What is plasma treating?

Plasma is used to clean or modify the surface of many plastic components in a variety of industries. We are committed to providing unparalleled plasma treatment solutions for every possible application. Some of these applications include: Cleaning. Removes contaminants and residue from material surfaces. Bonding.

Can you cut plastic with plasma cutter?

Dec 01, 2021 · Plasma treatment transforms plastic parts into high-value products such as catheters. Enhancing durability, printability, flow control in microfluidics, and coating adhesion can be critical to safety, quality, and efficiency of plastic products.

How much does J Plasma treatment cost?

Treatment with plasma removes any foreign contaminants present on the surface of a material making it more suitable for further processing. Materials like plastics are prone to lose any type of printing or coating done on their surfaces because of their glossy texture unless treated.

What can plasma treat?

Mar 15, 2022 · Plasma treatment is a key surface modification technology that is critical to manufacturing cost-effective and environmentally responsible advanced composite materials. Plasma treatment for plastic packaging is extremely effective:

What are plasma treatments?

Overview. Convalescent plasma (kon-vuh-LES-unt PLAZ-muh) therapy uses blood from people who've recovered from an illness to help others recover. The U.S. Food and Drug Administration (FDA) has given emergency authorization for convalescent plasma therapy with high antibody levels to treat COVID-19 .Apr 28, 2021

How does plasma surface treatment work?

Plasma treatment is the process by which gas is ionized in a vacuum chamber to form plasma and alter the surface of a material. The plasma improves bonding, printing, coatings and primers; this is also known as increased wettability. The process is performed in a plasma chamber under vacuum pressure.

What is plasma treatment material?

Plasma surface treatment is a process that raises the surface energy of many materials so as to improve the bonding characteristics. One form of plasma treatment is also commonly known as a corona treatment, which was invented by Danish engineer Verner Eisby in the 1950s.

What is plasma treatment in manufacturing?

Essentially, plasma treatment is a low-pressure gas process that removes all traces of organic contamination to improve the outcomes of secondary applications.Jun 28, 2016

How long does plasma treatment last?

It will also take several days for the tiny scabs to disappear from the pinpoint wounds on the skin's surface. During this time you will begin to see the results of your treatment, and your skin will continue to improve over the next six months. After that, results generally last about three years.Aug 25, 2020

How long does plasma cleaning last?

Most plasma treatments last approximately 48 hours if the treated surface remains clean and dry. This time can vary depending on the treatment performed and the conditions parts are stored in.

What products use plasma?

It's used in pharmaceutical productsPlasma-based productUsed forIntravenous Immunoglobulin IVIgTreating some primary immune deficiency disordersAntithrombin concentratePreventing blood clots during surgery or childbirthFactor IX concentrateTreating patients with inherited bleeding condition haemophilia B4 more rows•Mar 27, 2017

What is plasma and how it is produced?

A plasma may be produced in the laboratory by heating a gas to an extremely high temperature, which causes such vigorous collisions between its atoms and molecules that electrons are ripped free, yielding the requisite electrons and ions. A similar process occurs inside stars.

What is plasma treatment for surface modification?

Plasma treatment is a surface modification technique that readily primes any surface for better acceptance of secondary manufacturing applications. Plasma is a reactive treatment process where positive and negative ions, electrons, and radicals react and collide as long as an electric potential difference exists.

What is plasma chamber used for?

The chamber is the plasma chamber or vacuum chamber which holds the process gas in low pressure. The chamber is designed as a pressure reservoir. It is made of a material not susceptible to etching from the process gases used, often stainless steel.

What are the benefits of using plasma treatment on injection or blow molded parts?

Plasma treatments can create competitive advantages and transform specific parts into specialized, engineered components with 10 times the value.

What impact does plasma treatment have on the surface properties of the molded part?

Plasma can transform the surface properties of plastic to achieve aims that normally would not be feasible without treatment.

What types of molded parts are now being plasma treated?

Plasma is now being used to treat everything from syringes to bumpers on trucks and automobiles.

