How to modify polymer surfaces?

Modification of polymer surfaces can be performed cleanly and rapidly by plasma treatment as a result of the possibility of the formation of various active species on the surface of polymers such as PE, polypropylene, and PTFE.

How do you make a polymer stronger?

How to Make Polymers Stronger. To measure the number of loops, the researchers first design polymer chains that incorporate a chemical bond, in a specific location, that can be broken using hydrolysis. Once the polymer crosslinks into a gel network, the researchers treat it with a base that cleaves this chemical bond, known as an ester.

How can I improve the wetting and friction properties of polymers?

Abstract. Wetting and friction properties of polymers can be improved by a simple plasma treatment, demonstrated on PC and EPDM, respectively. However, the deposition of ultra-thin layers by plasma enables the adjustment of wetting properties, using siloxane-based or fluorocarbon films, and further reduction of the friction coefficient,...

What is the plasma treatment of polymers?

The plasma treatment of different polymers (PMMA, PET, PC, PC/ABS, PP, PS, PE and EPDM) were carried out in a symmetrical, capacitively coupled rf discharge reactor. The measurement of the maximum excitation voltage V 0 (V rf (t)=V 0 sin (ωt)) shows that well-defined conditions over a wide parameter range are present .

What makes a polymer stronger?

As well as the arrangement of molecules, the properties of a polymer are also determined by the length of the molecular chain. In a nutshell, longer equals stronger. This is because, as a molecule gets longer, the total binding forces between molecules are greater, making the polymer chain stronger.

How can improve the polymer properties?

Overall, the main ways to change and tune the properties of a polymer include changing the length of the polymer chains, creating branched chains from linear polymer chains, crosslinking the polymer chains and adding plasticizers into the polymer.

How can you increase the surface energy of plastic?

In general, there is 2 main way to increase the surface energy and make plastic bonding process easier as following:Using Plasma Surface Treatment. ... Using Primer or Adhesion Promoter.

How can polymer adhesion be improved?

One of the major energetic treatments applied to polymers is UV/ozone radiation. Previous studies showed that this treatment significantly improves the adhesion strength of several polymers [1. Adhesion to polyethylene and polypropylene.

How do you make a polymer more rigid?

At first, adding cross-links between polymer chains makes the polymer more elastic. The vulcanization of rubber, for example, results from the introduction of short chains of sulfur atoms that link the polymer chains in natural rubber. As the number of cross-links increases, the polymer becomes more rigid.

Which polymer additives are added to improve?

Polymer Additives. The most common polymer additives are stabilizers, plasticizers, lubricants and flame retardants. Stabilizers are added to prolong the useful life of a polymer formulation by protecting it from thermal and light-assisted oxidation.

How do you increase surface energy?

In order to ensure proper adhesion and help boost surface energy, the substrate must be fully dry and free of any moisture. Another way to increase surface energy is to roughen the surface of the substrate. Sanding is one easy way to do this, creating peaks and valleys on the substrate.

How can surface adhesion be improved?

There are various ways to increase the surface energy of a material, improving the ability to bond....Surface CleanlinessReduced contact between adhesive and substrate, preventing a bond.De-tackified adhesive, preventing effective wet out.Reduced bond strength.

What is plastic treatment?

To overcome the problem faced by conventional technologies such as incineration and landfills, various advanced plastic treatment technologies have been developed, for instance, pyrolysis, photodegradation, thermodegradation, and biodegradation.

What is adhesion in polymer?

Definition. Polymer adhesion is the phenomenon of adhesive-bonded joint formation between polymer material and other solids brought into contact.

What is in polymer adhesive?

A polymer based adhesive, or polymer dispersion adhesive is a milky white coloured mixture that is based on polyvinyl acetate (PVA). Widely recognised as one of the most efficient ways of bonding woods, these adhesive types are extensively used across the board in wood working projects of every nature.

Which of the following is a synthetic adhesive?

1 Classification of Wood AdhesivesClassResin typeTypical adhesive systemElastomericStyrene butadiene rubber (SBR)ThermoplasticVinylPolyvinyl acetate (PVAc) Polyvinyl alcohol (PVA)Hot-meltsEthylene vinyl acetate (EVA)Natural14 more rows

What is plasma based polymer surface modification?

Concurrently the plasma based technologies are also emerging as polymer surface modification technique which allows the surface of a polymer to be modified without affecting its bulk properties. Plasma based technologies can also be used to synthesize a new class of polymeric materials, with a unique set of properties from an organic or mixed organic−inorganic precursor, for which the structure–property relationships can be varied considerably depending on the final application. By controlling the plasma parameters and by understanding the plasma chemistry, it is possible to effectively modify surfaces of polymeric materials.

What is surface modification?

For halogenated polymers, such as chlorinated and fluorinated polymers, surface modification involves significant dehalogenation, the removal of chlorine and fluorine atoms from the surface molecules. In general, surface treatments can be viewed as a transfer of energy to the surface of plastics.

What is polymer 54?

