Full Answer

What is the final outcome of the heat treatment process?

The final outcome depends on many different factors. These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. The parameters depend on the heat treatment method, type of metal and part size. Over the course of this process, the metal’s properties will change.

What factors affect the outcome of heat treating?

Other factors affecting the final outcome are oil films on the surface and the type of heat source used. Many heat treating methods have been developed to alter the properties of only a portion of an object.

What is heat treatment process?

Heat treatment is a process of heating the metal to a certain temperature, keeping it there for some time, and then cool it down. During the whole process, grain crystallization happens, which helps alter the mechanical, chemical, and electric properties of metals. What are the different types of heat treatment?

How does heat treatment affect the properties of metals?

The temperatures metals are heated to, and the rate of cooling after heat treatment can significantly change metal's properties. The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance.

What happens after heat treatment?

Heat treatment is the process of heating and cooling metals to change their microstructure and to bring out the physical and mechanical characteristics that make metals more desirable. The temperatures metals are heated to, and the rate of cooling after heat treatment can significantly change metal's properties.

What does heat treatment do?

Heat treating can soften metal, to improve formability. It can make parts harder, to improve strength. It can put a hard surface on relatively soft components, to increase abrasion resistance. It can create a corrosion-resistant skin, to protect parts that would otherwise corrode.

What properties does heat treatment change?

Heat treating is often used to alter the mechanical properties of a metallic alloy, manipulating properties such as the hardness, strength, toughness, ductility, and elasticity.

What is the effect of heat treatment on a metal?

Heat Treating of steel and other metals can lead to: Improved wear resistance. Increased resistance to deformation and warpage and. Increased strength or toughness.

What are the benefits brought by the heat treatment process in the present?

There are many advantages of heat treatment, including: It can change a material's physical (mechanical) properties and it aids in other manufacturing steps. It relieves stresses, making the part easier to machine or weld. Increases strength, making the material ductile or more flexible.

How does heat treatment increase hardness?

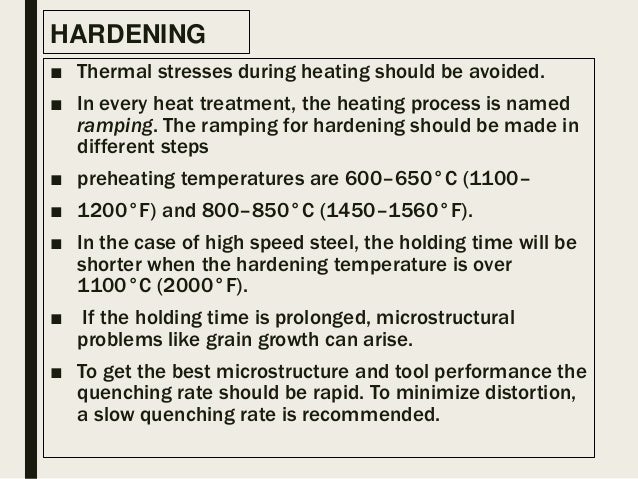

The hardening process consists of heating the components above the critical (normalizing) temperature, holding at this temperature for one hour per inch of thickness cooling at a rate fast enough to allow the material to transform to a much harder, stronger structure, and then tempering.

How does heat affect the material?

Heat Affects the Volume of Solids, Liquids and Gases As the average energy of particles increases, the space between the particles increases. They expand (increase their volume) as the temperature increases.

What is the effect of heat treatment on the mechanical properties of the material?

During the heat treatment process, the material usually undergoes phase microstructural and crystallographic changes [14]. The purpose of heat treating carbon steel is to change the mechanical properties of steel, usually ductility, hardness, yield strength tensile strength and impact resistance.

Why is heat treatment important?

Heat treatment is an essential process in the material science industry to improve metal properties for commercial purposes. It is one of the key processes that help gain the desired mechanical and chemical properties of metals.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

How does heat treatment help metals?

Heat treatment assist in improving the ductility of metal in the annealing process. Heat treatment helps in hardening metals. Case hardening helps in hardening only the outer surface of the metal piece keeping the rest of the portion soft and ductile. Machinability of metals gets improved.

How is annealing done?

Annealing is done by heating the metals at the above critical temperature , hold them there for some time and then cool it at a very slow rate in the furnace itself. Annealing is usually done on ferrous and non-ferrous metals to reduce hardness after the cold working process.

What is the process of increasing the hardness of a metal?

Curborization. In carburization, the hardness of the metal piece is increased by increasing the carbon content. The metal piece is heated below the melting point with high carbon materials such as charcoal. The heated metal piece then absorbs carbons to make it more hard and brittle.

How does tampering work?

Tampering is a very common process for machine tools, knives, etc. Tampering is usually done by heating the metal at a relatively low temperature. The temperature depends on the required mechanical properties of metals.

