What happens when the water in the sedimentation basin short circuits?

When the water in the sedimentation basin short-circuits, the floc does not have enough time to settle out of the water, influencing the economy of the plant and the quality of the treated water. The degree of short-circuiting is the deviation of the actual flow pattern to the ideal flow pattern.

What causes a short circuit in a hydrological system?

Short circuits are generally caused by the stratification of the water in the basin and are common during summer and winter. There should be a proper mixing and baffling of the influent with the water in the basin.

How do inlets prevent short-circuiting in sedimentation systems?

In addition to preventing short-circuiting, inlets control the velocity of the incoming flow. If the water velocity is greater than 0.15 m/ sec, then floc in the water will break up due to agitation of the water. Breakup of floc in the sedimentation basin will make settling much less efficient.

What causes basins to short-circuit?

Basin shape and design, along with design of the inlet and outlet, can cause short-circuiting. You may remember from the last lesson that a long, thin sedimentation basin is less likely to short-circuit than is a short broad one.

What causes short-circuiting in sedimentation tank?

(Short circuiting is the term used for a situation in which part of the influent water exits the tank too quickly, by flowing across the top or along the bottom of the tank.) The baffle is sometimes designed as a wall across the inlet, with holes perforated across the width of the tank.

What is short-circuiting in water treatment?

A condition that occurs when water flows along a nearly direct pathway from the inlet to the outlet of a tank or basin, often resulting in shorter contact, reaction, or settling times in comparison with the calculated or presumed detention times.

What are the factors that affect sedimentation?

Factors that affect the sedimentation process include the shape and size of particles, the density of particles, water temperature, particle charge, dissolved substances in the water, environmental effects, and characteristics of the basin.

What happens during sedimentation in water treatment?

A sedimentation tank in wastewater treatment removes particles from the water. The accumulated solids, or sludge, form at the bottom of the sedimentation tank and are removed periodically. Coagulants are typically added to the water before sedimentation to aid in the settling process.

Does water cause short circuit?

Water can cause electrical outlets to short-circuit and even ignite, presenting considerable risk.

What do you mean by short circuit?

short circuit. noun. a faulty or accidental connection between two points of different potential in an electric circuit, bypassing the load and establishing a path of low resistance through which an excessive current can flow. It can cause damage to the components if the circuit is not protected by a fuse.

Which of the following factors will have an effect on the sedimentation rate of a particle during centrifugation?

The viscosity of the sample solution and the physical properties of the particles also affect the sedimentation rate of each particle.

How does temperature affect sedimentation?

The rate of sedimentation typically doubles for a 20°C rise in temperature. At higher temperatures (>50°C), sedimentation becomes difficult. This is due to increase in solubility of the carbonates. Table 1: Variation of Sedimentation Parameters with Temperature.

What increases the rate of sedimentation?

By using alum in the water, the rate of sedimentation can be increased. This process is called 'Loading'. Here all the insoluble solid particles of the mixture get accumulated on alum leading to the separation of solid from insoluble solid particles.

What causes sedimentation?

Sedimentation occurs when eroded material that is being transported by water, settles out of the water column onto the surface, as the water flow slows. The sediments that form a waterway's bed, banks and floodplain have been transported from higher in the catchment and deposited there by the flow of water.

What happens during the sedimentation process?

Sedimentation is the process of allowing particles in suspension in water to settle out of the suspension under the effect of gravity. The particles that settle out from the suspension become sediment, and in water treatment is known as sludge.

What are the 4 types of sedimentation process?

Type 1 – Dilutes, non-flocculent, free-settling (every particle settles independently.) Type 2 – Dilute, flocculent (particles can flocculate as they settle). Type 3 – Concentrated suspensions, zone settling, hindered settling (sludge thickening). Type 4 – Concentrated suspensions, compression (sludge thickening).

How to tell if a tank is short circuiting?

If the tank or vessel is short-circuiting then the graph will be lopsided indicating that something is amiss in the system. Another way to discover short-circuiting is with an infrared camera. These detect temperature gradients inside a tank or vessel caused by the build-up of solids on the tank floor.

Why does a liquid take the shortest route from the inlet to the outlet?

