What is a jar test?

jar test. A laboratory procedure that simulates coagulation/flocculation with differing chemical doses. The purpose of the procedure is to estimate the minimum coagulant dose required to achieve certain water quality goals. Samples of water to be treated are placed in six jars.

What type of water should be used for jar test?

Different dosages of coagulants are tested using a jar test, which mimics the conditions found in the treatment plant. The first step of the jar test involves adding coagulant to the source water and mixing the water rapidly (as it would be mixed in the flash mix chamber) to completely dissolve the coagulant in the water.

How can I project the dosage results from a jar test?

The jar test is a method of measuring the effect of coagulation, flocculation, and sedimentation on turbidity. Although the procedure is not outlined in Standard Methods, it is used in most water treatment plants to find the best coagulant dosages under varying conditions.

How do you test a dynamic jar?

Mar 30, 2021 · Jar testing is a pilot-scale test of the treatment chemicals used in a particular water plant.It simulates the coagulation/flocculation process in a water treatment plant and helps operators determine if they are using the right amount of treatment chemicals, and, thus, improves the plant's performance.

What is the meaning of jar test?

Jar test is a pilot-scale laboratory test that simulates coagulation or flocculation with differing chemical doses. The purpose of the jar test is to estimate the minimum coagulant dose required to achieve certain water quality goals.

Why the jar test is important for water treatment?

The purpose of this test is to estimate the minimum coagulant dose required to achieve certain water quality goals. In other words, jar test helps to determine the right amount of treatment chemicals: the lowest dose of chemicals that provides satisfactory settling is the dose used to treat the water.Oct 7, 2021

How do you conduct a jar test?

1:0917:53Jar Test Procedure for Water Treatment - YouTubeYouTubeStart of suggested clipEnd of suggested clipBecause if particles are not properly coagulated. They won't flocculate. And if they don'tMoreBecause if particles are not properly coagulated. They won't flocculate. And if they don't flocculate they won't settle. And if they aren't properly coagulated they won't filter.

How do you use jar test apparatus?

0:000:53Jar Testing Apparatus - Flocculator - YouTubeYouTubeStart of suggested clipEnd of suggested clipPhilosophy later or jar test apparatus is a philosophy Asian tests on water and effluent samples aMorePhilosophy later or jar test apparatus is a philosophy Asian tests on water and effluent samples a digital display clearly indicates the speed of the rotational stainless steel paddles.

How is flocculation achieved in jar test?

This is accomplished by slowly stirring 100 or 200 mL of the substrate in a beaker and adding the polymer solution in 1 mL increments until flocculation begins to occur. This will be the starting dosage of jar testing.

Why do you aerate water?

In industrial water conditioning, one of the major objectives of aeration is to remove carbon dioxide. Aeration is also used to oxidize soluble iron and manganese (found in many well waters) to insoluble precipitates. Aeration is often used to reduce the carbon dioxide liberated by a treatment process.

Which coagulant is used in jar test?

The following jar test procedure uses alum (aluminum sulfate) a chemical for coagula- tion/flocculation in water treatment, and a typical six-gang jar tester. The results of this procedure can help optimize the performance of the plant.

What is the purpose of coagulation and flocculation in water treatment?

Coagulation and flocculation are both critical processes to separate and remove suspended solids in water and wastewater treatment. These processes improve the clarity of the water to reduce turbidity.

Why do surface water plants perform jar tests?

Surface water plants, in contrast, tend to treat water with a high turbidity which is susceptible to sudden changes in water quality. Operators at these plants will perform jar tests frequently, especially after rains, to adjust the coagulant dosage and deal with the changing source water turbidity. Purpose.

How to prepare a stock solution?

Once you decide on the strength and volume of stock solution to prepare, the procedure is as follows: Weigh out the proper quantity of the chemical using the analytical balance. Put an empty weigh boat on the balance and tare it. Then add the chemical slowly to the weigh boat until the desired weight has been achieved.

How long to record floc?

Record a description of the floc in each beaker 5, 10, 15, 20, 25, and 30 minutes after addition of the chemicals. Stop the stirring apparatus and allow the samples in the beakers to settle for 30 minutes. Record a description of the floc in each beaker after 15 minutes of settling and again after 30 minutes of settling.

How long to record floc?

