How does surface treatment work?

The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air. In the presence of a high voltage discharge in an air gap, free electrons, which are always present in the air, accelerate and ionise the gas.

What is the importance of surface treatment of metals?

Treatment of metals can be of essential importance in many industries. It is not a new proces, but a proces that dates back as early as mankind started using gold decoratively before 4000 BC. Today there can be several reasons why it is necessary to change the surface properties of metals. For example is surface treatment of metals used for:

Can heat treatment change the mechanical properties of a material?

If you apply a heat treatment and your microstructure is changing you really have to think seriously about your impact. If nothing is changing visually you still can have chemical changes (diffusion) or recovery (reduction of implemented strain) so that your material can show dramatic changes in mechanical properties.

Why do we need surface treatment of polymers?

Surface energy of solid materials and the need for surface treatment of polymers. It is often necessary to bond plastic materials to metals or other plastic materials, or simply print on a plastic surface. In order to successfully accomplish this the liquid adhesive, or ink should be able to wet the surface of the material.

What is the purpose of surface treatment?

Surface treatment is an additional process applied to the surface of a material for the purpose of adding functions such as rust and wear resistance or improving the decorative properties to enhance its appearance.

How does surface treatment improves surface function and serviceability?

Surface treatments are used in a variety of ways to improve the material properties of the component. Coating mechanical properties, for example, hardness, strength, and toughness, can improve the component wear, fatigue, and erosion properties, respectively.

What are the advantages of surface treatment?

BENEFITS OF SURFACE TREATMENT: Wear and Tear Resistance:It is additionally incredible at lessening the wear and tear your equipment experiences during the time of operation. Expands the Life :As the rate of corrosion falls, the usable life expectancy of the substrate increases!

Why are surface properties important?

There are many surface properties that materials scientists wish to manipulate to improve the functionality of the material. These surface properties include adhesion, conduction or insulation, optical transmission or reflection of electromagnetic radiation, hardness, (anti) friction or biocompatibility.

What is surface treatment in construction?

Surface treatment is an economical and effective method to improve the quality of surface layer and protect the concrete structure compared with other methods, such as decrease water to cement ratio and add admixtures etc. There are a variety of surface treatments that can be used for protection of concrete.

Why is surface engineering important in manufacturing?

The main reason for the growing importance of surface engineering (and its inclusion in this Handbook) is an increasing realisation that a component usually fails when its surface cannot withstand the external forces or environment to which it is subjected, e.g. wear, corrosion, fatigue, etc.

Why surface coating is necessary in industrial applications?

Surface coating that enables strong covalent bonding at the substrate–coating interface can offer an enhanced performance and long-term stability to a substrate. Nanoparticles and nanostructured coatings, recently, have gained increasing interest for industrial application such as wear and abrasion resistance.

How can coating improve a surface?

The first is improving the appearance of the old surface. That dull surface can be turned into something illuminating. The second is protecting the surface. As stated earlier, an unprotected surface is going to dull quickly.

What are types of surface treatment?

Types of surface treatmentsAluminum anodizing. Resistance, hardness and abrasion resistance of the material. ... Zinc coating. Corrosion protection. ... Nickel coating. High gloss and hardness. ... Tinning. Resistance to water corrosion and hygienic safety. ... Blackening. Decorative surface treatment.

What are surface properties?

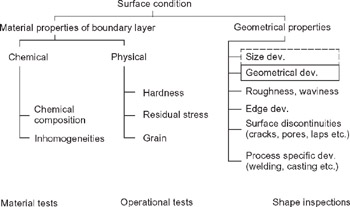

1 - Properties of the Surface These are chemical, mechanical, and geometrical properties. The chemical and mechanical properties comprise chemical composition, grain, hardness, strength, and inhomogeneities. The properties of the surface border zone may be different from those in the core zone.

Why Surface study is important?

Solution : It facilitates the adsorption of desired species . If surface is covered by the gases of air then it will not be available for adsorption of desired gases. So, it is very important to have clean surface in surface studies i.e. , study of surface chemistry.

What is surface property in biomaterial?

Biomaterial surface has different characteristic such as roughness, patterns, wettability, surface mobility, chemical composition, electrical charge, crystallinity, modulus and heterogeneity to biological reaction.

Can I treat 3D objects with plasma?

A plasma treatment is the ideal solution for your 3D parts because plasma gets almost everywhere. Therefore, it can cover regions of your parts whi...

Can the treatment be limited to certain parts of an object?

Theoretically, we could limit a treatment to certain regions by covering parts of an object. However, a plasma treatment usually does not have any...

How do I evaluate the success of a plasma treatment?

