There are three essential types of aeration systems that can be used in a wastewater treatment facility, which include a packed-tower aerator, a diffused-bubble aerator, and a spray aerator.

How is aeration used in wastewater treatment?

Wastewater Aeration as Part of a Treatment Process Wastewater aeration is typically used during the secondary treatment process. This process is most often an activated sludge process. Aeration in an activated sludge process is accomplished by pumping air into the tank or lagoon.

What are the different types of wastewater aeration systems?

This form of wastewater aeration is commonly used in the creation of pond treatment systems and lagoon treatment systems. The different pieces of equipment that you can use for surface aeration include spray nozzles, small waterfalls, and jet fountains. All of these water features can either be fixed or positioned on a pontoon.

What are the methods of aeration in activated sludge?

There are three methods for aeration in activated sludge process. 1. Diffused Air Aeration In diffused air aeration method compressed air is blown through the sewage and air is diffused in sewage by diffuser. Diffusers are of two types: Plate diffuser and Tube diffuser

What is the primary treatment of wastewater?

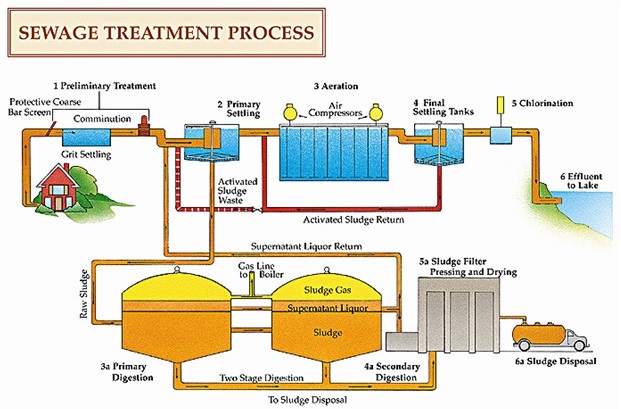

Primary treatment of wastewater involves filtering out large solid contaminants. Secondary treatment then purifies the wastewater through biofiltration, aeration, and oxidation. These are all processes that help to remove sediment from the water.

How many ways for aeration are there in wastewater treatment?

There are three essential types of aeration systems that can be used in a wastewater treatment facility, which include a packed-tower aerator, a diffused-bubble aerator, and a spray aerator.

What are two methods of aeration?

Methods of Aeration The two major ways of water aeration are surface aeration and subsurface aeration. The first kind involves placing the oxygen into the water through the surface. Usual executions of this method include using fountains and other aesthetically pleasing features to splash oxygenated water.

What is aeration process in wastewater treatment?

Aeration is the process of adding air into wastewater to allow aerobic biodegradation of the organic materials. The principal secondary treatment techniques used are the trickling filter and the activated sludge process and are often classified as fixed-film or suspended-growth systems respectively.

Which is most common method used in aeration process?

Cascade aerators can be used to oxidize iron and to partially reduce dissolved gases. They are the oldest and most common type of aerators. Cone aerators are used primarily to oxidize iron and manganese from the ferrous state to the ferric state prior to filtration.

Which of the following are method of aeration?

Methods. Aeration of liquids (usually water) is achieved by: passing air through the liquid by means of the Venturi tube, aeration turbines or compressed air which can be combined with diffuser(s) air stone(s), as well as fine bubble diffusers, coarse bubble diffusers or linear aeration tubing.

What are the 4 types of aeration?

Most common aeration typesFigure 1. Positive pressure aeration system.Figure 2. Negative pressure aeration system.Figure 3. Pull-up aeration system.Figure 4. Push-Pull aeration system.Figure 5. Manifold aeration system on two bins.Figure 6. Cross flow aeration system.Figure 7.

Why aeration technique is important for wastewater treatment?

Aeration provides oxygen to bacteria for treating and stabilizing the wastewater. Oxygen is needed by the bacteria to allow biodegradation to occur. The supplied oxygen is utilised by bacteria in the wastewater to break down the organic matter containing carbon to form carbon dioxide and water.

How many types of aerator are present?

four typesHow many types of aerators are present? Explanation: There are four types of aerators. They are gravity aerators, spray aerators, diffused air aeration systems and mechanical aerators.

How is aeration done?

