In carbon steels, tempering alters the size and distribution of carbides in the martensite, forming a microstructure called "tempered martensite". Tempering is also performed on normalized steels and cast irons, to increase ductility, machinability, and impact strength.

What is tempering and how is it done?

Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

What is troosite tempering microstructure?

Troosite tempering microstructure is the main product of medium-temperature tempering. Temperature range is 250 o C – 500 o C. Troosite is a highly elastic microstructure with hardness in a range of 40-50 HRC. Troosite tempering microstructure if water quenched from tempering temperature results in compressive stresses within the steel structure.

Does tempering temperature affect microstructure and mechanical properties of dual phase steels?

In this study, affect of tempering temperature on the microstructure and mechanical properties of dual phase steels was studied. The C–Mn steel specimens were put under intercritical annealing treatment (ICT) at 760 °C and quenched in water to obtain 31% martensite and then tempered within the range of 100–600 °C.

What is the difference between Low tempering and medium tempering?

The first stage is termed as Low-temperature tempering. Increase in Toughness: With martensite converting into ferrite and carbides converting into spheroids, toughness increases along with machinability of steel. The second stage is termed as Medium tempering temperature.

What happens to microstructure during tempering?

Changes in Martensite Structure The martensite itself also changes during tempering. One change that occurs is that the “tetragonality” of the martensite is reduced as the martensite becomes more and more like cubic ferrite as the carbon leaves the martensite.

How does tempering affect steel microstructure?

During tempering, dislocations have enough thermal activation to migrate gradually. Carbon atoms precipitate from a-Fe in the form of cementite, and the solid solution strengthening effect of carbon atoms is weakened. When tempering at 510°C, the structure of martensite is retained to a great extent.

How does heat treatment effect microstructure?

The heating and cooling treatment of the steel specimens have a great effect on the phase of the microstructure of the steel specimen. The addition of alloys or coarsening of the austenitic grain structure increase the hardenability of steel.

Does heat treatment change microstructure?

The industrial and scientific application of any metal or alloy is determined by its properties. Heat treatment methods are used to alter the microstructure and mechanical properties of steel.

Does tempering change the microstructure?

As the last process of heat treatment, the tempering process can significantly affect both the microstructure and the mechanical properties of the steel, including the recovery of martensitic lath, reduction of dislocation density, reduction of hardness and yield strength, etc.

Does tempering increase grain size?

The grain size increased with increase in normalizing temperature and decreased with increase in tempering temperature as discussed in previous section (OM) (Fig. 3). FEGeSEM micrographs of samples normalized at 1333 K and tempered at 1033 K are shown in Fig.

How does heat treatment affect a steel grain structure?

Annealing changes a metal's properties by altering and realigning the grain structure using heat, making the metal softer and more ductile. In this process, the steel is heated to just above its re-crystallization point, allowing it to cool slowly.

How does annealing change microstructure?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

How does quenching change microstructure?

The rapid quenching changes the crystal structure of the steel, compared with a slow cooling. Depending on the carbon content and alloying elements of the steel, it can get left with a harder, more brittle microstructure, such as martensite or bainite, when it undergoes the quench hardening process.

How does heat treatment affect metal properties?

Heat treating can improve wear resistance by hardening the material. Metals (including steel, titanium, inconel, and some copper alloys) can be hardened either on the surface (case hardening) or all the way through (through hardening), to make the material stronger, tougher, more durable and more resistant to wear.

How does microstructure affect hardness?

IT is cLearLy concLuded ThaT boTh The sMaLLer grain size and The More precipiTaTions of carbides proMoTe The hardness increasing, buT onLy The sMaLLer grain size increases The corrosion resisTance. This May be caused by differenT effecTs of various MicrosTrucTures on The hardness and corrosion.

What happens to structure of metals when they are heated and how is this related to corrosion?

Metal expands when heated. Length, surface area and volume will increase with temperature. The scientific term for this is thermal expansion. The degree of thermal expansion varies with different types of metal.

