Full Answer

What is heat treatment and how does it work?

14 How does heat cause physical change? 15 Why are melting and boiling regarded as physical change explain with example? 16 How is a physical change different than a chemical change? 17 What about the physical change of liquid water boiling into steam is true?

How does heat treatment affect the properties of metals?

heat events. Increases in the overall temperature of the atmosphere and oceans associated with climate change cause changes in wind, moisture, and heat circulation patterns. These changes con tribute to shifts in extreme weather events, including extreme heat events. THE CLIMATE-HEALTH CONNECTION

What happens when you get too hot?

Jan 03, 2011 · Heat treating allows us to vary the properties (mechanical, physical, metallurgical) of a given material to optimize its design performance. We heat treat, therefore, quite literally because we must. It is the most cost-effective way to achieve the desired outcome.

What is the difference between heat treatment and normalizing?

However, severe heat treatments do cause substantial changes, e.g., dephosphorylation (~100 % in 1 h at 140 °C), aggregation (as indicated by changes in urea-PAGE or gel permeation chromatography), possibly due to the formation of inter-molecular disulphide and inter-molecular isopeptide bonds, cleavage of peptide bonds (formation of pH 4.6- or 12 % TCA …

Why can heat treatments cause a change in physical properties?

Annealing changes a metal's properties by altering and realigning the grain structure using heat, making the metal softer and more ductile. In this process, the steel is heated to just above its re-crystallization point, allowing it to cool slowly. A full anneal involves leaving the metal to cool in the furnace itself.Mar 9, 2021

What is effect of heat treatment?

The heat treatment develops hardness, softness, and improves the mechanical properties such as tensile strength, yield strength, ductility, corrosion resistance and creep rupture. These processes also help to improve machining effect, and make them versatile.

What properties can change during heat treatment process?

Heat treating is often used to alter the mechanical properties of a metallic alloy, manipulating properties such as the hardness, strength, toughness, ductility, and elasticity.

How does heat treatment change microstructure?

The difference in microstructure is attributed to a higher rate of cooling in normalizing, as compared to annealing. Tempering the normalized specimen at 580ºC leads to a reduction in hardness. This is due to the formation of smaller grains, which are finer.

Why is heat treatment performed in steels?

The Benefits of Steel Heat Treatment. Steel parts often require some form of heat treatment to achieve an increase in hardness and obtain maximum strength and durability. Through the many different processes of heat treatment, the properties of steel are changed via physical and mechanical channels.Nov 23, 2016

What is the importance and effect of heat treatment process?

Heat treating can improve wear resistance by hardening the material. Metals (including steel, titanium, inconel, and some copper alloys) can be hardened either on the surface (case hardening) or all the way through (through hardening), to make the material stronger, tougher, more durable and more resistant to wear.Sep 25, 2020

How does heat treatment change the properties of metal?

As metals are heated, their volume, surface and length will expand. The term for these actions is thermal expansion. Each metal will have a different rate of expansion when exposed to the heat. Another effect that heat treatments have on metals is that the structure of them will go through a transformation.Mar 16, 2020

What is hardening in heat treatment process?

The hardening process consists of heating the components above the critical (normalizing) temperature, holding at this temperature for one hour per inch of thickness cooling at a rate fast enough to allow the material to transform to a much harder, stronger structure, and then tempering.

What is hardening in heat treatment?

Hardening heat treatments invariably involve heating to a sufficiently high temperature to dissolve solute-rich precipitates. The metal is then rapidly cooled to avoid reprecipitation; often this is done by quenching in water or oil.

Why does hardness increase after heat treatment?

The reason for this increasing hardness is the formation of a finer pearlite and ferrite microstructure than can be obtained during slow cooling in ambient air. In principle, when steel cools quickly, there is less time for carbon atoms to move through the lattices and form larger carbides.

How does heat treatment affect hardness?

