Surface treatment can improve wettability of the material by raising the material’s surface energy and positively affect adhesive characteristics by creating bonding sites. The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air.

Full Answer

What are the most common surface treatments?

Of course, the most common surface treatment is painting. Examples of its functional value include: (i) car body paints are corrosion resistant; (ii) boats are painted with anti corrosion paint with (toxic) chemicals to avoid growth of barnacles, seaweed etc. Examples of aesthetic or decorative value are too numerous. Paints are of three types:

How does surface treatment work?

The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air. In the presence of a high voltage discharge in an air gap, free electrons, which are always present in the air, accelerate and ionise the gas.

What is three-dimensional electrical surface treatment?

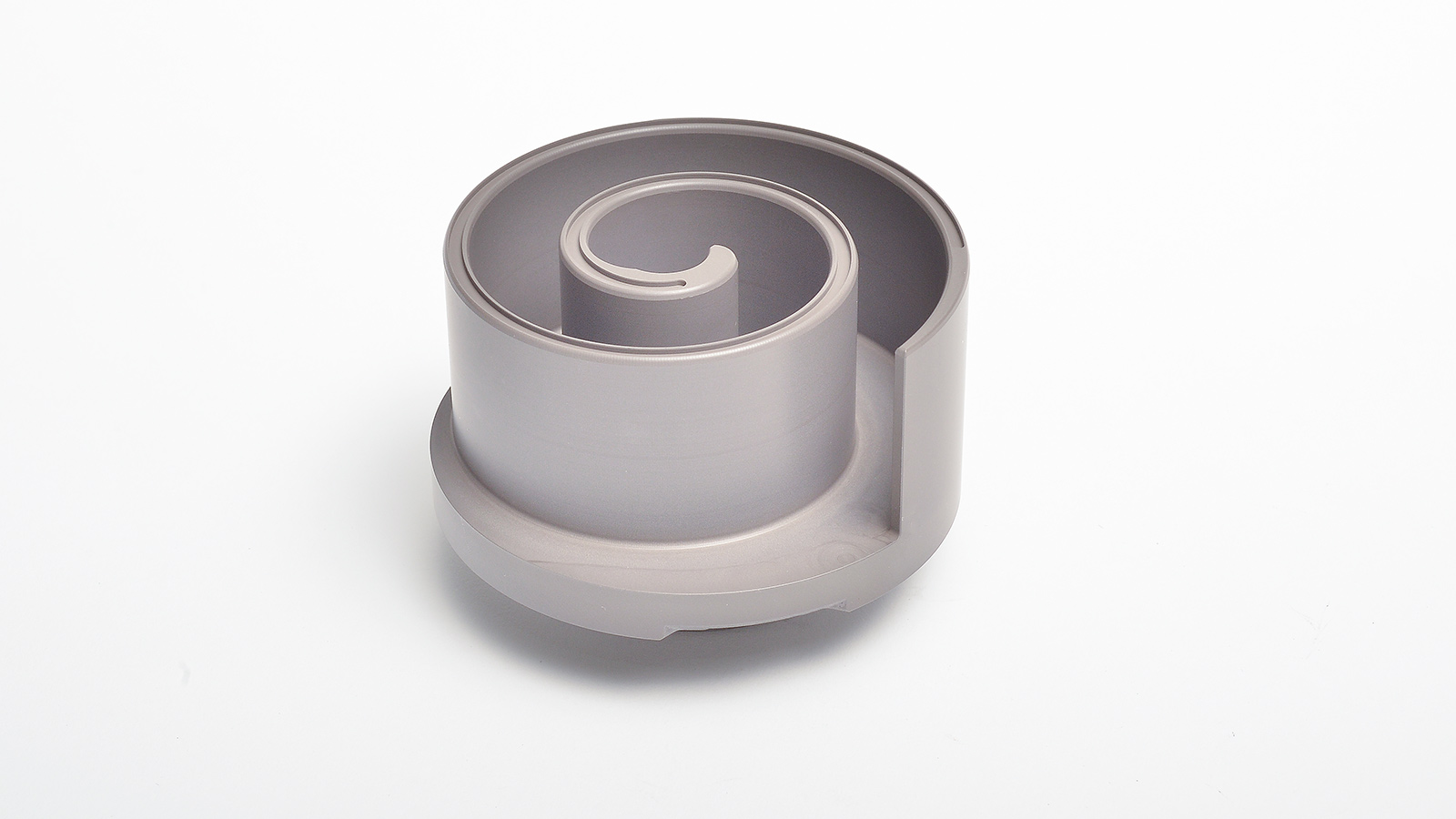

Tantec three-dimensional electrical surface treatment (EST) technology is based on the high voltage high frequency discharge in air. Three-dimensional objects are passed through a discharge region between two electrodes (Figure 3 to your right).

How does surface treatment improve wettability?

Surface treatment can improve wettability of the material by raising the material’s surface energy and positively affect adhesive characteristics by creating bonding sites. The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air.

How does surface treatment improve wettability?

What is surface energy?

What are the most effective free radicals in the presence of oxygen?

How is surface energy measured?

Can plasma be used on 3D parts?

Can you print on polymer after treatment?

Does Tantec have a custom machine?

See more

What is the function of surface treatment?

Surface treatment is an additional process applied to the surface of a material for the purpose of adding functions such as rust and wear resistance or improving the decorative properties to enhance its appearance.

What are types of surface treatment?

Types of surface treatmentsAluminum anodizing. Resistance, hardness and abrasion resistance of the material. ... Zinc coating. Corrosion protection. ... Nickel coating. High gloss and hardness. ... Tinning. Resistance to water corrosion and hygienic safety. ... Blackening. Decorative surface treatment.

What are the characteristics of the ideal surface modification technique?

