Methods of surface treatment

| Category | Process | Explanation |

| Cleaning | Cleaning | Cleaning is a process to remove oil, sur ... |

| Cleaning | Blasting | Cleaning is a process to remove oil, sur ... |

| Cleaning | Honing | Cleaning is a process to remove oil, sur ... |

| Polishing | Mechanical polishing | Polishing the surface to make it smooth. ... |

What is surface treatment and how does it work?

What Is Surface Treatment? Surface treatment is a process of artificially forming a surface layer on the surface of the base material that is different from the mechanical, physical, and chemical properties of the base body.

What are the methods of surface treatment painting?

Painting – Surface treatment painting is commonly specified by engineers to enhance a part’s appearance and corrosion resistance. Spray painting, electrostatic painting, dipping, brushing, and powder coat painting methods are some of the most common techniques used to apply the paint to the surface of the component.

How does the surface water treatment rule apply to your system?

In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water.

How is a metallic coating applied as a surface treatment?

There are many different methods by which a metallic coating can be applied as a surface treatment to increase the mechanical, electrochemical, and thermal performance of a material. The technique used largely depends on material application as well as the desired material coating or depth of the surface treatment.

What are the types of surface treatment?

Types of surface treatmentsAluminum anodizing. Resistance, hardness and abrasion resistance of the material. ... Zinc coating. Corrosion protection. ... Nickel coating. High gloss and hardness. ... Tinning. Resistance to water corrosion and hygienic safety. ... Blackening. Decorative surface treatment.

What is surface treatment of metals?

Metal surface treatment is a process where metal parts are prepared for painting. The preparation is commonly referred to as coatings pretreatment. This usually involves creating a physical barrier that will protect metal against a corrosive environment.

What is cleaning and surface treatment process?

Cleaning agents and surface treatments include liquid cleaners, degreasers, strippers, passivators, etchants, solutions, and additives for cleaning and surface preparation. They are used to clean contaminants such as grease or oil off of surfaces such as industrial equipment or mechanical components.

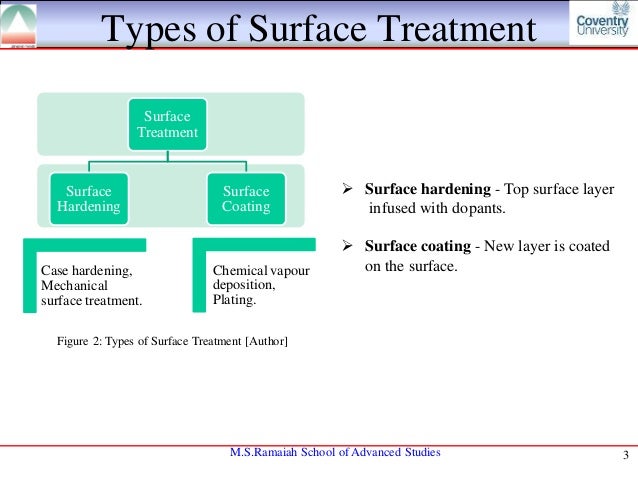

What are the two main categories of surface treatment?

Several surface treatments have been examined. These may be classified into oxidative treatments and nonoxidative treatments.

Why is surface treatment important?

The surface treatments of materials and processing of coatings are becoming increasingly important for imparting functional properties, repairing the surfaces, and protecting the surfaces from conditions of stress, temperature, and corrosive media.

What is surface treatment in construction?

Surface treatment is an economical and effective method to improve the quality of surface layer and protect the concrete structure compared with other methods, such as decrease water to cement ratio and add admixtures etc. There are a variety of surface treatments that can be used for protection of concrete.

What is surface heat treatment?

This group of thermal processes refers to a treatment where typically the surface layer has the requirement of a higher hardness which is typically more wear resistant than the core of material.

What is road surface treatment?

Surface Treatment is the application of an asphalt emulsion on either an existing asphalt road or a fresh, compacted granular surface immediately followed by the application of a cover aggregate.

What is surface treatment industry?

Further, increasing infrastructural and industrial activity is expected to propel the growth of surface treatment market by 2027. Surface treatment is a process applied to the surface of a material to make it better in some way, such as by making it more resistant to corrosion or wear.