As conclusion, the heat treatment done to the 22MnB5 with different type of quenching process has portrayed an encouraging result, particularly in the hardness of the 22MnB5. The higher the cooling rate of the quenching, the smaller the size of the grain size. Hence, it will increase the hardness of the steel.

Does heat treating change yield strength?

Most carbon steels and carbon alloy steels can be heat treated for the purpose of improving mechanical properties such as tensile and yield strength. This is accomplished due to the heat treatment fundamentally altering the microstructure of the steel.

How does heat treatment work?

Heat treatment, typically, proceeds as follows: 1 Item ‘A’ enters the heat treatment cell and is loaded into the first furnace 2 Item ‘A’ is brought to a predefined temperature and held (soaked) at that temperature for a specified time (soak time) 3 Item ‘A’ exits the furnace and is cooled (quenched), often rapidly, to another distinct temperature. 4 Following quenching, Item ‘A’ is loaded into a second furnace where it receives a second round of heating and soaking, to “fine-tune” the physical properties of Item ‘A’

What is heat treatment?

Simply stated, heat treatment is the process of using heat at various, staged levels to change the physical properties (microstructure) of a material; most often metals (i.e. steel or aluminum). Heating is carried out in large-scale, industrial “furnaces” (extremely different from a house-hold furnace, capable of reaching temperatures ...

What industries use heat treatment?

Making this more remarkable is the fact that heat treatment affects nearly all aspects of modern life: construction, automotive, aerospace, oil & gas, and military are just some industries that rely on heat treatment as part of their product pipeline. Everyday items, such as: steel plates, pipes, engine blocks, pistons, springs, ...

What is the process of shaping metals?

Process of shaping metals by hammering or pressing. Heat treating allows for a metal’s shape to be changed, more than if it were cold, without adding unnecessary strain in the metal

How does heat affect health?

Heat conditions can alter human behavior, the transmission of diseases, health service delivery, air quality, and critical social infrastructure such as energy, transport, and water. The scale and nature of the health impacts of heat depend on the timing, intensity and duration ...

What are the effects of temperature?

Temperature extremes can also worsen chronic conditions, including cardiovascular, respiratory, and cerebrovascular disease and diabetes-related conditions. Heat also has important indirect health effects.

How many people died in the 2010 heat wave?

In 2003, 70,000 people in Europe died as a result of the June-August event, in 2010, 56,000 excess deaths occurred during a 44-day heatwave in the Russian Federation. Exposure to excessive heat has wide ranging physiological impacts for all humans, often amplifying existing conditions and resulting in premature death and disability.

How to cool down your home at night?

Use the night air to cool down your home. Open all windows and shutters during the night and the early morning, when the outside temperature is lower (if safe to do so). Reduce the heat load inside the apartment or house. Close windows and shutters (if available) especially those facing the sun during the day.

How to avoid heat?

If you go outside, wear a wide-brimmed hat or cap and sunglasses. Use light bed linen and sheets, and no cushions, to avoid heat accumulation. Drink regularly, but avoid alcohol and too much caffeine and sugar. Eat small meals and eat more often.

How to help elderly people living alone?

Elderly or sick people living alone should be visited at least daily. If a person is taking medication, ask the treating doctor how it can influence thermoregulation and the fluid balance. Get training. Take a first-aid course to learn how to treat heat emergencies and other emergencies.

How long do heat cramps last?

Medical attention is needed if heat cramps last more than one hour. Consult your doctor if you feel unusual symptoms or if symptoms persist. If one of your family members or people you assist presents hot dry skin and delirium, convulsions and/or unconsciousness, call a doctor/ambulance immediately.

Heat-Treat Market Size

Heat treating in North America is conservatively estimated to be a $20-22.5 billion industry servicing more than 18,000 manufacturers. It can be further divided between captive shops (approximately 88-92%) and commercial (approximately 8-12%) shops. Further subdivisions are possible by process (Fig. 3 – online only, Table 1) and equipment (Fig.