3. Overview of surface modification techniquesClean implant material surface from contaminations prior to implantation.Increase bioactivity, cell growth and tissue attachments after implantation.Increase hardness of implant to reduce wear rate especially in articulation joint applications.More items...

What are surface treatment chemicals?

Chemical surface treatment is a modification of the aluminium surface through chemical processes. This type of surface treatment is used most often as a pretreatment method for subsequent finishing operations, such as anodising or powder coating.

What is surface treatment in construction?

Surface treatment is an economical and effective method to improve the quality of surface layer and protect the concrete structure compared with other methods, such as decrease water to cement ratio and add admixtures etc. There are a variety of surface treatments that can be used for protection of concrete.

What is surface treatment in building construction?

Ad. The purpose of surface treatment application is to improve surface aesthetics, repair, protect, and consequently increase service/ wear life of various surfaces.

What are surface characteristics?

1. The qualitative variables are the surface morphology, contamination, topography, micro structure, residual stress, and hardness considered as surface integrity characteristics.

What is surface modification technique?

Surface modification is the act of modifying the surface of a material by bringing physical, chemical or biological characteristics different from the ones originally found on the surface of a material.

What are surface properties of biomaterials?

Biomaterial surface has different characteristic such as roughness, patterns, wettability, surface mobility, chemical composition, electrical charge, crystallinity, modulus and heterogeneity to biological reaction.

What are the advantages of surface treatment?

BENEFITS OF SURFACE TREATMENT: Wear and Tear Resistance:It is additionally incredible at lessening the wear and tear your equipment experiences during the time of operation. Expands the Life :As the rate of corrosion falls, the usable life expectancy of the substrate increases!

What is surface heat treatment?

This group of thermal processes refers to a treatment where typically the surface layer has the requirement of a higher hardness which is typically more wear resistant than the core of material.

What is road surface treatment?

Surface Treatment is the application of an asphalt emulsion on either an existing asphalt road or a fresh, compacted granular surface immediately followed by the application of a cover aggregate.

Can I treat 3D objects with plasma?

