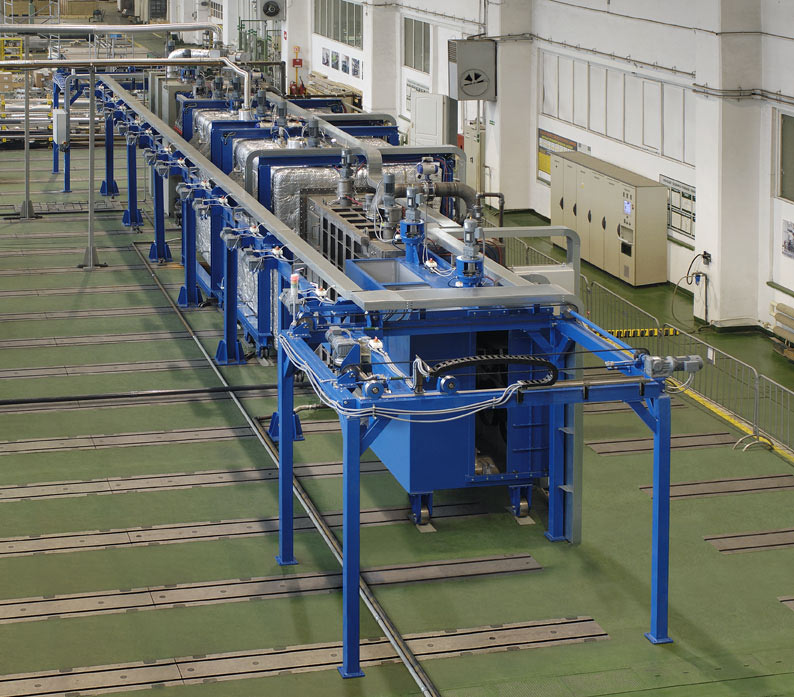

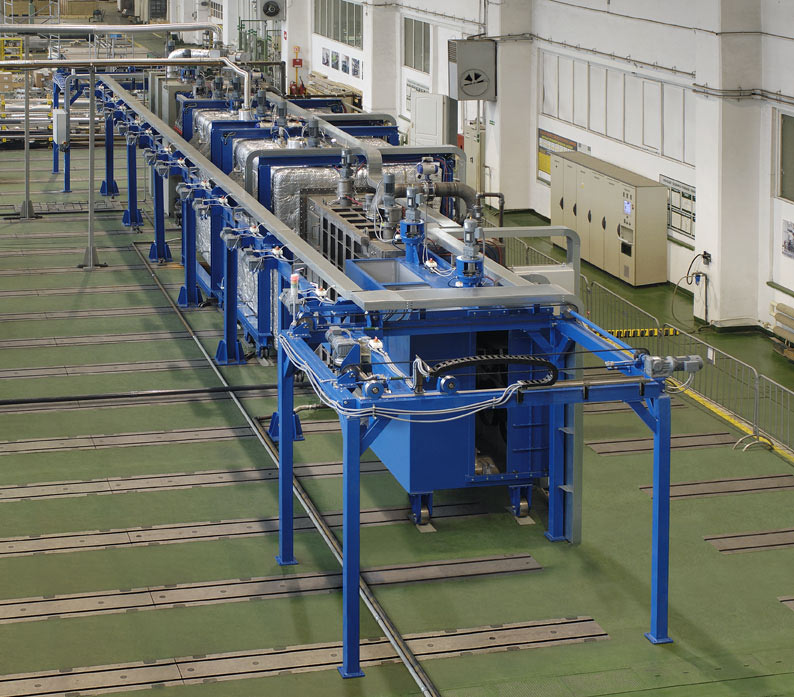

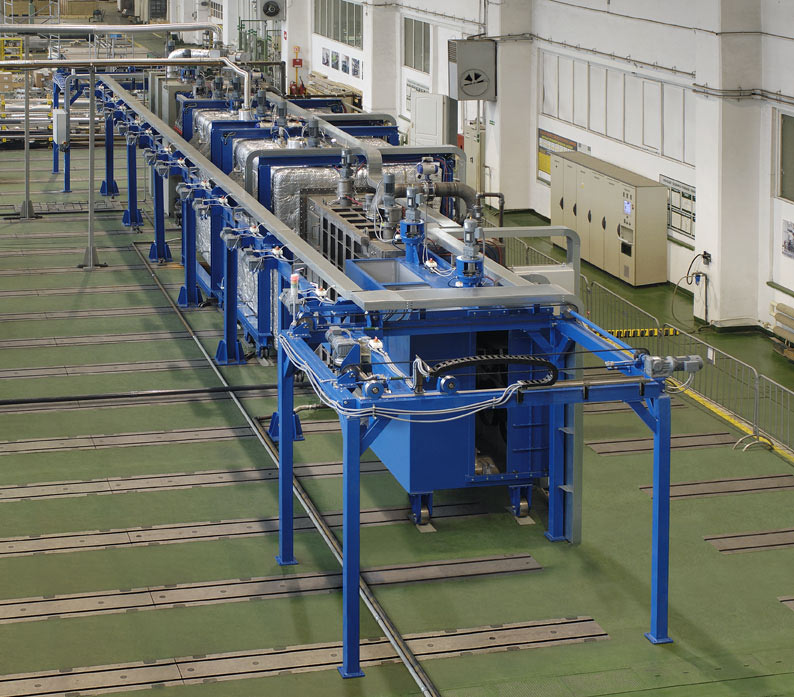

A controlled atmosphere heat treatment furnace provides an optimum environment for the metal components during the heat treatment process. By carefully controlling the composition and flow of the gas inside the furnace, precise temperature control and minimal oxidation or decarburisation is achieved.

What is the use of atmosphere in heat treatment?

An atmosphere of Ar can be used for the following heat treatment processes: A He atmosphere is typically used for HIP and vacuum heat treatment processes. A hydrogen-rich atmosphere is often implemented to reduce iron oxide to iron and decarburize steel. It also effectively aids in heat transfer and can react with any oxygen present.

What is a controlled atmosphere?

Controlled atmosphere (CA) means a close control of gases around fruits, which can maintain the synthetic atmosphere.

How do you protect the atmosphere in a heat treatment furnace?

The challenge in using a protective atmosphere in a heat treatment furnace lies in containing the atmosphere and requires the use of an atmosphere-controlled furnace. Establishing an atmosphere begins with purging the furnace of its existing atmosphere using the desired gas.

What gases are used in heat treatment?

Vacuum heat treatments can also be used to remove dissolved contaminants. The inert gases most commonly used in heat treatment processes are argon (Ar), helium (He), and nitrogen (N2), and they are often used in the following combinations: Ar/He, Ar/He/ N2, and N2/He.

What is furnace atmosphere?

The "furnace atmosphere" means a gas to be filled and heated in the furnace by which the. product (workpiece) is indirectly heat-treated. The atmosphere gases include air, inert gases, hydrogen (reducing gas), and others, which are heated up to 1000 - 2500℃