Summing Up

For the heat-treatment industry to survive it must remain the most cost-effective solution to our customer’s needs. It is important, therefore, that we understand what makes it such a vital part of the success of today’s products and anticipate how it must evolve to stay the choice for tomorrow’s innovations.

Abstract

In modern dairy technology, milk is almost always subjected to a heat treatment; typical examples are: thermization (65 ˚C × 15 sec), low temperature – long time pasteurization (65 ˚C × 30 min), high temperature – short time (72 ˚C × 15 sec) pasteurization, ultra-high temperature sterilization (140 ˚C × 5 sec), in-container sterilization (112 ˚C × 15 min).

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Suggested Reading

Fox, P. F. (Ed.). (1982b). Developments in dairy chemistry (Proteins, Vol. 1). London, UK: Applied Science. Google Scholar

About this chapter

Fox P.F., Uniacke-Lowe T., McSweeney P.L.H., O’Mahony J.A. (2015) Heat-Induced Changes in Milk. In: Dairy Chemistry and Biochemistry. Springer, Cham. https://doi.org/10.1007/978-3-319-14892-2_9

Can volumetric size change during heat treatment of steel be accurately predicted?

In most situations, volumetric size change during heat treatment of steel cannot be accurately predicted. However, by considering the different variables involved, a heat treater can provide a reasonable estimate that can help the shop prepare for final machining operations. One of the questions a commercial heat treater is most frequently asked ...

Can a heat treater be used to estimate a steel part?

While a precise forecast of a steel part’s size change during heat treating cannot be expected, by considering potential factors, a heat treater can provide a reasonable estimate that can help the shop prepare for final machining operations.

Why is heat treatment important?

It is very important manufacturing process that can not only help the manufacturing process but can also improve the product, its performance, and its characteristics in many ways. By Heat Treatment process, Example: The plain carbon steel. The following changes may be achieved: The hardness of Steel may be increased or decreased.

What are the changes in steel?

The following changes may be achieved: The hardness of Steel may be increased or decreased. Internal stresses that are set up due to cold or hot working may be relieved. The machinability of Steel may be enhanced. The mechanical properties like tensile strength the Talati shock resistance toughness etc may be improved.

Who is Amrit Kumar?

Amrit Kumar is the founder of Learn Mechanical, an Advisor at The Mechanical Engineering- a content-based website in Mechanical Engineering based in Delhi. He has 5+ years of teaching experience in the Core Mechanical Field.

What temperature does annealing take place?

Annealing consists of heating of steel parts to a temperature at or near the critical temperature 900 degree Celsius hold it at that temperature for a suitable time and when allowed to cool slowly in the Furnace itself. The heating done during annealing affects the metal in two stages of recovery and recrystallization.

What is annealing in metal?

Annealing is carried out for accomplishing one or more of the following: Softening of a metal or alloy. This may be done due to improving machinability. Relieving internal residual stresses caused by the various manufacturing process. Refining the grain size of the metal or alloy.

What is recrystallization in steel?

This causes complete recrystallization in steel to form New grain structure. This will release the internal stresses previously the strip in the steel and improve the machinability.

What is normalizing steel?

Normalizing is a heat treatment process similar to annealing in which the Steel is heated to about 50 degree Celsius above the upper critical temperature followed by air cooling. This results in a softer state which will be lesser soft than that produced by annealing.

How to prevent defects in heat treatment?

First and foremost, a method to prevent these usual defects of heat treatment is to perform heat treatment of steel in Vacuum or molten salts or a protective atmosphere. The protective atmosphere includes dried producer gas or dissociated products of ammonia.

What is heat treatment of steel?

Heat Treatment of steels is called the heating and cooling process to achieve certain microstructural features for a wide range of applications. If required properties and microstructural features do not match with criteria than the process is said to be defective.

Why do steels need martensitic formation?

