What are the functions of a water treatment plant?

Jun 18, 2020 · Sewage treatment plant – treated sewage; Water treatment plant – treated water; A treatment plant is necessary in an industrial process to treat wastewater. It reduces industrial water consumption and environmental pollution. A large volume of industrial on-site wastewater might be reusable by treating it in the treatment plant. Treatment plants also produce residual …

What is the purpose of a water treatment plant?

Centralized water treatment plants are based on coagulation, flocculation and disinfection processes and found to be most cost-effective in treating large quantities of water. However, they entail large infrastructure costs which is difficult to raise in rural regions of developing countries and are generally installed using government funding.

What are the steps of a water treatment plant?

Water treatment definition, the act or process of making water more potable or useful, as by purifying, clarifying, softening, or deodorizing it. See more. DICTIONARY.COM

What happens in a water treatment plant?

The Cañon City Water Treatment Plant is a conventional surface water treatment plant that diverts water from the Arkansas River to produce drinkable (potable) water, which meets or exceeds all Environmental Protection Agency (EPA) Safe Drinking Water Act and the Colorado Department of Public Health and Environment Primary Drinking Water Standards.

What is a water treatment plant?

A treatment plant refers to a plant or installation that is used to purify contaminated substances. These substances may be solid, liquid and semi-solids. Treatment plants are named after their treated substances, for example: Wastewater treatment plant – treated wastewater. Effluent treatment plant – treated effluent.Jun 18, 2020

What is a water treatment means?

Definition of water treatment noun. the act or process of making water more potable or useful, as by purifying, clarifying, softening, or deodorizing it.

What are the different types of water treatment plants?

Types of Water Treatment PlantsWastewater Treatment Plant (WWTP) ... Sewage Treatment Plants (STPs) ... Effluent Treatment Plants (ETP's) ... Demineralization (DM) Treatment Plants. ... Reverse Osmosis (RO) Water Treatment.May 10, 2021

What is the importance of water treatment plant?

The water treatment plants remove the chemicals, particulates, organic materials as well as other debris from the water and treat the water resulting in clean and potable water that can be used for cooking, cleaning, etc.Jul 14, 2017

Why is water treated?

As water works its way through some industrial processes it can pick up bacteria and chemicals that will cause corrosion to occur in the water vessel. The water must be treated so that this corrosion does not occur.Jun 23, 2017

What is water treatment and its types?

Portable water purificationConstituentUnit processesTurbidity and particlesCoagulation/ flocculation, sedimentation, granular filtrationMajor dissolved inorganicsSoftening, aeration, membranesMinor dissolved inorganicsMembranesPathogensSedimentation, filtration, disinfection1 more row

What are the two main types of water treatment plants?

Types of Wastewater Treatment PlantsEffluent Treatment Plant. ... Sewage Treatment Plant. ... Common and Combined Effluent Treatment Plants. ... Activated Sludge Plant.Feb 10, 2019

What are 3 different methods of water treatment?

Four Common Water Treatment Methods:Reverse Osmosis Water Filtration. Reverse Osmosis is a process where water pressure is employed to force water through a semi-permeable membrane. ... Ultraviolet Water Sterilization and Filtration. ... Filtration. ... Distillation.

What is the treatment for flocculation?

Also referred to as "Conventional" Treatment. Coagulation for flocculation. Coagulant aids, also known as polyelectrolytes – to improve coagulation and for more robust floc formation. Polyelectrolytes or also known in the field as polymers, usually consist of either a positive or negative charge.

What is chemical treatment?

Chemical treatments are techniques adopted to make industrial water suitable for use or discharge. These include chemical precipitation, chemical disinfection, chemical oxidation, advanced oxidation, ion exchange, and chemical neutralization.

What are the disadvantages of water cooling systems?

Disadvantages of water cooling systems include accelerated corrosion and maintenance requirements to prevent heat transfer reductions from biofouling or scale formation. Chemical additives to reduce these disadvantages may introduce toxicity to wastewater.

What is water cooling?

Water cooling is a method of heat removal from components of machinery and industrial equipment. Water may be a more efficient heat transfer fluid where air cooling is ineffective. In most occupied climates water offers the thermal conductivity advantages of a liquid with unusually high specific heat capacity and the option that of evaporative cooling. Low cost often allows rejection as waste after a single use, but recycling coolant loops may be pressurized to eliminate evaporative loss and offer greater portability and improved cleanliness. Unpressurized recycling coolant loops using evaporative cooling require a blowdown waste stream to remove impurities concentrated by evaporation. Disadvantages of water cooling systems include accelerated corrosion and maintenance requirements to prevent heat transfer reductions from biofouling or scale formation. Chemical additives to reduce these disadvantages may introduce toxicity to wastewater. Water cooling is commonly used for cooling automobile internal combustion engines and large industrial facilities such as nuclear and steam electric power plants, hydroelectric generators, petroleum refineries and chemical plants .