Are plasma treatment services available?

Yes .For molders who want plasma-treated parts or components without investing in in-house equipment, the solution is to utilize a contract processor.

What is plasma?

Plasma is one of the four fundamental states of matter. While the states solid, liquid and gas are well-known to all of us because they are part of...

What is plasma treatment used for?

Plasma treatment is used to modify the surface of an object. Many solid materials have a low surface energy, which results in a poor wettability an...

What are the main effects of Plasma treatment?

The major effects of a Plasma treatment are: 1. Surface cleaning: Treatment with plasma removes any foreign contaminants present on the surface of...

How does plasma treatment work?

Plasma consists of electrons, molecules or neutral gas atoms, positive ions, UV light along with excited gas molecules and atoms and carries a high...

Can I treat heat sensitive parts with plasma?

Plasma treatments performed at low temperatures can easily process materials that are heat sensitive. These types of plasma are sometimes referred...

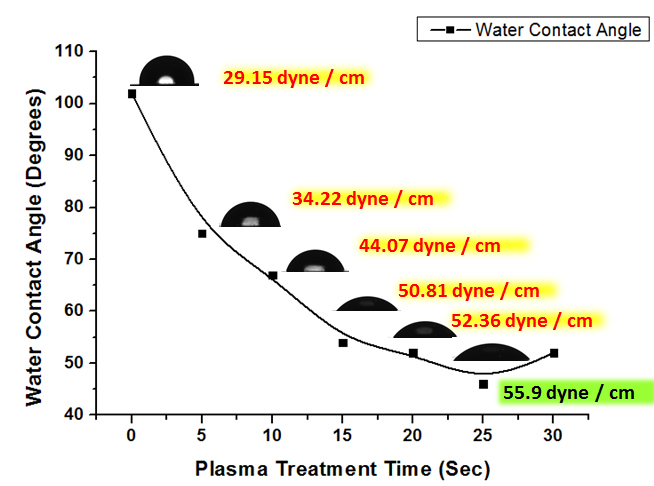

How long does a plasma treatment take?

Treatment cycle times are often short, between 2-120 seconds depending on the treatment technology, the treated material and size of the part.

How long do the effects of a plasma treatment last?

The lifetime of a plasma treatment can last from hours to years depending on the material and the applied treatment as well as the subsequent stora...

How good do plasma treated parts bond?

The enhancement can range from a 2-fold to a 10-fold improvement in lap-shear strength and peel- strength compared to untreated parts.

Which materials can benefit from Plasma treatment?

Nearly all materials can benefit from plasma treatment. Plastic and rubber materials are the most common materials that challenge our customers wit...

Is plasma treatment eco-friendly?

Plasma treatments are a lot more environmentally friendly than traditional surface treatment methods, which often rely on the use of high temperatu...

What is plasma treatment?

Plasma treatment for plastic packaging is extremely effective: 1 Openair-Plasma® surface modification technologies can achieve plastic activation at the highest level. It is not unusual to reach surface tensions of more than 72 mN/m. 2 Extremely long-lasting plasma activation increases storage life and facilitates subsequent processing up to 12 months later. 3 New material composites are only possible using targeted surface functionalization with Openair-Plasma®. 4 Openair-Plasma® treatment ensures targeted, exclusively single-sided surface pretreatment of plastic films.

When do VOCs occur?

VOCs occur when solvents and solvent-containing products are used, and they are harmful to the environment. Nevertheless, manufacturing in many industries still involves pre-treating surfaces with primers, bonding agents or other chemicals that release VOCs. With its Openair-Plasma process, Plasmatreat offers an environmentally friendly alternative.

Is Plasmatreat a class 6 cleanroom?

Consequently, the capacities of the technology and research center will now be expanded to include a class-6 cleanroom.

Can packaging industries get by without physical surface?

The packaging industry can no longer get by without physical surface pretreatment. It’s become a necessary step in extruding plastic films and using non-polar materials such as polypropylene, polyethylene and recycled materials.

Why is plasma treatment used for plastics?

