Full Answer

What is the normalizing heat treatment?

What is the Normalizing Heat Treatment?

- Normalizing Heat Treatment & Process. The metal is heated in a furnace for normalizing heat treatment process. ...

- Carbon Steel Normalizing. Carbon steel contains carbon in the range of 0.12 to 2%. ...

- Microstructure in Normalizing. ...

- Normalizing Equipment. ...

- Application of Normalizing. ...

What is the process of heat treatment?

Types of Heat Treatment

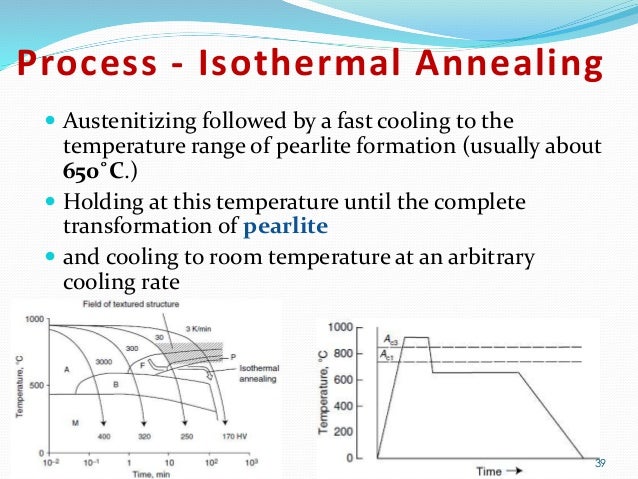

- Annealing. Annealing is one of the most important processes of heat treatment. ...

- Normalizing. Normalizing: The main aim of normalizing is to remove the internal stresses developed after the cold working process.

- Hardening. ...

- Tempering. ...

- Nitriding. ...

- Cyaniding. ...

- Carburising. ...

- Case Hardening or Surface Hardening. ...

What happens when metals undergo heat treatment?

The temperature metals are heated to and the rate of cooling after heat treatment can significantly change metal’s properties. The most common reasons metals undergo heat treatment are to improve their strength, hardness, toughness, ductility and corrosion resistance. Get a better idea of the process with the examples of common heat treatments that follow. Understanding Annealing

What is heat treating process?

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material.The most common application is metallurgical.Heat treatments are also used in the manufacture of many other materials, such as glass.Heat treatment involves the use of heating or chilling, normally to extreme temperatures ...

What is heat treatment normalizing?

Normalizing heat treatment helps to remove impurities and improve ductility and toughness. During the normalizing process, material is heated to between 750-980 °C (1320-1796 °F). The exact heat applied for treatment will vary and is determined based on the amount of carbon content in the metal.

Why normalizing is required in heat treatment?

The main purposes of the normalizing heat treatment on metals are: To remove structural irregularities or impurities and defects from the metal. To improve ductility that has been lost in some metal processing. To reduce the hardness that has been increased by mechanical or thermal hardening processes.

What are normalizing?

Normalizing is a process in which a metal is heated to a temperature below its melting point and allowed to cool in air in order to make it more ductile. Normalizing is a process in which a metal is cooled in air after being heated in order to relieve stress.

What is purpose of normalizing?

Normalizing is used because it causes microstructures to reform into more ductile structures. This is important because it makes the metal more formable, more machinable, and reduces residual stresses in the material that could lead to unexpected failure.

What is normalizing and tempering?

The process, called "normalize and temper", is used frequently on steels such as 1045 carbon steel, or most other steels containing 0.35 to 0.55% carbon. These steels are usually tempered after normalizing, to increase the toughness and relieve internal stresses.

What is normalizing and hardening?

Normalizing is a heat treatment process which is used to make metal, such as steel, more ductile and tough. Thermal and mechanical hardening processes decrease ductility and increase hardness of steel parts. Therefore, normalizing can reform the microstructure into more ductile structures.

What is the effect of normalizing?

Normalizing imparts both hardness and strength to iron and steel components. In addition, normalizing helps reduce internal stresses induced by such operations as forging, casting, machining, forming or welding.

How normalization is done?

The normalization is to be done by considering the difficulty level of each set, since the questions may be different in different sets and difficulty level of a particular set may be different from other sets.

What is normalization and its types?

Normalization is the process of organizing data into a related table; it also eliminates redundancy and increases the integrity which improves performance of the query. To normalize a database, we divide the database into tables and establish relationships between the tables.

Does normalizing increase hardness?

Normalization removes impurities in steel and improves its strength and hardness. This happens by changing the size of the grain, making it more uniform throughout the piece of steel. The steel is first heated up to a specific temperature, then cooled by air.

What are advantages of normalization?

Advantages of Normalization : Better execution is guaranteed which can be connected to the above point. As information bases become lesser in size, the goes through the information turns out to be quicker and more limited in this way improving reaction time and speed.