How do you inert the atmosphere in a furnace?

Continuous circulation of Nitrogen or Argon ensures inertness of lab furnace. If you have fluidized bed pyrolyzer, use inert gas as fluidizing gas. If batch, then pressurize reactor with inert gas before heating.

What is CP in furnace?

It is not possible to directly measure and control the carbon potential (CP) inside an atmospheric gas carburization furnace. Therefore, adjustment of the furnace atmosphere used to be performed by simply using a dew cell dew point indicator.

What type of furnace produces an atmosphere consisting of a gas air combustion product?

Exothermic Atmospheres: This name has been given to these atmospheres because these are produced by the exothermic combustion (i.e. without the addition of heat) of gas, and air, and are low-cost prepared furnace atmospheres.

What is meant by a reducing atmosphere?

A reducing atmosphere is one whose constituent gases will remove oxygen from the metal oxides on the surface of the components during heat treatment. The most common reducing gases used in heat treatment are hydrogen and carbon monoxide.

What is an inert environment?

The term inert means 'chemically inactive', so an inert atmosphere is an environment in which powder bed fusion can take place without the risk of contamination from reactive gases that exist in the air, such as oxygen and carbon dioxide.

What is CP measured in?

Joules per kilogramSpecific heat capacity (cp) by LFA The specific heat capacity is a thermophysical property with the SI unit of Joules per kilogram and Kelvin [J kg-1 K-1]. It defines a material's ability to store thermal energy.