Polymer ( 54) of 2- (vinyloxy)ethyl cinnamate is perhaps the first poly (vinyl ether) successfully commercialized as a specialty material. 7 Upon exposure to UV light, this polymer crosslinks via cyclodimerization of the cinnamate pendant groups 7 and serves as a negative photoresist material with a high sensitivity and resolution (1.0 μ m). 154 It was applied to the fabrication of integrated circuits for various artificial satellites and for the Viking mission for the exploration of Mars (1976).

Why is PP so hard to paint?

PP is a difficult material to paint and glue, because it is unable to interact strongly with adhesives. The reason for this is that it is quite impossible to wet, due to its low surface tension.

What is the process of modification of a polymer surface?

Unlike plasma treatment and chemical etching, this takes place only by altering the geometry of the surface through mechanical process.

How does plasma surface modification work?

This is done through polymer selective etching. For example, to attain a high compatibility between the polymer and exposed biological fluids, such as blood, both hydrophilic and hydrophobic surfaces are favored depending on the chemistry of the interacting molecule and surface morphology. By changing the surface hydrophilicity and morphology, it is possible either to increase or decrease the protein adsorption on the surface by changing the extend of chemical interactions between them [41].

What is plasma treatment?

Plasma treatments are mainly used for the surface modification of polymers or metals. The predominant surface effect is directly related to the nature of the gas subjected to the electric discharge. Chemically reactive gases such as ammonia (NH 3 ), nitrogen (N 2 ), oxygen (O 2), carbon dioxide (CO 2 ), water vapor (H 2 O), tetrafluoromethane (CF 4 )…especially support the reactions of functionalization: grafting of amine-type or amide-type functional groups in the case of NH 3 or N 2, grafting of peroxide or hydroxide functions in the case of O 2 or H 2 O, grafting of C O, C OH, C ( O)OH functions in the case of CO 2, grafting of CF x functions in the case of CF 4. Hydrogen (H 2) gas primarily supports the phenomenon of cross-linking. Chemically inert gases such as rare gases (argon (Ar), helium (He)) mainly support the effect of etching.

What is micromanipulation in biodegradable polymers?

Micromanipulation is a mechanical process that involves physical interaction with the polymer surface with the aid of microscope. In here, the polymer surface is carved at a microlevel or nanolevel with high precision for surface modification under scanning tunneling microscope or atomic force microscope, which are equipped with manipulator and tip of scanning probe. However, the feasibility of micromanipulation to modify the surface of biodegradable polymers is limited due to high cost and can only be used for polymers with high conductive surface.

What happens when a monomer is introduced into a plasma reactor?

So if the vapor phase of an unsaturated monomer is introduced into a plasma reactor just after the surface treatment of a polymer substrate, the radicals formed on the surface of the polymer substrate immediately cause the polymerization of the monomer. The process can also be implemented in solution.

What is surface modification?

Surface modification of polymers using a laser is an emerging technology and offers several benefits when compared to other surface modification methods. This method enables precise surface modification that can be easily controlled and is environmentally safe.

Can plasma be used to modify polymer surfaces?

Modification of polymer surfaces can be performed cleanly and rapidly by plasma treatment as a result of the possibility of the formation of various active species on the surface of polymers such as PE, polypropylene, and PTFE.

How can polymer surfaces be modified?

Polymer surfaces can be modified by a plasma treatment in different ways (etching, cleaning, activation, cross-linking), for example to improve wetting properties, to enhance the adhesion of plasma-deposited coatings, or to reduce friction.

How does plasma interact with polymer?

