Hardness will be highest after which of the following heat treatment process?

- Furnace cooling

- Air cooling

- Oil quenching

- Water quenching

Does heat treatment affect the hardness of metal?

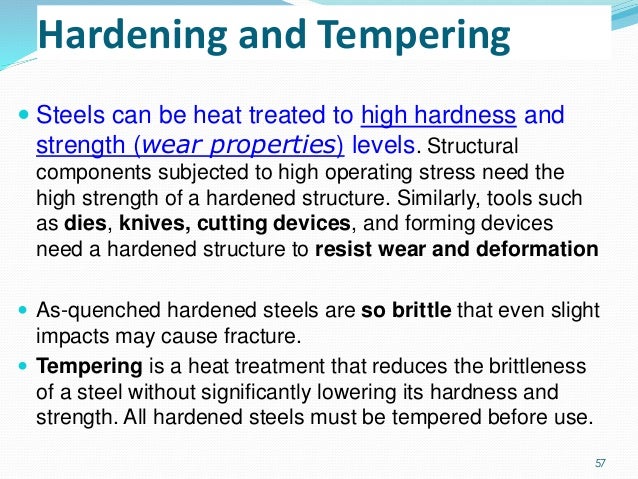

But, the amount of hardness you will lose can be controlled based on the temperature during tempering. While the other heat treatment processes of annealing, normalizing, and hardening always include temperatures above the metal’s upper critical point, tempering is always done at temperatures below it.

What is heat treated steel used for?

Suitable for alloy layout steel, alloy east-west steel and high-speed steel with high hardenability. Not only can it be used as the final heat treatment of various more important layouts, but also it can be used as a pre-heat treatment of certain tight parts, such as screws, to reduce deformation.

How do you reduce the hardness of steel?

Heat the steel to 30 – 50 degrees above Ac3 or Accm, after soaking, cool it at a cooling rate slightly larger than that of annealing. To reduce hardness, improve plasticity, cutting and pressure processing functions. To refinesgrains, improve mechanical functions, and prepare for next steps.

What is case hardening heat treatment?

Case hardening heat treatments, which includes nitriding, nitrocarburizing, carburizing, and carbonitriding, alter a part’s chemical composition—unlike previously mentioned annealing techniques—and focus on its surface properties.

Which heat treatment produces the hardest steel?

The DPH of martensite is about 1,000; it is the hardest and most brittle form of steel. Tempering martensitic steel—i.e., raising its temperature to a point such as 400° C and holding it for a time—decreases the hardness and brittleness and produces a strong and tough steel.

Does heat treatment increase hardness?

Heat treating can improve or change properties in metal, including: strength. hardness.

Which process improves the hardness more?

Full annealing: Benefits of annealing are: relieve stresses. increase softness, ductility and toughness. Reduce hardness and brittleness.

Which heat treatment process is best?

Hardening. The most common heat treatment process of all, hardening is used to increase the hardness of a metal.

How do you increase the hardness of steel?

Carburizing: adding carbon to the surface of steel, in a controlled atmosphere furnace, to increase the ultimate hardness, typically to a depth of 0.5 to 1.0 mm (0.020 to 0.040 in.). The process is followed by quenching and tempering.

Is HSS hardened?

It consisted of 2% carbon, 2.5% manganese, and 7% tungsten. The major advantage of this steel was that it hardened when air cooled from a temperature at which most steels had to be quenched for hardening.

Why does quenching increase hardness?

Depending on the carbon content and alloying elements of the steel, it can get left with a harder, more brittle microstructure, such as martensite or bainite, when it undergoes the quench hardening process. These microstructures result in increased strength and hardness for the steel.

What is hardening in heat treatment?

Hardening heat treatments invariably involve heating to a sufficiently high temperature to dissolve solute-rich precipitates. The metal is then rapidly cooled to avoid reprecipitation; often this is done by quenching in water or oil.

Which heat treatment of steel increases hardness but decreases strength and ductility?

Heat Treatment Steel: Hardening While hardening does increase strength, it also decreases ductility, making the metal more brittle. After hardening, you may need to temper the metal to remove some of the brittleness.

How do you increase the hardness of mild steel?

Carburizing is the process of diffusing carbon into the surface of low-carbon steels to increase hardness. The material is then quenched so the carbon is locked in place.

