What are the benefits of SBR sewage treatment plant?

SBR is a high-performance solution for wastewater treatment that can successfully handle batch and continuous flow operations. It is a proven technology with minimal costs and maintenance requirements. Due to high removal capacity and versatility, it is …

How are SBR, MBR and MBBR sewage treatment plants different?

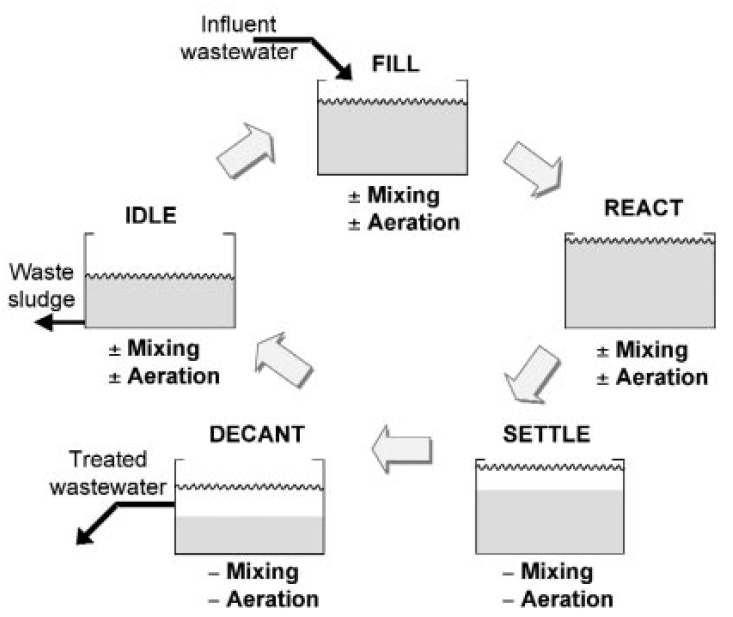

DESCRIPTION The sequencing batch reactor (SBR) is a fill-and- draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove undesirable components, and then discharged. Equali zation, aeration, and clarification can all be achieved using a single batch reactor.

What are the biggest problems in wastewater treatment?

Oct 26, 2020 · Sequencing batch reactors (SBR) or sequential batch reactors is a sludge activated system designed for wastewater treatment. They are able to stop solids to reduce organic matter found in wastewater, which is done over a number of cycles, depending on the size of the tank.

How does SBR technology work?

Sequencing batch reactors or SBRs use a separate pre-treatment section to mechanically hold back solids and a biological aeration and settling tank. Small SBR wastewater treatment systems clean incoming wastewater over a number of cycles. GRAF products achieve a cleaning performance of up to 98 %.

What is meant by SBR?

styrene-butadiene rubber (SBR), a general-purpose synthetic rubber, produced from a copolymer of styrene and butadiene.

What is SBR tank?

Sequencing batch reactors (SBR) or sequential batch reactors are industrial processing tanks for the treatment of wastewater. SBR reactors treat waste water such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches.

What are the advantages of SBR?

An SBR reduces both the mechanical and manual resources used. Since it uses one tank which does all three tasks, equalize, aerate and clarify the water, it does not require separate tanks for each of these. Therefore, reduces the resources required. It is mostly automated and hence, does not require supervision.Jun 10, 2019

How is SBR technology in STP?

One of the most advanced and high-class technology for treating wastewater, it works in various phases in a single batch reactor, often known as tanks. When sewage water is sent to the SBR tanks, then the activated sludge system gets activated.

What type of reactor is used for SBR?

The SBR process utilizes a fill-and-draw reactor in which cBOD oxidation, nitrification, denitrification, and settling are accomplished in a single reactor (Figure 12). The reactor is operated in six or more stages, which accomplish in time what an MLE process does in space.

What is MBR in wastewater treatment?

Membrane bioreactor (MBR) technology has emerged as a wastewater treatment technology of choice over the activated sludge process (ASP), which has been the conventional municipal wastewater technology over the last century.Jun 15, 2016

In which stage of the SBR is aeration performed?

This stage is also called the anoxic stage. 6. In which stage of the SBR is aeration performed? Clarification: The fixed or floating mechanical pumps are used or air is transferred into fine bubble diffusers fixed to the floor of the tank during the second stage aeration of the mixed liquor.

Is SBR an activated sludge process?

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches.

What is equalization tank?

EBPR Selectors. Flow equalization tanks are designed to buffer flows to a wastewater treatment plant with variations in influent flow due to diurnal variation and wet weather events. Mixing is required in these basins to maintain solids in suspension, preventing deposition and equalizing load to the treatment plant.

What is SBR decanter?

The decanter is a key piece of equipment within a sequencing batch reactor (SBR) system, removing clarified effluent from the basin during the decant phase of the operational cycle.Aug 31, 2000

What is DAF in water treatment?

Dissolved Air Flotation is a proven and effective physical/chemical technology for treating a variety of wastewater streams. DAF systems are designed to remove total suspended solids (TSS), biochemical oxygen demand (BOD), and oils and greases (O&G) from a wastewater stream.

What are the different types of sewage treatment plants?