How do you do tempering process?

Tempering steel process after hardening is the heat treatment process carried on as-quenched steel to a temperature that is lower than a lower crit...

How do you temper steel?

Before the start of the post-quench heat treatment process, it is better to bring some insight from the article, “Martensitic transformation” about...

What is quenching and tempering process?

Quenching is name of severe cooling of steel resulting in martensitic steel. Tempering steel process after hardening is the heat treatment process...

What is the difference between hardening and tempering?

Hardening is name of severe cooling of steel resulting in martensitic steel. While, on the other hand, Tempering steel process after hardening is t...

What happens during tempering?

Before the start of the post-quench heat treatment process, it is better to bring some insight from the article, “Martensitic transformation” about...

What is the purpose of tempering steel?

Tempering of steel is post quenching process being used for various reasons including stress relieving, increase in hardness or decress in hardness...

What is difference between annealing and tempering?

Annealing is the process of furnace cooling of steel. While Tempering is post quenching low temperature process.

What is a tempering microstructure used for machine tools?

The structure of this type developed during this post-quench heat treatment range is termed as Sorbite. Sorbite is a tempering microstructure used for machine tools.

What is the process of tempered steel?

Tempering steel process after hardening is the heat treatment process carried on as-quenched steel to a temperature that is lower than a lower critical temperature line to induce ductility and toughness .

What causes hardness to decline?

Formation of softer phase ferrite and coarsening of carbides is causing hardness declining trend. The softening stage involves coarsening and loss of coherence by carbides. Increase in hardness due to precipitation of alloy carbides initially dissolved in the matrix.

What happens to the temperature of an alloy steel?

In alloy steels the temperature at which transformations take place changes as a result of which the rate of softening is retarded. The transition carbides (e.g. -iron carbide) and the supersaturated martensitic structure becomes stable at higher tempering temperature and the precipitation and growth of cementite are also delayed.

What is the first stage of tempering steel?

First Stage. The first stage of the tempering steel process exists between 100-250oC. During the first stage, carbon starts nucleating from martensite and results in the formation of epsilon carbide. With depletion go carbon from carbon saturated BCT martensite, it transforms into low carbon martensite.

Why is heat treatment used?

In general, heat treatment is carried out to bring balance between hardness and toughness. With an increase in time and temperature, the hardness of steel decreases. Martensitic transformation is always accompanied by stresses. That’s why post-quench heat treatment can be used for stress relie ve as well.

Is epsilon carbide a single step process?

It must be understood that the formation of epsilon carbide and transformation of high carbon martensite into low carbon martensite is not a single step simultaneous process. With an increase in time and temperature for tempering steel after hardening, conversion takes place slowly.

How does deep tempering affect carbide?

Deep tempering affects the precipitation and dissolution behavior of carbides , and dynamically affects the second phase strengthening and solid solution strengthening effects in the steel. This is the main reason that different temperatures and different times of deep medium-temperature tempering affect the surface hardness of M50NiL steel.

What temperature should M50NiL steel be?

Compared to the initial-stated M50NiL steel, the deep tempering at 460 °C and 480 °C can slightly improve the surface hardness of the M50NiL steel, but 5-time tempering at 500 °C make the hardness of M50NiL steel slightly decreased.

What is carburizing steel?

In high-performance bearing steels, carburizing is usually a surface hardening method. The carbon content gradient in the outer layer after carburizing will cause the mechanical properties and structure of the carburized steel to change with the carburizing depth [ 18 ].

Abstract

In this study, affect of tempering temperature on the microstructure and mechanical properties of dual phase steels was studied. The C–Mn steel specimens were put under intercritical annealing treatment (ICT) at 760 °C and quenched in water to obtain 31% martensite and then tempered within the range of 100–600 °C.

1. Introduction

Dual phase steels have unique mechanical properties such as combination of low-yield strength and high ultimate tensile strength, high strain hardening exponent accompanied with high uniform elongation and a continuous yielding behavior (without a sharp yield point in their stress/strain curves) [1], [2].

