What are flocs in water treatment?

For the flocculation portion of drinking water treatment in Mesa, AZ, aluminum sulfate (alum) is mixed into the water, causing small impurities to stick together and form "flocs." Copyright © (top) City of Mesa, AZ, and (bottom) 2004 Microsoft Corporation, One Microsoft Way, Redmond, WA 98052-6399 USA.

Why is there floc in my effluent?

Also, floc can build up on the influent distribution structures that slow down the incoming flow and distribute it evenly along the bottom of the plates; this build up will eventually disturb this incoming flow and cause floc carryover into your effluent. Have you checked to make sure your flocculant or polymer dosage is not excessive?

What happens when water is flocculated?

When water is flocculated, the sediment has become bigger aggregated flakes, making it easier to spot and remove in the next stage. This process can happen naturally or can be forced using physical processes and/or flocculants. One of the major requirements to treat water from any resource is to eliminate the suspended solids.

What is flocculation and sedimentation in water treatment?

Flocculation followed by sedimentation are stages used in several water treatment systems, including industrial wastewater, stormwater, sewage water, and drinking water treatments. In the process of coagulation and flocculation, positively charged chemicals are included in the water to help neutralize the negative charges.

How is floc removed?

Coagulation and flocculation occur in successive steps intended to overcome the forces stabilising the suspended particles, allowing particle collision and growth of flocs, which then can be settled and removed (by sedimentation) or filtered out of the water.

Does flocculant dissolve in water?

Despite their very high effectiveness, flocculants suffer a major disadvantage: In the event of a spill or if residue sticks to the bottom of a shoe, the slightest contact with water can be disastrous. In contact with water, the flocculant dissolves and forms a viscous gel that is similar to hair gel.

What is the next step after flocculation process?

Conventional plants separate coagulation (or rapid-mix) stage from flocculation (or slow-mix) stage. These stages are followed by sedimentation, and then filtration.

What happens flocculation?

Flocculation is a process by which a chemical coagulant added to the water acts to facilitate bonding between particles, creating larger aggregates which are easier to separate. The method is widely used in water treatment plants and can also be applied to sample processing for monitoring applications.

How do you remove polymers from water?

In terms of water purification, >90% of the polymer (of molecular weight 160,000) was removed from solution by using 200 mg of the acidic clay per 50 mL of aqueous solution.

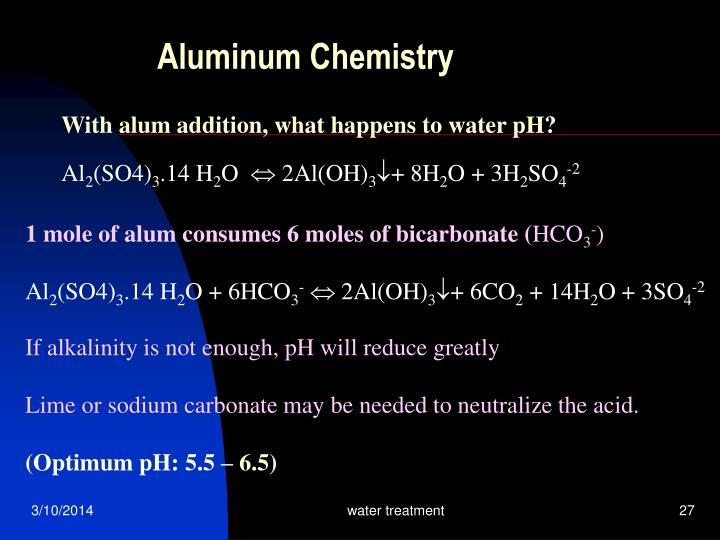

Does flocculant lower pH?

Because flocculants can affect the pH level, you'll want to start out with it at about 7.0 so you can make sure your sanitizer keeps working at maximum efficiency.

How long does flocculant need to circulate?

two hoursCirculate the Flocculant Run the pool pump for two hours to circulate the floc throughout the water. Remember to keep your filter set to “recirculate,” not “filter.”

What is floc in water treatment?