We provide different measurement techniques including surface energy test inks and pens as well as contact angle measurements to measure the effect...

Is in-line treatment possible?

Of course. We supply both standalone plasma treaters and in-line plasma treaters, which can easily be integrated into your existing production proc...

Which sizes can be treated?

We offer treatment solutions for almost any size. Smaller parts are often placed on trays, so that many parts can be treated simultaneously.

Materials for Solar Energy

Surface treatments can be used to modify the optical properties of an underlying material and thus enhance its ability to adapt to the conditions of the ambient radiation (cf. Fig. 1 ). Many specific types of solar energy materials are used in this way.

Radiation Effects in Structural and Functional Materials for Fission and Fusion Reactors

Surface treatment of PFMs, while extremely effective for the current day short-pulse tokamaks (pulses typically less than a few seconds), are of limited value for the next-generation (quasi-steady state) machines because of the significant surface erosion expected.

Ocean In Situ Sensors Crosscutting Innovations

Eric Delory, ... Seyed Morteza Sabet, in Challenges and Innovations in Ocean In Situ Sensors, 2019

Risk Assessment

To achieve this goal a new treatment approach was developed called the Surface Treatment Rule (STR). As part of the STR, all water utilities that use surface waters as their source of potable water would be required to provide filtration to remove Giardia and enough disinfection to kill viruses.

Mammalian Cell Culture

Bryan Griffiths, Florian Wurm, in Encyclopedia of Physical Science and Technology (Third Edition), 2003

Carbon Fibers

J.B. Donnet, ... T.K. Wang, in Encyclopedia of Physical Science and Technology (Third Edition), 2003

Sampling Theory and Methodology

C. Garcia-Jares, ... M. Llompart, in Comprehensive Sampling and Sample Preparation, 2012

Why is it important to change the surface properties of metals?

For example is surface treatment of metals used for: Decoration and/or reflectivity. Improved hardness (eg. for resistance to damage and wear) Prevention of corrosion. Treatment of metal surfaces plays an enormous role in extending the life of metals, ...

What is metal surface treatment?

The treatment of metal is a process in which parts or components made out of metal are treated before any actual coating takes place.

What is coating with oxides?

Coating with Oxides. Coatings done by the help of oxides are actually corrosion products that include an oxide with negligible thickness leading to good adhesion. These treatments are usually done through electrochemical reactions, heat, or chemicals.

What is coating pretreatment?

This type of treatment is usually known as the coatings pretreatment. Treatment of metal involves the creation of a barrier that acts like a wall protecting the metal in an environment that’s corrosive. The surface layer forming on a metal that is scheduled for chemical coating is created due to a chemical reaction that’s non-electrolytic in nature.

What is the surface layer of metal?

The surface layer forming on a metal that is scheduled for chemical coating is created due to a chemical reaction that’s non-electrolytic in nature. The reaction occurs between a solution and the metals surface. These layers are amorphous and adherent. For allowing the treatment of metal to form a shielding layer, ...

What is plasma treatment?

Plasma treatment creates an electron bombardment that breaks the surfaces chemical bonds while the ions hitting the surface are designed to alter the chemical composition of the surface. Plasma systems may also be used to treat a variety of material types including polymers, glass and ceramics.

What industries use metal surface treatment?

Among the industries who today use metal surface treatment include the following; the automotive industry, the construction industry, the Container industry, the electrical industry, the medical industry, industrial equipment, industries using laboratory equipment, aerospace, and several other industries. The range of components treated varies ...

What is surface treatment?

An Electrical Surface Treatment system consists of high frequency generator, high voltage transformer and treating electrodes. The generator produces an output signal whose frequency is automatically adjusted in the 15-25 kHz range depending on the load impedance, thus optimising the power available for treatment.

How does surface treatment improve wettability?

The treatment can improve wettability of the material by raising the material’s surface energy and positively affect adhesive characteristics by creating bonding sites. The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air.

How many times does a plastic discharge break molecular bonds?

When a plastic part is placed in the discharge path, the electrons generated in the discharge impact the surface with energies 2 to 3 times that necessary to break the molecular bonds on the surface of most substrates. This creates very reactive free radicals.

How long does pretreated plastic last?

The shelf life of pre-treated materials ranges from hours to years, depending on the plastic, its formulation, how it was treated and its exposure to elevated temperature after treatment. Material purity is the most important factor.

What is surface energy?

Surface energy of solid materials and the need for surface treatment of polymers . It is often necessary to bond plastic materials to metals or other plastic materials, or simply print on a plastic surface. In order to successfully accomplish this the liquid adhesive, or ink should be able to wet the surface of the material.

Can you print on polymer after treatment?