2. Experimental procedures

Hot-rolled steel bar 11 mm in diameter, containing 0.21% C, 1.18% Mn, 0.26% Si, 0.18% Cr, 0.2% Cu, 0.12% Ni, 0.03% P, 0.03% S was used. Tensile specimens of 15.5 mm gage length and 4.5 mm gage diameter were subjected to intercritical annealing at 760 °C for 1 h in a salt bath furnace using 80% BaCl 2 and 20% NaCl.

3. Results and discussion

In the previous works that have been conducted in this area, all the authors agreed that tempering time of 1 h is best for this tempering temperature, so in this study, we focused on tempering time of 1 h.

What is the process of tempering a metal?

Tempering is usually performed after quenching , which is rapid cooling of the metal to put it in its hardest state. Tempering is accomplished by controlled heating of the quenched work-piece to a temperature below its "lower critical temperature ".

What is the purpose of tempering?

Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the brittleness of the metal. Tempering is usually performed after quenching, which is ...

How does martempering work?

The steel is quenched to a much lower temperature than is used for austempering; to just above the martensite start temperature. The metal is then held at this temperature until the temperature of the steel reaches an equilibrium. The steel is then removed from the bath before any bainite can form, and then is allowed to air-cool, turning it into martensite. The interruption in cooling allows much of the internal stresses to relax before the martensite forms, decreasing the brittleness of the steel. However, the martempered steel will usually need to undergo further tempering to adjust the hardness and toughness, except in rare cases where maximum hardness is needed but the accompanying brittleness is not. Modern files are often martempered.

How to temper steel?

Tempering is most often performed on steel that has been heated above its upper critical (A 3) temperature and then quickly cooled, in a process called quenching, using methods such as immersing the hot steel in water, oil, or forced-air. The quenched-steel, being placed in or very near its hardest possible state, is then tempered to incrementally decrease the hardness to a point more suitable for the desired application. The hardness of the quenched-steel depends on both cooling speed and on the composition of the alloy. Steel with a high carbon-content will reach a much harder state than steel with a low carbon-content. Likewise, tempering high-carbon steel to a certain temperature will produce steel that is considerably harder than low-carbon steel that is tempered at the same temperature. The amount of time held at the tempering temperature also has an effect. Tempering at a slightly elevated temperature for a shorter time may produce the same effect as tempering at a lower temperature for a longer time. Tempering times vary, depending on the carbon content, size, and desired application of the steel, but typically range from a few minutes to a few hours.

Why is tempering important?

Tempering provides a way to carefully decrease the hardness of the steel, thereby increasing the toughness to a more desirable point. Cast-steel is often normalized rather than annealed, to decrease the amount of distortion that can occur.

What is tempered martensite?

Tempering is an ancient heat-treating technique. The oldest known example of tempered martensite is a pick axe which was found in Galilee, dating from around 1200 to 1100 BC. The process was used throughout the ancient world, from Asia to Europe and Africa. Many different methods and cooling baths for quenching have been attempted during ancient times, from quenching in urine, blood, or metals like mercury or lead, but the process of tempering has remained relatively unchanged over the ages. Tempering was often confused with quenching and, often, the term was used to describe both techniques. In 1889, Sir William Chandler Roberts-Austen wrote, "There is still so much confusion between the words "temper," "tempering," and "hardening," in the writings of even eminent authorities, that it is well to keep these old definitions carefully in mind. I shall employ the word tempering in the same sense as softening."

How long does it take to temper steel?

Tempering times vary, depending on the carbon content, size, and desired application of the steel, but typically range from a few minutes to a few hours.

Abstract

By means of microstructure observation, phase analysis and mechanical property tests, the effect of the quenching and tempering treatment on microstructure and mechanical properties of CSS-42L bearing steel were studied.