What is flocculation? Flocculation is the separation of a solution, commonly the removal of sediment from a fluid. The term is derived from floc, which means flakes of material; and when a solution has been flocculated, the sediment has formed into larger aggregated flakes, making them easier to see and remove.

What is floc waste?

FLOC. Waste residue generated directly from the shredding of scrap metal (at a waste facility specified by the EPA by notice published in the Gazette). Soil (not contaminated or VENM) SOIL. Clay, sand or topsoil.

What does flocculation not remove?

Suspended particles cannot be removed completely by plain settling. Large, heavy particles settle out readily, but smaller and lighter particles settle very slowly or in some cases do not settle at all.

How is floc formation controlled in the flocculation process?

How is floc formation controlled in the flocculation process? By the rate at which collisions occur between particles and the effectiveness of these collisions in promoting attachment between particles.

Why is floc not working?

Floc can't take care of live algae. All of the algae needs to be dead before you try to use floc. There are some other situations where floc might not work completely the first time, but they are far less common. The most common of the uncommon cases is probably not using enough floc.

What is floculation in water?

Flocculation is a water treatment process where solids form larger clusters, or flocs, to be removed from water. This process can happen spontaneously, or with the help of chemical agents. It is a common method of stormwater treatment, wastewater treatment, and in the purification of drinking water. One of the requirements for treated water leaving ...

What is the charge of suspended solid particles in wastewater?

Suspended solid particles in wastewater are negatively charged. In the first stage of flocculation, a coagulant like aluminium sulphate is added to the wastewater. The positively charged coagulant molecules neutralize the negatively charged solid particles suspended in the water.

Why is high energy mixing required in wastewater?

The wastewater must be agitated with mixers. High energy mixing is required initially to ensure that the coagulant spreads throughout the water. When flocculation is in progress the mixing energy is reduced to prevent the mass of particles from separating again.

Why is phosphorus limited in wastewater?

Phosphorus content must also be limited in wastewater as a release of phosphorus into rivers promotes algae growth. Uncontrolled releases of phosphorus have been known to cause mass die-offs of fish and other aquatic life.

How often does Sydney Water backwash?

Sydney Water uses sand filters for removing the floc from treated wastewater. They backwash the filters every 24 hours to remove the accumulated floc. Backwash water is returned to the primary treatment section of the plant where the floc is removed with other solids.

What is Cleanawater's solution?

Cleanawater offers a number of solutions for the wastewater industry to help keep wastewater within specification: Chemical dosing, in particular pH dosing, is a common method of wastewater treatment. Regulations require treated wastewater to be in a neutral pH range when discharged into the environment.

Why is Cleanawater important?

Cleanawater uses a chlorine-based system to achieve a high level of disinfection. This protects workers and the general public from potential health hazards associated with unwanted bacteria in the wastewater system. It is particularly important where water is recycled for use.

How does orthokinetic flocculation work?

Orthokinetic flocculation arises from induced velocity gradients in the liquid. It is here that primary particles are induced to approach close enough together, make contact and progressively form larger agglomerates, or flocs. The principal parameter governing the rate of orthokinetic flocculation is the velocity gradient applied. The degree or extent of flocculation is governed by both applied velocity gradients and time of flocculation. These two parameters influence the rate and extent of particle aggregation and the rate and extent of breakup of these aggregates.

What happens when you add coagulants to water?

When metal coagulants are added to water the metal ions (Al and Fe) hydrolyze rapidly but in a somewhat uncontrolled manner, forming a series of metal hydrolysis species. The efficiency of rapid mixing, the pH, and the coagulant dosage determine which hydrolysis species is effective for treatment.

What is the best coagulant for organics removal?

Organics removal and enhanced coagulation are effective with traditional coagulants like aluminum sulfate, ferric chloride and ferric sulfate, as well as formulations like polyaluminum chloride (PACl) and acid alum. Acid alum formulations are aluminum sulfate with 1 to 15-percent free sulfuric acid.

What are the variables in coagulation?

