Research has shown that heat treatments can loosen stiff joints and relieve achy muscles. Here is how it works. When you warm up a sore joint or tired muscle, your blood vessels get bigger. This allows more blood, oxygen, and nutrients to be delivered to the injured tissues. Better circulation means more relaxation for those stiff muscles and joints.

Is heat therapy effective for pain?

ARTICLE SUMMARY. Heat therapy is relaxing and a mild pain reliever, safer than any pain-killing drug and possibly as effective in some cases. Although far from proven or miraculous, it can probably and taking the edge off several kinds of pain, mostly duller and persistent pains associated with stiffness, cramping, and neuropathic sensitivity.

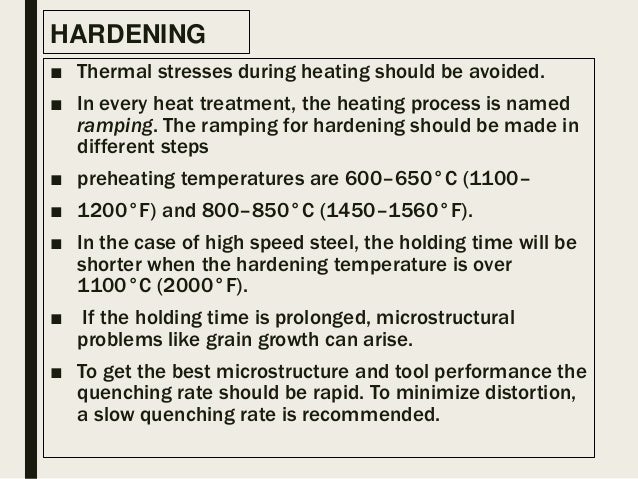

What are the disadvantages of heat treatment of steel?

The heat treatment atmosphere should be maintained in a manner to minimize the chances of oxidation. In certain cases, steel during heat treatment when heated above 650 o C, decarburizing or loss of carbon from the surface of steel takes place resulting in loss of mechanical properties like fatigue strength.

Does heat application every other day reduce pain and disability?

Moreover, statistically significant differences were found between the control and intervention group patients in terms of changes in the scores for physical function, pain and general health perception (p < 0.05). Conclusions: It was found that heat application every other day decreased pain and disability of the patients with knee osteoarthritis.

When is it OK to use heat on an injury?

If superficial tissue is sensitive to touch, if the skin is hot and red, if there is swelling, these are all signs that your injury is still fresh, and should not be heated. 5 If there’s no obvious/severe injury or infection, it’s okay to try a heat treatment.

Does heat treatment affect stiffness?

The elastic modulus is controlled by the strength of the iron-iron bonds, which does not change with heat treatment, strength, or hardness.

How does heat affect stiffness?

High temperature reduces material stiffness and strength, while low temperature increases material stiffness and strength. Almost all materials creep over time if exposed to elevated temperatures under applied load.

What are the effects of heat treatment?

The heat treatment develops hardness, softness, and improves the mechanical properties such as tensile strength, yield strength, ductility, corrosion resistance and creep rupture. These processes also help to improve machining effect, and make them versatile.

How does heat treatment affect mechanical properties?

The temperatures metals are heated to, and the rate of cooling after heat treatment can significantly change metal's properties. The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance.

Does annealing decrease stiffness?

With rising annealing time hardness and reduced modulus steadily increase. Along with the variation of the hardness also changes of the elastic properties were found, Fig.

How does tensile strength change with heat treatment?

Grain characteristics are controlled to produce different levels of hardness and tensile strength. Generally, the faster a metal is cooled, the smaller the grain sizes will be. This will make the metal harder. As hardness and tensile strength increase in heat-treated steel, toughness and ductility decrease.

What are the advantages of heat treatment?

WHAT ARE THE BENEFITS OF HEAT TREATMENT?It can change a material's physical (mechanical) properties and it aids in other manufacturing steps.It relieves stresses, making the part easier to machine or weld.Increases strength, making the material ductile or more flexible.More items...•

Why can heat treatments cause a change in physical properties?