Is carburizing the same as case hardening?

Carburizing, also referred to as Case Hardening, is a heat treatment process that produces a surface which is resistant to wear, while maintaining toughness and strength of the core. This treatment is applied to low carbon steel parts after machining, as well as high alloy steel bearings, gears, and other components.

How many types of hardening techniques are there?

Each metal hardening process includes three main steps: heating, soaking and cooling the metal. Some common types of hardening include strain hardening, solid solution strengthening, precipitation hardening, and quenching and tempering.

How does heat treat harden metal?

In heat treating to harden a metal, the metal is heated to a temperature where the elements in the metal become a solution. Before doing this, defects in the crystal lattice structure of metal are the primary source of ‘give’ or plasticity. Heat treating addresses those deficiencies by bringing the metal into a reliable solution with fine particles to strengthen the metal. Once the metal is thoroughly heated to the right temperature to produce a solid solution, it is quickly quenched to trap the particles in solution.

What is heat treating?

Heat treating can be applied to the part before to make the material more machinable, or the components may be machined before the final hardening and heating stages. Heat treating can affect a number of different aspects of the metal including strength, hardness, toughness, machinability, formability, ductility, and elasticity.

Why is steel treated in air cooled?

The heat treating in normalization causes smaller austenitic grains, while air cooling produces more refined ferritic grains. This process improves machinability, ductility, and strength of the steel.

Why is case hardening used?

High heat is used in combination with other elements and chemicals to produce a hardened outer layer. Because hardening can make metals more brittle, case hardening can be useful for applications that require a flexible metal with a durable wear layer.

Why is heat treatment important?

The heat treatment can be an essential part of the precision machining process to transform metals and ensure your pieces and parts perform as you need them to. Talk to one of our qualified precision engineers about your requirements and how to find the right method of heat treating for your precision engineering project.

What happens when metal is heated to the right temperature?

Once the metal is thoroughly heated to the right temperature to produce a solid solution, it is quickly quenched to trap the particles in solution. In precipitation hardening, impurity particles are added to the metal alloy to increase strength further.

What is the purpose of a tempered metal?

TEMPERING. Tempering is a method of heat treating used to increase the resilience of iron-based alloys like steel. Iron-based metals are very hard, but they are often too brittle to be useful for most purposes. Tempering can be used to change the hardness, ductility, and strength of metal, which usually makes it easier to machine.

What are some heat treatments?

But there are many different heat treatments, such as quenching, tempering, aging, stress relieving, and case hardening. To eliminate confusion, here’s a look at the most common heat treatments, along with their purposes and their pros and cons.

Why do people heat treat metal?

Long before many of today’s technological advances, people have heat-treated metals to improve their physical and chemical properties for a given application . In the middle ages, blacksmiths forged and tempered metals (albeit in a relatively crude fashion) to create blades, tools, and goods for everyday life.

What steels are martensitic?

Not all ferrous alloys are eligible for this hardening mechanism, but martensitic stainless steels such as 17-4, 15-5, and 13-8 are excellent candidates, as well as maraging steels. (The term “maraging” combines the two words "martensitic" and "aging.".

What are the properties of quenching and tempering?

For parts with additional heat treat processes used to modify surface properties, quench and temper determine a part’s core properties such as hardness, strength, and ductility.

What is precipitation hardening?

Precipitation hardening is a special annealing step also known as age hardening due to certain metals hardening over time at sub-critical temperatures. As noted, this method of strengthening metals is limited to those that have undergone quenching and are an over-saturated solution, meaning the material is in a non-equilibrium state with regard to the phases present.

How thick is a compound zone?

Deeper hardened layers require more time. Compound zone thicknesses can be up to 0.002-in. thick, and it’s a function of which alloy is being nitrides, the time, and temperature. How the part is nitrided also affects zone depth. Nitriding can be performed via gas or ion (plasma).

How does steel quench?

The steel is then quenched, a process that rapidly cools the steel by placing it in water, oil, or a polymer solution. This “freezes” its microstructure.

How to harden steel?

To harden most steels, you would use the first two stages of heat treatment (slow temperature heat followed by soaking by a specified time to a uniform temperature), the third stage is different. When you harden metals, you rapidly cool them by plunging them into water, oil, or brine.