Introduction

The main shaft bearing is one of the most essential parts of aero-engines, which has the characteristics of high-temperature resistance, corrosion resistance and high strength (Ref 1, 2, 3, 4, 5 ), and the most widely used bearing steels currently are high carbon bearing steel and carburized bearing steel.

Experimental Materials and Methods

The material used in this research was CSS-42L steel, which belongs to low carbon high alloy steel. It was prepared by vacuum induction (VIM) + vacuum consumable (VAR) duplex process, and the chemical composition is shown in Table 1. The dimension of the sample was 15 mm × 15 mm × 15 mm.

Results and Discussion

Figure 4 shows the microstructure of the test steel after quenching. It can be seen that when the solution temperature was 1020°C, the microstructure of the test steel was mainly composed of lath martensite (M), retained austenite (RA) and undissolved carbide (UC), as shown in Fig. 4 a.

Acknowledgments

This work is supported by the Liaoning Educational Committee (LJ2019014). The opinions, interpretations, recommendations and conclusions are those of the authors.

Author information

School of Mechanical Engineering, Shenyang University of Technology, Shenyang, 110870, China

Additional information

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

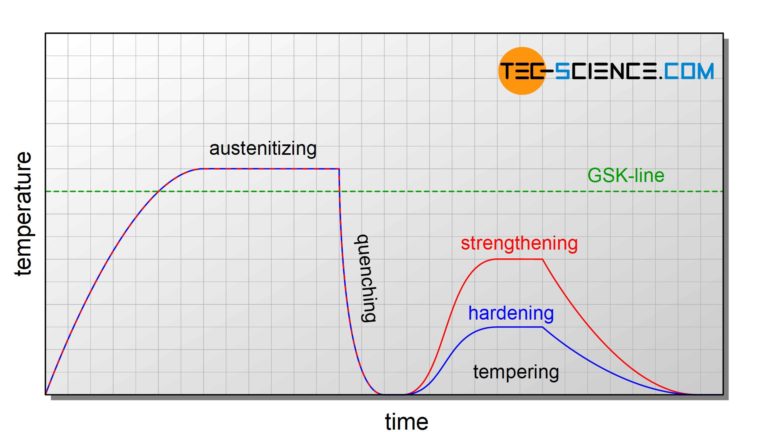

What is the process of quenching and tempering?

Quensching and tempering can be divided into three basic steps: austenitizing → heating to above the GSK line into the austenite region.

What temperature does steel have to be to be tempered?

When a steel has to become very hard, it is only tempered at relatively low temperatures in the range of 200 °C to 400 °C, while it becomes tougher and high load capacity at higher temperatures (in the range of 550 °C to 700 °C). Figure: Temperature curve during quenching and tempering.

What is martensite microstructure?

The martensite microstructure formed after quenching is characterized by a very high hardness, but is much too brittle for most applications! In order to give the quenched steel the toughness required for use, the microstructure must be treated again afterwards. This is done by subsequent tempering.

What happens when austenite is not cooled?

If the austenitized steel is not cooled slowly but quickly, the dissolved carbon no longer has enough time to diffuse out of the austenite lattice. Such rapid cooling is also called quenching.

Why does martensite diffuse out?

Due to the increased temperatures during tempering, the forcibly dissolved carbon atoms in the tetragonal martensite can partially diffuse out again. Accordingly, with the decline of the tetragonal martensite, the lattice distortion partially decreases. This reduces the hardness and strength slightly, but the steel gains significantly in toughness!

What happens to the carbon atoms in ferrite during quenching?

During quenching, the carbon remains forcibly dissolved in the forming ferrite lattice despite the transformation of the lattice. The body-centered cubic elementary cells of the ferrite structure are expanded tetragonally by the carbon atoms forcibly dissolved therein.

What is the process of ferrite turning into austenite?

Austenitizing. In the first process step, the steel is heated above the GSK-line. This completely transforms the body-centered cubic lattice structure of ferrite into the face-centered austenite. Therefore, this process is also called austenitizing.