As metals are heated, their volume, surface and length will expand. The term for these actions is thermal expansion. Each metal will have a different rate of expansion when exposed to the heat. Another effect that heat treatments have on metals is that the structure of them will go through a transformation.

What is the effect of heat treatment on a metal?

Heat Treating of steel and other metals can lead to: Improved wear resistance. Increased resistance to deformation and warpage and. Increased strength or toughness.

What properties does heat treatment change?

Heat treating is often used to alter the mechanical properties of a metallic alloy, manipulating properties such as the hardness, strength, toughness, ductility, and elasticity.

Which of the following property is affected by heat treatment?

Which of the following property is affected by heat treatment? Explanation: Heat treatment involves changes in the micro structure and hence all the internal properties are effected.

What effect does the heat treatment annealing have on properties of steel?

Annealing changes a metal's properties by altering and realigning the grain structure using heat, making the metal softer and more ductile. In this process, the steel is heated to just above its re-crystallization point, allowing it to cool slowly. A full anneal involves leaving the metal to cool in the furnace itself.

How does heat therapy work?

The next several sections explore different mechanisms and details of how heating might be helpful to people in pain:

Why is therapeutic heating better than cryotherapy?

Therapeutic heating — “thermotherapy” for therapy geeks, the opposite of its trendier cousin, cryotherapy — is more useful than most people realize, mainly because muscle is a source of more and worse pain than most people realize, and muscle pain seems to respond well to heat. Muscle pain caused by over-exertion, muscle cramps and spams, and especially trigger points (muscle “knots”) are all common and sometimes severe, but often mistaken for other kinds of problems.

What is infrared heat?

And infrared is radiation is warming — it jostles our molecules — which is why it is also often called heat radiation. Infrared saunas sound fancy, like they are emitting some kind of special radiation, not just heating rays but healing rays. In fact, an infrared heater is just a … heater.

Why does penetrating heat matter?

The only reason to think that “penetrating” heat matters is the idea that there’s something about far infrared radiation that is actually helpful to our biology in some way. And while there is endless speculation and belief that effects like this exist — for instance, there are very closely related beliefs about lasers, infrasound, ultrasound, and electric current — even though most enthusiastic experts concede that we don’t actually know. For instance, Vatansever and Hamblin (cited above) conclude their over-excited review like this:

What is heat used for?

What heat is for: mostly non-inflammatory body pain. Heat is primarily for relaxation, comfort, and reassurance, and taking the edge off several kinds of body pain, mostly duller and persistent pains associated with stiffness, cramping, and/or sensitivity, which can be loosely categorized: Acute soreness from over-exertion: ...

Is pain medication more common than ice?

The competition: common pain meds. Over-the-counter (OTC) pain medications 19 are probably the only self-prescribed treatment for pain and fresh injury more common than ice/heat, but their risks and benefits could not be more different.

Does heat help soreness?

Heat can penetrate a few centimetres into tissue, and cells and biochemistry speed up when the tissue temperature rises, which might have therapeutic implications. For instance …. Heat may have an effect on the common painful phenomenon known as “trigger points.”. Heat may help soreness after exercise.

How do alloying elements affect heat?

Alloying elements have a strong influence on heat-treating, because they tend to slow the diffusion of atoms through the iron lattices and thereby delay the allotropic transformations. This means, for example, that the extremely hard martensite, which is normally produced by fast quenching, can be produced at lower cooling rates.

How does steel change properties?

A third way to change the properties of steel is by adding alloying elements other than carbon that produce characteristics not achievable in plain carbon steel. Each of the approximately 20 elements used for alloying steel has a distinct influence on microstructure and on the temperature, holding time, and cooling rates at which microstructures change. They alter the transformation points between ferrite and austenite, modify solution and diffusion rates, and compete with other elements in forming intermetallic compounds such as carbides and nitrides. There is a huge amount of empirical information on how alloying affects heat-treatment conditions, microstructures, and properties. In addition, there is a good theoretical understanding of principles, which, with the help of computers, enables engineers to predict the microstructures and properties of steel when alloying, hot-rolling, heat-treating, and cold-forming in any way.