Aeration brings water and air in close contact by exposing drops or thin sheets of water to the air or by introducing small bubbles of air (the smaller the bubble, the better) and letting them rise through the water.

How many types of aerators are commonly used in the treatment of water Mcq?

4 typesExplanation: There are 4 types of aerators namely Gravity aerators, Spray aerators, Diffusers and Mechanical aerators.

How Wastewater Aeration Works

Before you start to use a wastewater aeration system, it’s important to understand how these systems work. There are two different system types that you can select from, which include subsurface aeration systems and surface aeration systems, both of which have their advantages.

What does Aeration Do To Wastewater?

Aeration is commonly used as a kind of secondary treatment method to rid wastewater of contaminants. In many situations, this process will be a part of the activated sludge process, which can be used to oxidize biological matter and assist with the eradication of wastewater contaminants.

Why Aeration is Important for Wastewater

Aeration is important for wastewater for a number of reasons. For one, aeration is able to keep costs down compared to other treatment methods. In most situations, using a natural treatment will be more affordable than a chemical treatment or similar solution.

How does aeration work in wastewater treatment?

This is the step in the wastewater treatment process that uses aeration to help further break down the wastewater. Air and “seed” sludge from the previous treatment step are added to the wastewater. Air is pumped into large aeration tanks which mixes the wastewater and seed sludge. This process stimulates the growth of oxygen-using bacteria and other tiny organisms that are naturally present in the sewage. Most of the remaining organic materials is consumed by these beneficial microorganisms, producing heavier particles that will settle to the bottom. The aerated wastewater then moves to another set of holding tanks where the heavier particles formed from the aeration process will settle to the bottom.

What is a Genesis aerator?

The Genesis Aerator from Louk’s Engineering is the nation’s premiere aeration unit that is innovative and affordable. Louk’s solar-powered circulation equipment may be used for wastewater treatment and fresh water applications. Genesis delivers energy-saving power to effectively aerate wastewater, supplying the oxygen needed for microorganisms to break down and remove organic materials.

How long does it take for filtered water to be disinfected?

After the aeration process and the remaining sludge has been removed, the filtered wastewater must now be disinfected before returning to local streams and lakes. The wastewater will must spend a minimum of 15-20 minutes in chlorine-contact tanks to kill any remaining harmful bacteria or organisms. From here, the treated wastewater, now called effluent, is released to local waterways such as streams and lakes. Now the water may be cleansed and purified by nature’s own processes.

What is wastewater aeration?

Wastewater aeration is the process of adding air to assist the aerobic microorganisms in the consumption of pollutants. Wastewater aeration is a vital part of most every biological treatment system. A well designed and operated wastewater aeration system will accomplish two main jobs:

What is the second job of wastewater aeration?

The second job of wastewater aeration is mixing the wastewater. Proper mixing keeps solids in suspension thus avoiding a buildup of sludge. Mixing also ensures that there are no anaerobic (without air) zones in the wastewater. A common problem, especially with lagoons, is that there is less oxygen present on the bottom.

How does aeration work in activated sludge?

Aeration in an activated sludge process is accomplished by pumping air into the tank or lagoon. Proper aeration promotes the growth of microorganisms or microbes in the wastewater. The microbes feed on the organic pollutants and form flocs which can easily settle out. The flocs are allowed to settle out in a separate settling tank or lagoon.

How does a subsurface aeration system work?

A sub-surface aeration system provides oxygen to microorganisms by injecting air into the wastewater. Blowers or air pumps compress the air which is delivered through airlines to diffusers installed on the bottom of the tank or lagoon. The diffusers are installed in a pattern on the bottom of the tank or lagoon for uniform coverage. The diffusers have tiny holes that create bubbles that come into contact with the water. Diffusers come in two basic types: fine bubble and course bubble.

What equipment is used for surface aeration?

Equipment used for wastewater surface aeration includes low waterfalls, jet fountains and spray nozzles. These can be fixed or on pontoons. Wastewater comes into contact with the air through the agitation created when it is sprayed or transported. This type of aeration creates the maximum possible mixing and a high level ...

What is a laminar flow diffuser?

This type of diffuser has thousands of tiny openings that create small fine bubbles at low flow. A laminar flow of small bubbles is advantageous in that they have a greater surface area for the absorption of oxygen into the water.

What is the purpose of mechanical aeration?