What is case hardening?

Case hardening or surface hardening is a hardening heat-treatment process. In the case of hardening, the complete metal piece is heated. But in the case of case hardening, only the outer surface is heat-treated to make it hardened. The inner metal is still soft and ductile.

Why is heat treatment called an arrest?

This temperature is referred to as an "arrest" because at the A temperature the metal experiences a period of hysteresis.

What is the process of heating something to alter it?

Process of heating something to alter it. Heat treating furnace at 1,800 °F (980 °C) Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the ...

How much carbon is in hypoeutectoid steel?

A hypoeutectoid steel contains less than 0.77% carbon. Upon cooling a hypoeutectoid steel from the austenite transformation temperature, small islands of proeutectoid-ferrite will form. These will continue to grow and the carbon will recede until the eutectoid concentration in the rest of the steel is reached.

How does steel change carbon?

When steel is heated in an oxidizing environment, the oxygen combines with the iron to form an iron-oxide layer, which protects the steel from decarburization. When the steel turns to austenite, however, the oxygen combines with iron to form a slag, which provides no protection from decarburization. The formation of slag and scale actually increases decarburization, because the iron oxide keeps oxygen in contact with the decarburization zone even after the steel is moved into an oxygen-free environment, such as the coals of a forge. Thus, the carbon atoms begin combining with the surrounding scale and slag to form both carbon monoxide and carbon dioxide, which is released into the air.

What happens when an alloy is cooled to an insoluble state?

If the alloy is cooled to an insoluble state, the atoms of the dissolved constituents (solutes) may migrate out of the solution. This type of diffusion, called precipitation, leads to nucleation, where the migrating atoms group together at the grain-boundaries.

What is a semi continuous batch furnace?

These upgraded furnaces are a very commonly used piece of equipment for heat-treating.

Why are metals annealed?

Most non-ferrous alloys that are heat-treatable are also annealed to relieve the hardness of cold working.

What is heat treatment?

Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Both ferrous as well as non-ferrous metals undergo heat treatment before putting them to use. Over time, a lot of different methods have been developed. Even today, metallurgists are constantly working to improve ...

What is the most common heat treatment process?

The most common heat treatment process of all, hardening is used to increase the hardness of a metal. In some cases, only the surface may be hardened. A work piece is hardened by heating it to the specified temperature, then cooling it rapidly by submerging it into a cooling medium. Oil, brine or water may be used.

What metals are heat treated?

Although ferrous metals account for the majority of heat treated materials, alloys of copper, magnesium, aluminium, nickel, brass, and titanium may also be heat treated. About 80% of heat treated metals are different grades of steel.

Why does the temperature of a metal change?

During the process, the metal part will undergo changes in its mechanical properties. This is because the high temperature alters the microstructure of the metal. And microstructure plays an important role in the mechanical properties of a material. The final outcome depends on many different factors.

What is a schedule in metals?

For that they develop new schedules or cycles to produce a variety of grades. Each schedule refers to a different rate of heating, holding and cooling the metal. These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties.

What happens after soaking metal?

After the soaking stage is complete, the metal must be cooled in a prescribed manner. At this stage, too, structural changes occur. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors.

What are the factors that affect the final outcome of a metal treatment?

These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. The parameters depend on the heat treatment method, type of metal and part size. Over the course of this process, the metal’s properties will change.

What is heat treatment?

Heat treatment is the process of heating and cooling metals to change their microstructure and to bring out the physical and mechanical characteristics that make metals more desirable. The temperatures metals are heated to, and the rate of cooling after heat treatment can significantly change metal's properties.

Why do metals need heat treatment?

The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance. Common techniques for heat treatment include the following: Annealing is a form of heat treatment that brings a metal closer to its equilibrium state.

What happens to metals when they are heated?

The actual structure of metal also changes with heat. Referred to as allotropic phase transformation, heat typically makes metals softer, weaker, and more ductile. Ductility is the ability to stretch metal into a wire or something similar. Heat also can impact the electrical resistance of metal.

What temperature does a metal lose its magnetism?

Metals heated to certain temperatures also can lose their magnetism. By raising temperatures to between 626 degrees Fahrenheit and 2,012 degrees Fahrenheit, depending on the metal, magnetism will disappear. The temperature at which this happens in a specific metal is known as its Curie temperature.

How long does it take for precipitation hardening to take place?

It can take anywhere from an hour to four hours to carry out the process. The length of time typically depends on the thickness of the metal and similar factors.

Why is tempering used in steelmaking?

Commonly used in steelmaking today, tempering is a heat treatment used to improve hardness and toughness in steel as well as to reduce brittleness. The process creates a more ductile and stable structure.