With short-circuiting, the fluid or solids mixture takes the shortest route from the inlet to the outlet because gravity and hydraulics try to push the liquids in the shortest possible way to any outlet. This also means that not all the solids may be pumped out, but some may be left sitting against the tank or vessel walls.

Why did the mill add baffles to the system?

At first the mill added baffles to the system to increase the retention time in an attempt to fix a problem they did not fully understand.

How long does lithium trace last?

A decision was made to do a lithium trace and it came up with a seven-day retention time, not 28 days. The lagoon barge, used to maneuver aerators around as well as to service them, was used to collect several thousand water samples around the aerators as they were turned off and on.

How does a sanitizer work?

It can reduce the effects of any chemicals reacting with the fluids being treated. It can increase the amounts of chemicals being added to the system far beyond what should be added. It may create dead-zones in the system where no desired reactions are taking place.

Can short circuits be fired?

Short-circuiting can overwhelm and negate any attempts to control a process by adding more chemicals, changing system computer control programs and yes, even firing operators and supervisors for incompetence and negligence, if environmental license limits are exceeded or the process runs poorly.

Can an autothermal thermophilic aerobic digestion system have short circuiting?

Even an autothermal thermophillic aerobic digestion (ATAD) system can have short-circuiting and is not a normal flow through system. The fluids and solids are retained in each of the two or three pressure vessels making ...

What are the benefits of sedimentation?

Sedimentation of water is one of the most basic processes of purifying water, making it a process that is commonly used and understood throughout the world. It may be used as a preliminary step in some water treatment processes. It provides the following benefits to municipalities that employ it: 1 Fewer chemicals are required for subsequent water treatment. 2 It makes any subsequent process easier. 3 The cost is lower than some other methods. 4 There is less variation in the quality of water that goes through the process.

Why do you add coagulants to water?

Coagulants are typically added to the water before sedimentation to aid in the settling process. After sedimentation, there are often other treatment steps. AOS professionals can discuss sedimentation and other water treatment services that we can provide to enhance the quality of your water.

What are the benefits of water treatment?

It provides the following benefits to municipalities that employ it: Fewer chemicals are required for subsequent water treatment. It makes any subsequent process easier. The cost is lower than some other methods. There is less variation in the quality of water that goes through the process.

Why is sedimentation important?

The advantage of sedimentation is that it minimizes the need for coagulation and flocculation. Typically, chemicals are needed for coagulation and flocculation, but improved sedimentation controls the need for additional chemicals.

Why does water thicken when it is still?

This process happens naturally when water is still because gravity will pull the heavier sediments down to form a sludge layer. However, this action can be artificially stimulated in the water treatment process. This mechanical assistance is called thickening.

What is a scada system?

SCADA is a supervisory computer system that continuously collects and analyzes data.

What is water treatment?

Water treatment is the process of making water ready for human use. While there are several critical aspects, sedimentation water treatment is of particular importance. It is essential to understand the whole water treatment process in order to ensure the process is completed safely and efficiently for the general public.

Is sedimentation a theoretical process?

Although sedimentation is an accepte d process within the water treatment industry, it is still theoretical. The process can be varied depending on the concentration of particles. For example, small concentrations often settle unhindered or without mechanical assistance.

What is sedimentation in water?

Sedimentation, or clarification, is the processes of letting suspended material settle by gravity. Suspended material may be particles, such as clay or silts, originally present in the source water. Suspended material or floc is typically created from materials in the water and chemicals used in coagulation or, in other treatment processes, such as lime softening (see Lime Softening chapter).

How does water temperature affect settling?

When water temperature decreases, the rate of settling becomes slower. The result is that, as the water cools, detention time in the sedimentation tank must increase and the operator must make changes to the coagulant dosage to compensate for the decreased settling rate. In most cases, temperature does not have a significant effect on treatment. A water treatment plant has the highest flow demand in the summer when the temperatures are highest and settling rates are the best. When water is colder, the flow in the plant is at its lowest and, in most cases; detention time in the plant is increased so floc has time to settle in the sedimentation basin.

What is a circular basin?

Circular basins are often referred to as clarifiers. These basins share some of the performance advantages of the rectangular basins, but are generally more prone to short circuiting and particle removal problems. For square tanks the design engineer must be certain that some type of sludge removal equipment for the corners is installed.

