What is HAZ in welding?

This specific area affected by the thermal energy of the welding is called Heat Affected Zone or HAZ. The welding thermal cycle produced by the welding works similar to heat treatment and changes the HAZ properties (microstructural & mechanical properties such as microstructure, hardness, yield strength & toughness).

How does heat affect the HAZ of a welding process?

Mar 29, 2018 · A heat-affected zone (HAZ) is the portion of the base metal that was not melted during brazing and cutting/welding, but whose microstructure and mechanical properties were altered by the heat. This alteration can be detrimental, causing stresses that reduce the strength of the base material, leading to catastrophic failures.

What is the heat-affected zone in fusion welding?

Nov 25, 2019 · The heat affected zone (or simply HAZ) is something that occurs when metal is subject to high temperatures. It has a negative impact on the design and structure of the metal. This article discusses those effects and how to reduce them. Some manufacturing procedures that produce the HAZ are mechanical cutting, thermal cutting and welding.

What is HAZ and how to treat it?

In fusion welding, the heat-affected zone (HAZ) is the area of base material, either a metal or a thermoplastic, which is not melted but has had its microstructure and properties altered by welding or heat intensive cutting operations. The heat from the welding process and subsequent re-cooling causes this change from the weld interface to the termination of the sensitizing …

Why is the HAZ important in welding?

The HAZ is the crucial area in welding because, once the steel has been selected, the HAZ and its properties have to be accepted, whereas a weld metal can be changed if necessary. In welding steels, the HAZ is important as an area where cracking can occur as well as a region whose properties can be reduced by welding.

How is HAZ calculated in welding?

We can calculate the HAZ width by using the HARDNESS test along the welding line and note the variation of hardness values . Finite element analysis of the welding, Hardness and macroscopic analysis of the welded region could be the techniques used to find out FZ, HAZ and BM width.

What are the effects of HAZ?

Effects of the HAZ. The heat affected zone leads to structural changes in the metal that weaken the part in this area. A metal's mechanical properties such as fatigue resistance, distortion, and surface cracking are affected.Nov 25, 2019

How do you control HAZ?

HAZ problems can be mitigated by performing a pre- and/or post-weld heat treatment. Weld geometry also plays a role in the size of the HAZ. During high-temperature cutting operations, the depth of the HAZ is associated with the cutting process, cutting speed, material properties, and material thickness.

What is the hardest metal to weld?

Originally Answered: What kind of metal is the most difficult to weld? Titanium is probably the most difficult. It has to be surrounded by an inert gas like argon.

What are the two major categories of welding processes?

The welding process may be classified into two broad categories namely plastic welding and fusion welding....Although there are several types of welding, the following are the most commonly used welding processes:Gas Welding: ... Arc Welding: ... Resistance Welding: ... Solid-State Welding: ... Thermit Welding:

What does HAZ mean?

HAZAcronymDefinitionHAZHealth Action Zone (est. 1977; initiative; UK)HAZHazardous CargoHAZHazard/HazardousHAZHIV/AIDS Zimbabwe (charity)5 more rows

Why weld usually fails in HAZ?

Tempering a metal in a controlled way changes the metal's phase and makes it stronger. However, in the HAZ, the heating and cooling of the metal is fairly uneven, so phase changes can occur within the metal's structure that inherently make the weld weaker.Jan 3, 2017

What are the causes of welding defects?

Most defects encountered in welding are due to an improper welding procedure. Once the causes are determined, the operator can easily correct the problem. Defects usually encountered include incomplete penetration, incomplete fusion, undercutting, porosity, and longitudinal cracking.

How do you stop your HAZ from cracking?

Avoiding a susceptible microstructure requires:Using moderate welding heat input so that the weld does not cool quickly.Apply pre-heat so that the HAZ cools more slowly; in multi run welds, maintain a specific interpass temperature.Nov 9, 2015

What are the different welding defects?

Following are the types of welding defects:Porosity and Blowholes.Undercut.Weld crack.Incomplete fusion.Slag inclusion.Incomplete penetration.Spatter.Distortion.More items...•Jul 24, 2021

How do you reduce hardness in welding?

Hardness problems in the weld metal can be minimized by altering the consumables to avoid the use of active fluxes or decrease the alloy level in the wire. Active fluxes contribute elements to the weld metal that cause the chemistry to be richer, producing a higher hardness.

