An air compressor can help with desalination, ensuring a wastewater treatment plant can remove salt and produce potable water for domestic or municipal use. 3. Wastewater Disposal — Air compressors may be used to power central vacuum systems that drive the disposal of wastewater.

Why use air compressors for wastewater treatment?

With efficient compressed air supplying wastewater treatment equipment, operators can be better equipped to manage various wastewater treatment processes reliably and with ease. Here’s a closer look at wastewater treatment, along with the value of air compressors for wastewater treatment plants.

How can I reduce the amount of compressed air used in wastewater?

If only agitation is required, it is usually to keep solids in suspension, then there are a range of options to replace or reduce compressed air usage including such mechanical devices as propellers, paddles, etc. As you look at your wastewater system, let your imagination be your guide. As they say, “think outside the box”.

What is an air compressor used for?

Air compressors are used in industries as well as in domestic purpose where compressed air is required. The pressure equals to force per unit area, so when the area is reduced pressure will be increased. An air compressor uses this principle to increase the pressure of the air.

What are the different types of air compressors used in mobile applications?

While gas/diesel-powered and electric air compressors are among the most popular, air compressors that utilize vehicle engines, power-take-off, or hydraulic ports are also commonly used in mobile applications. [7] The power of a compressor is measured in HP ( horsepower) and CFM ( cubic feet per minute of intake air). [8]

What is air compressor and its function?

An air compressor is a pneumatic device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure.

What is the process of air compressor?

Air compressors work by forcing air into a container and pressurizing it. Then, the air is forced through an opening in the tank, where pressure builds up. Think of it like an open balloon: the compressed air can be used as energy as it's released.

Where is an air compressor used?

Compressed air also powers air guns. Probably the most common use of air compressors in everyday life, refrigerators, freezers and air conditioners all use air compressors to chill the air. Air compressors are included in vehicle engines for heating and cooling, as well as in air brakes for larger trucks and trains.

Why do we use air compressor?

Compressors are used throughout industry to provide shop or instrument air; to power air tools, paint sprayers, and abrasive blast equipment; to phase shift refrigerants for air conditioning and refrigeration; to propel gas through pipelines; etc.

What is air compressor and its types?

Rotary screw, vane and reciprocating air compressors are the three most common types of air positive displacement compressors found in small and medium sized industries. Dynamic. Dynamic air compressors include centrifugal and axial machines, and are used in very large manufacturing facilities.

What is air compressor PDF?

An air compressor, as the name indicates, is a machine to compresses the air and raises its pressure. The air compressor absorbs air from the atmosphere and compresses it. Then it sends to a storage vessel under high pressure.

What is a compressor in HVAC?

An AC or heat pump compressor is the part of an outdoor air conditioner or heat pump that compresses and pumps refrigerant to meet household cooling requirements.

What is a compressor made of?

With a piston air compressor, the type of material involved refers to the metal used in the pump or shaft that surrounds the piston. These compressors are typically constructed of one of two materials – cast iron or aluminum.

Which of the following is the function of compressor?

A compressor is a device that increases the pressure of a substance (usually a gas) by reducing the volume of the substance. Compressors are used in many applications, most of which involve increasing the pressure inside a gas storage container, such as: Compression of gases in petroleum refineries and chemical plants.

What is compressed air technology?

compressed air, air reduced in volume and held under pressure. Force from compressed air is used to operate numerous tools and instruments, including rock drills, train brake systems, riveters, forging presses, paint sprayers, and atomizers.

What is the purpose of a compressed air pump?

There are three primary uses of compressed air in all wastewater treatment applications: Aeration to supply the processing bacteria with oxygen support. Agitation to keep the solids in suspension and, A continuous, driving pump to move the material.

Why is compressed air important?

Compressed air is often needed to supply oxygen support to the processing bacteria

How much compressed air is used in a 220 scfm tank?

Current use measured 220 scfm at 90 psig compressed air regulated to 15 psig to supply agitation to maintain clarity. The air is delivered to the bottom of each tank from which it bubbles up through the water.

How does a pump eductor work?

How They Work: Liquid pumped into the eductor nozzles exits at high velocity, drawing an additional flow of the surrounding solution through the educator. This additional flow (induced liquid) mixes with the pumped solution and multiplies its volume five-fold. The source of the pumped liquid (input) can be a pump or filter chamber discharge.

What pressure is the 3/4 air line?

After the tank was cleared of solids and reset to avoid a reoccurrence, a 3/4" air line at 90 psig entry pressure was opened into the bottom side of the tank. The measured flow was 80 scfm, it did do the job.