How to change the mechanical properties of steel?

Adjusting the carbon content is the simplest way to change the mechanical properties of steel. Additional changes are made possible by heat-treating—for instance, by accelerating the rate of cooling through the austenite-to-ferrite transformation point, shown by the P-S-K line in the figure. (This transformation is also called the Ar 1 transformation, r standing for refroidissement, or “cooling.”) Increasing the cooling rate of pearlitic steel (0.77 percent carbon) to about 200° C per minute generates a DPH of about 300, and cooling at 400° C per minute raises the DPH to about 400. The reason for this increasing hardness is the formation of a finer pearlite and ferrite microstructure than can be obtained during slow cooling in ambient air. In principle, when steel cools quickly, there is less time for carbon atoms to move through the lattices and form larger carbides. Cooling even faster—for instance, by quenching the steel at about 1,000° C per minute—results in a complete depression of carbide formation and forces the undercooled ferrite to hold a large amount of carbon atoms in solution for which it actually has no room. This generates a new microstructure, martensite. The DPH of martensite is about 1,000; it is the hardest and most brittle form of steel. Tempering martensitic steel — i.e., raising its temperature to a point such as 400° C and holding it for a time—decreases the hardness and brittleness and produces a strong and tough steel. Quench-and-temper heat treatments are applied at many different cooling rates, holding times, and temperatures; they constitute a very important means of controlling steel’s properties. (See also below Treating of steel: Heat-treating .)

How fast does steel cool?

Cooling even faster—for instance, by quenching the steel at about 1,000° C per minute —results in a complete depression of carbide formation and forces the undercooled ferrite to hold a large amount ...

What elements are used to improve hardenability?

Improved hardenability is achieved by adding such elements as manganese, molybdenum, chromium, nickel, and boron. These alloying agents also permit tempering at higher temperatures, which generates better ductility at the same hardness and strength.

How does strengthening metals work?

In principle, the strengthening of metals is accomplished by increasing the resistance of lattice structures to the motion of dislocations. Dislocations are failures in the lattices of crystals that make it possible for metals to be formed.

What is a quench and temper?

Quench-and-temper heat treatments are applied at many different cooling rates, holding times, and temperatures; they constitute a very important means of controlling steel’s properties. (See also below Treating of steel: Heat-treating .)

What happens when you flex steel?

When we flex the steel, we are stretching or compressing the atomic bonds between atoms, as illustrated by springs in this image [2]:

Why is the stress on a knife blade lower?

The stress on the blade is also lower due to the stress being inversely proportional to the thickness squared. Sometimes knifemakers will state that they heat treat them to a lower hardness to ensure flexibility. As described in this article that is a misunderstanding of the steel behavior.

How to tell if a knife is too soft?

The hardness does not change the degree to which the edge deflects. The test is also claimed to be good for determining if a blade is too soft or too brittle. In practice it requires a relatively soft knife to permanently bend in this test with typical geometry knife edges, but if the knife was too soft then the yield point would be exceeded and the edge would be plastically deformed. If the knife was brittle then the edge would chip, as very brittle materials barely deform at all prior to cracking as shown in the figure comparing the “brittle” and “ductile” materials in a tensile test; however, the steel would have to be very brittle. Therefore, the test may give some limited information on if the steel is much too soft or much too hard but a hardness test would tell much more. It is more useful for getting a feel for how much the edge may flex based on its geometry.

What happens to the slope of a tensile test?

In a tensile test if you stay in the modulus region of the material, the behavior is completely linear, pulling the material causes it to elongate, and removing the load causes it to return to its original length. The slope of the line is equal to the Elastic Modulus. Applying more load leads to more elongation:

When the yield stress is exceeded, what happens to the steel?