Why is the heat affected zone important?

The heat affected zone (HAZ) is a very important area because weld faults may occur in this zone . As can be seen in above Figure, the transformations that take place in the HAZ depend on the highest temperature attained at each point of the zone during welding. This figure illustrates what happens to a steel that has been cold worked before welding.

What is heat affected zone welding?

What is Heat Affected Zone or HAZ in Welding? Most people think that a weld is only the portion of metal fused during welding. This is a very limited way of looking at a weld. A more accurate way is to consider a weld as the area affected by the heat input during welding. According to this definition, a weld is composed ...

What is haz welding?

In theory, the HAZ refers to all areas of the base metal heated to above ambient temperature during welding. In practice, the term HAZ is used to describe the areas altered by welding heat input.

Why does stainless steel have a temper?

They are caused by the surface oxidation process specifically in stainless steel. However, these temperatures causing the ‘temper colors’ are much lower temperatures than those which form the heat-affected zone. Also, these color bands can extend for some distance beyond the actual heat-affected zone.

What is a heat affected zone?

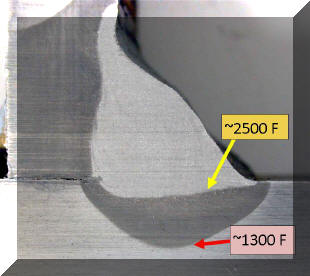

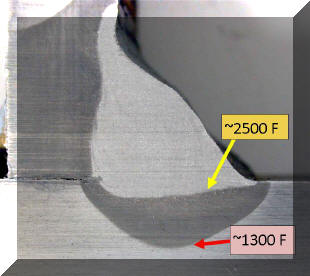

The heat-affected zone ( HAZ) is an area generated when a metal is subjected to very high temperatures (Example: Welding, Mechanical Cutting, Laser Cutting, Plasma Cutting, etc). This is the non-melted zone near the exact worked area. The mechanical properties of the heat-affected zone are altered due to being exposed to high temperatures. So, the heat-affected zone or HAZ can be defined as the area between the melted metal and the base metal where microstructural changes occur. Refer to the Fig. 1 below:

What is the fusion zone?

The Fusion zone is a mixture of molten metal and filler metal. Next, the narrow mushy zone consisting of partially melted metal is the weld interface. The next region that suffers a peak temperature below the melting point temperature creating microstructural changes is known as the heat-affected zone.

What is the most important factor influencing the size of the heat-affected zone?

The amount of heat input during the welding or cutting process normally exceeds the melting temperature and subsequent cooling leads to microstructural changes. Thermal diffusivity is the single most important factor influencing the size of the heat-affected zone. The level of thermal diffusivity is dependent on the metals:

What are the properties of welding?

The extent and magnitude of property change depends primarily on: 1 Base material 2 Weld filler metal 3 Amount and concentration of heat input by the welding process

What is preferential corrosion?

Preferential corrosion of a heat-affected zone is a widely known phenomenon. High-temperature exposure and welding can significantly affect the microstructure and properties of the heat-affected zone that makes them more susceptible to corrosion.

What does faster cutting speed mean?

Cut speed - In general, faster speeds result in a smaller HAZ. Amperage (when using plasma) - For a given thickness of metal, a higher amperage (and consequently a faster cut speed) results in a smaller HAZ. Type of metal being cut - Increased temperatures and longer cutting times will result in a wider HAZ. All thermal cutting processes create ...

What causes heat tint?

Factors that further affect the formation of these heat tints are: 1 Surface condition – Rougher surfaces oxidise faster producing more pronounced colouration. 2 Surface contamination – Impurities like rust, paint and oil also effect the tint. The contamination may change the heat tint but the extension of the HAZ is unaffected. 3 Oxygen availability – As limiting access to oxygen reduces oxidation, using an electrode coating or a protective gas for welding can affect the heat tint. 4 Chromium content – Chromium increases oxidation resistance. Therefore, higher chromium content reduces the intensity of the heat tint.

What is heat affected zone?

The heat affected zone (or simply HAZ) is something that occurs when metal is subject to high temperatures. It has a negative impact on the design and structure of the metal. This article discusses those effects and how to reduce them. Some manufacturing procedures that produce the HAZ are mechanical cutting, thermal cutting and welding.

