Full Answer

How much does a water treatment system cost?

The average water treatment system price range is between $2,100 and $3,300 nationally, with most homeowners paying around $2,500 for a reverse osmosis system with a sediment filter installed for the entire house.

How does EPA estimate treatment costs?

To estimate treatment costs, EPA developed several engineering models using a bottom-up approach known as work breakdown structure (WBS). The WBS models: Provide EPA with comprehensive, flexible and transparent tools to help estimate treatment costs Each WBS engineering model contains a work breakdown for a particular treatment process.

Are there any cost models available for the treatment technologies?

WBS cost models are available to the public for the following treatment technologies: PTA uses towers filled with a packing media to mechanically increase the area of water exposed to non-contaminated air.

How much does a 100 gpm water treatment system cost?

That said, a 100 to 200 GPM system would likely range between $50,000 and $250,000 for low pressure applications, and $500,000 to $1.5 million for high pressure applications. Raw water treatment systems. A standard 200 to 1000 GPM capacity raw water treatment system can range from $975,000 to $3 million, depending upon flow rate and water quality.

Are water treatment plants expensive?

It's a fact. Operating a wastewater treatment plant is expensive. Much of that expense comes from the energy it takes to run it.

How much does it cost to treat produced water?

Well completion water costs can average $0.75/bbl for freshwater, and disposal costs can average $2.25/bbl at public disposal wells, with disposal costs increasing exponentially as the trucking distance from the well site to the disposal site increases.

What is the cost of STP?

Now, the NMC has estimated the cost of 120 MLD capacity STP (200 MLD but augmentation will be of 120 MLD) at Rs 297.60 crore. The cost of 1 MLD comes to Rs 2. 48 crore. However, a senior NMC official said that the project cost of STP will be around Rs 170 crore and remaining is operation and maintenance cost.

How much does a water treatment plant cost UK?

On average, the domestic sewage treatment plant itself ranges in price from between £1,700 – £3,500, depending on the system you opt for. Most firms offering treatment plant installation will provide a quote for both supply and fit, which will sit at around £7,000-£9,000.

Is water purification expensive?

Installing a whole-house water treatment and purification system will purify your water and remove particles and harmful contaminants. A home water filtration system costs about $2,058 for the unit and installation. On the low end, expect to pay $1000; on the high end, you could spend $3,100 or more.

How much does it cost to build a water treatment plant in Canada?

The cost to build a water treatment plant is estimated at $204 million.

How do you reduce STP costs?

The reduce life cycle cost of STP, and recover full value of water and sludge, consider treatment technology that has zero power consumption for primary treatment with Anaerobic technology followed by polishing with high efficiency aeration and lastly to ensure bacteriological quality compliance such that the treated ...

What is STP full form?

STP. abbreviation. Medical Definition of STP (Entry 2 of 2) standard temperature and pressure.

What is commerce ETP?

ETP (Effluent Treatment Plan)

What is the best wastewater treatment system?

To give a short answer, the best system on the market is the ClearFox Nature. This is a totally non-electric plant, and it is the only non-electric treatment plant in the world that does not require replacement parts or media. So, the best non-electric sewage treatment plant is without a doubt the ClearFox Nature.

How often should you empty a sewage treatment plant?

annualDo sewage treatment plants need emptying? Yes; the job of a sewage treatment plant is to clean the water. Sludge is the build-up of solids and just like within a septic tank, it needs to be removed periodically. Most manufacturers recommend annual emptying.

Can I install my own sewage treatment plant?

Installing a Domestic Sewage Treatment Plant Being upfront and honest, we do not recommend installing a sewage treatment plant yourself unless you are 100% confident in your ability to do so. If incorrectly installed, an off-mains sewage system can leave you in a nasty mess; both physically and legally.

How much does an industrial water treatment system cost?

System costs can range significantly due to these variables, with some simple, low-flow systems running as low as $45,000, to high-end, high-capacity systems with price tags exceeding tens of millions of dollars. While an accurate estimate of system cost is virtually impossible without taking your specific process needs into account, we’ve compiled some ballpark estimates by system type:

How much does a microfiltration system cost?