How long does a filter run?

The filter runs a 4-hr cycle. A 30-minute final press requires 150’ of head pressure at end of each cycle. Prior to the final press, head pressure is 30 to 40 feet for 3.5 hour per cycle.

What is a continuous pump?

A continuous, driving pump to move the material.

How are air and microorganisms used in wastewater?

Air and microorganisms are used to biologically oxidize organic pollutants, producing waste sludge containing oxidized materials ; in simpler terms, the suspended solids are separated from wastewater via a sedimentation process. The air in conventional activated sludge systems must be oil-free to avoid contamination of the water.

Why is it important to have a continuous oil free air supply?

As bacteria can't survive without oxygen, a continuous oil-free air supply is important for the quality of your wastewater treatment process. The supply of wastewater can vary during the day, so it's crucial that your blower installation can handle a variable airflow demand. We offer you both fixed speed blowers with a high turndown, as well as energy-efficient variable speed drive blowers.

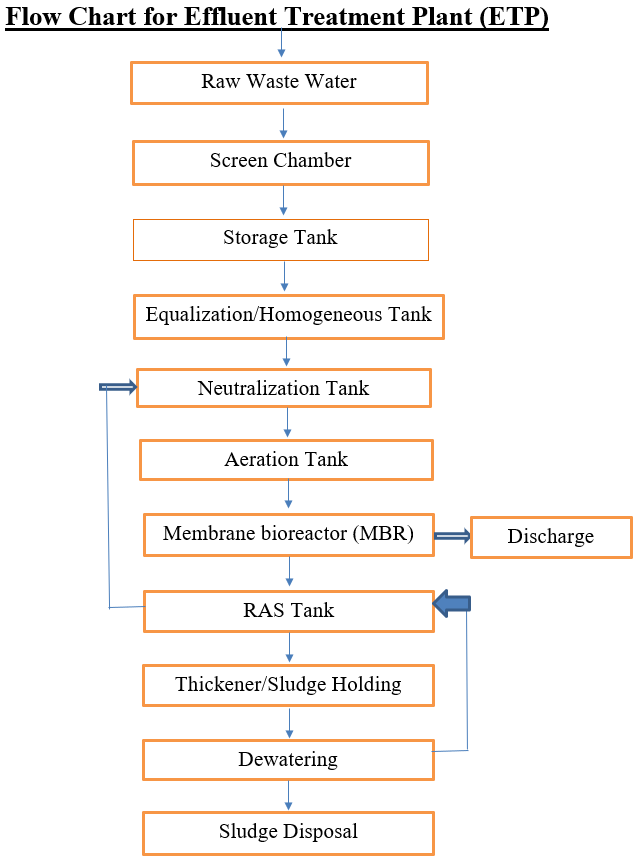

What is MBR in wastewater treatment?

MBR is a version of the conventional activated sludge system where the solid and liquid separation is completed via a membrane ( micro- or ultrafiltration). This results in advantages for process control and product water quality but high energy consumption and intensive bio-treatment process. Another benefit of MBR is that this method can be scaled to fit any size wastewater treatment plant.

How many psig is a lobe blower?

20-5,600 cfm | 4.4-14.5 psig

Why is diffuse aeration important?

Diffused Aeration. As bacteria can't survive without oxygen, a continuous oil-free air supply is important for the quality of your wastewater treatment process. The supply of wastewater can vary during the day, so it's crucial that your blower installation can handle a variable airflow demand.

What is activated sludge?

Utilized in medium- to large-scale industrial plants, the activated sludge process separates the flocculants, or suspended solids, from the wastewater through sedimentation.

What is biogas treatment?

Microorganisms break down this waste into CO2, methane, ammonia, and other gases; these biogases are treated via filters prior to being injected into a generator; they can also be removed and flared to reduce greenhouse gas emissions.

What is an air compressor?

An air compressor is a pneumatic device that converts power (using an electric motor, diesel, or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the tank’s pressure reaches its engineered upper limit, the air compressor shuts off.

How does a compressor work?

Once the pressure reaches a specified level, the compressor stops running. As you use the stored air to power a tool, the compressor restarts to build the air pressure back up.

What is the difference between a single stage and multi stage compressor?

When you need more power, the multi-stage compressor is the way to go. While single-stage compressors will get the job done for smaller projects such as woodworking and metalworking, multi-stage compressors provide the power needed for intense construction, such as auto assembly and maintenance. Multi-stage reciprocating compressors can reach up to 30 horsepower.

