Grain growth as a result of heat treatment can affect properties such as strength and fatigue life. It is reported that grain size is one of the factors that cause fatigue failure. Taylor et al show that the threshold value for fatigue crack growth increases with increasing grain size and decreasing yield strength.

Full Answer

What is grain growth in Materials Science?

Conventional case-hardening steels show heavy grain coarsening at temperatures higher than 1000 °C. To counter this problem, microalloying elements such as …

How does the time of heating affect the grain size?

Aug 01, 2010 · Conventional case-hardening steels show heavy grain coarsening at temperatures higher than 1000 °C. To counter this problem, microalloying elements such as Nb and Ti are commonly added to resist austenite grain growth at high process temperatures. However, abnormal grain growth may still occur even when microalloying is employed.

Does microalloying prevent austenite grain growth in case hardening steels?

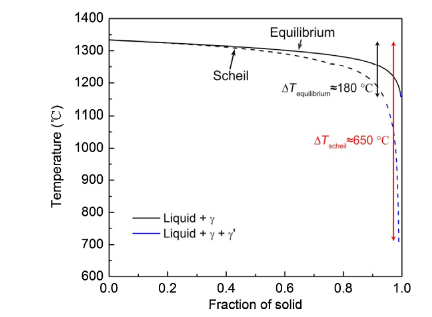

treatment for grain growth was a supersolvus heat treatment : specimens were held for 4 hours in a furnace kept at 1205°C. The grain size was measured by quantitative image analysis of etched sections of tensile specimens. Because the microstructure was …

What is ideal grain growth?

Although there is an economic advantage to high-temperature carburisation, this process is not widespread because of the problem of abnormal grain growth. Conventional case-hardening steels show heavy grain coarsening at temperatures higher than 1000 °C. To counter this problem, microalloying elements such as Nb and Ti are commonly added to resist austenite …

How grain size increases with temperature?

Yes, the grain size increases with increasing the annealing temperature. This is because increasing the annealing temp. leads to increase the crystallinity of the material and hence increases the number of crystallites.Sep 25, 2014

How does temperature affect grain boundaries?

Medium-energy grain boundaries exhibit the same behavior at the highest temperatures; however, at lower temperatures the diffusion mechanism becomes anisotropic, with a higher, misorientation-dependent activation energy.

What is the driving force for grain growth during annealing and how does it affect on materials strength?

(b) The driving force for grain growth is the reduction in grain boundary energy as the total grain boundary area decreases.

What is the reason for grain growth in ferrous metal?

Recrystallisation and grain growth in hot working of steels The reason for this growth is the reduction of the internal energy obtained by decreasing the total austenite grain boundary area.

Why does changing the grain size improve toughness?

In toughness mechanism, finer grains tend to obstruct dislocation in a material hence, the smaller the grain size, the better a material withstands dislocation or crack.

What are the factors that control the grain size of a metal?

According to kinetics, time and temperature are two factors that affect the grain growth. But increasing temperature is much more effective than increasing time.

How does grain size affect material properties?

Grain size effect on properties Grain size has a measurable effect on most mechanical properties. For exam- ple, at room temperature, hardness, yield strength, tensile strength, fatigue strength and impact strength all increase with decreasing grain size.

How does grain size affect corrosion?

In Pure metals the presence of grain boundaries will decrease the corrosion resistance. Therefore smaller the grains more will be grain boundaries and less corrosion resistance (in terms of intergranular corrosion).

What happens if grain size increases?

At the same time, a grain boundary that is finer is known to raise ductility. When the density of grain boundaries increases, these dislocations are anchored and evenly distributed within the material.Oct 14, 2019

What is nucleation and grain growth?

Grain nucleation and growth are important phenomena in polycrystalline materials such as metals and most ceramics. They govern the kinetics of many phase transformations and recrystallization processes that take place during processing.

What are the factors affecting grain size?