The efficiency of the coagulation-flocculation process is dependent on many variables. For a particular water these may include: 1 Type of coagulant used 2 Coagulant dosage 3 Final pH 4 Coagulant feed concentration 5 Type and dosage of chemical additives other than primary coagulant (e.g. polymers) 6 Sequence of chemical addition and time lag between dosing points 7 Intensity and duration of mixing at rapid mix stage 8 Type of rapid mix device 9 Velocity gradients applied during flocculation stage 10 Flocculator retention time 11 Type of stirring device used 12 Flocculator geometry.

What are some examples of coagulation operations?

Coagulation operations can be useful in some cases for the removal of inorganics. Examples of successful applications are copper and mercury reductions from wastewaterplant effluents. Two applications discussed in more detail below are arsenic and fluoride removals in potable water treatment:

Why is coagulation important?

Coagulation is also important in several wastewater treatment operations. A common example is chemical phosphorus removal and another, in overloaded wastewatertreatment plants, is the practice of chemically enhancing primary treatment to reduce suspended solids and organic loads from primary clarifiers.

Why are synthetic polymers more effective than flocculants?

They are, in general, more effective as flocculants because of the level of control made possible during manufacture. Important mechanisms relating to polymers during treatment include electrostatic and bridging effects.

What is the purpose of coagulation and flocculation?

Coagulation and flocculation are essential components of both drinking water and wastewater treatment. They provide a reliable process for treating water turbidity (the cloudiness or haziness of a fluid typically invisible to the naked eye) which is a key test of water quality.

What is the difference between flocculation and coagulation?

Coagulation and flocculation are two, separate, crucial parts of water and wastewater treatment. Coagulation destabilises the minute suspended particles by static charge neutralisation, while flocculation helps them to bind together to form much bigger morphologies, so they can be more easily separated from the liquid phase.

What coagulants remove suspended solids?

Organic coagulants. Both polyamine and poly-DADMAC coagulants have been proven to be very effective at removing most suspended solids. Tannates are particularly good at oils and fats. Enable relatively low charge density to neutralise lower charged suspended particles, more effectively.

What destroys the process whereby tiny particles repel each other and promotes their consolidation to bigger ones that are able

The coagulation process. This destroys the process whereby tiny particles repel each other and promotes their consolidation to bigger ones that are able to stick together. The bigger the particle, the easier it is to separate from the liquid.

What are the two types of coagulants?

Types of coagulants. Today, there are two types of coagulants that are most commonly used in water and wastewater treatment. Organic and inorganic. Inorganic coagulants include: Iron coagulants - e.g. ferric sulphate, ferrous sulphate, ferric chloride and ferric chloride sulphate. Organic coagulants include:

How long does it take for a suspended particle to settle out of the water?

This causes them to remain suspended rather than clumping together and settling out of the water. They might take days or even up to centuries to settle out! Coagulation and flocculation are two separate processes, used in succession, to overcome the forces stabilising the suspended particles. While coagulation neutralises the charges on ...

Why do water particles repel each other?

The smallest particles (colloids) are stabilised by the action of physical forces (static electricity) on the particles themselves and, because they all have a negative charge when suspended in water, they repel each other.

Why do flocculants work?

These two basic concepts are the reasons that flocculants work. When the particles come together, they get heavier. When they get heavier, the water molecules cannot push them around as easily as they used to, and gravity pulls them to the bottom of the water container. The result is water with less dirt in it!

How does pH affect flocculant performance?

Additionally, the water's pH can affect the performance of a flocculant. The pH scale (see Figure 7) is used to determine how acidic or basic the water is. Most flocculants work best at neutral conditions (pH 7) while some work independently of the pH.

Why do flocculants accumulate mass?

Because they are so large, small particles can get trapped in the curves of the polymer causing them to accumulate a mass heavy enough to prevent their retention in solution. Many other flocculants are currently used in water treatment today and even more are being studied by engineers and researchers around the world.

Why do colloids settle out of water?

Another reason that colloids take a long time to settle out of water is surface charges. Surface charges can form on a particle in several ways.

What is the measurement of the cloudiness of water?