What are the two main processes of water treatment?

Processes. Two of the main processes of industrial water treatment are boiler water treatment and cooling water treatment . A large amount of proper water treatment can lead to the reaction of solids and bacteria within pipe work and boiler housing. Steam boilers can suffer from scale or corrosion when left untreated.

What to do when living away from drinking water?

Living away from drinking water supplies often requires some form of portable water treatment process . These can vary in complexity from the simple addition of a disinfectant tablet in a hiker's water bottle through to complex multi-stage processes carried by boat or plane to disaster areas.

What are the risks of contaminated water?

In general terms, the greatest microbial risks are associated with ingestion of water that is contaminated with human or animal (including bird) faeces. Faeces can be a source of pathogenic bacteria, viruses, protozoa and helminths.

What is centralized water treatment?

Centralized water treatment plants are based on coagulation, flocculation and disinfection processes and found to be most cost-effective in treating large quantities of water.

What is the water district in Orange County?

Orange County Water District (OCWD). OCWD located between Los Angeles and San Diego counties in southern California manages the groundwater basin that supplies about 3.0 × 10 8 m 3 per year potable water to a population of more than 2 million.

What is the water used in CMF-S?

Raw (surface) water is pre-screened, and dosed with lime and carbon dioxide in a contact reactor to control alkalinity and corrosion. Next, water is dosed with a coagulant, liquid aluminium chlorohydrate (ACH) prior to entering the CMF-S plant to remove colour, some organic content, and dissolved metals.

What is the Bendigo water treatment plant?

I. Bendigo water treatment plant (BWTP). The 12.54 × 10 4 m 3/day (33 MGD) BWTP has been producing drinking water for nearly 1 million people in central Victoria, Australia since 2002. It is one of the largest if not the largest MF plant in the world. The plant combines submerged microfiltration (CMF-S), ozonation and biological activated carbon (BAC) to treat a variable and difficult raw water. Raw (surface) water is pre-screened, and dosed with lime and carbon dioxide in a contact reactor to control alkalinity and corrosion. Next, water is dosed with a coagulant, liquid aluminium chlorohydrate (ACH) prior to entering the CMF-S plant to remove colour, some organic content, and dissolved metals. The coagulant dosage is typically 5–6 mg/l. The coagulant precipitate is removed by MF. The coagulant/CMF-S process removes up to 15% of the dissolved organic carbon.64

What is water treatment automation?

Automation of water treatment plant involves the control system opening and closing valves and starting and stopping equipment in predefined sequences to complete specific tasks or to provide the desired process plant output. To achieve these results the automation system relies on signals from correctly selected and placed instruments, devices such as actuators and motor control circuits and reliable control logic. The degree of automation to be used is fundamental to developing an automation system.

What is make up water treatment?

Make up water treatment. Treated raw water is mixed with potable water and pumped to the boiler feedwater treatment system. The system is designed to remove 99% of the dissolved minerals and provide high-purity water to the boiler.

What is raw water pretreatment?

The raw water pretreatment plant is designed principally for solids removal from the incoming Hanover county sewage effluent (grey water), backwash water and wastewater from the oily water collection system. Raw water enters a coagulation/flocculation chamber followed by a clarifier and dual media depth filters. Backwash water from the filters is periodically returned to the clarifier. Clarifier sludge is dosed with polymer before being thickened and then sent to the filter press for dewatering. The cake is sent to landfill and the recovered water returned to the clarifier.

What is media filtration?

Media filtration systems promote the filtration of water through a prescribed filter medium, including: 1 Sand filters; 2 Granular activated carbon; 3 Woven or nonwoven fabric; and 4 Metal screens.

What is the process of removing solid particles from a liquid?

Filtration is the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that allows the fluid to pass through while retaining the solid particles. Filtration may mean the use of a physical barrier, chemical, and/or a biological process.

What are the requirements for filtration?

Basic requirements for filtration are: a filter medium (thin or thick barriers); a fluid with suspended solids; a driving force to cause the fluid to flow; and a the filter that holds the filter medium, contains the fluid, and permits the application of force.