The grain size increase is attributed to a decrease in volume fraction and an increase in size of V4C3 particles with increasing temperature.

Abstract

As carburisation is a time-consuming process, it might seem advisable to shorten the process by increasing the carburising temperature. Although there is an economic advantage to high-temperature carburisation, this process is not widespread because of the problem of abnormal grain growth.

1. Introduction

Grain growth is a diffusion-controlled process driven by the reduction in grain boundary energy of a polycrystalline material as the grain size is increased.

2. Description of the model

Grain growth is described by phase-field simulation by means of the commercial software MICRESS® [12]. The phase-field approach was developed for modelling phase transformations in multi-component systems. It allows the calculation of a transformed phase fraction as well as a description of the microstructure evolution [13], [14].

3. Numerical simulation

To determine the influence of the initial microstructure and the precipitates on grain size evolution during carburising, several parameters were varied in the simulation. Fig. 2, Fig. 3, Fig. 4 present examples of microstructure evolutions based on the initial microstructure ( Fig.

4. Comparison of simulated and experimental results

Additional simulations for the detailed investigation of abnormal grain growth were performed for two selected steels, 20MnCr5B + Nb and 16MnCr5 + Nb/Ti. The chemical composition of these steels, presented in Table 1, are based on the standard chemical composition of case-hardening steels but with the addition of Nb and Nb + Ti respectively.

5. Variation of the simulation scenario for abnormal grain growth

To investigate the factors that promote abnormal grain growth, additional calculations that vary the initial grain diameter and the pinning force are compared to one another. The different scenarios are illustrated in Fig. 8 and Table 3.

6. Conclusions

A rigorous numerical approach using the phase-field method for the prediction of microstructure evolution has been developed. It is demonstrated that the increase of pinning force leads to a change in the grain growth character. Moreover, the initial grain size strongly influences grain growth behaviour.

How does heating affect grain size?

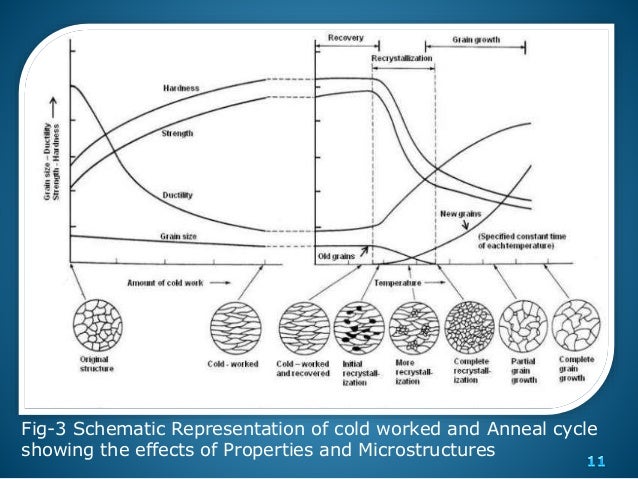

The effect of time of heating on grain size depends upon temperature at which the recrystallization is taking place. A certain amount of time is required in which recrystallization is to be completed but this amount of time decreases as temperature increases. The shorter the time of annealing, the finer is the grain size.

What is the process of replacing distorted grains of cold worked metal?

It is a process by which distorted grains of cold worked metal are replaced by new strain free grains during heating above a minimum temperature called recrystallization temperature. During recrystallization, there is a sharp decrease in hardness and strength and an increase in ductility.

Why is recovery important?

The recovery is important for releasing internal stresses in forging, welded and fabricated equipment, without decreasing the strength acquired during and working.

What is recovery in metals?

In metals, the individual properties, recover at different rates. By recovery, stresses are relieved from cold worked alloys which prevent stress corrosion cracking. Stress relieving can be achieved without much affecting the mechanical properties.

What is primary recrystallization?

Primary Recrystallization: It occurs when cold worked metal is heated. It is defined as the nucleation and growth of strain-free grains, from the matrix of cold worked metal. When primary recrystallization occurs, there is some degree of recovery and sub-grain formation.