What is normalizing heat treatment?

Normalizing heat treatment services for metal and metal components. The functions of normalizing may overlap with or easily be confused with those of annealing, hardening, and stress relieving; however, they are not interchangeable, and the final use of the product must be considered when determining which method to use.

What temperature is normalizing heat?

Normalizing heat treatment helps to remove impurities and improve ductility and toughness. During the normalizing process, material is heated to between 750-980 °C (1320-1796 °F). The exact heat applied for treatment will vary and is determined based on the amount of carbon content in the metal.

What is normalizing in physics?

Normalizing is a high-temperature austenitizing heating cycle followed by cooling in still or agitated air that is performed for a variety of reasons but primarily is performed to homogenize the microstructure and remove any segregation or non-uniformities that may exist at the microscopic level.

What happens to pearlite after heating?

After heating, material is cooled to room temperature. The rate of cooling significantly influences both the amount of pearlite and the size and spacing of the pearlite lamellae. At higher cooling rates, more pearlite forms, and the lamellae are finer and more closely spaced.

Is normalizing more expensive than annealing?

For this reason, normalizing is typically a less expensive process than annealing or stress relief. The shorter cooling time in the normalizing process produces metal that is less ductile and has a higher hardness value than the annealing process.

When to use normalizing?

Normalizing has broad practical applications across industries, including: In general, it is the best practice to use normalizing in circumstances when manufacturing activities are expected to place considerable stress on the material or in situations where dimensional stability is vital to the product.

Is normalizing faster than annealing?

For this reason, normalizing is typically a less expensive process than annealing or stress relief.

What is the purpose of normalizing heat?

The main purposes of the normalizing heat treatment on metals are: To remove structural irregularities or impurities and defects from the metal. To improve ductility that has been lost in some metal processing.

What is normalizing a metal?

Normalizing is defined as a heat treatment process where a material is heated to a predecided elevated temperature, hold at that temperature for a certain period of time (usually 10-20 minutes), and then allowed to cool freely in the air to reach room temperature. The normalizing process is usually applied to metals that have been subjected to thermal or mechanical hardening processes and require their microstructure to be normalized. After normalizing, the metal gets back its ductility and the hardness is reduced.

What happens to metals after normalizing?

After normalizing, the metal gets back its ductility and the hardness is reduced.

How to normalize steel?

Steel normalizing is a heat treatment process performed after rolling, welding, or forging processes to refine the distorted grains in the microstructure. The normalizing process of steel involves the following steps: 1 Steel is heated to about 40-50 0 C (Refer to Fig. 1) above the upper critical temperature (A 3 or A cm ). 2 The alloy is then held at that temperature for around 10-20 minutes. 3 Cooling it in still or slightly agitated air to bring back to room temperature.

What is steel normalizing?

Steel normalizing is a heat treatment process performed after rolling, welding, or forging processes to refine the distorted grains in the microstructure. The normalizing process of steel involves the following steps:

How is the internal stress relieved during normalizing?

In the recovery stages of normalizing, the internal stresses are relieved by heating the material. Then the metal is heated to elevated temperatures above the recrystallization temperature of the metal where new grains are formed.

What metals can be normalized?

For the normalizing treatment of a metal, it must be receptive to normalizing. Various metals and alloys are suitable to be normalized like. Iron-based alloys like Carbon steel, stainless steel, alloy steel, cast iron, etc. Nickel alloys. Copper.

What is normalizing metal?

What Is Normalizing? Normalizing is a heat treatment process that is used to make a metal more ductile and tough after it has been subjected to thermal or mechanical hardening processes. Normalizing involves heating a material to an elevated temperature and then allowing it to cool back to room temperature by exposing it to room temperature air ...

Why is normalizing important?

This is important because it makes the metal more formable, more machinable, and reduces residual stresses in the material that could lead to unexpected failure.

What is the difference between annealing and normalizing?

The main difference between annealing and normalizing is that annealing allows the material to cool at a controlled rate in a furnace. Normalizing allows the material to cool by placing it in a room temperature environment and exposing it to the air in that environment. This difference means normalizing has a faster cooler rate than annealing.

What are the stages of normalizing?

There are three main stages to a normalizing process. Recovery stage. Recrystallization stage. Grain growth stage. Recovery Stage. During the recovery stage, a furnace or other type of heating device is used to raise the material to a temperature where its internal stresses are relieved. Recrystallization Stage.

Why is heat treatment important?

It is important that the material used for any project possesses the correct mechanical properties for the specific application . Heat Treatment processes are often used to alter the mechanical properties of a metal, with one of the more common heat treatment processes being Normalizing.

Why is normalizing less expensive than annealing?

Normalizing is also generally less expensive than annealing because it does not require additional furnace time during the cool down process.

What is Normalizing Heat Treatment?