Using plasma treatment, it is possible to prepare and clean plastic and composite materials, and make them ready for finishing. The increase in surface energy from plasma treatment improves the measure of adhesion and assures the effectiveness of an applied coating. The results of this study demonstrate that heat-sensitive substrates like plastics and composites can be prepared with plasma treatment and successfully coated with UV-cured powder without degrading or deforming the integrity of the substrate.#N#UV-curable powder is 100% solid material, solvent- and water-free, durable, and has a high measure of adhesion when applied to a properly prepared and pretreated -substrate.

What is plasma treatment?

Plasma treatment convert s a low-energy surface to a high-energy surface, and makes it more hydrophilic and wettable. Adhesion of a coating has a direct correlation to wettability, the more wettable a surface the better the adhesion. Plasma has six components; electrons, ions, free radicals, byproducts, photons and neutrals.

What is plasma in science?

Plasma is often referred to as the fourth state of matter; solid, liquid and gas being the primary three (Figure 3). Thermal energy, its addition or removal, is the intervening input that changes the nature of matter. Plasma is a gas that has the capacity to conduct electricity.

What is the first measurable test for adhesion?

Testing adhesion is the first measurable test when evaluating performance of a coating material, regardless of the type substrate - metal, wood, plastic, composite, paper, glass or engineered materials. In lay terms, this can be expressed as “does it stick to the substrate,” and if so, “what is the measure of adhesion?” The measurement of adhesion applies to all forms of coatings - liquids, powder coatings, varnishes and inks. A coating’s curing system or mechanism is independent of the measure of adhesion. Regardless of the type of curing - ambient air, thermal energy or radiation energy (UV or electron beam (EB)) - the coating has to “stick” to the substrate. A coating that is applied and cured correctly does not guarantee the coating will adhere to the substrate. Proper preparation of the substrate prior to coating is the most important and determinate factor in achieving the desired measure of adhesion for any coating on any substrate.

What is the wettability of a material?

Wettability refers to the interaction between a fluid and solid phase, and measures the tendency of a material to spread and flow on a solid surface.

What are the benefits of UV coating?

UV-cured powder coatings offer many operational benefits: lower energy consumption, the application system has a smaller plant footprint, and increased productivity. In addition to these operational benefits, UV-cu red powder coatings also have health, safety and regulatory benefits.

What is the ASTM D3359 method?

ASTM D3359 1 is the standard and accepted method to measure and classify adhesion of a coating material to a substrate. The coating is cross-cut scribed at specified spacing using a knife or a cutting device (Figure 1). A pressure-sensitive tape is applied over the scribed area and then pulled sharply off the substrate. Adhesion is classified by the percentage of paint removed by the tape from the substrate (Figure 2). 5B is the optimum classification, 4B is often acceptable, anything less is a failure and not acceptable. This classification method is used throughout this study.

What is plasma treatment?

For many applications, plasma treatments are utilized to increase the surface energy of the material. Surface energy is the sum of all intermolecular forces on a material, the degree of attraction or repulsion force a material surface exerts on another material.

What is plasma used for?

According to Blaik, plasma is being used to treat everything from syringes to bumpers on trucks and automobiles. “Plastic parts manufacturers are always looking for unique ways to gain a technology edge to become a market leader,” Blaik said.

Why do we coat plastic?

Coating Plastics to Prevent Leaching. Using plastic labware can raise concerns about leaching. Since plastic labware is susceptible to leaching from plasticizers, stabilizers and polymerization residues, plasma is used to coat the inside of containers with a quartz-like barrier material.

Can plastic be bonded to metal?

Bonding Plastic with Dissimilar Materials. In the automotive industry, there is a push to use different plastic materials to reduce the vehicles' weight and make them safer. However, getting plastic to adhere to metal, rubber or other types of plastic can sometimes be exceedingly difficult.

What is plasma in chemistry?