Martensitic steels are commonly used in the defense industry, powder metallurgy, and cutting tools industry. These types of steel undergo a series of heat treatments for achieving desired hardness and strength. After heat treatment, not getting desired hardness or strength can become a cause of stress.

Why is low alloy steel hot?

Hot work products of low alloy steel are used widely in the form of fasteners, and machine tools because of properties like high strength, fatigue strength, and good toughness. Improper hot working of low alloy steel imparts a reduction in ductile properties of materials with faceted fracture surfaces making it unsuitable for practical applications. These conditions are normally caused by Overheating or burning of steel.

What is the variation of hardness in steel from point to point called?

This variation of hardness in quenched steel from point to point is termed as Soft Spots.

What is Rockwell hardness test?

Rockwell hardness test is used for finished parts which are considered non-destructive in nature and will not affect surface features of steel parts. For Laboratory testing and specific hardness of phases in steel, the Vicker hardness test is used. Several reasons which might cause soft spots in steel are;

What happens to steel when it is heated?

During the heat treatment of steel in an open atmosphere, steel may get exposed to environmental gases like oxygen, carbon dioxide, and water vapors. They may react with steel at high temperature and given rise to two important defects of heat treatment in steel; Oxidation of steel. Decarburization of steel.

Key Facts

Overview

