What are the key processes of heat treatment?

Jan 10, 2019 · Heat Treatment, Heat Treatment Process, Hardening, Toughening, Carbo Normalizing & Carbo-Nitro Normalizing , Carbon Restoration, Case Hardening – Carburizi...

How do you choose the right heat treatment method?

Hardening. As the name suggests, hardening is used to increase the hardness of a metal. This is usually done by heating the metal above normalization temperature, keeping it at normalization temperature, and then rapidly quenching ( Cooling) it in water, oil, or brine solution. The heat required depends on the size and the required mechanical ...

How long has heat treatment been around?

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, …

What is heat treatment process in metal casting?

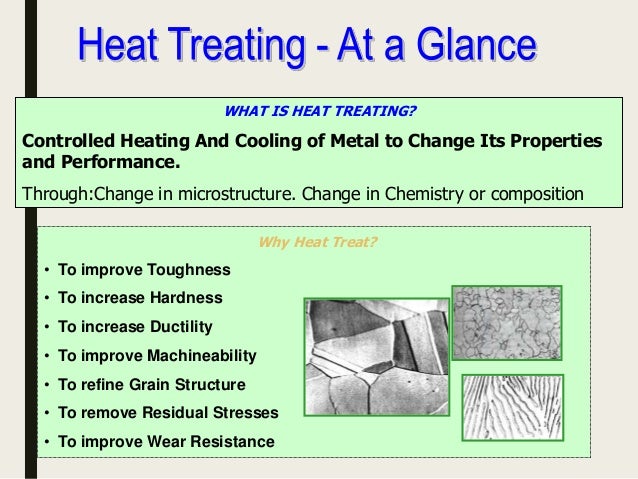

Dec 31, 2020 · The following are the purposes of heat treatment. To improve mechanical properties such as tensile strength, hardness, ductility, shock resistance, and resistance to corrosion. Improve machinability. To relieve the internal stresses of the metal-induced during cold or hot working. To change or refine grain size.

What is the process of heat treatment?

Heat Treatment Process StepsHeating. Jet engine parts going into a furnace. ... Holding. During the holding, or soaking stage, the metal is kept at the achieved temperature. ... Cooling. After the soaking stage is complete, the metal must be cooled in a prescribed manner. ... Annealing. ... Normalising. ... Hardening. ... Ageing. ... Stress Relieving.More items...•Feb 13, 2020

What are the five basic heat treatment process?

There are five basic heat treating processes: hardening, case hardening, annealing, normalizing, and tempering. Although each of these processes bring about different results in metal, all of them involve three basic steps: heating, soaking, and cooling. Heating is the first step in a heat-treating process.

What are the four types of heat treatment?

In this post, we'll cover the four basic types of heat treatment steel undergoes today: annealing, normalizing, hardening, and tempering.Jul 14, 2020

What are the two types of heating technologies used in heat treatment?

Electric Process Types of Heating Systems Through direct electric heating, an electrical current is transmitted through the object — exciting the electrons inside of the object. In contrast, indirect electric heating involves the energy being conducted onto a separate heat element and then into the material.Aug 28, 2020

What are the 3 stages of heat treatment process?

Stages of Heat TreatmentThe Heating Stage.The Soaking Stage.The Cooling Stage.Jul 7, 2020

What is heat treatment process and types?

Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

What is the purpose of heat treatment of materials?

Heat treatment is a controlled process used to alter the microstructure of metals and alloys such as steel and aluminium to impart properties which benefit the working life of a component, for example increased surface hardness, temperature resistance, ductility and strength.

What is tempering in heat treatment?

Tempering is a heat treatment that improves the toughness of hard, brittle steels so that they can hold up during processing. Tempering requires that the metal reaches a temperature below what's called the lower critical temperature — depending on the alloy, this temperature can range from 400-1,300˚F.Nov 16, 2021

What are the objectives of heat treatment?

The main objectives of heat treatment as follows:to increase strength, hardness and wear resistance (bulk hardening, surface hardening)to increase ductility and softness (tempering, re-crystallization annealing)to increase toughness (tempering, re-crystallization annealing)More items...

What are the two classification of heat treatment?

Heat-treating furnaces can be divided into two main types: batch and continuous. The fundamental difference between these two styles is not in the materials of construction, although there are differences due to inherent design requirements.Oct 20, 2010

What are the 3 types of heat transfer?

Heat can be transferred in three ways: by conduction, by convection, and by radiation.Conduction is the transfer of energy from one molecule to another by direct contact. ... Convection is the movement of heat by a fluid such as water or air. ... Radiation is the transfer of heat by electromagnetic waves.

What are the three types of heating systems?