Plasma is a state of matter, like a solid, liquid or gas, created by combining energy and gas, which causes ionization. Injection and blow molders can control the collective plasma properties (i.e.-ions, electrons and reactive species) to clean, activate, chemically graft and deposit a wide range of chemistries onto a material.

Is synthetic polymer hydrophobic?

However, untreated synthetic polymers are highly hydrophobic and provide inadequate binding sites for cells to anchor effectively to their surfaces. To improve biomolecule attachment, survivability and proliferation, the material must be surface modified using plasma to become more hydrophilic.

What is a microfluidic device?

Typically, microfluidic systems used for medical or industrial applications transport, mix, separate or otherwise process small amounts of fluids using channels made of plastics, which measure from tens to hundreds of microns.

How long does plasma treatment last?

On many materials, the treatment can last for several months if stored in a dust-free environment.

What are the benefits of plasma coating?

Plasma Treatment of Plastics 1 Increase surface wettability 2 Improve printing and bonding characteristics 3 Low friction plasma coatings on seals and o-rings

What is plasma gasification?

In plasma gasification, feedstock (trash) is introduced into a vessel of extremely high heat (~2,000 deg F) capable of breaking all organic chemical bond and reducing all trash including plastic, paper, glass, yard waste, food, filth, etc. to basic elements. The heat also melts metals, which are recovered.

How can we increase recycling?

On the other hand, there are multiple efforts to increase plastic recycling through the following: 1 Inventing new chemistry of plastics to become recyclable; 2 Reuse packages and products made of plastics; and 3 Developing new biodegradable plastic formulas to provide the required performance.

What is syngas used for?

Depending on the regional economics, syngas can be used for electrical power, methanol or liquid fuels such as jet fuel, diesel, synthetic natural gas generation and others. Plasma gasification is not to be confused with incineration, which is the burning of waste-emitting greenhouse gases and creating ash.

How much of MSW goes to landfill?

This means that if all the multitude of incremental plastic recycling claims were successful and financially viable to deal with all plastic types, 84% of waste would still go to landfill. The waste management infrastructure is ripe for a disruption.

When did China stop recycling?

The decision that went into effect January 2018 by China’s government (“National Sword”) to stop accepting all United States recycling has exposed the vulnerability and ineffectiveness of our current processes for recycling and all forms of municipal solid waste (MSW). As it stands today, our municipalities are now all scrambling ...

When was the first landfill opened?

The first municipal sanitary landfill to open was in 1937 in Fresno, CA. It was considered innovative at the time with new techniques of trenching, compacting and covering of waste with soil. Since then because of the considerable amount of open and cheap land we have accepted the practice of landfills in the U.S., and now there are more than 10,000 municipal landfills that have reached maximum capacity, leaving 3,091 active landfills according to the EPA. Long gone are the days where every town had its own dumpsite. According to the EPA, there are seven states that will be running out of landfill space in the next five years. With the closure of the Fresh Kills landfill, New York City is sending its trash to Ohio, Pennsylvania, West Virginia and elsewhere. Large city centers are especially challenged and driving waste further and further to reach landfills creating higher costs and increased carbon emissions.

Is glass recyclable?

Consider also glass, a material that’s 100% recyclable, yet 67% of glass doesn’t get recycled and is wasted. Paper and paperboard are recyclable, yet prices are at a historical low for these materials and only 65% of paper and paperboard waste is recycled.

Why do we treat plastic?

Innumerable plastics are treated each and every day for improved wettability leading to proper adhesion of paints, in ks, coats etc. Although, the problem of attaining good quality adhesion of coatings, glues, sealants and paints as compared to other conventionally ...

What is Rototec X?

Our RotoTEC-X product for example, offers a cost-effective method, of treating plastic materials. It is an example of a machine which treats plastic materials such as PP, PE, PEEK, ABS, PC, PS and others. Click here to see the machine.

Is polyolefin polar or nonpolar?

Normally, polyolefin has a non-polar surface or low surface energy which is unresponsive to printing, bonding, coating or painting etc. unless you’re willing to apply treatments that are damaging to the environment and require a lot of effort. Solving your adhesion problems.