What is the process of quenching metal?

The quenching process stops the cooling process from altering the metal's microstructure.

What is heat treatment?

Heat treatment is the process of heating metal without letting it reach its molten, or melting, stage, and then cooling the metal in a controlled way to select desired mechanical properties. Heat treatment is used to either make metal stronger or more malleable, more resistant to abrasion or more ductile.

How many stages of heat treatment?

Stages of Heat Treatment. There are three stages of heat treatment: Heat the metal slowly to ensure that the metal maintains a uniform temperature. Soak, or hold, the metal at a specific temperature for an allotted period of time. Cool the metal to room temperature.

What happens when you heat metal?

All of the typical processes performed on metals produce heat, whether it’s welding or cutting, and any time you heat metal, you change the metallurgical structure and properties of it. Inversely, you can also use heat treatment to restore metals to its original form.

How to determine the soaking period of a metal?

To determine the correct length of time, you will need the chemical analysis and mass of the metal. For uneven cross-sections, you can determine the soaking period using the largest section.

What is the cooling stage of metal?

The Cooling Stage. In the cooling stage, you’ll want to cool metal back to room temperature, but there are different ways to do this depending on the type of metal. It may need a cooling medium, a gas, liquid, solid, or combination thereof. The rate of cooling depends on the metal itself and the medium for cooling.

Why do you need to heat parts slowly?

Larger parts or parts with uneven cross sections need to be heated more slowly than small parts to allow the inside temperature to be close to the surface temperature. Otherwise, there’s a risk of cracking or excessive warping.

Does quenching harden metals?

Usually quen ching is associated with hardening because most metals that are hardened are cooled rapidly with quenching, but it is not always true that quenching or otherwise rapid cooling results in hardening. Water quenching, for example, is used to anneal copper, and other metals are hardened with slow cooling.

How to cool down after heatstroke?

To cool your body to a normal temperature, your doctor may use these heatstroke treatment techniques: 1 Immerse you in cold water. A bath of cold or ice water has been proved to be the most effective way of quickly lowering your core body temperature. The quicker you can receive cold water immersion, the less risk of death and organ damage. 2 Use evaporation cooling techniques. If your core body temperature is not in the heatstroke range and if cold water immersion is not available, health care workers may try to lower your body temperature using an evaporation method. Cool water is misted on your body while warm air is fanned over you, causing the water to evaporate and cool your skin. 3 Pack you with ice and cooling blankets. Another method is to wrap you in a special cooling blanket and apply ice packs to your groin, neck, back and armpits to lower your temperature. 4 Give you medications to stop your shivering. If treatments to lower your body temperature make you shiver, your doctor may give you a muscle relaxant, such as a benzodiazepine. Shivering increases your body temperature, making treatment less effective.

How to bring down temperature?

If possible, take a cool shower, soak in a cool bath, or put towels soaked in cool water on your skin . If you're outdoors and not near shelter, soaking in a cool pond or stream can help bring your temperature down. Loosen clothing. Remove any unnecessary clothing and make sure your clothes are lightweight and nonbinding.

What tests are needed for heatstroke?

If your doctors suspect your heat exhaustion may have progressed to heatstroke, you may need additional tests, including: A blood test to check for low blood sodium or potassium and the content of gases in your blood. A urine test to check the concentration and composition of your urine and to check your kidney function, ...

Can heat exhaustion be diagnosed?

Diagnosis. If you need medical attention due to heat exhaustion, it may be apparent to medical personnel that you have heat exhaustion, or they may take your rectal temperature to confirm the diagnosis and rule out heatstroke.

When should steel be cold treated?

Application key: (1) Steel parts should be cold treated immediately after quenching, and then tempered at low temperature to eliminate internal stress during low temperature cooling; (2) Cold treatment is mainly applicable to tight tools, measuring tools and tight parts made of alloy steel.

How long to keep steel in furnace?

Heat the steel to 80 – 200 degrees, keep it for 5 – 20 hours or longer , then take it out of the furnace and cool it in the air.

How hot should carburizing medium be?

Put the steel parts in the carburizing medium, heat it to 900-950 degrees and keep it warm, so that the surface of the steel parts can obtain a carburizing layer with a certain concentration and depth.

What temperature is steel tempered at?

After heat preservation, quenching is performed, and then tempered at a temperature of 400-720 degrees.

What is normalizing steel?

Normalizing is usually used as a pre-treatment process for forgings, weldments and carburized parts. For low- and medium-carbon carbon layout steels and low-alloy steel parts with low functional requirements can be performed with the final heat treatment.

What temperature is quenched steel?

The quenched steel parts are cooled in a low-temperature medium (such as dry ice, liquid nitrogen) to -60 to -80 degrees or lower , and the temperature is uniformly taken out and then allowed to reach room temperature.