Eventually, these components migrate to the surface of clean polymers. It is therefore recommended to print or bond to the material soon after treatment. However, once the treated surface has been interfaced with a coating, ink, adhesive, or another material, the bond becomes permanent.

What are some similar processes to QPQ coating?

There are many other processes used to treat metal parts which are like QPQ Coating. Among the most popular ones, we can find Nitride, DLC Coating, and Black Oxidize. The main similarity is that they are all used to improve the properties of the finished part. However, there are many other similarities.

What materials can be treated with QPQ?

Several materials can be treated by applying the QPQ coating. Ferrous materials are the most commonly treated by this process. This is because it is mainly used to improve corrosion resistance. That said, here are some of the QPQ coating applicable materials: Carbon steels. Stainless steels.

Is QPQ coating a good process?

Unfortunately, the QPQ coating is not a perfect process. The QPQ treatment will help you improve those properties you need. But, there are a few drawbacks to consider. The most important disadvantages of QPQ coating are: Sometimes post washing or post polishing is required, and this increases turnaround times.

Is quench polish good for corrosion?

Also, for many industries and applications, it is essential to increase corrosion resistance. So, quench polish quench becomes a very helpful treatment for them. Some of the most relevant advantages of applying QPQ treatment include: Improved corrosion resistance.

Is QPQ coating ferrous?

However, the QPQ coating is limited to ferrous materials. So, if you are thinking about treating other types of material, you may want to look for a different process. You must also consider your budget. Higher energy consumption and the equipment required make it more expensive than others.

What are the factors that affect the final outcome of a metal treatment?

These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. The parameters depend on the heat treatment method, type of metal and part size. Over the course of this process, the metal’s properties will change.

What happens after soaking metal?

After the soaking stage is complete, the metal must be cooled in a prescribed manner. At this stage, too, structural changes occur. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors.

What is the most common heat treatment process?

The most common heat treatment process of all, hardening is used to increase the hardness of a metal. In some cases, only the surface may be hardened. A work piece is hardened by heating it to the specified temperature, then cooling it rapidly by submerging it into a cooling medium. Oil, brine or water may be used.

What metals are heat treated?

Although ferrous metals account for the majority of heat treated materials, alloys of copper, magnesium, aluminium, nickel, brass, and titanium may also be heat treated. About 80% of heat treated metals are different grades of steel.

What is heat treatment?

Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Both ferrous as well as non-ferrous metals undergo heat treatment before putting them to use. Over time, a lot of different methods have been developed. Even today, metallurgists are constantly working to improve ...

What is the process of ageing?

Ageing or precipitation hardening is a heat treatment method mostly used to increase the yield strength of malleable metals. The process produces uniformly dispersed particles within a metal’s grain structure which bring about changes in properties.

Why does the temperature of a metal change?

During the process, the metal part will undergo changes in its mechanical properties. This is because the high temperature alters the microstructure of the metal. And microstructure plays an important role in the mechanical properties of a material. The final outcome depends on many different factors.

Which mechanical properties are affected by heat treatment?

Heat treatments are induce changes in the micro-structure. Hence, all mechanical properties such as strength, hardness and toughness are affected by heat treatment.

What happens if you apply heat treatment?

If you apply a heat treatment and your microstructure is changing you really have to think seriously about your impact. If nothing is changing visually you still can have chemical changes (diffusion) or recovery (reduction of implemented strain) so that your material can show dramatic changes in mechanical properties.

What is heat treatment?

Heat treatment (HT) is a method to modify the properties of metal parts. Since some of the mechanical properties are mutual dependent and others are direct dependent, HT is generally used to improve one or more feature within the part but this would influence negatively other features!

Can you see precipitates in nanoscale?

You can generate or solute precipitates in nano scale, i.e., effects you only can see in high resolving SEM or even in transmission electron microscope. All depends on the temperature you applied, Therefore, heat treatment is a very complicated and often expensive tool and needs to adapted for each material. Cite.

Why is pressure treated wood used?

Pressure-treated timber is placed inside a pressurised treatment vessel so that the protective fluid can penetrate the timber. This process extends the lifespan of wood, protecting it against rot. This is beneficial as it is often bought for outdoor use, generally by the building trade or gardeners.

Why do you soak wood in oil?

Oil and wax soak into timber and can be used to enhance the natural appearance of the timber. Often kitchen worktops and chopping boards are oiled or waxed so that the surface repels water.

Do I need to paint or stain a dip treated fence?

Decking and garden fences are often made from pressure-treated timber, and there is no need to paint, stain, varnish or coat the timber in any other way. Dip-treated timber offers limited protection as the preservatives only penetrate the surface of the wood.