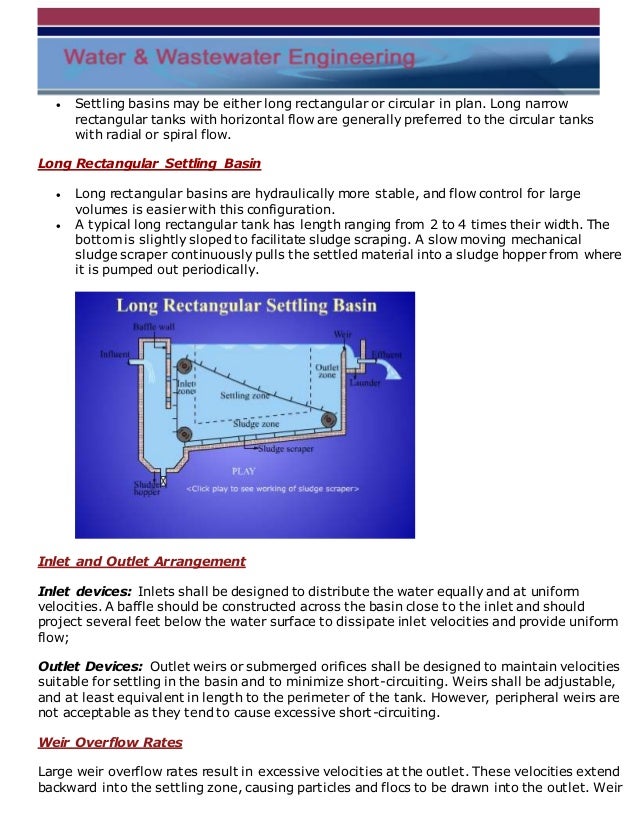

How does a basin outlet work?

The basin outlet zone (or launder) should provide a smooth transition from the sedimentation zone to the outlet from the tank. This area of the tank also controls the depth of water in the basin. Weirs set at the end of the tank control the overflow rate and prevent the solids from rising to the weirs and leaving the tank before they settle out. The tank needs enough weir length to control the overflow rate, which should not exceed 20,000 gallons per day per foot of weir.

What is an influent zone?

The inlet or influent zone should distribute flow uniformly across the inlet to the tank. The normal design includes baffles that gently spread the flow across the total inlet of the tank and prevent short circuiting in the tank. (Short circuiting is the term used for a situation in which part of the influent water exits the tank too quickly, by flowing across the top or along the bottom of the tank.) The baffle is sometimes designed as a wall across the inlet, with holes perforated across the width of the tank.

Where is the sludge zone in a tank?

The sludge zone, located at the bottom of the tank , provides a storage area for the sludge before it is removed for additional treatment or disposal. Basin inlets should be designed to minimize high flow velocities near the bottom of the tank. If high flow velocities are allowed to enter the sludge zone, the sludge could be swept up and out of the tank. Sludge is removed for further treatment from the sludge zone by scraper or vacuum devices which move along the bottom.

What is a high rate tube settlers?

High rate tube settlers are designed to improve the characteristics of the rectangular basin and to increase flow through the tank. The tube settlers consist of a series of tubes that are installed at a 60 degree angle to the surface of the tank. The flow is directed up through the settlers. Particles have a tendency to flow at an angle different than the water and to contact the tube at some point before reaching the top of the tube. After particles have been removed from the flow and collected on the tubes, they tend to slide down the tube and back into the sludge zone.

What is sedimentation in water treatment?