5 Different Types of Heating SystemsForced Air Systems. A forced air heating system is the most common option that is found in a residential home. ... Electric Systems. ... Geothermal Systems. ... Radiant Heat Systems. ... Steam Radiant Heat Systems.Jan 8, 2015

Why is heat treatment important?

Heat treatment is an essential process in the material science industry to improve metal properties for commercial purposes. It is one of the key processes that help gain the desired mechanical and chemical properties of metals.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

How is annealing done?

Annealing is done by heating the metals at the above critical temperature , hold them there for some time and then cool it at a very slow rate in the furnace itself. Annealing is usually done on ferrous and non-ferrous metals to reduce hardness after the cold working process.

What is the first step in heat treatment?

The first step in the heat treatment process is heating the metal. The temperature depends on the types of metal and the technique used. Sometimes you need to heat the outer surfaces of the metal, and sometimes you need to heat the whole body. That depends on what kind of alteration you want in the mechanical structure.

How does tampering work?

Tampering is a very common process for machine tools, knives, etc. Tampering is usually done by heating the metal at a relatively low temperature. The temperature depends on the required mechanical properties of metals.

What happens after holding a furnace?

After the holding process, cooling starts. The cooling must be done in a prescribed manner. During cooling, there are some structural changes occur. Different media such as water, oil, or forced air is used to aid in cooling. You can also use furnaces for cooling purposes as the control environments help inefficient cooling.

How does heat treatment help metals?

Heat treatment assist in improving the ductility of metal in the annealing process. Heat treatment helps in hardening metals. Case hardening helps in hardening only the outer surface of the metal piece keeping the rest of the portion soft and ductile. Machinability of metals gets improved.

How to make a bolt?

A summary of the production process: 1 Wire - Uncoiled, straightened and cut to length. 2 Cold forging - Molding the steel into the right shape at room temperature. 3 Bolt head - Progressively formed by forcing the steel into various dies at high pressure. 4 Threading - Threads are formed by rolling or cutting. 5 Heat treatment - The bolt is exposed to extreme heat to harden steel. 6 Surface treatment - It depends on the application. Zinc-plating is common to increase corrosion resistance. 7 Packing/stocking - After quality control to ensure uniformity and consistency, the bolts are packaged.

What is cold forging?

Once perfected, cold forging ensures bolts can be produced quickly, in large volumes, and with high uniformity. For more complex bolt designs, which cannot be contoured through cold forging alone, some additional turning or drilling may be needed. Turning involves spinning the bolt at high speed, while steel is cut away to achieve ...

What is zinc plated fastener?

This is a process whereby the bolt is submerged in a liquid containing zinc, and an electric current is applied so that the zinc forms a coating over the bolt.

What is a liquid patch?

A liquid patch will help improve thread-forming torque. Once these steps are complete, the bolt is finished. Now all that remains is some form of quality control to ensure uniformity and consistency before the bolts can be packaged and shipped.

What is zinc plating?

Surface treatment - It depends on the application. Zinc-plating is common to increase corrosion resistance. Packing/stocking - After quality control to ensure uniformity and consistency, the bolts are packaged.

Why do we heat treat?

There are various reasons for carrying out heat treating. Some procedures make the metal soft, while others increase hardness. They may also affect the electrical and heat conductivity of these materials.

What is each schedule?

Each schedule refers to a different rate of heating, holding and cooling the metal. These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties.

Is an alloy a solid solution?

Heating is carried out in line with a prescribed thermal profile. An alloy may exist in one of three different states when heated. It may either be a mechanical mixture, a solid solution, or a combination of both. A mechanical mixture is analogous to a concrete mixture where cement binds sand and gravel together.

What is the role of microstructure in mechanical properties?

And microstructure plays an important role in the mechanical properties of a material. The final outcome depends on many different factors. These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. The parameters depend on the heat treatment method, ...

Is a solid solution a mixture?

A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. Different media such as brine, water, oil or forced air control the rate of cooling. The sequence of cooling media named above is in decreasing order of effective rate of cooling.

What are the properties of metal?

Among those properties are electrical resistance, magnetism, hardness, toughness, ductility, brittleness and corrosion resistance.

Is aluminium a heat treatment?

Aluminium is suitable for heat treatment methods such as annealing, solution heat treating, natural and artificial ageing. Heat treatment for aluminium is a precision process. Process scope must be established and it should be controlled carefully at each stage for the desired characteristics.

Why are metals annealed?

Most non-ferrous alloys that are heat-treatable are also annealed to relieve the hardness of cold working.

What is a heat treating furnace?

Heat treating furnace at 1,800 °F (980 °C) Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass.

Why are nonferrous alloys annealed?