What is the purpose of a straining cloth?

Straining is a very simple method of filtration in which water is poured through a piece of cloth , and can remove some of the suspended silt and solids, destroying some pathogens in the process.

What is clarified water?

In the water industry, clarified water is the goal of the filtration process. Filtration primarily is used for storm water, wastewater, and drinking water applications, but it also has uses in industrial manufacturing, power plants, food and beverage production facilities, mining and other heavy duty applications..

How is impure water purified?

These writings describe early water treatment as: “Impure water should be purified by being boiled over a fire, or heated in the sun or by dipping a heated iron into it and then allowed to cool, or it may be purified by filtration through sand and coarse gravel” (Jadhav, Aasawari, 2014).

What is a pressure filter?

Pressure filters are contained in a steel pressure vessel. Perforated pipes or a steel plate with nozzles collect the filtered water and for distribution of the wash water and air scour.

How are ions removed from a solution?

First, positively charged ions are removed by a cation exchange resin in exchange for a chemically equivalent amount of hydrogen ions. Second, negatively charged ions are removed by an anion exchange resin for a chemically equivalent amount of hydroxide ions. The hydrogen and hydroxide ions introduced in this process unite to form water molecules. The term is often used interchangeably with demineralization. The cation resin is regenerated with an acid and the anion resin is regenerated with sodium hydroxide (caustic soda).

What is activated alumina?

A medium made by treating aluminum ore so that it becomes porous and highly adsorptive. Activated alumina will remove several contaminants including fluoride, arsenic, and selenium. It requires periodic cleaning with a regenerant such as alum, acid and/or caustic.

What is the process of adsorption?

Adsorption is a physical process which occurs without chemical reaction.

What is the plant life that is found in stagnant water?

Algae. Plant life (green scum) containing chlorophyll is usually found in stagnant surface water. Excessive growths may create taste and odor problems, and consume dissolved oxygen during decay. Sometimes it may be controlled in a pond by the addition of Potassium Permanganate.

What is an air gap in a sewer line?

An air gap is used to prevent cross connection between a water treatment device and a possible source of wastewater thereby preventing a reverse flow of water from the sewer into the water supply system. Without an air gap, such reverse flow could occur due to an increase in the pressure in the sewer system or the creation of a negative pressure in the water supply line. Local plumbing codes usually require the air gap to be twice the diameter of the inlet with a minimum width of 1 1/2 inches.

How many liters are in a gallon?

A common unit of liquid volume; the US gallon has a volume of 231 cubic inches or 3.78533 liters; the British (Imperial) gallon has a volume of 277.418 cubic inches or 4.54596 liters.

What is the quantitative capacity of a water or water solution to neutralize an alkali or base?

It is usually measured by titration with a standard solution of sodium hydroxide, and expressed in ppm or mg/L of its calcium carbonate equivalent.

What does "purifying water" mean?

noun. the act or process of making water more potable or useful, as by purifying, clarifying, softening, or deodorizing it.

Can fluoride be used in drinking water?

Placed in drinking water, fluoride can serve people who otherwise have poor access to dental care. In secret, before the referendum, the council went ahead and fluoridated the water anyway. Urbanity ushers in water that needs no apology, and gives a zest to the worst vintage.

What is the process of flocculation?

The flocculation process promotes contact between the floc particles and the particulates (sediment) in the water. Generally, these contacts or collisions between particles result from gentle stirring created by a mechanical or hydraulic means of mixing.

How does sedimentation work?

Sedimentation is accomplished by decreasing the velocity of the water being treated below the point where it can transport settleable suspended material, thus allowing gravitational forces to remove particles held in suspension. When water is almost still in sedimentation basins, settleable solids will move toward the bottom of the basin. This process of sedimentation removes almost ninety percent of the solids in the water. The clearer water on the surface is collected in the launder tubes that direct the water to the filter gallery to remove the remaining ten percent of solids.

How does the pre sedimentation process work?

The raw water is delivered to the headworks of the water treatment plant where the first of 5 major unit water treatment processes start the treatment to make the water safe to drink. The 5 major unit processes include chemical coagulation, flocculation, sedimentation, filtration, and disinfection (described below). There are chemicals added to the water as it enters the various treatment processes.

How is potable water run?

Potable water is run backwards through the filters releasing the entrapped particulates that are collected in drain troughs. The backwash water is sent to the Backwash Recovery Pond and, after a settling process, the backwash water is returned to the raw water settling pond for re-use.