Commonly Used Sewage Treatment Plants in IndiaRotating Disc System.Activated Sludge Plant (ASP)Suspended Media Filters (SMF)Submerged Aerated Filter (SAF)Non-Electric Filter.Trickling Filter.Sequencing Batch Reactor (SBR)Moving Bed Biofilm Reactor (MBBR)More items...•Dec 5, 2019

What is SBR wastewater treatment?

At GRAF, all our wastewater treatment products use SBR technology, which allows the water to be treated in batches at various points. Below we explain more about what an SBR wastewater treatment system is and how it works.

Why is SBR used?

Because SBR technology uses a storage and batching system, the effluent can be stored at peak periods and treated in smaller batches throughout the course of any given day . This means each batch is given full treatment time and peak surges are avoided.

What is GRAF sewage treatment plant?

GRAF’s one2clean sewage treatment plant is an SBR system which features a single tank and chamber, using only 3 steps to produce clean water. No odours are emitted via the system, and requires little maintenance, lower power consumption and reduces less sewer sludge to help the local environment.

How many steps are involved in SBR?

There are four steps involved when using an SBR system: Charging cycle – There are two chambers involved in the process, with the wastewater first entering the primary treatment chamber via the inlet. This is where any solid substances will be held before being moved in the secondary chamber. Aeration cycle – The second batch can now begin, ...

Do you need a sedimentation tank for SBR?

There is no need for final sedimentation tanks or return activated sludge pumping as everything is conducted within a single tank. This also means SBR systems take up a smaller footprint as fewer tanks are required.

How does SBR work?

How does SBR technology work? Sequencing batch reactors or SBRs use a separate pre-treatment section to mechanically hold back solids and a biological aeration and settling tank. Small SBR wastewater treatment systems clean incoming wastewater over a number of cycles.

Where does wastewater go in a SBR tank?

From there, the wastewater is fed into the SBR tank (2nd chamber). 2. Aeration. The actual biological cleaning by microorganisms now takes place in the SBR tank.

What is the short aeration and rest phase?

Short aeration and rest phases alternate in a controlled cleaning process. The so-called activated sludge can now develop with millions of microorganisms and clean the water thoroughly. 3. Rest phase. A rest phase now follows, during which the live sludge sinks to the bottom of the system.

What happens after aeration in Rewatec SBR?

After aeration, remaining solids – including microorganisms – sink to the bottom of the tank. Some remain in the Rewatec SBR to treat the next batch of wastewater.

What is the name of the liquid that settles on the bottom of a septic tank?

This tank allows liquids to separate from solids. Solids that settle on the bottom of the tank are called primary sludge. They are removed from the tank by a septic pumper as often as needed. In some cases, a fine screen takes the place of the primary treatment tank.

What is SBR in Bunbury?

An SBR in Bunbury. To remove phosphorus compounds from the liquor, aluminium sulfate (alum) is often added during this period. It reacts to form non-soluble compounds, which settle into the sludge in the next stage. The settling stage is usually the same length in time as the aeration.

How long does sludge settle in a tank?

The sludge is allowed to settle until clear water is on the top 20 to 30 percent of the tank contents.

What is sequential batch reactor?

Sequencing batch reactors ( SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

What is the purpose of oxygen in wastewater?

Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

How does a reactor purged of oxygen?

In this case, the reactors are purged of oxygen by flushing with inert gas and there is no aeration. As the bacteria multiply and die, the sludge within the tank increases over time and a waste activated sludge (WAS) pump removes some of the sludge during the settling stage to a digester for further treatment.

What is the bioselector in a tank?

In some systems, tanks contain a section known as the bio-selector, which consists of a series of walls or baffles which direct the flow either from side to side of the tank or under and over consecutive baffles.

Where do aerobic bacteria settle in a tank?

During this stage the sludge formed by the bacteria is allowed to settle to the bottom of the tank. The aerobic bacteria continue to multiply until the dissolved oxygen is all but used up. Conditions in the tank, especially near the bottom are now more suitable for the anaerobic bacteria to flourish.

What is an SBR system?

bioprocessH2O’s bioCYCLETM Sequencing Batch Reactor (SBR) is a compact system that is used for the treatment of industrial and municipal wastewater. The SBR utilizes a fill-and-draw activated sludge process within a single tank to achieve several biological processes, including aerobic and anoxic treatment.

What can an SBR system be used for?

The bioCYCLE™ SBR may be used for the removal of pollutants including COD, BOD, ammonia, nitrate, and phosphorus. Once the cycles are complete, the treated effluent may be discharged directly into the environment or to the sewer.

How do Sequencing Batch Reactors work?

Charging - The wastewater goes first into the first holding chamber, where the solid substances are filtered. From there, the wastewater is directed into the SBR tank.

What is a sequencing batch reactor?

A sequencing batch reactor (SBR) is the ideal wastewater treatment solution for commercial and municipal projects striving for high performance with minimal energy consumption.

Available models

No two projects are the same. That is why we offer a range of Rewatec SBR systems, each designed according to your unique wastewater treatment needs and preferences.

Additional options

When regulations call for tighter controls, take advantage of our additional treatment options to maximize the performance of your Rewatec SBR system.

Get a free quote

Contact our expert in your area for more information about the Rewatec SBR and additional treatment options that are right for you.