When the yield stress is exceeded then “plastic deformation” occurs where the steel will remain permanently bent. In terms of a stress-strain curve, unloading will not lead to a return to zero, but retains some amount of deformation, or displacement [8]:

Does steel change stiffness?

Larrin. One concept that can be difficult to understand intuitively is that the hardness or strength of steel does not change its stiffness. Meaning, “flexing” steel without permanently bending it is not changed by its hardness.

How are plastic properties of metals influenced by heat?

These processes change the structure, and the dislocations.

Does steel change with heat treatment?

The mechanical properties of steel will certainly change with heat treatment and microstructure but this statement pertains to the properties that are governed by plasticity, e.g ., strength, hardness, ductility, toughness, etc.

Does effective modulus change with entropy?

From thermodynamics point of view, as the effective modulus changes during the external resources of energy, thus it should be change while you change entropy of total absorbed energy. I think before conducting numerical model, try to perform experiments and then figure out to simulate it.

Does heat treatment affect ductility?

A heat treatment, or alloy addition can increase or decrease the strength of the metal, its ductility but not the slope of the stress strain curve in the elastic region. it is only affected by temperature, with an increase in the operating temperature, the modulus of elasticity decreases. Cite. 2 Recommendations.

Does temperature affect Young's modulus?

Temperature in the metal can increase the vibration of atoms in the crystal structure, which will increase the atomic distance and decrease the atomic force and this will cause the changes of lattice potential energy and curvature of the potential energy curve, so the Young's modulus will also change.

Does heat treatment change Young's modulus?

As some literature and my experience have shown, the different heat treatments could probably leads to change of Young's modulus as Dr. Patrick N.B.Anongba has answered, but usually this effect is small and is not considered in FE analysis. While the different heat treatment will significantly affect the yield property of material, such as initial yield stress and subsequent yield.

Does Young's modulus change with heat?

As far as I know , Young's Modulus (E) is not affected by any kind of heat treatment! E is also a function of atomic distances, thus, it is affected in elevated temperature. Imagine this, If you are testing your material in two condition, one in room temperature and the other in higher temperature, you should change E but if you are only conducting your FEA in room temperature, it does not matter what kind of hear treatments you have done. You should implement a constant E in your FEA while the deformation temperature is constant!

Why is steel hard after heat treatment?

After heat treatment, not getting desired hardness or strength can become a cause of stress. Following are common reasons for lower hardness and stress in steel after heat treatment; Lower hardening temperature. For higher hardness and strength, martensitic formation is very important.

What is heat treatment of steel?

Heat Treatment of steels is called the heating and cooling process to achieve certain microstructural features for a wide range of applications. If required properties and microstructural features do not match with criteria than the process is said to be defective.

How does alloying affect martensitic formation?

We discussed above; alloying elements delay the Pearlitic formation thereby shifting c-shape TTT – curve towards right. This lowers the critical cooling rate necessary for martensitic formation. The use of slower heating to reduce the temperature difference between the center and surface of the steel part can prevent a generation of large thermal stresses in the material.

Why is quenching important?

Quenching plays a very important role. A slight decrease in the degree of cooling may cause the start of diffusion-based transformation mentioned in the TTT diagram of steel. This results in Pearlitic formation which has lower hardness as compared to martensite. The cooling rate higher than the critical cooling rate is essential for achieving higher hardness and strength in steel.

Why do steels need martensitic formation?

Martensitic steels are commonly used in the defense industry, powder metallurgy, and cutting tools industry. These types of steel undergo a series of heat treatments for achieving desired hardness and strength. After heat treatment, not getting desired hardness or strength can become a cause of stress.

What is the variation of hardness in steel from point to point called?

This variation of hardness in quenched steel from point to point is termed as Soft Spots.

How does slow heating and cooling affect steel?

In the case of slow heating and cooling, steel will get enough time to release stresses by bringing change in dimensions. With severe cooling, heat distribution in the sample will not be uniform bringing step-wise changes to cause the development of internal stresses.