A plasma treatment is the ideal solution for your 3D parts because plasma gets almost everywhere. Therefore, it can cover regions of your parts whi...

Can the treatment be limited to certain parts of an object?

Theoretically, we could limit a treatment to certain regions by covering parts of an object. However, a plasma treatment usually does not have any...

How do I evaluate the success of a plasma treatment?

We provide different measurement techniques including surface energy test inks and pens as well as contact angle measurements to measure the effect...

Is in-line treatment possible?

Of course. We supply both standalone plasma treaters and in-line plasma treaters, which can easily be integrated into your existing production proc...

Which sizes can be treated?

We offer treatment solutions for almost any size. Smaller parts are often placed on trays, so that many parts can be treated simultaneously.

Surface treatment of stainless steel and metals - See now

Almost every industry will have a need for metal surface treatment equipment. Among the industries who today use metal surface treatment include the following; the automotive industry, the construction industry, the container industry, the electrical industry, the medical industry, industrial equipment, industries using laboratory equipment, aerospace, and several other industries.

What is Surface Treatment - Conformal Coating USA

What is surface treatment? Surface energy of solid materials and the need for surface treatment of polymers. It is often necessary to bond plastic materials to metals or other plastic materials, or simply print on a plastic surface.

SECTION 6 SURFACE TREATMENTS

Basic Asphalt SURFACE TREATMENTS AEMA Emulsion Manual Rev. 1 Mar 2004 6-1 SECTION 6 SURFACE TREATMENTS Asphalt surface treatment is a broad term embracing several types of asphalt and as-phalt-aggregate applications, usually less than 25 millimeters (1 in.) thick and applied

Lecture 9. Surface Treatment, Coating, Cleaning

4 Figure 2. Sputtering processes [source: ece.utep.edu] 9.5. Electroplating This is a process by which a thin layer of metal is deposited on the surface of an electrically conducting part.

Surface Treatment - an overview | ScienceDirect Topics

Surface Treatment. During surface treatment, the alkoxy group in the silane coupling agent is hydrolyzed generating silanol groups (–Si–OH) that can react with functional groups on the surface of the filler forming siloxane bonds, while the sulfur-containing group can form covalent bonds with an olefinic unit in the elastomer during vulcanization (Alkadasi et al., 2004a;

Surface Wettability

Figure 1 to your right helps illustrate the difference between good and poor wettability.

Surface Energy Solid Materials

Figure 2 to your right shows absolute values of surface energy for solid materials and the surface tension of many plastics including polyethylene and polypropylene is often insufficient for bonding or printing.

Basics of high voltage discharge in air and its application to surface treatment

In the presence of a high voltage discharge in an air gap, free electrons, which are always present in the air, accelerate and ionise the gas. When the electric discharge is very strong, collisions of high velocity electrons with molecules of gas result in no loss in momentum, and electron avalanching occurs.

Shelf life of treated surfaces

The shelf life of pre-treated materials ranges from hours to years, depending on the plastic, its formulation, how it was treated and its exposure to elevated temperature after treatment.

Applications of Tantec Electrical Surface Treatment Technology ( EST)

The following materials have been successfully treated using EST technology:

What is surface treatment?

Simply put, a surface treatment is a process applied to the surface of a material to make it better in some way. This could be from a performance perspective, such as improving adhesion and surface wetting characteristics.

What is surface energy?

Surface energy is the energy of a material available at it’s surface to interact with the world around it. A low surface energy means the surface prefers to be itself and not react, whereas a high surface energy will pull liquids closer, interacting strongly.

Surface treatment for plastics

The surface energy of many plastics, such as polyethylene and polypropylene, is actually insufficient for bonding or printing.

How long do surface treatments last?

The shelf life of pre-treated materials is dependent on a number of factors, including the type of plastic, it’s formulation and how it was treated. It even depends on whether it was exposed to elevated temperatures following treatment. As a result, shelf life can range from just a couple of hours to even a few years!

How is curved surface printing done?