How does metal cutting work?

In metal cutting, the metal absorbs the heat at a very high rate. The cooling provided by the coolant is also immediate. This can significantly change a metal’s microstructure and properties in the affected area.

Does stainless steel corrode?

Stainless steel may even corrode in the heat affected zone. Extreme heat leads to precipitation of chromium carbides near the grain boundaries. This reduces the chromium content of stainless steel below 10.5 percent.

What is welding similar to?

Welding, similarly to thermal cutting, uses very high temperatures to either add molten metal or melt the parts themselves. As the formation of the heat affected zone has a considerable effect on the quality of the final product, it is good to understand the different aspects of it.

What is thermal diffusivity?

In simple words, thermal diffusivity of a metal is the measure of how fast heat will be transmitted through its body. If the thermal diffusivity is high, the metal will be able to transmit heat sooner. This leads to faster cooling and the HAZ will be narrower. On the other hand, low thermal diffusivity will keep heat in ...

What are the mechanical properties of heat affected metals?

A metal’s mechanical properties such as fatigue resistance, distortion, and surface cracking are affected.

Reference

BS EN 1011-2:2001 Welding - Recommendations for welding of metallic materials. Arc welding of ferritic steels

Further information

See further information about Materials and Corrosion Management, or please contact us .

Post Weld Heat Treatment (PWHT) or Stress Relieving

Post Weld Heat Treatment (PWHT), or also called stress relief (SR) is a method for reducing and redistributing the residual stresses in the material that have been introduced by welding.

Why Post Weld Heat Treatment or PWHT is required?

The development of residual stresses approaching or even exceeding the yield stress is possible when welding thick sections. For certain industry sectors, eg. Petrochemical, Chemical, Oil and Gas, etc. the existence of residual stress of this magnitude is completely unacceptable.

Effect of Post Weld Heat Treatment or PWHT on material

Post weld heat treatment will generally result in a modification of the microstructure of both the weld metal and heat affected zone. With the exception of the 9Cr1Mo and 12Cr1MoV materials, the microstructure of all other materials should contain a mixture of ferrite and iron or alloy carbide.

Benefits of Post Weld heat Treatment or stress relieving (SR)

1. Improving the diffusion of hydrogen out of weld metal#N#2. Softening the heat affected zone and thus improving toughness (although not weld metal toughness)#N#3. Improving dimensional stability during machining.#N#4. Improving ductility.#N#5. Improving the resistance to stress corrosion cracking.#N#6. Reducing the effects of cold work.

Difference between post heating & stress reliving

Hydrogen induced cracking (HIC) often occurs when high levels of ambient hydrogen permeate into a material during welding. By heating the material after welding, it is possible to diffuse hydrogen from the welded area, thus preventing hydrogen induced cracking.

How to perform Post Weld heat Treatment (PWHT)

Most of the requirements for post weld heat treatment can be found in the fabrication Standard to which the vessel or other structural parts are constructed. For example, AWS D1.1 for structural parts, ASME Section VIII for pressure vessels and ASME B31.3 for Piping.

Heating & Cooling Rates in PWHT

These are specified in most of the construction Standards, and are reasonably similar.

What is post weld heat treatment?

What Does Post Weld Heat Treatment (PWHT) Mean? A post weld heat treatment is a process that involves elevating the temperature of a material or materials following a welding process. A post weld heat treatment is performed to alleviate residual stresses, increase the strength, increase or decrease the hardness, and reduce the risk of cracking.

Why is post weld heat treatment important?

Post weld heat treatment is critical for precipitation hardened alloys that have been welded because they rely on precipitates to block dislocations in the crystalline structure of the metal to increase their strength and hardness.

What happens when you weld carbon steel?

When welding is performed on a steel with high amounts of carbon, the rapid heating and cooling of the welding process can cause these hard, brittle microstructures to form. These microstructures are more susceptible to hydrogen cracking than that of ferrite or pearlite.

How are precipitates formed?

These precipitates are formed to the correct size through a heat treatment process known as artificial aging. When a precipitation hardened metal is exposed to the heat from welding, the precipitates in the heat affected zone of that metal are likely to have been changed and rendered less effective. Therefore, it is important to post weld heat ...