What is surface treatment in interior design?

Surface modifications are intently surface preparation processes and may impart radically different surface qualities such as textures, ionization, etc. At another level Surfaces Modifications are not attempted, but such situations are negotiated with technologies.

Which of the following is not the surface treatment process?

Explanation: Lapping, honing, polishing, burnishing are superfinishing processes. Broaching both cutting and finishing process. Hence Turning is not a finishing process.

Can I treat 3D objects with plasma?

A plasma treatment is the ideal solution for your 3D parts because plasma gets almost everywhere. Therefore, it can cover regions of your parts whi...

Can the treatment be limited to certain parts of an object?

Theoretically, we could limit a treatment to certain regions by covering parts of an object. However, a plasma treatment usually does not have any...

How do I evaluate the success of a plasma treatment?

We provide different measurement techniques including surface energy test inks and pens as well as contact angle measurements to measure the effect...

Is in-line treatment possible?

Of course. We supply both standalone plasma treaters and in-line plasma treaters, which can easily be integrated into your existing production proc...

Which sizes can be treated?

We offer treatment solutions for almost any size. Smaller parts are often placed on trays, so that many parts can be treated simultaneously.

How is curved surface printing done?

For curved surface printing, the ink is placed in a gravure engraved with characters or patterns, and then the characters or patterns are copied onto the curved surface, and then the characters or patterns are transferred to the surface of the molded product by using the curved surface.

What is heat transfer printing?

The principle of heat transfer printing is to print a digital pattern through a printer and print it on a special transfer paper with a special transfer ink, and then use a special transfer machine to accurately transfer the pattern to the product surface at high temperature and pressure to complete the product printing.

What is shot blasting?

Shot blasting is a cold working process that uses pellets to bombard the surface of the workpiece and implant residual compressive stress to improve the fatigue strength of the workpiece.

How is ink transferred to the substrate?

When printing, the ink is transferred to the substrate through the mesh of the graphic part through the squeezing of the blade to form the same graphic as the original. 14. Direct thermal printing. Direct thermal printing refers to applying a heat sensitive agent to paper to make it a heat sensitive recording paper.

What is etching in chemistry?

Generally speaking, the etching is also called photochemical etching, which refers to removing the protective film of the area to be etched after exposure to plate and development , and contacting the chemical solution during etching to achieve the effect of dissolving and corroding, forming unevenness or hollow molding.

What is laser carving?

Laser carving, also called laser engraving or laser marking, is a process of surface treatment using optical principles. Laser beams are used to engrave permanent marks on the surface of objects or inside transparent materials.

Is planography an indirect method?

Therefore, planography is an indirect printing method. 17. Curved surface printing.

SURFACE TREATMENT SERVICES OF METAL

What Is Surface Treatment? Surface treatment is a process of artificially forming a surface layer on the surface of the base material that is different from the mechanical, physical, and chemical properties of the base body.

Process Differentiation Of Surface Treatment

1.Mechanical Surface Treatment: sand blasting, shot blasting, polishing, rolling, polishing, brushing, spraying, painting, oiling, etc.

Why use metallic coating?

There are many different methods by which a metallic coating can be applied as a surface treatment to increase the mechanical, electrochemical, and thermal performance of a material. The technique used largely depends on material application as well as the desired material coating or depth of the surface treatment.

What is PVD coating?

Physical Vapor Deposition (PVD): This is the category of processes where the material surface coating is applied through the condensation of the vaporized alloy coating onto the material surface, in a physical process involving the movement of particles across physical material phase boundaries (from gas to solid). To put it simply, the surface coating alloy is first vaporized and then sprayed onto the surface of the base metal (typically within a vacuum). There are other variations and subsets of PVD, but this is the basic operative principle behind the concept. PVD is commonly used to apply thin coatings of titanium nitride (TiN) in order to harden metal cutting tools and greatly increase wear resistance of the tool.

What is surface treatment?

Surface treatment is an additional process applied to the surface of a material for the purpose of adding functions such as rust and wear resistance or improving the decorative properties to enhance its appearance.

