Heat treatment to increase strength of aluminum alloys is a three-step process :

- Solution heat treatment : dissolution of soluble phases

- Quenching : development of supersaturation

- Age hardening : precipitation of solute atoms either at room temperature (natural aging) or elevated temperature (artificial aging or precipitation heat treatment).

What happens when you add heat to a solution?

Definition of solution heat treatment : heating of an alloy to a temperature at which a particular constituent will enter into solid solution followed by cooling at a rate fast enough to prevent the dissolved constituent from precipitating

How does heat effect the solubility of a solution?

· Solution treatment refers to a heat treatment process in which the alloy is heated to a high temperature single-phase zone to maintain the temperature, and the excess phase is sufficiently dissolved in the solid solution and then rapidly cooled to …

What are examples of heat of solution?

Solution annealing (also referred to as solution treating) is a common heat-treatment process for many different families of metals. Stainless steels, aluminum alloys, nickel-based superalloys, titanium alloys, and some copper-based alloys all may require solution annealing. The purpose of solution annealing is to dissolve any precipitates present in the material, and transform the …

What is the effect of heat on solubility?

Solution treatment is the heating of an alloy to a suitable temperature, holding it at that temperature long enough to cause one or more constituents to enter into a solid solution and …

What is the difference between solution and precipitation heat treatment?

Solid solution strengthening involves formation of a single-phase solid solution via quenching. Precipitation heat treating involves the addition of impurity particles to increase a material's strength.

Is solution heat treatment the same as annealing?

The main difference between heat treatment and annealing is that heat treatment is used to obtain different desired properties (ex: increased strength, increased hardness, impact resistance, softening, increased ductility, etc.) whereas annealing is mainly done to soften a metal.

What is solution heat treatment of aluminum?

Solution treatment involves heating the aluminum to a temperature of 430-540°C (800-1000°F), at which alloying constituents are taken into solution (i.e., brought near their melting point) prior to a rapid quench.

What is solution treatment of steel?

Solution Treatment is the common heat treatment method for stainless steel castings. Solution treatment refers to the heat treatment process that heating stainless steel castings to a high temperature and keeping constant temperature, so that the excess phase is fully dissolved into the solid solution.

What is the quenching method for solution heat treatment?

Quenching is a type of metal heat treatment process. Quenching involves the rapid cooling of a metal to adjust the mechanical properties of its original state.

Why is solution annealing done?

The purpose of solution annealing is to dissolve any precipitates present in the material, and transform the material at the solution annealing temperature into a single phase structure.

What happens during solution treatment?

Solution treatment is the heating of an alloy to a suitable temperature, holding it at that temperature long enough to cause one or more constituents to enter into a solid solution and then cooling it rapidly enough to hold these constituents in solution.

Why is solution annealing necessary for stainless steel?

Solution annealing 300 series stainless steels improves corrosion resistance by putting carbides into solution in the microstructural matrix. A rapid quench inhibits carbides from reforming during cooling. Austenitic stainless steels are not solution annealed to appreciably change mechanical properties.

What are the three stages of heat treatment?

Stages of Heat TreatmentThe Heating Stage.The Soaking Stage.The Cooling Stage.

What are the five basic heat treatment process?

There are five basic heat treating processes: hardening, case hardening, annealing, normalizing, and tempering. Although each of these processes bring about different results in metal, all of them involve three basic steps: heating, soaking, and cooling. Heating is the first step in a heat-treating process.

What is tempering in heat treatment?

Tempering is a heat treatment that improves the toughness of hard, brittle steels so that they can hold up during processing. Tempering requires that the metal reaches a temperature below what's called the lower critical temperature — depending on the alloy, this temperature can range from 400-1,300˚F.

How is solution annealing performed?

In the solution annealing heat treatment, austenitic stainless steels shall be generally soaked at the temperature no less than 1900°F[1038°C] for a long enough time to bring carbon in the steel into a solid solution. The material is then rapidly quenched by water or cool air to prevent the carbon's reprecipitation.

Is annealing a type of heat treatment?

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable.

What is meant by solution annealing?

Solution Annealing is a heat treatment process which alters the metallurgical structure of a material to change its mechanical or electrical properties. Typically, this process is used to decrease metal crack sensitivity of aged material that needs to be returned to a weldable state.

What are the three stages of annealing?

There are three main stages to an annealing process.Recovery stage.Recrystallization stage.Grain growth stage.

What is annealing heat treatment process?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

What is solution treatment?

Solution treatment refers to a heat treatment process in which the alloy is heated to a high temperature single-phase zone to maintain the temperature, and the excess phase is sufficiently dissolved in the solid solution and then rapidly cooled to obtain a supersaturated solid solution.

Can solution treatment eliminate residual stress?