Most non-ferrous alloys that are heat-treatable are also annealed to relieve the hardness of cold working. These may be slowly cooled to allow full precipitation of the constituents and produce a refined microstructure. Ferrous alloys are usually either " full annealed" or " process annealed.".

What is a semi continuous batch furnace?

These upgraded furnaces are a very commonly used piece of equipment for heat-treating.

What is a bell furnace?

Bell-type furnace. Bell furnaces have removable covers called bells, which are lowered over the load and hearth by crane. An inner bell is placed over the hearth and sealed to supply a protective atmosphere. An outer bell is lowered to provide the heat supply.

Why are liquids used in chemistry?

Liquids may be used, due to their better thermal conductivity, such as oil, water, a polymer dissolved in water, or a brine. Upon being rapidly cooled, a portion of austenite (dependent on alloy composition) will transform to martensite, a hard, brittle crystalline structure.

What is the difference between alpha and gamma iron?

The alpha iron has no spaces for carbon atoms to reside , while the gamma iron is open to the free movement of small carbon atoms.

Why is heat treatment done?

The heat treatment is done to improve the machinability. To improve magnetic and electrical properties. To increase resistance to wear, heat and corrosion, ...

What are the different types of heat treatment?

Types of Heat Treatment. 1. Annealing. Annealing is one of the most important processes of heat treatment. It is one of the most widely used operations in the heat treatment of iron and steel and is defined as the softening process.

How is steel heated?

The steel is heated above its critical temperature range. It is held at that temperature for a definite period of time. The steel is then rapidly cooled in a medium of quenching.

Who is Saif M.?

Saif M. is a Mechanical Engineer by profession. He completed his engineering studies in 2014 and is currently working in a large firm as Mechanical Engineer. He is also an author and editor at www.theengineerspost.com

What is the purpose of normalizing steel?

Normalizing. Normalizing: The main aim of normalizing is to remove the internal stresses developed after the cold working process. In this, steel is heated 30 – 50°C above its upper critical temperature and cooling it in the air. It improves mechanical and electrical properties, machinability & tensile strength.

What temperature is steel heated to?

The steel is heated to a temperature of about 40° to 50°C above its upper critical temperature. It is held at this temperature for a short duration. The steel is then allowed cool in still air at room temperature, which is known as air quenching.

What is tempered steel?

It is an operation used to modify the properties of steel hardened by quenching for the purpose of increasing its usefulness. Tempering or draw results in a reduction of brittleness and removal of internal strains caused during hardening. Steel must be tempered after the hardening process.

Why is heat treatment important?

The process of heat treatment involves the use of heating or cooling, usually to extreme temperatures to achieve the desired result . It is a very important manufacturing processes that can not only help the manufacturing process but can also improve product, its performance, and its characteristics in many ways.

What is heat treatment?

Heat treatment could be said to be a method for strengthening materials but could also be used to alter some mechanical properties such as improving formability, machining, etc. The most common application is metallurgical but heat treatment of metals can also be used in the manufacture of glass, aluminum, steel and many more materials.

How does hardening work?

Hardening Hardening involves heating of steel, keeping it at an appropriate temperature until all pearlite is transformed into austenite, and then quenching it rapidly in water or oil. The temperature at which austentizing rapidly takes place depends upon the carbon content in the steel used. The heating time should be increased ensuring that the core will also be fully transformed into austenite. The microstructure of a hardened steel part is ferrite, martensite, or cementite. Tempering Tempering involves heating steel that has been quenched and hardened for an adequate period of time so that the metal can be equilibrated. The hardness and strength obtained depend upon the temperature at which tempering is carried out. Higher temperatures will result into high ductility, but low strength and hardness. Low tempering temperatures will produce low ductility, but high strength and hardness. In practice, appropriate tempering temperatures are selected that will produce the desired level of hardness and strength. This operation is performed on all carbon steels that have been hardened, in order to reduce their brittleness, so that they can be used effectively in desired applications. Annealing Annealing involves treating steel up to a high temperature, and then cooling it very slowly to room temperature, so that the resulting microstructure will possess high ductility and toughness, but low hardness. Annealing is performed by heating a component to the appropriate temperature, soaking it at that temperature, and then shutting off the furnace while the piece is in it. Steel is annealed before being processed by cold forming, to reduce the requirements of load and energy, and to enable the metal to undergo large strains without failure. Normalizing Normalizing involves heating steel, and then keeping it at that temperature for a period of time, and then cooling it in air. The resulting microstructure is a mixture of ferrite and cementite which has a higher strength and hardness, but lower ductility. Normalizing is performed on structures and structural components that will be subjected to machining, because it improves the machinability of carbon steels. Carburization Carburization is a heat treatment process in which steel or iron is heated to a temperature, below the melting point, in the presence of a liquid, solid, or gaseous material which decomposes so as to release carbon when heated to the temperature used.