How does the nucleus grow?

Once the nucleus is formed, it grows by motion of boundary. The rate of growth during recrystallization is independent of time but increases with the degree of deformation and with annealing temperature. The presence of impurities decreases the rate of growth, i.e., recrystallization rate.

When annealing of a deformed sample is continued beyond the primary recrystallization, or the sample

When annealing of a deformed sample is continued beyond the primary recrystallization, or the sample is heated at higher temperature, the usual grain growth is interrupted. Some grains suddenly experience very rapid growth. The dimensions of these rapidly grown grains may be of the order of few centimeters, while the rest of the grains small. These grains expand at the cost of other grains. This is called secondary recrystallization.

How is grain growth studied?

Grain growth has long been studied primarily by the examination of sectioned, polished and etched samples under the optical microscope. Although such methods enabled the collection of a great deal of empirical evidence, particularly with regard to factors such as temperature or composition, the lack of crystallographic information limited the development of an understanding of the fundamental physics. Nevertheless, the following became well-established features of grain growth: 1 Grain growth occurs by the movement of grain boundaries and not by coalescence (i.e. like water droplets) 2 Boundary movement is discontinuous and the direction of motion may change suddenly. 3 One grain may grow into another grain whilst being consumed from the other side 4 The rate of consumption often increases when the grain is nearly consumed 5 A curved boundary typically migrates towards its centre of curvature 6 When grain boundaries in a single phase meet at angles other than 120 degrees, the grain included by the more acute angle will be consumed so that the angles approach 120 degrees.

What is grain growth?

In materials science, grain growth is the increase in size of grains ( crystallites) in a material at high temperature. This occurs when recovery and recrystallisation are complete and further reduction in the internal energy can only be achieved by reducing the total area of grain boundary.

What is Hall-Petch effect?

Most materials exhibit the Hall–Petch effect at room-temperature and so display a higher yield stress when the grain size is reduced (assuming abnormal grain growth has not taken place). At high temperatures the opposite is true since the open, disordered nature of grain boundaries means that vacancies can diffuse more rapidly down boundaries leading to more rapid Coble creep. Since boundaries are regions of high energy they make excellent sites for the nucleation of precipitates and other second-phases e.g. Mg–Si–Cu phases in some aluminium alloys or martensite platlets in steel. Depending on the second phase in question this may have positive or negative effects.

What is the driving force of a grain?

Driving force. The boundary between one grain and its neighbour ( grain boundary) is a defect in the crystal structure and so it is associated with a certain amount of energy. As a result, there is a thermodynamic driving force for the total area of boundary to be reduced.

What is the difference between continuous and discontinuous grain growth?

Distinction between continuous (normal) grain growth, where all grains grow at roughly the same rate, and discontinuous (abnormal) grain growth, where one grain grows at a much greater rate than its neighbours.

What is the problem with refractories at room temperature?

Certain materials especially refractories which are processed at high temperatures end up with excessively large grain size and poor mechanical properties at room temperature. To mitigate this problem in a common sintering procedure, a variety of dopants are often used to inhibit grain growth.

What is boundary movement?

Boundary movement is discontinuous and the direction of motion may change suddenly. One grain may grow into another grain whilst being consumed from the other side. The rate of consumption often increases when the grain is nearly consumed. A curved boundary typically migrates towards its centre of curvature.

How to control austenite grain size?

Several ways to control austenite grain size include using aluminum additions, microalloying, and thermomechanical processing (3,4,6,8,9).

Is sintered steel heat treated?

Compared to wrought steels, sintered steels are ‘heat treated’ (= sintered) at very high temperatures. Compared to the standard austenitizing temperature of a structural steel, the common sintering temperatures are extremely high. Therefore, excessive austenite grain growth would be expected, which is, however, not the case (see Fig. 14 ).