Record a description of the floc in each beaker 5, 10, 15, 20, 25, and 30 minutes after addition of the chemicals. Stop the stirring apparatus and allow the samples in the beakers to settle for 30 minutes. Record a description of the floc in each beaker after 15 minutes of settling and again after 30 minutes of settling.

What is a jar test?

The jar test is a method of measuring the effect of coagulation, flocculation, and sedimentation on turbidity. Although the procedure is not outlined in Standard Methods, it is used in most water treatment plants to find the best coagulant dosages under varying conditions.

How to prepare a stock solution?

Once you decide on the strength and volume of stock solution to prepare, the procedure is as follows: Weigh out the proper quantity of the chemical using the analytical balance. Put an empty weigh boat on the balance and tare it. Then add the chemical slowly to the weigh boat until the desired weight has been achieved.

Do surface water plants have turbidity?

Surface water plants, in contrast, tend to treat water with a high turbidity which is susceptible to sud den changes in water quality . Operators at these plants will perform jar tests frequently, especially after rains, to adjust the coagulant dosage and deal with the changing source water turbidity. Equipment .

Can you use a magnetic stirrer to test for lime?

If lime is used , it is best to use a magnetic stirrer since lime is not completely soluble in water. In other cases, magnetic stirrers can still be useful. Collect a two gallon sample of the water to be tested. This should be the raw water. Measure 1,000 mL of raw water and place in a beaker.

Why do we use jar testing?

Jar testing is a pilot-scale test of the treatment chemicals used in a particular water plant.It simulates the coagulation/flocculation process in a water treatment plant and helps operators determine if they are using the right amount of treatment chemicals, and, thus, improves the plant's performance.

How do you conduct a jar test?

First, using a 1,000 milliliter (mL) gradu- ated cylinder, add 1,000 mL of raw water to each of the jar test beakers. Record the temperature, pH, turbidity, and alkalinity of the raw water before beginning.

Is alum a coagulant or flocculant?

To accomplish this, the water is treated with aluminum sulfate, commonly called alum, which serves as a flocculant. Raw water often holds tiny suspended particles that are very difficult for a filter to catch. Alum causes them to clump together so that they can settle out of the water or be easily trapped by a filter.

What causes flocculation?

In dispersed clay slurries, flocculation occurs after mechanical agitation ceases and the dispersed clay platelets spontaneously form flocs because of attractions between negative face charges and positive edge charges.

Does alum increase pH?

Ionic species present in alum solutions are highly dependent on the degree of reaction with hydroxyl ions. It is tempting to say that "the composition is pH-dependent." However, in the vicinity of pH=4.3 the composition of alum solutions changes a great deal with very little change in pH.

What is a flocculation test?

A Flocculation Test Procedure is used to determine how much Flocculants need be added to solids in suspension (slurry or pulp) to cause the individual particles to collect in the form of flocs. The formation of flocs aids in improved settling rates, better overhead clarity and/or faster filtration rates.

What is the test used to select the type of coagulant required?

The dose of the coagulant to be used can be determined via the jar test. The jar test involves exposing same volume samples of the water to be treated to different doses of the coagulant and then simultaneously mixing the samples at a constant rapid mixing time.

What is a jar test?

Jar testing can be used as a tool to help select the proper coagulant and dose for the reduction of pathogens and disinfection by-product pre-cursors. However, existing jar testing procedures can be involved, time consuming and may not provide the necessary data to make informed decisions on the selected coagulant type and dose for transferable full-scale plant performances.

How often should you perform a jar test?

Ideally, performing at least one set of jar testing per week will help keep procedures fresh in memory and to maintain skills and confidence. Maintain database record of coagulant, doses, filtrate and indirect DOC performances for any operator/engineer to review for seasonal water quality. Initial skill and confidence building will require several hours of jar testing and practice.

What is the effect of pre-oxidation on a jar?

Pre-oxidation can improve filtrate turbidity, enhance DOC reduction, improve taste and odors and reduce coagulant dose. Jar testing with and without ozonation, potassium permanganate and chlorine as pre-oxidants were evaluated.

Jar Test and Flocculation: from the laboratory to the wastewater treatment plant

Jar Test enables the correct choice and dosage of chemical coagulants aimed at removing suspended matter and pollutants in water treated in wastewater treatment plants.