Why is steel annealed?

Steel is annealed before being processed by cold forming, to reduce the requirements of load and energy, and to enable the metal to undergo large strains without failure. Normalizing Normalizing involves heating steel, and then keeping it at that temperature for a period of time, and then cooling it in air.

What is surface hardening?

This can be achieved by local austentitizing and quenching, and diffusion of hardening elements like carbon or nitrogen into the surface. Processes involved for this purpose are known as flame hardening, induction hardening, nitriding and carbonitriding.

How to heat treat a sandpaper?

Heat treatment processes require the following three main steps [2]: 1 Heating the material to a specific temperature (in the range of up to 2400 °F / 1316 °C) 2 Soaking, or maintaining the specific temperature for a certain amount of time (varying from seconds to more than 60 hours) 3 Cooling at a suitable rate following prescribed methods. The material can be cooled rapidly, slowly (in the furnace), or can be quenched (using water, brine, oils, polymer solutions, salts, or gases).

What metals can be treated with heat treatment?

The heat treatment process can be applied to ferrous metals such as cast-iron, AHSS, stainless steel and other alloy steels, as well as non-ferrous metals such as aluminium, magnesium, titanium, copper, or brass [2].

How long has heat treatment been around?

Most metals and alloys are heat treated in one way or another, and the understanding and science of heat treatment have been developed over the past 100 to 125 years. The importance of heat treatment is evident in many products in the automotive, aerospace, construction, agriculture, mining, and consumer goods industries, ...

What is case hardening?

This is also known as case hardening. It includes over a dozen treatments in which the surface of the material is hardened creating a hard ‘case’ while the core remains tough or soft. This provides improved wear resistance for parts such as gears, cams and sleeves. This process is one of the most common for steel and iron.

What is the process of quenching?

This rapid cooling process is known as quenching and is generally applied to stainless and high-alloy steels, primarily to produce controlled amounts of martensite in the microstructure and obtain increased hardness [2]. Hardening is often used in cast-irons and steels alloyed with metals such as nickel and magnesium.

What is the process of holding metal at a temperature?

After the metal is heated to the proper temperature,it is held at that temperature until the desired internalstructural changes take place. This process is calledS OAKING. The length of time held at the proper

Can water be used to quench steel?

Water can be used to quench some forms of steel,but does not produce good results with tool or other alloysteels. Water absorbs large quantities of atmosphericgases, and when a hot piece of metal is quenched, thesegases have a tendency to form bubbles on the surface ofthe metal. These bubbles tend to collect in holes orrecesses and can cause soft spots that later lead tocracking or warping.

What are the four types of heat treatment?

Four basic types of heat treatment are used today.They are annealing, normalizing, hardening, and tem-pering. The techniques used in each process and howthey relate to Steelworkers are given in the followingparagraphs.

Does caustic soda have a higher cooling rate than water?

solution of water and caustic soda, containing 10percent caustic soda by weight, has a higher cooling ratethan water. Caustic soda is used only for those types ofsteel that require extremely rapid cooling and is NEVERused as a quench for nonferrous metals.

What is the opposite of annealing?

In general, annealing is the opposite of hardening,You anneal metals to relieve internal stresses, softenthem, make them more ductile, and refine their grainstructures. Annealing consists of heating a metal to aspecific temperature, holding it at that temperature fora set length of time, and then cooling the metal to roomtemperature. The cooling method depends on the

What is normalizing metal?

Normalizing is a type of heat treatment applicableto ferrous metals only. It differs from annealing in thatthe metal is heated to a higher temperature and thenremoved from the furnace for air cooling.

What is brine in science?

Brine is the result of dissolving common rock saltin water. This mixture reduces the absorption of atmos-pheric gases that, in turn, reduces the amount of bubbles.As a result, brine wets the metal surface and cools itmore rapidly than water. In addition to rapid and uni-form cooling, the brine removes a large percentage ofany scale that may be present.

The Benefits

Heat Treatment Process Steps

- Heat treatment is a standard process for all bolts, which involves exposing the bolt to extreme temperatures in order to harden the steel. Threading is usually applied before heat treatment, either by rolling or cutting when the steel is softer. Rolling works much like cold forging, and involves running the bolt through a die to shape and mold the ...

Phase Diagrams

Common Heat Treatment Methods

What Metals Are Suitable For Heat Treating?

- In simple terms, heat treatment is the process of heating the metal, holding it at that temperature, and then cooling it back. During the process, the metal part will undergo changes in its mechanical properties. This is because the high temperature alters the microstructure of the metal. And microstructure plays an important role in the mechanical properties of a material. Th…