In this method the surface of sewage is agitated violently with the help of some mechanical equipment to encourage absorption of oxygen from atmosphere. There are two well known forms of mechanical aerator. Vertical surface aerator and Horizontal surface aerator.

How to aerate activated sludge?

There are three methods for aeration in activated sludge process. 1. Diffused Air Aeration. In diffused air aeration method compressed air is blown through the sewage and air is diffused in sewage by diffuser. Diffusers are of two types: Plate diffuser and Tube diffuser.

What is sewage made of?

They are rectangular/square plates made of crystalline alumina or high silica sand. In this method the compressed air is blown through a perforated plate diffuser. The air comes out through the holes of the diffuser plate and rises upward in the form of bubbles. Thus the sewage absorbs oxygen from the air.

What is the process of absorbing oxygen from air called?

The process of absorbing oxygen from air is known as aeration. High amount of O 2 is provided in the aeration tank because of high BOD in sewage. This cannot be provided naturally therefore aerators are used to provide O 2 artificially.

Where is the aeration plate located in a sewage tank?

The aeration of sewage is done by air diffusers as well as mechanical aerators. Air diffuser plates are located at the bottom of tank and the submerged paddles rotate in the direction opposite to that in which the compressed air rises up from the air diffusers.

How does a perforated tube work?

It consists of a perforated tube suspended in the waste water near the bottom and can be taken out while cleaning. The compressed air is dent through the tube. The air comes out through the holes with great force and agitates the sewage.

What is the primary treatment of wastewater?

Primary treatment of wastewater involves filtering out large solid contaminants. Secondary treatment then purifies the wastewater through biofiltration, aeration, and oxidation. These are all processes that help to remove sediment from the water.

What is the final stage of tertiary wastewater treatment?

The final stage of the tertiary wastewater treatment process involves removing the chlorine that was used to disinfect the water. This step is very important because chlorine is harmful to aquatic life. Chlorine also reduces biological water quality when it is present in high concentrations. To remove the chlorine, a compound called sodium ...

What is the process of adding chlorine to wastewater?

Disinfection. An important part of wastewater treatment involves the addition of chlorine to the final effluent before discharge. This process injects chlorine into the headworks of a serpentine effluent detention chamber.

What is the purpose of chlorination in wastewater treatment?

Chlorination in wastewater treatment kills bacteria and viruses, and eliminates parasites such as Giardia and Cryptosporidium, which can cause very serious illnesses. In summary, this process disinfects water so that it is safe to reuse or recycle.

What is tertiary treatment?

Tertiary Treatment of Wastewater – Methods and Process. Tertiary water treatment is the final stage of the multi-stage wastewater cleaning process. This third stage of treatment removes inorganic compounds, bacteria, viruses, and parasites.

What is the third stage of sewage treatment?

This third stage of treatment removes inorganic compounds, bacteria, viruses, and parasites. Removing these harmful substances makes the treated water safe to reuse, recycle, or release into the environment. To find out how tertiary sewage treatment works, take a look at this overview of the methods and processes involved in ...

Can alum be removed by a filter?

Alum also causes any solids that were not removed by primary and secondary wastewater treatment to group so they can be removed by filters. When necessary, the filters are backwashed to remove the build-up of floc, which allows the filters to continue operating effectively.

Types of Aeration Systems

Maintenance of Aeration Systems

Why Aeration Wastewater Treatment?

- Fine Bubble Diffusers

Fine bubble diffusers are energy efficient submersible aeration systems for wastewater treatment. Fine Bubble diffuser systems disperse the diffused gas volume to transfer an equal amount of oxygen as a coarse bubble system, according to Environmental Dynamics Internation… - Coarse Bubble Diffusers

Coarse bubble diffusers produce a larger diameter of bubble to displace, churn and mix the wastewater effectively. Fine pores typically release bubbles with a diameter between 0-3 millimeters, while coarse bubble diffusers release bubbles with a diameter ranging from 3-50 mil…

How to Pick The Right Aeration System For Your Wastewater Treatment

- There are three essential types of aeration systems that can be used in a wastewater treatment facility, which include a packed-tower aerator, a diffused-bubble aerator, and a spray aerator. It’s important to understand the difference between these types of aerators because each system operates differently and comes with its own benefits that you m...