What is the first chemical added to water?

The first chemical added is chlorine dioxide and it is an oxidant used to break down naturally occurring organic matter such as decaying leaves and other plant material. A chemical coagulant known as aluminum sulfate is used as the primary coagulant. A polymer, a long chain of synthetic organic compounds, is also added to the water as a coagulant aid to help in strengthening the primary coagulant’s bonding chains. The coagulants are added at the rapid mix unit; this is a unit that creates turbulent mixing energies to help thoroughly disperse the chemical coagulants into the raw water and to begin the coagulation process. The coagulants that cause very fine particles to clump together into larger particles that can then be removed later in the treatment process by settling, skimming, draining or filtering.

What is a PLC in water treatment?

Devices known as programmable logic controllers ( PLCs) that are networked together with other PLCs control the water treatment plant and the treatment processes. The PLCs track over 1,500 signals or data points to ensure optimized treatment. The computer signals and data are collected by the Supervisory Collection and Data Acquisition ( SCADA) system and provide information to the Operator on shift whenever any item requires Operator intervention.

What is the best concentration of fluoride in water?

The United States Public Health Service has determined the optimum concentration for fluoride in United States water to be in the range of 0.7 to 1.2 parts per million.

How does a water treatment unit work?

Even though EPA regulates and sets standards for public drinking water, many Americans use a home water treatment unit to: 1 Remove specific contaminants 2 Take extra precautions because a household member has a compromised immune system 3 Improve the taste of drinking water

What is the process of boiled water?

Distillation is a process in which impure water is boiled and the steam is collected and condensed in a separate container, leaving many of the solid contaminants behind. Disinfection. Disinfection is a physical or chemical process in which pathogenic microorganisms are deactivated or killed.

What are the steps of water treatment?

Today, the most common steps in water treatment used by community water systems (mainly surface water treatment) include: Coagulation and flocculation are often the first steps in water treatment. Chemicals with a positive charge are added to the water.

What is a CCR report?

Every community water supplier must provide an annual report, sometimes called a Consumer Confidence Report, or “CCR,” to its customers. The report provides information on your local drinking water quality, including the water’s source, contaminants found in the water, and how consumers can get involved in protecting drinking water.

Why is surface water more contaminated than ground water?

Typically, surface water requires more treatment and filtration than ground water because lakes, rivers, and streams contain more sediment and pollutants and are more likely to be contaminated than ground water. Some water supplies may also contain disinfections by-products, inorganic chemicals, organic chemicals, and radionuclides.

What is a water softener?

Water Softeners. A water softener is a device that reduces the hardness of the water. A water softener typically uses sodium or potassium ions to replace calcium and magnesium ions, the ions that create “hardness.”. Distillation Systems.

What is the most common type of water treatment system?

The most common types of household water treatment systems consist of: Filtration Systems. A water filter is a device which removes impurities from water by means of a physical barrier, chemical, and/or biological process. Water Softeners. A water softener is a device that reduces the hardness of the water.

What are the most important problems in water?

If the water originates from a surface water supply such as a river, lake, or dam, then the suspended particles are the most important problem. Different techniques to remove suspended particles include the addition of coagulants and the use of membranes.

What is membrane technology?

The development of large-scale modules with lower-energy consumption reduced costs significantly. Especially in the water industry, membrane technology has grown much more than coagulation and ozonation, since membranes require minimal addition of aggressive chemical reagents and produce no by-products.

What is the most effective method of removing bacteria and viruses from raw water prior to conventional treatment?

zooplankton) and macro-invertebrate filter feeders also reduce pathogen numbers. Apart from pre-chlorination, storage is the most effective method of removing bacteria and viruses from raw water prior to conventional treatment.

What is biological waste water treatment?

Biological waste water treatment is the primary method of preparing food-processing waste water flows for return to the environment. Increasing waste water loads on existing plants and more stringent government discharge requirements have put considerable pressure on the food-processing industry to refine and understand better the design and management of biological waste water treatment processes. Though activated sludge and other biological treatment processes are still frequently operated by general guidelines and ‘rules of thumb,’ facility design and operation must be guided by consideration of both the physical and biological aspects of waste water treatment. Various modifications and combinations of aerobic and anaerobic biological treatment processes are commonly used in the food-processing industry.

What is MF water treatment?

MF is used to remove turbidity and larger microorganisms. Water treatment in existing installations uses immersed membrane modules that are simply placed in water tanks where a vacuum at the permeate side drives the collection of purified water.