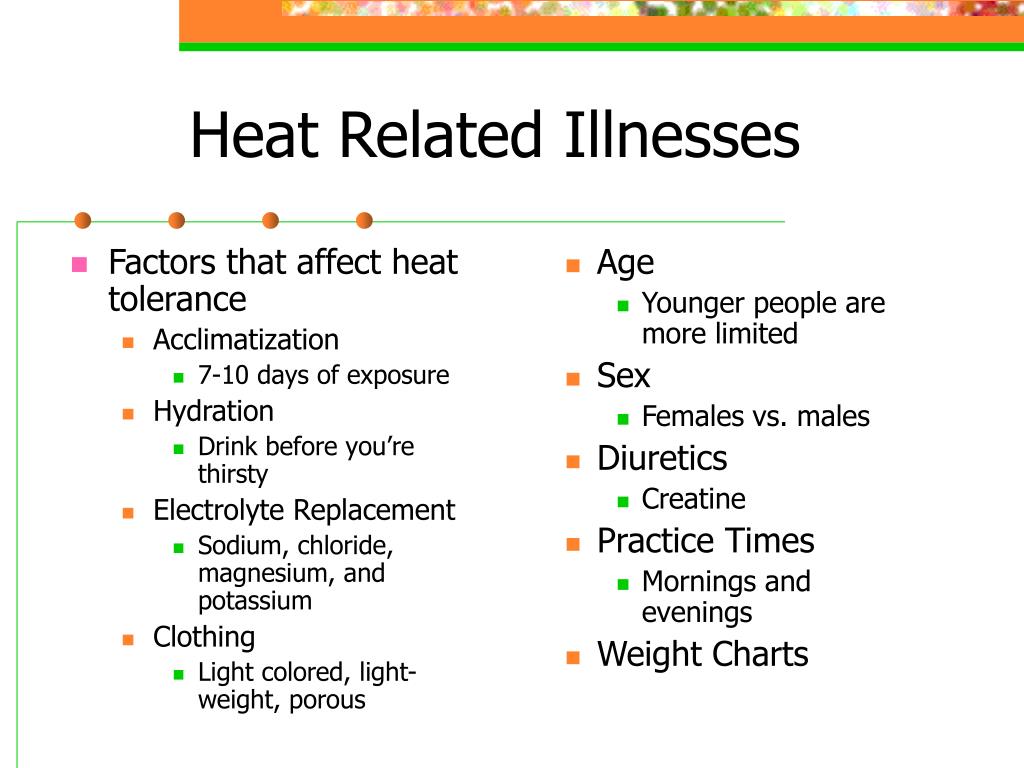

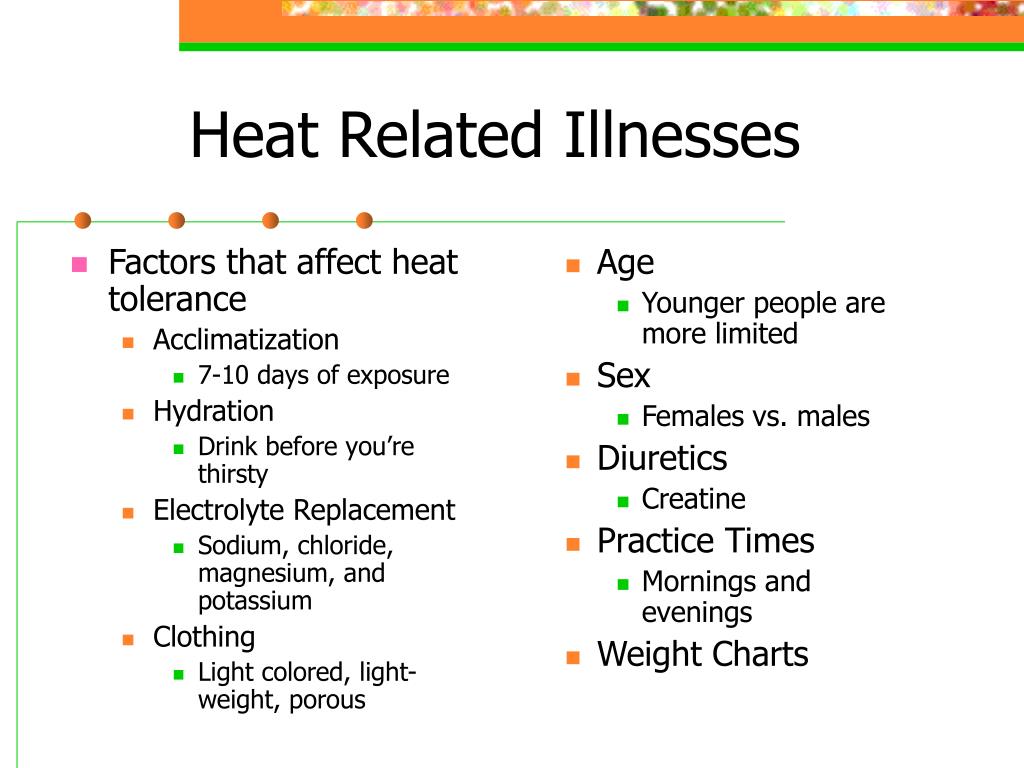

- Global temperatures and the frequency and intensity of heatwaves will rise in the 21st century as a result ofclimate change. Extended periods of high day and nighttime temperatures create cumulative physiologicalstress on the human body which exacerbates the top causes of death globally, including respiratory andcardiovascular diseases, diabetes mellitus and renal disease. …

Who Is Affected?

- Rising global ambient temperatures affect all populations. However, some populations are more exposed to,or more physiologically or socio-economically vulnerable to physiological stress, exacerbated illness, and anincreased risk of death from exposure to excess heat. These include the elderly, infants and children,pregnant women, outdoor and manual workers, athletes, and th…

How Does Heat Impact Health?

- Heat gain in the human body can be caused by a combination of external heat from the environment andinternal body heat generated from metabolic processes. Rapid rises in heat gain due to exposure to hotterthan average conditions compromises the body’s ability to regulate temperature and can result in a cascadeof illnesses, including heat cramps, he...

What Actions Should The Public take?

- Keep your home cool 1. Aim to keep your living space cool. Check the room temperature between 08:00 and 10:00, at 13:00 and atnight after 22:00. Ideally, the room temperature should be kept below 32 °C during the day and 24 °C duringthe night. This is especially important for infants or people who are over 60 years of age or have chronichealth conditions. 2. Use the night air to coo…