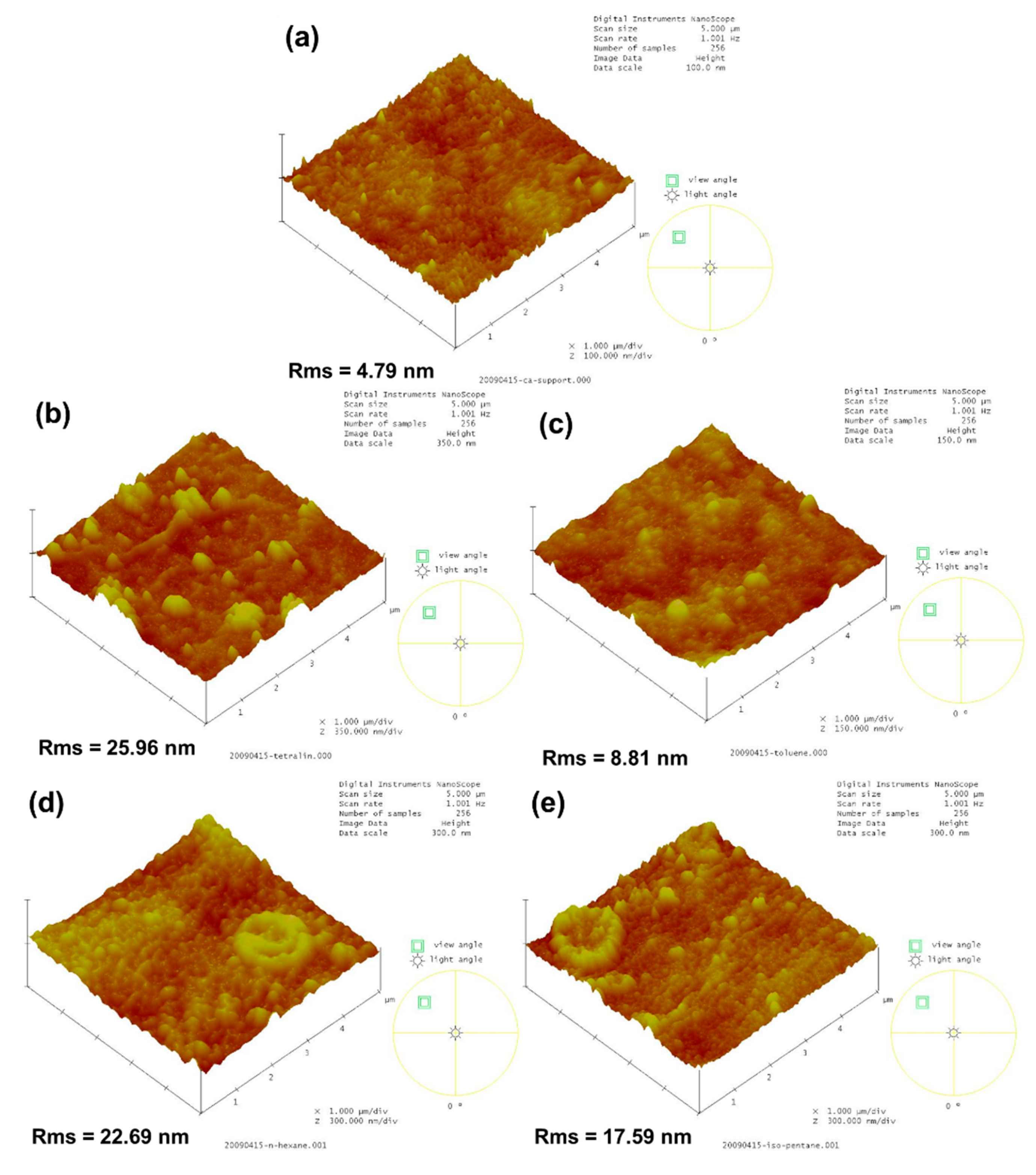

A plasma interacts in numerous ways with a polymer surface. At rather severe conditions, the polymer surface is subject to etching effects, whereby the polymer is continuously degraded. While chemical etching is promoted by radicals as in O 2, CF 4 and SF 6 discharges, physical etching occurs under strong ion bombardment, as for example in Ar plasmas [8]. As can be seen in Fig. 2, different polymers exhibit different etch rates under nominally equal plasma conditions (Ar plasma, 350 W, 0.2 mbar), where O-containing polymers are more degradable. However, the plasma–surface interaction leads to a competition between chain scission and cross-linking in the near-surface layer [9]. By varying the plasma gases used (2 min, 350 W, 0.2 mbar), a polypropylene surface, for example, is not only degraded by high-energy ions as in Ar discharges, but can also be reinforced by cross-linking, promoted mainly by VUV radiation as in He or N 2 ( Fig. 3 ).

What is friction polymer?

Friction. 1. Introduction. Polymers are distinguished by their low density, flexibility, ease of manufacture, and cost-effectiveness. However, their surface properties often do not meet the demands regarding scratch-resistance, wettability, biocompatibility, gas transmission, adhesion, or friction. Hence, an additional surface modification is ...

Why is plasma used for rubber?

In particular, rubber surfaces exhibit high coefficients of friction due to their high tackiness. Therefore, a plasma treatment can be suitable to reduce the friction coefficient of a rubber like EPDM, due to cross-linking of the near-surface layer.

Surface Treatment of Polymers by Plasma

Please review our Terms and Conditions of Use and check box below to share full-text version of article.

Summary

Plasmas can be generated in a wide range of pressures from a few Pa up to atmospheric pressure. Generating plasmas at low and medium pressures has the advantage of larger plasma volumes, allowing the surface modification of bigger objects with complex surface geometries.

Abstract

An overview of surface modification and coating techniques for plastics is presented for changing the surface properties to meet the performance requirements in a variety of applications.

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Most recent answer

Article Surface Characteristics and Hydrophobicity of Ni-Ti Alloy th...

All Answers (6)

In general, I would point you towards the roughness of your NiTi surface.

Similar questions and discussions

What is the difference between crystallite size and grain size? Is the both terms are same for all materials or different for different materials?

Most recent answer

you can do so through surface activation in a dry process that work on the surface only without affecting the desired bulk properties. I test the electron beam in improving surface hydrophilicity of PET and it really works. the water contact angle decreases from 90 to about 20 degrees.

All Answers (4)

May I know what type of polymer? Generally, we can alter the hydrophobicity of a polymer by playing around with the structure. For example in EVA copolymer, if we want to get EVA with less hydrophobicity, we can increase the vinyl acetate (VA) to ethyl ratio, as VA is the hydrophilic component in EVA.

Similar questions and discussions

How can I increase hydrophobicity of polypropylene based material using additives?