In this lesson, we focus on the removal of solids. Turbidity —To measure water cleanliness prior to consumption, we use the concept of turbidity. Derived from the word turbid, turbidity is a measurement of the "cloudiness" of water. It essentially tells us the amount of solids in the water.

What are the contaminant types in water?

Several contaminant types are found in water including chemicals (such as salts and sugars), microorganisms (such as bacteria and algae), and solids (such as clay and sand). Most of these contaminants are removed in the water treatment cycle. In this lesson, we focus on the removal of solids.

Does flocculant affect the volume of solution?

The volume of solution and flocculant can also affect flocculation. Chances are, if a large amount of water is being cleaned, a larger amount of flocculant is needed. The most effective dose may also change depending on the flocculant type, which is often dictated by the available charges or size of the flocculant.

How long does it take for a sanitizer to work?

After allowing this acidic solution to work for at least 12 hours, drain the acidic solution to the wastewater treatment holding tank, and then rinse the plates with a hose followed by a high-pressure water spray to all accessible areas.

Why do clarifier plates look slimy?

If you see and feel a dark, slimy film, it is likely bacteria growth. Furthermore, if you feel a scaly residue on the plates, this can serve as a great home to bacteria. Since removal of the clarifier plate packs for cleaning is usually not very feasible for most plants, you can clean them in place.

Why does my clarifier bubble?

The other cause of rising gas bubbles with sludge in the clarifier is bacteria growth within the sludge or on the clarifier plates . Over a period of time, even with good sludge removal, the metal hydroxide sludge will find places to collect within the lower portions of the clarifier.

Does floc build up in the bottom of the plate?

Also, floc can build up on the influent distribution structures that slow down the incoming flow and distribute it evenly along the bottom of the plates; this build up will eventually disturb this incoming flow and cause floc carryover into your effluent.

How often should I use floc?

Nevertheless, floc should be applied 5-7 days between each treatment.

How long does it take for floc to settle in a pool?

Follow the instructions in the body of the product. Step 4: Pour the floc to the pool’s corners and run the pool pump for about an hour to allow the flocculant to disperse around the pool. After an hour, turn the pump off and allow the water to settle for about 8 hours to collect the tiny debris and algae.

What happens if you add too much flocculant to a pool?

When you add too much flocculant to your pool, it will cause too many tiny particles to clump together. When this happens, the pool becomes cloudy. This often doesn’t last as it tends to clear within hours. However, you would have to run your pump as many times as possible until it clears.

How does flocculant work?

A flocculant works more like clarifiers, and they are meant to give your pool a crystal-clear appearance. However, they work in different ways. A clarifier could take days to achieve its result while a flocculant works almost immediately. Cloudy pools after floc are normal things you should experience while trying to give your pool a clearer look. ...

Why is my pool cloudy?

As earlier said, there are several reasons why your pool is cloudy white, mostly resulting from the excessive use of chemicals. Here are things to know: Improper Use of Chemicals: Good chemicals turn bad in your pool when applied wrongly.

What is a floculant in a pool?

Flocculants are meant to act as a final solution to your pool cleaning when every other method fails. When applied to your pool, it clumps together lightweight debris that cannot sink to the bottom of the pool for vacuuming.

Is it normal to have a cloudy pool after adding floc?

Cloudy pools after floc are normal things you should experience while trying to give your pool a clearer look. Here is the thing, after adding floc to your pool, you would experience a cloudy appearance in your water. In fact, in its natural form, floc will clump tiny particles together, which sinks down to the bottom of the pool, ...

Coagulation and Flocculation in Water and Wastewater Treatment

The Coagulants

Removal of Natural Organic Matter

Pathogen Removal

Removal of Inorganics

Wastewater Treatment

Factors Affecting Coagulation Operations

Rapid Mixing

Flocculation

- Orthokinetic flocculation arises from induced velocity gradients in the liquid. It is here that primary particles are induced to approach close enough together, make contact and progressively form larger agglomerates, or flocs. The principal parameter governing the rate of orthokinetic flocculation is the velocity gradient applied. The degree or ex...

Testing and Control