What is meant by carbon potential?

A measure of the capability of a furnace atmosphere to impart carbon into a steel during heat treatment. The carbon potential of an atmosphere is defined as the carbon content of a thin sheet of pure iron in equilibrium with the atmosphere.

What does CP stand for in thermodynamics?

specific heat at constant pressureCP is the specific heat at constant pressure. It is the amount of energy released or absorbed by a unit mass of substance with the change in temperature at constant pressure. In other words, it is the energy transferred between a system and its surrounding under constant pressure.

Why is the atmosphere important in furnaces?

Why Furnace Atmosphere Is Important. The atmosphere in a heat treatment process can be a critical factor: it may act as a carrier for key elements in the process, or it may act to protect the part being heat treated from the effects of exposure to air while also exposed to substantially elevated temperatures.

Why nitrogen is used in furnace?

Nitrogen (N2) - displaces air/oxygen in the furnace atmosphere; excellent for copper. Water vapor (H2O) - specified by dew point, the temperature where moisture in gas condenses; generally undesirable as it inhibits braze flow except in certain copper brazing applications.

Why is there nitrogen in blast furnace?

The technology provides for the use of nitrogen during the fanning of blast furnaces after construction or overhaul, feeding of nitrogen - in place of blast-furnace gas and steam - into the space between the bells of the charging apparatus to equalize pressure, and addition of nitrogen to the blast during problems with ...

What gases are used in heat treatment furnaces?

There are several gases commonly used in heat treatment furnaces in addition to air, and these often include hydrogen, nitrogen, oxygen, helium, argon, carbon monoxide, carbon dioxide, ammonia, propane, methane, and butane. Of these, oxygen is the most reactive – as an atmosphere, air behaves like oxygen – and results in serious issues like oxidation and decarburization which can compromise the quality and performance of a part. In this article, we will be focusing on inert gases (helium, argon, and nitrogen) as well as hydrogen.

Why is the atmosphere important in furnaces?

The atmosphere in a heat treatment process can be a critical factor: it may act as a carrier for key elements in the process, or it may act to protect the part being heat treated from the effects of exposure to air while also exposed to substantially elevated temperatures.

How is endothermic gas produced?

The endothermic gas is produced when a mixture of air and fuel at a very low air-to-gas ratio is introduced into an externally heated retort that itself contains an active catalyst (usually nickel) for cracking the mixture . When this gas leaves the retort, it is rapidly cooled before it arrives in the furnace.

What gases are in the atmosphere?

These atmospheres may include inert gases such as nitrogen, helium, or argon; endothermic mixtures; or hydrogen. The focus of this article will be on inert atmospheres and hydrogen atmospheres, including the types of heat treatment processes they support.

What is the preferred atmosphere for annealing?

Bright annealing: performed in an inert atmosphere of nitrogen, hydrogen, or argon to limit oxidation; pure hydrogen is usually the preferred atmosphere. Brazing: when done on copper and silver, an atmosphere of pure hydrogen or, in some cases, dissociated ammonia.

What happens if you don't have a protective atmosphere?

Depending on the heat treatment process being performed, the lack of a controlled protective atmosphere could lead to chemical reactions on the surface of a part that would compromise its quality and performance, leading to rejected parts.

What is the role of the atmosphere in the surface of a part?

As a carrier, the atmosphere is chemically reactive with the surface and leads to improved surface characteristics to support processes such as hardening. As a protective atmosphere, its task is the opposite: it protects the surface of the part from chemically reacting with potentially harmful elements in the atmosphere.

Why is it important to have a heat treat department?

One of the great benefits of having a community of heat treaters is to challenge those habits and look at new ways of doing things.

What to do before changing carbon controller?

Before making a change to the carbon controller, make sure the atmosphere that the carbon probe and carbon controller are reading is matching up to an alternate method of atmosphere. This can be done using a number of different methods: dew point, shim stock, carbon bar, 3 gas analysis, coil (resistance), etc.

What is COF/PF on carbon controller?

The COF/PF on the carbon controller should be modified to adjust the carbon controller reading to the appropriate carbon atmosphere. It is important to make sure that the alternate method of verifying atmosphere is done properly (sampling ports, time for atmosphere exposure, sample prep, etc).