What is the difference between tempering and heat treatment?

Tempering consists of the same three stages as heat treatment. The main difference is the temperature of tempering and its effect on hardness, strength, and, of course, ductility. When you temper a steel part, you reduce the hardness that was caused by hardening and you develop certain physical properties. Tempering always follows hardening and, ...

Why is steel normalized?

The purpose of normalizing is to remove any internal stresses from heat treatment, machining, forging, forming, welding, or casting. Metal failure can result from uncontrolled stress, so normalizing steel before any hardening can help ensure the success of projects.

What is the purpose of annealing steel?

Heat Treatment Steel: Annealing. The purpose of annealing is to do the opposite of hardening. You anneal metals to relieve stress, soften the metal, increase ductility, and improve their grain structures. Without an appropriate preheating stage, welding can lead to a metal with uneven temperatures, even molten areas next to areas ...

Why is steel hard?

The answer may be to temper the steel to reduce that brittleness and remove or relieve the internal stresses.

Does hardening steel make it stronger?

The intent of hardening is not just to harden the steel, but also to make it stronger. Unfortunately, there aren’t just plusses to hardening. While hardening does increase strength, it also decreases ductility, making the metal more brittle.

Does tempering soften steel?

Tempering always follows hardening and, while it reduces brittleness, it also softens steel. Unfortunately, the soften ing of steel with tempering is unavoidable. But, the amount of hardness you will lose can be controlled based on the temperature during tempering.

Flame Hardening

This is probably the oldest method to increase wear resistance of the tops of flights. AISI 4140 steel is usually purchased by screw manufacturers in the heat-treated condition. Normally, this condition is 28-32 Rc (269-321 BHN) which gives good mechanical strength of around 100,000 psi (6,900 bar) tensile yield.

Induction Hardening

This process gives the same result as flame hardening but uses induction heat created by magnetic flux reversals rather than a flame.

Nitriding (Ion or Gas)

A very hard outside case can be obtained by subjecting screws or barrels to a high nitrogen atmosphere (usually ammonia gas) at elevated temperatures. The temperature is around 950°F (510°C). This comparatively low temperature gives minimal distortion, but a very high case hardness of around 55 – 65 Rc.

Precipitation Hardening

Precipitation hardening is a low temperature process used to harden certain grades of stainless steels. 17-4 PH stainless steel is an example of this type where the PH stands for precipitation hardening. These grades are usually supplied in Condition A (Solution Treated) which is similar to being annealed.

What gas is used to cool steel?

The flame incinerated with oxygen-acetylene mixed gas is sprayed onto the surface of the steel part, and the steel is heated rapidly. When it reaches the quenching temperature, to spray with water to cool the steel immediately.

How hot should carburizing medium be?

Put the steel parts in the carburizing medium, heat it to 900-950 degrees and keep it warm, so that the surface of the steel parts can obtain a carburizing layer with a certain concentration and depth.

Why is stainless steel quenched?

Sometimes when high-alloy steel (such as stainless steel, wear-resistant steel) is quenched, it is to obtain a single uniform austenite arrangement to improve wear resistance and corrosion resistance.

What temperature is steel tempered at?

After heat preservation, quenching is performed, and then tempered at a temperature of 400-720 degrees.

What is normalizing steel?

Normalizing is usually used as a pre-treatment process for forgings, weldments and carburized parts. For low- and medium-carbon carbon layout steels and low-alloy steel parts with low functional requirements can be performed with the final heat treatment.

What temperature is quenched steel?

The quenched steel parts are cooled in a low-temperature medium (such as dry ice, liquid nitrogen) to -60 to -80 degrees or lower , and the temperature is uniformly taken out and then allowed to reach room temperature.

How many mm is a high frequency induction hardened layer?

(2) Because of the skin effect, the high-frequency induction hardened hardened layer is usually 1 to 2 mm, the intermediate frequency hardened is usually 3 to 5 mm, and the high frequency hardened is usually greater than 10 mm.

All Answers (5)

The best heat treatment consist of heating to 840 degree centigrade quenching in oil and tempering 650 degree centigrade during 1 hour. The objective of this heat treatment is to obtain a sorbitic structure whit maximun impact resistence

Similar questions and discussions

What is the difference and relationship between flexural strength and bending strength in ceramics?