How to improve the taste of water?

1. Understand the treatment need: For many consumers, simply improving the taste of the water is their primary treatment need. For some, there may be health contaminants that must be treated. And others may have very hard water, causing issues with lime scale around fixtures and possibly damaging appliances. 2.

What will the future of brewing water systems be like?

Brewery water treatment systems of the future will be very flexible, allowing breweries to tailor-make their water for different products. At the same time, these future water treatment systems will aim to achieve optimum efficiency in terms of operating cost and especially wastewater produced. The advances in analysis techniques will inevitably lead to further challenges, as it will be possible to detect certain components that are not an issue today but will then need to be removed. It will also continue to be vital for brewers to pay attention to their water supply to avoid surprising and unexpected quality defects in the finished product.

What is the most serious problem in steam?

Corrosion is one of the most serious problems within steam systems that consume high volumes of water. Fresh water has high amounts of dissolved oxygen. When this oxygen is mixed with elevated temperatures, it becomes highly corrosive, particularly for the steel piping in boiler systems that are made of carbon.

What is feedwater treatment?

Feedwater treatment is a pre-water treatment process to control deposition, eradicate impurities and prevent corrosion within a boiler system. In a boiler system, water is transformed into steam and expands by as much as 1000 times as it passes through steam pipes at rates of 100km/hr.

Overview

Water treatment is any process that improves the quality of water to make it appropriate for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment. Water treatment removes contaminantsand undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use. This treatment is cruci…

Drinking water treatment

Water contamination is primarily caused by the discharge of untreated wastewater from enterprises. The effluent from various enterprises, which contains varying levels of contaminants, is dumped into rivers or other water resources. The wastewater may have a high proportion of organic and inorganic contaminants at the initial discharge. Industries generate wastewater as a result of fabrication processes, processes dealing with paper and pulp, textiles, chemicals, and fro…

Heavy Metals

Heavy metals in wastewater have become a serious environmental issue in recent years, owing to the high damage they pose to ecosystems and human health even at extremely low concentrations. Heavy metal pollution is a substantial environmental burden due to its flexibility, accumulation, non-biodegradability, and persistence. Its effluent is discharged into the environment by industries such as paper, Insecticides, tanneries, metal plating, mining operations, …

Water Treatment Technologies

Elimination of hazardous chemicals from the water, many treatment procedures have been applied. The selection of wastewater treatment systems is contingent on a number of factors: (1)The degree to which a method is necessary to raise the waste water quality to a permissible level; (2) The control method's flexibility; (3) The process's cost; and (4) The process's environmental compatibility.

Standards

Many developed countries specify standards to be applied in their own country. In Europe, this includes the European Drinking Water Directive and in the United States the United States Environmental Protection Agency (EPA) establishes standards as required by the Safe Drinking Water Act. For countries without a legislative or administrative framework for such standards, the World Health Organizationpublishes guidelines on the standards that should be achieved. China …

Industrial water treatment

Two of the main processes of industrial water treatment are boiler water treatment and cooling water treatment. A large amount of proper water treatment can lead to the reaction of solids and bacteria within pipe work and boiler housing. Steam boilers can suffer from scale or corrosionwhen left untreated. Scale deposits can lead to weak and dangerous machinery, while additional fuel is required to heat the same level of water because of the rise in thermal resistance. Poor q…

Developing countries

Appropriate technology options in water treatment include both community-scale and household-scale point-of-use (POU) or self-supply designs. Such designs may employ solar water disinfection methods, using solar irradiation to inactivate harmful waterborne microorganisms directly, mainly by the UV-A component of the solar spectrum, or indirectly through the presence of an oxide photocatalyst, typically supported TiO2 in its anatase or rutile phases. Despite progress in SODISte…

Regulation

The Safe Drinking Water Act requires the U.S. Environmental Protection Agency (EPA) to set standards for drinking water quality in public water systems (entities that provide water for human consumption to at least 25 people for at least 60 days a year). Enforcement of the standards is mostly carried out by state health agencies. States may set standards that are more stringent than the federal standards.

Definition

- Filtrationis the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that allows the fluid to pass through while retaining the solid particles. It may mean the use of a physical barrier, chemical, and/or a biological process. The removal of particlestakes place with processes including: straining, flocculation, sedimentation and surfac…

What Are The Uses in The Water Industry?