Result evaluation for full-scale application and optimized performance

The Jar Test helps water treatment plant lab operators to avoid overfeeding or overdosing, especially with coagulants saving resources and optimizing processes. VELP solutions for Jar Test are robust products with strong resistance to chemical and mechanical corrosion.

What is a successful jar testing procedure?

A successful jar testing procedure must successfully incorporate all the mixing factors for flash mixing and flocculation and settling in order to be an effective predictor of the performance of the plant.

What is dynamic jar test?

Dynamic jar tests can be used to identify the optimum mixing intensity in the flocculator of the full scale plant. They can also be used to select the appropriate mixing intensity and flocculation time that will be used during conventional jar tests.

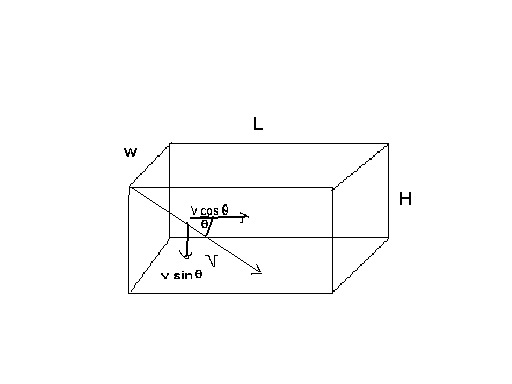

What is an air diffuser?

Air diffusers are a special category of coagulation-flocculation units. The air is typically diffused several feet below the surface of the water, and the coagulant or other chemical is injected below the surface and just above the air diffuser(s). The velocity gradient is calculated as follows:

Why do surface water treatment plants use a multi-barrier approach?

Because of the potential to transmit pathogens or other harmful constituents in surface water to the customers, surface water treatment plants (SWTPs) use a multi-barrier approach to remove and inactivate bacteria, viruses, and protozoa and protect public health. SWTP barriers . Removal and inactivation .

What is the SOR for sedimentation basins?

The design of sedimentation basins is normally based on Hydraulic Detention Time (HDT) or Surface Overflow Rate (SOR). In jar testing, the SOR is the most convenient term to work with.

What is feed rate?

Feed rate: The feed rate is the measure of how much chemical is added to the treatment process per unit of time. Please note that the term “feed rate” is not the same as “dose” and is not directly related to the volume of water or the flow rate in the treatment unit to which it is added. It is only the measure of how much chemical is being fed, regardless of how much water it is being added to. Normal expressions of feed rate include:

What would happen if we fed a dry chemical, such as HTH, the only difference we would have to

If we were feeding a dry chemical, such as HTH, the only difference we would have to make to this equation would be a Concentration factor. Equation 7 would become:

What is the best pH for a jar test?

A jar test procedure as described above can help to establish the optimum pH within the 7.5 to 11 range. For adjusting pH, sodium hydroxide is recommended. However, other common chemicals can be used — such as soda ash and lime. For some applications (nickel complexes) magnesium hydroxide is an effective reagent.

What is the insoluble particle formed by adding a precipitating reagent to a wastewater solution?

The suspended stability of such particles is due to both their small size and to the electrical charge (usually negative) on their surface causing them to repel their neighboring particles.

What happens when oxidizers are added to wastewater?

These reaction are: 1) the reduction of the oxidizers and 2) the precipitation of the metals. This, of course, increases the amount of precipitant required for total metals precipitation.

What is the function of cationic polymers in precipitants?

Some precipitants contain cationic polymers that neutralize the precipitated particles. The cations (positive charges) from the polymer reduce or reverse the negative charges of the precipitate which, in turn, permits the coagulation and flocculation of the particles.

How can heavy metals be precipitated?

That is, dissolved heavy metal ions can be precipitated chemically by adjusting the pH of a wastewater stream. The pH is important because all metals have a pH at which their solubility is minimal. Although this pH differs for all metals, it generally lies between 7.5 and 11.

What is the effect of low solubility on precipitants?

These precipitants, with low solubility, can achieve very high removal efficiencies. When used as a “polishing” precipitant, the dosage of a precipitant can be lowered depending on the quantity of metals that are precipitated as hydroxides by pH adjustment.

What is precipitation in science?

Precipitation is the chemical conversion of soluble substances (including metals) into insoluble particles. Coagulation and flocculation causes a chemical reaction that promotes the formation, agglomeration or clumping of such particles to facilitate their removal from solution. The amount or dosage of a precipitant, ...