For curved surface printing, the ink is placed in a gravure engraved with characters or patterns, and then the characters or patterns are copied onto the curved surface, and then the characters or patterns are transferred to the surface of the molded product by using the curved surface.

What is laser carving?

Laser carving, also called laser engraving or laser marking, is a process of surface treatment using optical principles. Laser beams are used to engrave permanent marks on the surface of objects or inside transparent materials.

What is etching in chemistry?

Generally speaking, the etching is also called photochemical etching, which refers to removing the protective film of the area to be etched after exposure to plate and development , and contacting the chemical solution during etching to achieve the effect of dissolving and corroding, forming unevenness or hollow molding.

What conditions are needed for concrete surface treatments?

The surface treatments must be applied to a clean, dry, and sound substrate at moderate temperature and humidity conditions in a well-ventilated space. A relatively smooth surface is needed for liquid-applied membranes. All concrete repairs should be completed and allowed to cure before applying most of the surface treatments.

What is surface applied corrosion inhibitor?

Surface-applied corrosion inhibitors are designed to reduce the rate of corrosion. The effectiveness and life expectancy of these materials varies with the properties of the concrete, site conditions and type of inhibitor material.

What is a penetrating sealer?

Penetrating sealers are materials that are generally absorbed within the repaired concrete. The depth of penetration varies by the product, the size of the sealer molecule, and the size of the pore structure in the concrete. Deep penetration of sealers is usually not an important factor, but it is desirable for abrasion resistance of surfaces.

What is epoxy resin used for?

Epoxy resins are commonly used repair materials that generally have good bonding and durability characteristics and can be mixed with fine aggregates to improve abrasion and skid resistance.

How can corrosion be prevented?

This can be done by restricting corrosion which can be achieved through reducing the existing moisture level in the concrete and preventing further ingress of moisture and chlorides.

What is a preformed sheet?

Preformed sheets are sealed at the edges to form a continuous waterproofing membrane. Most of these membranes are resistant to water absorption and bridge small (less than 0.25 mm) moving or nonmoving cracks.

Is surface hardener good?

Surface hardeners; ultra-violate, wear, and abrasion resistance are generally good when compared with coatings or membrane systems.

Why use metallic coating?

There are many different methods by which a metallic coating can be applied as a surface treatment to increase the mechanical, electrochemical, and thermal performance of a material. The technique used largely depends on material application as well as the desired material coating or depth of the surface treatment.

What is chromium coated?

Chromium is a metal that is frequently electroplated onto materials to add wear resistance or even simply a decorative finish to the material , like what is commonly seen in a large number of “chrome-plated” automotive parts. Thicker electrodeposited chromium coatings provide excellent abrasion and wear resistance.

What is the process of electroplating?

Electroplating: This is an electro-chemical process where metallic ions are deposited onto the surface of the bulk material via a cathodic polarization reaction. Chromium is a metal that is frequently electroplated onto materials to add wear resistance or even simply a decorative finish to the material, like what is commonly seen in a large number of “chrome-plated” automotive parts. Thicker electrodeposited chromium coatings provide excellent abrasion and wear resistance.

Why is surface important?

Surface has an important role in healing time for osseointegration and, ultimately, the success of implant treatment. 3 It is the only part of the implant exposed to the surrounding oral environs, and its chemical, physical, mechanical, and topographic surface characteristics are all crucial to maximizing the likelihood of successful osseointegration. 3

What are mechanical treatments?

Mechanical treatments: These include grinding, blasting and machining to create rougher or smoother surfaces.

What material is used for dental implants?

Titanium has been long established as the standard bearer for dental implant material. However, when considering the factors that can affect dental implant success both long and short term, one of the most crucial is undoubtedly the implant’s surface.

Which stem cells adhere to and proliferate on all Tiultra implant areas equally?

Figure 7 Human mesenchymal stem cells adhere to and proliferate on all TiUltra implant areas equally. All implant zones osseointegrate with high bone-to-implant contact. (15,19)

Is Tiultra a porous surface?