- In the water industry, clarified water is the goal of the filtering. It is primarily used for storm water, wastewater, and drinking water applications, but it also has uses in industrial manufacturing, power plants, food and beverage production facilities, mining and other heavy duty applications.. Water filtrationcan remove or reduce the concentration of suspended particles, parasites, bacter…

History

- Before the industrial revolution, there is evidence that it was used in the manufacture of dyes, wines and beers. There are drawings and writings from more than 6000 years ago that illustrate simple water filtration processes. Most notably, Ancient Sanskrit and Greek writings recommended water treatment methods. These writings describe early water treatment as: “Imp…

What Are The Different types?

- There are different types of water filters, such as strainers, precoat filters, slow sand filters, rapid gravity and pressure filters, membrane filters, and granular media filters.

A -

- Absolute Filter Rating

1. Filter rating meaning that 99.9 % (or essentially all) of the particles larger than a specified micron rating will be trapped on or within the filter. - Absorption

1. The process in which one substance penetrates into the body of another substance, termed the absorbent. An example is the absorption of water into soil.

B -

- Backflow

1. Flow of water in a pipe or line in a direction opposite to the normal flow; often associated with back siphonage or the flow of possibly contaminated water into a potable water system. - Backflow Preventor

1. A device or system installed in a water line to stop backflow from a non-potable source.

C -

- Calcite

1. Calcium carbonate (CaCO3). A trade name for finely ground limestone, very high in calcium carbonate, which is used to raise the pH of acidic water. - Calcium ( Ca )

1. One of the primary elements of the earth's crust commonly found in water as a dissolved solid. The presence of calcium in water is a factor contributing to the formation of scale and insoluble soap curds which are means of clearly identifying hard water. It is sometimes referred to as lime.

D -

- Dealkalization

1. A process for the reduction of alkalinity in a water supply. It is generally accomplished by a chemical feed processor combined cation and anion exchange systems. - Deashing

1. The removal from solution of inorganic salts by means of adsorption by ion exchange resins of both the cations and the anions that comprise the salts.

E -

- Eductor

1. A venturiwith an opening at the throat used to educt (suck in) air or liquid. The common method of introducing brine into a water softener. - Efficiency

1. The effectiveness of the operational performance of an ion exchanger. Efficiency in the adsorption of ions is expressed as the quantity of regenerant required to effect the removal of a specified unit weight of adsorbed material, e.g., pounds of acid per kilogram of salt removed.

F -

- Ferric Iron

1. Small solid iron particles containing trivalent iron, usually as gelatinous ferric hydroxide or ferric oxide (Fe2O3), which are suspended in water and visible as "rusty" water. Ferrous (iron in solution) is readily converted to ferric iron by exposure to oxygen found both in water and air. Ferric iron c… - Ferrous Iron

1. Usually ferrous hydroxide which when dissolved in water produces a clear solution. Often called clear water iron, it can be removed by ion-exchange.

G -

- Gallon

1. A common unit of liquid volume; the US gallon has a volume of 231 cubic inches or 3.78533 liters; the British (Imperial) gallon has a volume of 277.418 cubic inches or 4.54596 liters. - GAC

1. Granular Activated carbon.

H -

- Halite

1. A geological term for rock salt, a mineral which is more than 95 percent sodium chloride. Also known as native or fossil salt. - Halogens

1. A family of elements that includes bromine, chlorine, fluorine, astatine, and iodine. They are very active chemically. They are commonly found as the ionic component in compounds with various other elements.

I -

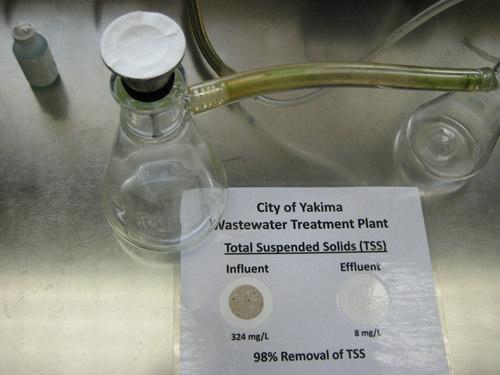

- Influent

1. The water entering a water treatment devise. - Inorganic Matter

1. Matter which is not derived from living organisms and contains no organically produced carbon; includes rocks, minerals and metals.

J -

- Jackson Turbidity Unit ( JTU )

1. An arbitrary unit of turbidity originally based on a suspension of specific type of silica with the turbidity measured in a Jackson Candle Turbidimeter. This has been replaced by the nephelometric turbidity unit (NTU).