While MF/UF are often cited for their cost-effectiveness, their costs can range widely depending upon the materials used and the flow rate needed. A basic 10 to 20 GPM MF/UF system would likely cost less than $100,000, while a larger 100 to 200 GPM unit would run between $150,000 and $450,000 depending upon the quality of materials used.

How much does a 100 to 200 GPM boiler cost?

That said, a 100 to 200 GPM system would likely range between $50,000 and $250,000 for low pressure applications, and $500,000 to $1.5 million for high pressure applications.

What is system flow rate?

System flow rate is usually measured in gallons per minute (GPM) and/or gallons per day (GPD). When you budget for a new water treatment system, keep in mind that the higher the GPM or GPD capacity, the higher your investment will likely be. Flow rates are always factored into the system cost, so be sure you have an accurate measurement of your process needs when requesting a quote for a new water treatment system.

What is a pretreatment system?

Pretreatment and process water treatment systems are generally used to optimize performance and service life by preventing scaling, fouling, or other damage to downstream equipment. The cost for design, engineering, equipment, installation, and startup for process water treatment systems can vary greatly from one application to the next:

How does space affect water treatment?

Space requirements. When planning for any water treatment system, the size of your system and your plant location will affect cost. If physical space is very expensive at your plant, for example, it may be more cost-effective to invest in technology with a compact footprint. Depending upon your specific water treatment goals and process conditions, you may not have much flexibility in system size, however it pays to take the system footprint into account if you are considering various treatment technologies.

What is industrial water treatment?

Industrial water treatment is a complex family of technologies and systems, serving a wide range of industries and applications. Whether your needs include water treatment, process purification and separation, wastewater treatment, or a combination of these, you’re probably wondering “How much does an industrial water treatment system cost?”.

How much does a water treatment system cost?

The average water treatment system cost range is between $500 and $2,500 nationally, with most homeowners paying around $2,000 for a reverse osmosis system with a sediment filter installed for the entire house.

How much does Aquasana cost?

They carry a full range of products, including ultrafiltration, reverse osmosis, and water softening. They have a cost range of $800 to $5,000.

How much does an ultrafiltration filter cost?

Of all filter types, this one will be the most expensive, costing between $2,000 and $9,000. Ultrafiltration uses a membrane-style unit similar to reverse osmosis to provide an extremely filtered drinking source. The liquid is pushed through the membrane under pressure, until most contaminants, solids, minerals, and other particulates have been filtered out. It can remove viruses, silt, proteins, smog, and plastics, making it a better, more efficient filter than carbon or sediment-based systems. These are larger filters that are meant to work on your entire home.

What is ultrafiltration system?

Ultrafiltration Costs. Ultrafiltration uses a membrane-style system similar to reverse osmosis to provide extremely filtered water. The water is pushed through the membrane under pressure, until most contaminants, solids, minerals, and other particulates have been filtered out.

How much does a reverse osmosis system cost?

These systems are priced from $200 to $400. If you like the idea of reverse osmosis or ultrafiltration systems but do not have the space necessary for a whole-house setup, this can be a good choice for you. As the name implies, these units have multiple steps in removing contaminants from the source. They usually get large particles out in the first stage and then removes things like odor, chlorine, and other chemicals in the latter stages. They work a little more slowly but pass the water through different filters, so you get cleaner, better-tasting H2O.

What is reverse osmosis water?

Reverse osmosis is one of the most popular types of water purification. It is also one of the strongest, with the ability to remove a wide range of contaminants from water, including dissolved solids, heavy metals, bacteria, waterborne cysts, and some dissolved particulates. This system improves the taste of water the most out of any other and offers some of the best purification. During reverse osmosis, the water is forced through a membrane under pressure. The clean water is stored inside a pressurized tank for drinking later, while the contaminated water and what is left behind on the filter are washed away and disposed of.

How much does Ecowater cost?