15 At collar level it is minimally rough (Sa ~ 0.5 μm) and non-porous, with a nanostructured oxide layer. It then transitions to the apex in terms of roughness (from Sa ~ 0.9 to 1.4 μm), and a low-to-high pore density. 15

How is plating achieved?

In this case, the plating is achieved by a purely chemical reaction in the solution that causes the metal to be deposited. This process can be used to plate non-conducting parts with a layer of metal. The most common use of this process is deposition of Nickel –the reduction of Nickel chloride in solution by Sodium hypophosphite, which causes Ni metal to be deposited on the part. The deposited metal is not in crystalline form, so this process is followed by heat-treatment and quenching. Ni-coating using this method is used for making tool coatings that are quite hard (up to 1000 HV).

What is the process of deposited metal on the surface of an electrically conducting part?

This is a process by which a thin layer of metal is deposited on the surface of an electrically conducting part. The part is used as a cathode, and the depositing material forms the anode. The electrodes are dipped in a solution of the appropriate salt, such that on application of voltage, the metal from the anode is dissolved into the solution, and deposited on the cathode. A simple example of this process is copper plating using CuSO4 solution, using Copper anodes.

How to control surface texture?

Reasons for controlling the surface texture: 1 Improve the service life of the components. 2 Improve fatigue resistance. 3 Reduce frictional wear. 4 Have a close dimensional tolerance on the parts. 5 Reduce corrosion by minimizing the depth of irregularities.

What is surface texture?

The surface texture is one of the important factors that control friction. Each manufacturing process, (such as the many kinds ...

What is surface waviness?

Surface waviness : Surface waviness is known as the secondary texture. It results from the factor such as a machine or work deflections, vibrations, chatter, heat treatment or working strains. waviness is the component of surface roughness upon which roughness is superimposed.

Why is surface texture important?

The surface texture is one of the important factors that control friction. Each manufacturing process, (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture.

Which surface wears more quickly, smooth or rough?

The rough surface usually wears more quickly and have higher friction coefficients than the smooth surface.

How to reduce corrosion?

Reduce corrosion by minimizing the depth of irregularities.

How does surface treatment improve wettability?

The treatment can improve wettability of the material by raising the material’s surface energy and positively affect adhesive characteristics by creating bonding sites. The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air.

What is surface energy?

Surface energy of solid materials and the need for surface treatment of polymers . It is often necessary to bond plastic materials to metals or other plastic materials, or simply print on a plastic surface. In order to successfully accomplish this the liquid adhesive, or ink should be able to wet the surface of the material.

What are the most effective free radicals in the presence of oxygen?

These free radicals in the presence of oxygen can react rapidly to form various chemical functiona groups on the substrate surface. Functional groups resulting from this oxidation reaction are the most effective at increasing surface energy and enhancing chemical bonding to the resin matrix. These include carbonyl (-C=O-). carboxyl (HOOC-), hydroperoxide (HOO-) and hydroxyl (HO-) groups.

How is surface energy measured?

Surface energy, like surface tension is measured in mN/m. The surface energy of the solid substrate directly affects how well a liquid wets the surface. The wettability, in turn, is easily demonstrated by contact angle measurements. The contact angle is the angle between the tangent line at the contact point and the horizontal line of the solid surface.

Can plasma be used on 3D parts?

A plasma treatment is the ideal solution for your 3D parts because plasma gets almost everywhere. Therefore, it can cover regions of your parts which cannot be reached by traditional treatment methods. You can even treat the inside of small parts like syringes or the inside of a closed plastic bag.

Can you print on polymer after treatment?

Eventually, these components migrate to the surface of clean polymers. It is therefore recommended to print or bond to the material soon after treatment. However, once the treated surface has been interfaced with a coating, ink, adhesive, or another material, the bond becomes permanent.

Does Tantec have a custom machine?

Tantec has both standard machines, but also custom-designed machines.