Normalizing is the treatment of steel by heating above the transformation temperature, holding for a certain time, and then cooling to room temperature in still or slightly agitated air. This is done to remove processing stress and provide a more uniform structure.

Logistics

Normalizing is offered at our Burton Ave location in Waterloo, Iowa. Click the button below to learn what other heat treat services are offered at the same location.

What is normalizing steel?

What is normalizing? Normalizing is a heat treatment process which is used to make metal, such as steel, more ductile and tough. Thermal and mechanical hardening processes decrease ductility and increase hardness of steel parts. Therefore, normalizing can reform the microstructure into more ductile structures.

How does normalizing metal work?

While the metal gets cooled at a controlled rate in a furnace during the annealing process, normalizing allows to cool the material at room temperature. Typically, this is simply done by exposing the material to air.

Why is normalizing important?

Therefore, normalizing can reform the microstructure into more ductile structures. This reduces the residual stress of the work piece. Further, normalizing makes the steel more formable and machinable. In the process of normalizing, the steel gets heated to a specific temperature.

Why are ferritic stainless steel stamps normalized?

Here are a few examples: Automotive industry: Typically, ferritic stainless steel stampings are normalized for the use in the automotive industry, in order to reduce the hardness which occurs during the forming process.

Why is normalizing less expensive than annealing?

Normally, this leads to a less ductile and harder material in comparison to annealing. Because of the shortened time in the furnace, normalizing is less expensive than annealing.

Why are nickel alloys normalized?

Nuclear industry: In the nuclear industry, nickel-based alloys are often normalized due to alterations to the thermal microstructure. These modifications usually occur during the welding process. Work hardening: Normalizing is used to make carbon steel less brittle after cold- rolling. To the Overview.

What happens in the second stage of a metal refractory process?

In the second stage, the metal gets heated to a temperature between the recrystallization and the melting temperature. Thus, new grains form which are not affected by the preexisting stresses.

What is normalizing steel?

Normalizing is a heat treatment process similar to annealing in which the Steel is heated to about 50 degree Celsius above the upper critical temperature followed by air cooling. This results in a softer state which will be lesser soft than that produced by annealing.

What is normalizing carried for accomplishing?

Normalizing carried for accomplishing one or more of the following: To refine the grain size. Reduce or remove internal stresses. Improve the machinability of low carbon steel. Increase the strength of medium carbon steel. And also To improve the mechanical properties of the medium Carbon Steel.

What are the changes in steel?

The following changes may be achieved: The hardness of Steel may be increased or decreased. Internal stresses that are set up due to cold or hot working may be relieved. The machinability of Steel may be enhanced. The mechanical properties like tensile strength the Talati shock resistance toughness etc may be improved.

What is nitriding used for?

Nitriding is generally employed to Steel parts which are moving like engine parts such a cylinder, crankshaft, etc. 6. Cyaniding: Cyaniding is also a surface hardening process in which the heated parts to be surface hardened are immersed in a bath of molten sodium or potassium cyanide.

What is recrystallization in steel?

This causes complete recrystallization in steel to form New grain structure. This will release the internal stresses previously the strip in the steel and improve the machinability.

What is annealing in metal?

Annealing is carried out for accomplishing one or more of the following: Softening of a metal or alloy. This may be done due to improving machinability. Relieving internal residual stresses caused by the various manufacturing process. Refining the grain size of the metal or alloy.

What temperature does annealing take place?

Annealing consists of heating of steel parts to a temperature at or near the critical temperature 900 degree Celsius hold it at that temperature for a suitable time and when allowed to cool slowly in the Furnace itself. The heating done during annealing affects the metal in two stages of recovery and recrystallization.

Carbon Steel Normalizing

- Carbon steel contains carbon in the range of 0.12 to 2%. As the percentage of carbon content increases, the steel becomes harder, tougher and less ductile. Low carbon steels usually do not need normalizing. However, they can be normalized on the requirement. In normalizing heat trea…

Microstructure in Normalizing

- The thickness of carbon steel can have a significant effect on the cooling rate and thus the resulting microstructure. The thicker pieces cool down slower and become more ductile after normalizing than thinner pieces. After normalizing the portions of steel containing 0.80% of carbon are pearlite while the areas having low carbon are ferrites. The redistribution of carbon at…

Normalizing Equipment

- The equipment in use for normalizing comes in both batch and continuous operations. Bell furnace offers an economical method of heat treatment and different bell lifting mechanisms. Continuous furnaces heat treats the metal in the continuous fashion. The conveyor runs at constant speed, and the product is carried to desired conditions after heat treatment.

Application of Normalizing

- The low cost of the normalizing process makes it one of the most extensively used industrial process when compared to annealing. The furnace is available for the next batch as soon as heating and holding periods are over. Normalizing is used to: 1. Improve the grain size refinement and machinability of cast structures of castings 2. Recover the original mechanical properties o…