How does a dynamic air compressor work?

Dynamic air compressors generate horsepower by bringing in the air with rapidly rotating blades and then restricting the air to create pressure. The kinetic energy is then stored as static within the compressor.

Why do centrifugal air compressors slow down?

Centrifugal air compressors slow and cool the incoming air through a diffuser in order to build up potential energy. Because of the multi-phase compression process, centrifugal compressors are able to produce a high amount of energy in a relatively small machine.

What voltage do compressors work on?

Many home-use compressors function on a 120-volt household current, but larger models may have different requirements. A portable electric compressor requires a suitable extension cord, which limits mobility.

What happens when the pressure of an air compressor reaches its lower limit?

When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from a pump because it works for any gas/air, while pumps work on a liquid.

What is an air compressor?

Air compressor is a pneumatic device that converts mechanical energy into potential energy (Compressed air). Air compressors are used in industries as well as in domestic purpose where compressed air is required. The pressure equals to force per unit area, so when the area is reduced pressure will be increased.

How does an air compressor work?

When compressed air pressure reached its lower level air compressor turns on and re-pressurized the tank, and turns off when tank pressure reached its higher level .

What is the difference between a single stage compressor and a two stage compressor?

Difference between single-stage and two-stage air compressor is the number of time the air gets compressed before stored into the tank. Single-stage compress air single time and two-stage compressor compress two times.

How does a centrifugal compressor work?

Centrifugal compressor imparts kinetic energy into the air by the rotor. That kinetic energy eventually converted into pressure energy by slow down the flow through a diffuser. This way the centrifugal compressor works. Low-pressure Compressor gives maximum discharge pressure of 10.4 bar.

What is a single stage compressor?

For reciprocating compressor single-stage and two-stage compressors are generally used. In Single-stage compressor air gets compressed one time only . single-stage compressors can get the job done for smaller projects such as woodworking and light metalworking, etc.

How many types of air compressors are there?

According to the working nature air compressor can be classified into 4 types –. Reciprocating Compressors. Rotary-screw Compressors. Rotary-vane Compressors.

What is the effect of a two stage compressor?

In Two-stage compressor air gets compressed twice, so compression effect will be double. Two-stage or multi-stage compressors can provide the power needed for intense construction, such as auto assembly, maintenance, etc.

What is an air compressor?

What are air compressors? Technically, air compressors are machines that convert one form of energy into another form, which can then be stored and used at a later point in time. But neither that brief explanation, nor the more detailed description below, do this invention - and its profound impact on our lives - justice.

How does compressed air work?

To understand the importance of compressed air – and the compressors that generate it – let’s first take a closer look at the physics of it. Compressed air is simply regular air that is forced into a much smaller space. When this happens, its molecules speed up and so-called “kinetic energy” is created. That kinetic energy can either be used right away or it can be stored and released later.

Why is compressed air so important?

One of the reasons compressed air has become so indispensable is its versatility. Just about every industry relies on compressed air in some form – from manufacturing plants to cars, ships and trains, construction sites to hospitals, compressed air is used all around it.

How much of the electricity used in manufacturing is compressed air?

The numbers back up this bold statement. It is estimated that 10% of all electricity consumed by the manufacturing industry is used for compressed air.

Is a dentist's drill the same as an industrial compressor?

After all, the small and quiet compressor that powers a dentist’s drill should not be the same as the industrial compressor that keeps an entire manufacturing plant going.

How is compressed air used?

The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank.

What is an air compressor?

Air compressor supplies air into a nail gun. An air compressor is a pneumatic device that converts power ( using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i .e., compressed air ). By one of several methods, an air compressor forces more and more air into a storage tank, ...

Why do air compressors need to be cooled?

Due to adiabatic heating, air compressors require some method of disposing of waste heat. Generally this is some form of air- or water-cooling, although some (particularly rotary type) compressors may be cooled by oil (that is then in turn air- or water-cooled). The atmospheric changes are also considered during cooling of compressors. The type of cooling is determined by considering the factors such as inlet temperature, ambient temperature, power of the compressor and area of application. There is no single type of compressor that could be used for any application.

What is a dynamic displacement air compressor?

Dynamic displacement air compressors include centrifugal compressors and axial compressors. In these types, a rotating component imparts its kinetic energy to the air which is eventually converted into pressure energy. These use centrifugal force generated by a spinning impeller to accelerate and then decelerate captured air, which pressurizes it.

What is the typical voltage of a garage compressor?