Can you run carbon probes in a furnace?

If you’re having atmosphere problems with a furnace that has been operating normally for some time, avoid the temptation to remove the carbon probe. There are several tests you can run on nearly all carbon probes while the probe is still in the furnace, at temperature, in a reducing atmosphere.

Why do we use atmospheres in heat treating?

Atmospheres are used in heat treating to protect the part from scaling at the elevated temperatures used during austenitizing. The atmospheres range from simple wrapping the part in stainless steel or tantalum foil for small tool room parts, to protective atmospheres containing inert or protective gases. Figure 1: Typical sequence ...

What is endothermic gas?

Endothermic atmospheres are commonly used during the heat treatment of steel. It is used as a carrier gas for atmosphere additions for carburizing or carboni triding. Using an endothermic generator, either natural gas or propane is used. If nitrogen-methanol is injected in the furnace, then methanol is the carbon source.

What are protective gases?

On an industrial scale, these protective gases are usually mixtures of carbon monoxide (CO), hydrogen (H2), nitrogen (N2), carbon dioxide (CO2), and trace amounts of water vapor. These gases are produced using either endothermic generators with natural gas or propane as the carbon source, or injection directly in the furnace using nitrogen ...

How much nitrogen is needed for a furnace?

One gallon of methanol dissociates to form 240 standard cubic feet of CO and H2, so for 1,000 SCF of atmosphere needed for a furnace, then 400 standard cubic feet of nitrogen is required, and 600 standard cubic feet of CO and H2 are required.

What are the three gases in a gas analyzer?

These often are called three gas analyzers. The advantage of three gas analyzers, is that the three gases measured are CO, CO2, and CH4. This enables the user to optimize the generator (or nitrogen-methanol system) setting to first achieve a 20 percent CO.

What is the difference between theoretical vales and those typically used in the shop?

The difference between the theoretical vales and those typically used in the shop are associated with reaction kinetics. For nitrogen-methanol, the mixture is a bit more difficult as methanol is a liquid. To obtain the proper atmosphere, the total volume will be 40% nitrogen.

What is controlled atmosphere?

Controlled atmosphere (CA) can be defined as a creation of altered atmosphere, in order to provide an appropriate atmosphere for slowing down the respiration, decreasing fungal and physiological deteriorations, and prolonging storage duration.

What are the gases used in controlled atmospheres?

The gases most commonly used are nitrogen to displace oxygen and carbon dioxide. There are only a few places around the world where controlled atmospheres are used routinely. The main problems with controlled atmospheres are long exposure times (typically 15 days or longer), the need for a high level of sealing, and the large volumes of gas required to establish or maintain concentration of >40% for carbon dioxide and 99% for nitrogen (< 1% oxygen). Despite these limitations, both types of controlled atmospheres are used where these constraints are not limiting or where special requirements exist.

What is CA treatment?

CA treatments based on either nitrogen or carbon dioxide atmosphere storage provide technical alternatives to methyl bromide uses for disinfestation of bulk or bagged grain. But their use is constrained by the cost of the implementation of CO 2 fumigation or long-term generation of low-O 2 atmosphere by a burner or an atmospheric-nitrogen purifier. The slow speed of action of CA atmospheres is not really an inconvenience in tropical countries and several strategic reserves of cereals are preserved from deterioration by this technique in specific situations (e.g., in Indonesia or Singapore).

How does optimal conditions affect the marketable life of a commodity?

Under optimal conditions (that vary depending on the species/variety to be stored and the composition/developmental stage of the commodity), the marketable life of the commodity can be greatly extended and quality can be retained for a longer time.

Where is nitrogen used?

For example, nitrogen has been used in Australia at Newcastle, New South Wales, where a large grain-storage capacity allows grain to be held for treatment. There is a large industrial source of liquid nitrogen close by, and the storage was constructed to a suitable level of gastightness.

What is heat treatment?

Heat Treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. Heat treatment is sometimes done inadvertently due to manufacturing processes that either heat or cool the metal such as welding or forming.

Why are steels heat treated?

Steels are heat treated for one of the following reasons: 1. Softening. 2. Hardening. 3. Material Modification.