How many mm is a high frequency induction hardened layer?

(2) Because of the skin effect, the high-frequency induction hardened hardened layer is usually 1 to 2 mm, the intermediate frequency hardened is usually 3 to 5 mm, and the high frequency hardened is usually greater than 10 mm.

What is the cooling rate of annealing?

The cooling rate depends upon the types of metals being annealed . For example, ferrous metals such as steel are usually left to cool down to room temperature in still air while copper, silver and brass can either be slowly cooled in air or quickly quenched in water.

What happens when you cool a material?

Cooling the material at a specific rate causes new grains to develop. After which the material will be more workable. Subsequent operations to alter mechanical properties can be carried out following annealing.

What is annealing process?

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable.

Why do metals need to be annealed?

In addition, some metals are annealed to increase their electrical conductivity.

What are the advantages of annealing?

The main advantages of annealing are in how the process improves the workability of a material, increasing toughness, reducing hardness and increasing the ductility and machinability of a metal. The heating and cooling process also reduces the brittleness of metals while enhancing their magnetic properties and electrical conductivity.

How does annealing work?

Annealing works in three stages – the recovery stage, recrystallization stage and the grain growth stage. These work as follows: 1. Recovery Stage. This stage is where the furnace or other heating device is used to raise the temperature of the material to such a point that the internal stresses are relieved. 2.

Overview

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extre…

Physical processes

Metallic materials consist of a microstructure of small crystals called "grains" or crystallites. The nature of the grains (i.e. grain size and composition) is one of the most effective factors that can determine the overall mechanical behavior of the metal. Heat treatment provides an efficient way to manipulate the properties of the metal by controlling the rate of diffusion and the rate of cooling within th…

Effects of composition

The specific composition of an alloy system will usually have a great effect on the results of heat treating. If the percentage of each constituent is just right, the alloy will form a single, continuous microstructure upon cooling. Such a mixture is said to be eutectoid. However, If the percentage of the solutes varies from the eutectoid mixture, two or more different microstructures will usually form sim…

Effects of time and temperature

Proper heat treating requires precise control over temperature, time held at a certain temperature and cooling rate.

With the exception of stress-relieving, tempering, and aging, most heat treatments begin by heating an alloy beyond a certain transformation, or arrest (A), temperature. This temperature is referred to as an "arrest" because at the A temperature the metal experiences a period of hystere…

Techniques

Complex heat treating schedules, or "cycles", are often devised by metallurgists to optimize an alloy's mechanical properties. In the aerospace industry, a superalloy may undergo five or more different heat treating operations to develop the desired properties. This can lead to quality problems depending on the accuracy of the furnace's temperature controls and timer. These operation…

Specification of heat treatment

Usually the end condition is specified instead of the process used in heat treatment.

Case hardening is specified by hardness and case depth. The case depth can be specified in two ways: total case depth or effective case depth. The total case depth is the true depth of the case. For most alloys, the effective case depth i…

Furnace types

Furnaces used for heat treatment can be split into two broad categories: batch furnaces and continuous furnaces. Batch furnaces are usually manually loaded and unloaded, whereas continuous furnaces have an automatic conveying system to provide a constant load into the furnace chamber.

Batch systems usually consist of an insulated chamber with a steel shell, a hea…

See also

• Carbon steel

• Carbonizing

• Diffusion hardening

• Induction hardening

• Retrogression heat treatment

The Benefits

Heat Treatment Process Steps

- In simple terms, heat treatment is the process of heating the metal, holding it at that temperature, and then cooling it back. During the process, the metal part will undergo changes in its mechanical properties. This is because the high temperature alters the microstructure of the metal. And microstructure plays an important role in the mechanical properties of a material. Th…

Phase Diagrams

- Each metal alloy has its own phase diagram. As previously said, heat treatment is done according to these diagrams. They show the structural changes that take place at different temperatures and different chemical compositions. Let’s use the iron-carbon phase diagram as an example, as this is the most known and widely taught one at universities. The iron-carbon phase diagramis a…

Common Heat Treatment Methods

- There are quite a few heat treatment techniques to choose from. Every one of them brings along certain qualities. The most common heat treatment methods include: 1. Annealing 2. Normalising 3. Hardening 4. Ageing 5. Stress relieving 6. Tempering 7. Carburisation

What Metals Are Suitable For Heat Treating?

- Although ferrous metals account for the majority of heat treated materials, alloys of copper, magnesium, aluminium, nickel, brass, and titanium may also be heat treated. About 80% of heat treated metals are different grades of steel. Ferrous metals that can be heat treated include cast iron, stainless steel and various grades of tool steel. Processes like hardening, annealing, norma…