Sedimentation is the next step in conventional filtration plants. (Direct filtration plants omit this step.) The purpose of sedimentation is to enhance the filtration process by removing particulates. Sedimentation is the process by which suspended particles are removed from the water by means of gravity or separation. In the sedimentation process, the water passes through a relatively quiet and still basin. In these conditions, the floc particles settle to the bottom of the basin, while “clear” water passes out of the basin over an effluent baffle or weir. Figure 7-5 illustrates a typical rectangular sedimentation basin. The solids collect on the basin bottom and are removed by a mechanical “sludge collection” device. As shown in Figure 7-6, the sludge collection device scrapes the solids (sludge) to a collection point within the basin from which it is pumped to disposal or to a sludge treatment process. Sedimentation involves one or more basins, called “clarifiers.” Clarifiers are relatively large open tanks that are either circular or rectangular in shape. In properly designed clarifiers, the velocity of the water is reduced so that gravity is the predominant force acting on the water/solids suspension. The key factor in this process is speed. The rate at which a floc particle drops out of the water has to be faster than the rate at which the water flows from the tank’s inlet or slow mix end to its outlet or filtration end. The difference in specific gravity between the water and the particles causes the particles to settle to the bottom of the basin. Some plants have added baffles or weirs in their sedimentation basins to limit short-circuiting through the basins, promoting better settling.

How much does sedimentation reduce turbidity?

Sedimentation may remove suspended solids and reduce turbidity by about 50 to 90 percent, depending on the nature of the solids, the level of pretreatment provided, and the design of the clarifiers. Common values are in the 60 to 80 percent range (Hudson, 1981).

What is a sludge blanket clarifier?

Sludge blanket clarifiers are a variation of solids contact units in which coagulated water flows up through a blanket of previously formed solids. As the small, coagulated particles enter the sludge blanket, contact with other particles in the blanket causes flocculation to occur. The floc grows in size and becomes part of the blanket. A blanket depth of several feet is required for efficient clarification (AWWA and ASCE, 1998).

How does a flotation clarifier work?

Dissolved air flotation clarifiers bubble air into the flocculated water and cause the floc particles to float to the surface. Dissolved air flotation clarification allows for loading rates up to 10 times that of conventional clarifiers (AWWA and ASCE, 1998). Dissolved air flotation consists of saturating a sidestream with air at high pressure and then injecting it into a flotation tank to mix with incoming water. As the side-stream enters the flotation tank, the pressure drop releases the dissolved air. The air bubbles then rise, attaching to floc particles and creating a layer of sludge at the surface of the tank. The clarified water is collected near the bottom of the tank.

What is the purpose of optimization of the clarification process?

Optimization of the clarification process will minimize solids loading on the filters and will contribute to enhanced filter performance and better overall treated water quality.A water system should consider the following items when evaluating sedimentation basins:

What is the process of coagulation, flocculation, sedimentation, and filtration?

The water treatment process of coagulation, flocculation, sedimentation, and filtration remove the pathogens. The disinfection water treatment process inactivates them. The small particles in water may consist of silt and clay, color bodies, precipitated iron or manganese oxides, and even bacteria and algae. Together, these particles make the water ...

What are the factors that control the reaction of aluminum and ferric salts in water?

As the particles collide in the mixing area they begin to stick together a form larger and larger flocs. Temperature, pH, alkalinity, and the amount of turbidity in the water control the reactions of aluminum and ferric salts in the water.

What is coagulation in water treatment?

History of Coagulation in Drinking Water Treatment. Coagulation has been an important process in high-rate filtration plants in the United States since the 1880s. Aluminum and iron salts have been used in the coagulation process since the beginning. These salts are still the most commonly used coagulants today.

What is turbidity in water?

This cloudiness is known as turbidity . Visual turbidity is unpleasant to consumers. Visual turbidity is also an indicator to operators and regulators that the water may still contain pathogens. The Surface Water Treatment Rule therefore requires that turbidity be removed to very low levels.

What is the process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the

Coagulation . Coagulation is defined as the water treatment process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the grains of a filter bed. Many surface water supplies contain particles that are too small to settle out of solution on their own.

How does contact time work in water treatment?

In order for systems to be sure that they are properly disinfecting the filtered water, the Surface Water Treatment Rule requires systems to provide enough contact time. Contact time (CT) is a function of the known disinfection concentration and the amount of time that the disinfectant is in contact with the water. Contact time is expressed in terms of mg/L-min. The EPA has published tables that show how much CT credit water systems will receive. In order to use these tables you use the concentration of chlorine, time, water temperature and pH.

How does surface water treatment work?

In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to settle out of solution via gravity during sedimentation. Any remaining particles and pathogens will be removed during the filtration treatment process. Finally, the water is disinfected to inactivate any remaining pathogens prior to entering the water system’s distribution system.