Common workshop/garage compressors are 110-120 Volt or 230-240 Volt. Compressor tank shapes are: "pancake", "twin tank", "horizontal", and "vertical". Depending on a size and purpose compressors can be stationary or portable.

How does a positive displacement compressor work?

Positive-displacement compressors work by forcing air in a chamber whose volume is decreased to compress the air. Once the maximum pressure is reached, a port or valve opens and air is discharged into the outlet system from the compression chamber. Common types of positive displacement compressors are

What is the range of a piston compressor?

Piston compressors generally fall into two basic categories, single-stage and two-stage. Single stage compressors usually fall into the fractional through 5 horsepower range. Two-stage compressors normally fall. Technical Illustration of a portable single-stage air compressor. into the 5 through 30 horsepower range.

Why are air compressors so useful?

These are highly useful portable machines that power single air tools. The main advantage of air compressors is that they’re much more powerful than regular tools, and they don’t require their own bulky motors.

How does an air compressor work?

Air compressors work by forcing air into a container and pressurizing it. Then, the air is forced through an opening in the tank, where pressure builds up. Think of it like an open balloon: the compressed air can be used as energy as it’s released.

How many screws does a rotary screw compressor have?

Rotary screw compressors have two internal “screws” that rotate in opposite directions, trapping and compressing air between them. The two screws also generate constant movement as they rotate around. This is a common type of air compressor and is one of the easiest to take care of.

What is a rotary vane compressor?

Rotary Vane. Rotary vane compressors are like rotary screw compressors, but instead of screws, vanes are mounted on a rotor and rotated inside the cavity. The air compresses between the vane and its casing and is then pushed out at a different exhaust port.

What type of compressor is best for industrial use?

Some types of positive displacement compressors are better equipped for industrial workloads while others are better for hobbyists or private projects. Here are the three main types of air compressors that use positive displacement: 1. Rotary Screw.

What is a piston compressor?

A piston ( reciprocating) compressor uses pistons controlled by a crankshaft to deliver the gas at high pressure. These are typically found at smaller worksites and aren’t designed for continuous use.

How does a dynamic displacement compressor work?

Dynamic displacement compressors utilize a rotating blade powered by an engine to generate airflow. The air is then restricted to create pressure, and the kinetic energy is stored within the compressor.

What is a Guardair 79WG?

The first is the Guardair 79WG Syphon Water Jet Cleaning Gun which allows you to connect your air compressor fittings to a garden hose . The air compressor attaches to the handle of this device and then the garden hose attaches to the hose adapter.

Can you turn an air compressor into a pressure washer?

Though, you can’t literally turn your air compressor into a pressure washer, you can attach a jet cleaning gun that connects your air compressor and typical garden spray gun together. The results will of course not be the same, mainly due to the pressure difference.

What is the acceptable concentration of air compressor lubricant in wastewater?

For example, allowable concentrations of contaminants in wastewater can range from 10 ppm to 100 ppm. It is important to note that such standards usually apply to total plant effluent, not only that from a compressor.

What happens when compressed air is cooled?

Once compressed, the air flows into an after-cooler. As it cools, most water and hydrocarbon vapors condense. Additional condensation takes place as the air is further cooled in piping and in air dryers. The condensed moisture must be removed to prevent damage to downstream components and processes.

Why use biodegradable lubricants?

The use of biodegradable lubricants enables plant engineers to send low levels of compressor condensate directly to a sanitary sewer without pretreatment. With approval, biodegradable lubricants would eliminate the costs of separation systems as well as concerns regarding long-term performance.

How is oil condensate collected?

The condensate passes through automatic drain valves and is piped to oil/water separators to remove the oil from the condensate prior to dis charge to a drain. If not treated, condensate can be collected into drums or storage tanks . The drums or tanks are then taken to an approved disposal facility.

How much oil is in a condensate?

Since condensate is approximately 99% water and 1% oil, oil/water separators have been developed to reduce or eliminate the amount of oil in the condensate (Fig. 1).

What is the process of condensate generation?

Condensate generation. During the process of compressing air, atmospheric air along with water vapor and airborne contaminants, are drawn into the compressor intake. Additionally, the compression chamber of most compressors requires oil for lubrication, sealing, and cooling.

How much oil is in a chemical separator?

The life of the chemical separator depends on the quantity of oil in the condensate. Oil concentration in the condensate can be as low as 40 ppm but can reach much higher values. Actual oil concentration is dependent on the type and condition of the compressor, the type of oil used, and the amount of water vapor in the ambient air (Fig. 3).