Methods of surface treatment

The most commonly used surface treatments include the following methods. Surface treatments that use electricity and require a dedicated power supply are indicated in red letters in the table.

Surface treatment process

There are several types of surface treatment, but here we will use plating as an example and explain electrolytic plating. There are several types of electrolytic plating: gold, silver, copper, nickel, zinc, and chrome.

The Role of Power Supplies in Surface Treatment

Today, surface treatment technologies are used in a variety of industries. Electrolytic plating, in particular, will continue to expand its applications and will require high-quality, economical technology.

What are some examples of surface treatments?

One example worth noting is a plastic impregnated ceramic coating that provides wear resistance and a slick, non-stick, surface.

Why do engineers use finishing treatment?

In an effort to prevent corrosion or simply improve appearance, engineers will often specify an additional finishing treatment process for a portion, or all, of a metal part’s exterior surface after it has been machined or fabricated. In addition, some of these treatments also provide enhanced mechanical or electrical properties ...

What is electroplating process?

Electroplating – This process forms a thin metallic coating on the substrate. The electroplating process passes a positively-charged electrical current through a solution containing dissolved metal ions and a negatively charged electrical current through the metallic part to be plated.

What is reduction agent plating?

A reduction agent replaces the electricity, and it is contained in the plating solution. Chemical Treatment – This method involves processes that create thin films of sulfide and oxide by means of a chemical reaction. Typical uses are for metal coloring, corrosion protection, and priming of surfaces to be painted.

What is thermal spraying?

Thermal Spraying – This type of surface treatment involves melted or heated materials that are accelerated, then collided and bonded mechanically to the target surface. A wire or powder feedstock, usually metal or ceramic, is melted by injecting it into a flame, electrical arc, or plasma stream.

What is the most common method of applying paint to metal?

Spray painting, electrostatic painting, dipping, brushing, and powder coat painting methods are some of the most common techniques used to apply the paint to the surface of the component. There are many types of paint formulations to protect metal parts in a wide range of physical environments.

Does Keller Technology provide surface treatments?

While surface treatments are necessary processes for virtually every system we manufacture, Keller Technology Corporation does not provide surface treatments as a standalone service. Engineers often specify an additional finishing treatment process for a portion, or all, of a metal part’s exterior surface.

How does surface water treatment work?

In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to settle out of solution via gravity during sedimentation. Any remaining particles and pathogens will be removed during the filtration treatment process. Finally, the water is disinfected to inactivate any remaining pathogens prior to entering the water system’s distribution system.

What is the purpose of the Surface Water Treatment Rule?

The goal of the SWTR is to reduce illnesses related to pathogens in drinking water. These pathogens include coliform, Giardia, and Cryptosporidium .

What is coagulation in water treatment?

History of Coagulation in Drinking Water Treatment. Coagulation has been an important process in high-rate filtration plants in the United States since the 1880s. Aluminum and iron salts have been used in the coagulation process since the beginning. These salts are still the most commonly used coagulants today.

What is turbidity in water?

This cloudiness is known as turbidity . Visual turbidity is unpleasant to consumers. Visual turbidity is also an indicator to operators and regulators that the water may still contain pathogens. The Surface Water Treatment Rule therefore requires that turbidity be removed to very low levels.

What is the process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the

Coagulation . Coagulation is defined as the water treatment process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the grains of a filter bed. Many surface water supplies contain particles that are too small to settle out of solution on their own.

How does contact time work in water treatment?

In order for systems to be sure that they are properly disinfecting the filtered water, the Surface Water Treatment Rule requires systems to provide enough contact time. Contact time (CT) is a function of the known disinfection concentration and the amount of time that the disinfectant is in contact with the water. Contact time is expressed in terms of mg/L-min. The EPA has published tables that show how much CT credit water systems will receive. In order to use these tables you use the concentration of chlorine, time, water temperature and pH.

What is the process of coagulation, flocculation, sedimentation, and filtration?

The water treatment process of coagulation, flocculation, sedimentation, and filtration remove the pathogens. The disinfection water treatment process inactivates them. The small particles in water may consist of silt and clay, color bodies, precipitated iron or manganese oxides, and even bacteria and algae. Together, these particles make the water ...