Ecowater units remove odors, minerals, and dissolved solids. This includes some sediment filters and reverse osmosis systems, ranging from $750 to $3,000, depending on the model. Ecowater prides itself on its use of smart technology that monitors your unit remotely using an app. A disadvantage of this product is that it uses salt, which increases the sodium levels of the source and damages pipes over time.

How much does it cost to test well water?

Having a lab test well water samples can cost a nominal fee at government or university labs, or $50-$500 or more for private labs, depending on the lab and the number and type of compounds tested. Water testing by a lab should include a written analysis of the results and clear recommendations.

What is the treatment for ground water?

Treatment might include filtration, oxidation, ion-exchange, ultraviolet irradiation, aeration or pH neutralization, depending on the contaminants present. The American Ground Water Trust lists common problems and solutions for domestic water treatment for homeowners.

How much does a water tester cost?

Expect to pay $10-$75 or more for a small digital or electronic water tester that measures total dissolved solids in the water to determine when to replace a filter in a water purifier or softener. For example, the TDS-3 Meter with Carrying Case [ 5] with an LCD screen and built-in digital thermometer costs $25-$35.

What to do if water is leaking from a well?

Treatment might include a water softener, a water filter or purifier, or other options. The testing laboratory or a water well contractor can recommend what's best for a particular problem. Search for local water well contractors through the National Ground Water Association [ 11] .

What should be included in a well water test?

At a minimum, well water should be tested annually for bacteria and nitrites, plus any contaminants of local concern such as total dissolved solids, pH levels, arsenic or radon.

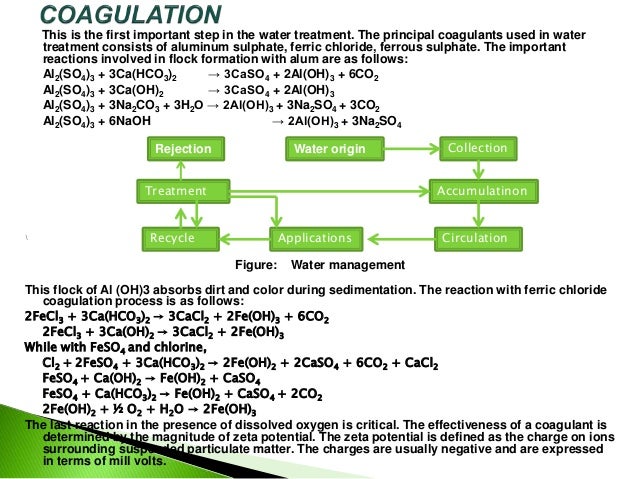

What is biological treatment of drinking water?

Biological treatment of drinking water uses indigenous bacteria to remove contaminants. It is useful for removal of contaminants including nitrate and perchlorate.

What is treatment technology?

Treatment technologies remove or destroy pollutants (such as arsenic, disinfection byproducts, and waterborne pathogens).

What is RO and NF?

RO and NF are membrane separation processes that physically remove contaminants from water.

How much does a well water system cost?

A well water treatment system typically costs between $700 and $3,000. The average cost is around $1,800. Costs vary depending on the type of treatment your well water needs, which can include:

What is water treatment system?

Water treatment systems remove a variety of different contaminants from water. The specific contaminants present in your water will help determine which type of water treatment system you want to buy. Bacteria: Bacteria often lives in well water or other untreated water.

What is the best way to purify well water?

Well water often has bacteria living in it. To purify the water, you need a water treatment system with distillation, reverse osmosis or UV radiation.

What is the best way to treat water with UV filters?

If your water source is a well or another source that might host harmful bacteria, then a UV filter water treatment system will serve you well. Distillation. Distillation is not as commonly used as it was in the past, but it does have a long history and is an effective method of treating water.

Why is water treatment important?

Water treatment systems are used to improve the quality of the water in a household, business, restaurant or elsewhere. If a municipality’s water treatment system is not sufficient, or if a consumer is relying on water from a well source, then a home water treatment system becomes a viable option for cleaner, safer water.

Is a saltless water softener electric?