The solution treatment can only eliminate the residual stress generated during the welding process of the bellows.

Heat treatment services for stainless steel and metal alloys

Solution annealing (also referred to as solution treating) is a common heat-treatment process for many different families of metals. Stainless steels, aluminum alloys, nickel-based superalloys, titanium alloys, and some copper-based alloys all may require solution annealing.

High-quality solution heat treatment

We recognize how important it is to our clients that the finished product we create demonstrates exceptional quality, and purity.

What is solution heat treatment?

When it comes to the heat treatment of Aluminum parts, solution heat treatment is one of the most common processes. The end result of solution heat treatment is similar to that of annealing as they both seek to make the part easier to work with. However, solution heat treatment achieves this end result in a different way and adds a quenching step to lock in the part’s softened state.

Why do you anneal before heat treatment?

Annealing can be performed prior to solution heat treatment in order to make the part even easier to work with. This additional heat treatment step is not always required.

How long does a softening solution last?

With quenching alone, the softened state will only last a couple of hours. By storing the parts at below-freezing temperatures, this state can be preserved for up to a few days.

How long should a part be heated?

But, there is a rule of thumb to follow. In general, parts should be heated for one hour for every inch of cross-section thickness. The thicker the part is, the longer it will need to be heated so that the elements in the center of the cross-section can be dissolved.

What is quenching in furnace?

Quenching is performed after solution heat treatment so that the resumption of the age-hardening process is postponed. Without quenching, the age-hardening will resume almost immediately once the part is taken out of the furnace and begins to cool to the ambient temperature.

What is solution heat treatment?

Solution heat treatment and annealing are the common method of heat treating nonferrous metals. in a previous post, I examined the process of heat treating, ferrous metals like steel. Today you’ll get to know the following process of heat treatment which includes solution heat treatment and annealing. you’ll also learn about precipitation hardening, nitriding, cold working, decarburization.

What happens to the solid solution obtained during the heating process?

The solid solution obtained during the heating process remains stable due to the cooling process.

How does cold working change metals?

This process is not a heat-treating process, but it is used to change the characteristics of metals. It is performed by deforming metals at room temperature without fractioning. Cold working gives more tensile strength and better machinability to the metal. However, it changes its shape.

What is precipitation hardening?

Precipitation hardening helps to increase the yield strength of malleable materials.

What happens when precipitation hardens metals?

When precipitation hardening metals are quenched, its alloying elements trapped in solution which causes a soft metal, and when solutionized metal undergoes aging, it allows the alloying elements to diffuse through the mere structure and form intermetallic particles.

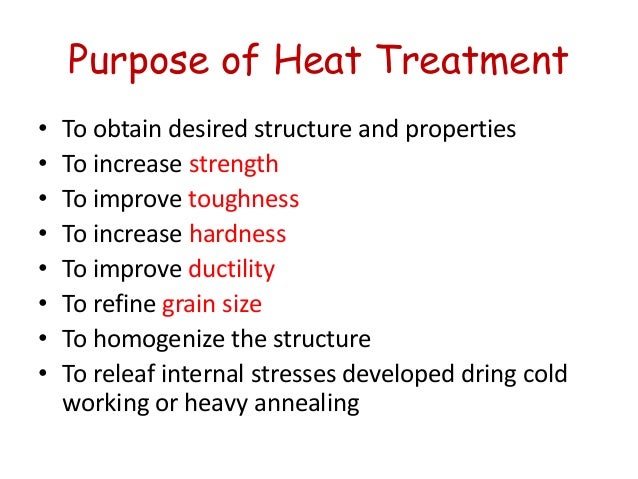

Why is heat treatment important?

It is very important manufacturing process that can not only help the manufacturing process but can also improve the product, its performance, and its characteristics in many ways. By Heat Treatment process, Example: The plain carbon steel. The following changes may be achieved: The hardness of Steel may be increased or decreased.

Why is heat treated steel used?

This heat treatment process is usually carried for low and medium carbon steel as well as alloy steel to make the grain structure more uniform and relieve the internal stresses.

What is hardening steel?

Hardening is a heat treatment process carried out to increase the hardness of Steel.

What is recrystallization in steel?

This causes complete recrystallization in steel to form New grain structure. This will release the internal stresses previously the strip in the steel and improve the machinability.

Does nitriding help with corrosion?

Beside increasing surface hardness and wear resistance nitriding provides good resistance to corrosion due to water, air, and steam.

What is surface hardening?

Surface hardening is used to impart desirable properties in the surface of the component that are not needed (or achievable) through the part.

What is hardening alloy?

Hardening is the process by which heat treatments are employed to harden an alloy. Hardenability is the capability of an alloy to be hardened by heat treatment. There are several hardening treatments.