its initial path. A number of factors affect the scattering of light by suspended particles.

Why are polymers added to flocculants?

They are added as part of the flocculation process to help strengthen and increase the settling weight of the floc. Polymers can be either natural or synthetic. Natural polymers also date back to ancient times, with Sanskrit literature from around 2000 BC referencing the use of crushed nuts to clarify water.

What is the purpose of coagulation and flocculation?

Coagulation and flocculation are essential components of both drinking water and wastewater treatment. They provide a reliable process for treating water turbidity (the cloudiness or haziness of a fluid typically invisible to the naked eye) which is a key test of water quality.

What is the difference between flocculation and coagulation?

Coagulation and flocculation are two, separate, crucial parts of water and wastewater treatment. Coagulation destabilises the minute suspended particles by static charge neutralisation, while flocculation helps them to bind together to form much bigger morphologies, so they can be more easily separated from the liquid phase.

What are the advantages of hydroxides?

They offer a number of advantages: Enable highly charged ions to give a high charge density to neutralise suspended particles, which allows hydrated inorganic hydroxides to form and produce short polymer chains that enhance microfloc formation and heavy floc.

What coagulants remove suspended solids?

Organic coagulants. Both polyamine and poly-DADMAC coagulants have been proven to be very effective at removing most suspended solids. Tannates are particularly good at oils and fats. Enable relatively low charge density to neutralise lower charged suspended particles, more effectively.

What destroys the process whereby tiny particles repel each other and promotes their consolidation to bigger ones that are able

The coagulation process. This destroys the process whereby tiny particles repel each other and promotes their consolidation to bigger ones that are able to stick together. The bigger the particle, the easier it is to separate from the liquid.

What are the two types of coagulants?

Types of coagulants. Today, there are two types of coagulants that are most commonly used in water and wastewater treatment. Organic and inorganic. Inorganic coagulants include: Iron coagulants - e.g. ferric sulphate, ferrous sulphate, ferric chloride and ferric chloride sulphate. Organic coagulants include:

What are the three forms of organic flocculants?

Organic flocculants come in three forms: solid; emulsion (polymer in an organic solvent emulsion); solution (approximately 20 g · L –1 in a water-based medium). The use of solid or emulsion flocculants always requires a specially prepared solution.

What is the best treatment for urban wastewater?

urban wastewater (physical-chemical treatments) When used in conjunction with a mineral coagulant, the anionic flocculant tends to be the best option. When the only requirement is the removal of suspended solids, a synthetic flocculant can be used on its own.

What is organic coagulant?

Given the limited number of cationic charges that can be used, organic coagulants are mainly of interest when dealing with fine suspended solids or lightly laden colloids (low zeta potential) where their use is simple and cost-effective.

What is activated silica?

activated silica. Activated silica was the first flocculent to be used. It produces good results mainly when combined with aluminium sulphate in cold water. Not very stable, activated silica must be prepared immediately before use by partly neutralising the alkalinity of a sodium silicate solution.

Is synthetic flocculant cationic or anionic?

In clarification applications, the synthetic flocculant will be used in conjunction with a coagulant. The best polymer will usually be anionic and, more rarely, a non-ionic or very slightly cationic polymer.

Can organic coagulants be used on their own?

In some cases, organic coagulants used on their own will not enable us to achieve the quality of water produced by a mineral coagulant. The combined use of these two coagulants means that we can significantly reduce the amount of mineral coagulant required (40 to 80%), while producing smaller quantities of sludge.

Can coagulant be used in seawater filtration?

In seawater filtration applications, the coagulation reaction can be combined with a premature and prejudical reaction involving precipitation of the coagulant due to the high salinity level. Therefore, only a few coagulants will be suitable.