Offers water softeners and conditioners. Its saltless softener water system is non-electric and applies downflow and double backwash methods. Uses diagnostics for consistent water quality and comes with lifetime warranty.

Does Kinetico water treatment system run on electricity?

Nonelectric systems: Kinetico’s water treatment systems do not run on electricity.

What factors affect water treatment system pricing?

However, in general, the things that will impact pricing for a commercial system the most are flow rate requirements, system volumes ,materials of construction, the state of your influent stream and targeted water quality.

What are the components of a water treatment system?

Among these are clarifiers , which remove suspended solids that are floating in the water, as well as particle filters to remove smaller contaminants. Softeners and membrane filtration will alter the quality of the water and its composition, while reactors, chemical additives or other options can affect hardness, pH, alkalinity and other facets.

How much does a feed and control system cost?

State-of-the-art feed and control systems may cost $10,000 or more. These also can be provided with long term water treatment service contracts. Chemicals and special services are required to make these systems treat and disinfect the water on a regular basis. These systems can test the systems constantly and alert the facility if a failure occurs.

What is water treatment?

Water treatment typically includes what happens to the water to ready it for use around the facility. For example, boilers and cooling towers need chemicals added to the water to preserve the water’s quality and prevent corrosion. This chemical balance provides the most common form of water treatment.

How does water treatment work for boilers?

Water treatment for boilers starts with preventing scale deposits. Scale prevention saves your facility money in energy costs because higher levels of scale reduce the boiler’s ability to heat water. For instance, a firetube-type boiler with only 1/32-inch of scale inside wastes 2% of fuel, which could increase the operating cost each year by $72,000.

What is reverse osmosis water?

Reverse osmosis treated water removes all minerals and extra chemicals to make it as pure as possible. Some manufacturing processes require purified water. However, the cooling and heating components of the facility also need purified water. For example, starting with purified water in a closed loop system ensures that corrosion inhibitors can effectively do their jobs in the water. Minerals or chemicals in untreated water can interfere with this and other additives in closed loop water.

How to prevent scale in boiler water?

One involves using various chemicals to off-set the effects of dissolved solids in the boiler water. The second prevention method uses blowdown, which removes feedwater and replaces it with water with a lower level of solids.

How does reverse osmosis affect water treatment?

Multiple factors affect the total cost of water treatment. For instance, choosing reverse osmosis will increase the cost because this form of purification requires more expensive equipment to ensure purity of the water. Additionally, choosing self-cleaning filers over single-use filters will increase the upfront cost of the water treatment facility but reduce the costs of labor, replacements and total cost of ownership compared to single-use filters.

Why is reverse osmosis more expensive than standard filtration?

Reverse osmosis forces water through filters to remove salts and dissolved solids more effectively than standard filtration. Therefore, compared to a basic plant that only filters water, a reverse osmosis water plant may cost more due to more extensive filtration and purification required of the process.

What is process water?

Process water provides an integral part of plant operations for all types of manufacturing facilities. On-site water treatments provide the greatest amount of control over the quality of the process water. Many production processes require water for operations, but municipal water supplies may not meet the requirements for these applications.

What’s Included in An Industrial Water Treatment System?

The Main Cost Factors of An Industrial Water Treatment System

- There are four main factors that determine the costof industrial water treatment systems: 1. What are the flow-rate requirements of the system? In other words, how fast will you need to process a given volume of water? 2. What is the chemistry and quality of your influent stream? 3. What is the target level of quality for treated water? 4. What construction materials are required? Answering …

The Bottom Line

- Industrial water treatment systems cover a diverse range of applications, and are used across plants of varying size and process complexity. System costs can range significantly due to these variables, with some simple, low-flow systems running as low as $45,000, to high-end, high-capacity systems with price tags exceeding tens of millions of dolla...

Can Samco Help?

- SAMCO has over 40 years’ experience custom-designing and manufacturing industrial water treatment systems for a range of industries and solutions, so please feel free to reach out to us with your questions. For more information or to get in touch, contact us here to set up a consultation with an engineer or request a quote. We can walk you through the steps for develop…