Practically nothing can be manufactured without heat treating, a process in which metal is heated and cooled under tight controls to improve its properties, performance and durability. Heat treating can soften metal, to improve formability. It can make parts harder, to improve strength.

What is heat treatment and why is it done?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness, ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

What are the different heat treatment processes?

The Heart Of Industry. Practically nothing can be manufactured without heat treating, a process in which metal is heated and cooled under tight controls to improve its properties, performance and durability. Heat treating can soften metal, to improve formability. It can make parts harder, to improve strength.

What happens during heat treatment?

Feb 13, 2020 · Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Both ferrous as well as non-ferrous metals undergo heat treatment before putting them to use. Over time, a lot of different methods have been developed.

What are the stages of heat treatment process, chemistry?

Dec 31, 2020 · Heat treatment consists of heating the metal near or above its critical temperature, held for a particular time at that finally cooling the metal in some medium which may be air, water, brine, or molten salts. The heat treatment process includes annealing, case hardening, tempering, normalizing and quenching, nitriding, cyaniding, etc.

What is the use of heat treatment process?

Heat treatment is commonly used to alter or strengthen materials' structure through a heating and cooling process. It offers many advantages, including: It can change a material's physical (mechanical) properties and it aids in other manufacturing steps. It relieves stresses, making the part easier to machine or weld.Feb 26, 2020

What are the examples of heat treatment?

For example, aluminum alloy automotive castings are heat treated to improve hardness and strength; brass and bronze items are heat treated to increase strength and prevent cracking; titanium alloy structures are heat treated to improve strength at high temperatures.

What is the heat treatment process for materials?

Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

What metals can be heat treated?

Ferrous heat-treated metals often include cast iron, alloys, stainless steel and tool steel, whereas some heat-treated non-ferrous metals include aluminum, copper, brass and titanium.Dec 8, 2017

What materials should be heat treated?

Although ferrous metals account for the majority of heat treated materials, alloys of copper, magnesium, aluminium, nickel, brass, and titanium may also be heat treated. About 80% of heat treated metals are different grades of steel.Feb 13, 2020

Why do we use heat treatment in materials?

Heat treating can improve wear resistance by hardening the material. Metals (including steel, titanium, inconel, and some copper alloys) can be hardened either on the surface (case hardening) or all the way through (through hardening), to make the material stronger, tougher, more durable and more resistant to wear.Sep 25, 2020

What are the 3 stages of heat treatment process?

Three stages of heat treatmentHeating: Heating is the first stage in a heat-treating process. ... Soaking: Soaking is the stage at which the complete part of the heated metal completely changes in its structure. ... Cooling: The third stage of heat treatment is cooling.Dec 12, 2019

What are the five basic heat treatment process?

There are five basic heat treating processes: hardening, case hardening, annealing, normalizing, and tempering. Although each of these processes bring about different results in metal, all of them involve three basic steps: heating, soaking, and cooling. Heating is the first step in a heat-treating process.

What improvements can be made in steel by heat treatment?

The temperatures metals are heated to, and the rate of cooling after heat treatment can significantly change metal's properties. The most common reasons that metals undergo heat treatment are to improve their strength, hardness, toughness, ductility, and corrosion resistance.Oct 7, 2019

What is heat treatment process of steel?

Heat treatment involves heating a metal or alloy to a specific temperature and then cooling it to harden the material. Heat treatment can be used at different stages in the manufacturing process to change certain properties of that metal or alloy.

What is annealing in heat treatment process?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

What is solution heat treatment?

Solution treatment is the heating of an alloy to a suitable temperature, holding it at that temperature long enough to cause one or more constituents to enter into a solid solution and then cooling it rapidly enough to hold these constituents in solution.

How long has heat treatment been around?

Most metals and alloys are heat treated in one way or another, and the understanding and science of heat treatment have been developed over the past 100 to 125 years. The importance of heat treatment is evident in many products in the automotive, aerospace, construction, agriculture, mining, and consumer goods industries, ...

What metals can be treated with heat treatment?

The heat treatment process can be applied to ferrous metals such as cast-iron, AHSS, stainless steel and other alloy steels, as well as non-ferrous metals such as aluminium, magnesium, titanium, copper, or brass [2].

How to heat treat a sandpaper?

Heat treatment processes require the following three main steps [2]: 1 Heating the material to a specific temperature (in the range of up to 2400 °F / 1316 °C) 2 Soaking, or maintaining the specific temperature for a certain amount of time (varying from seconds to more than 60 hours) 3 Cooling at a suitable rate following prescribed methods. The material can be cooled rapidly, slowly (in the furnace), or can be quenched (using water, brine, oils, polymer solutions, salts, or gases).

What is case hardening?

This is also known as case hardening. It includes over a dozen treatments in which the surface of the material is hardened creating a hard ‘case’ while the core remains tough or soft. This provides improved wear resistance for parts such as gears, cams and sleeves. This process is one of the most common for steel and iron.

What is the process of quenching?

This rapid cooling process is known as quenching and is generally applied to stainless and high-alloy steels, primarily to produce controlled amounts of martensite in the microstructure and obtain increased hardness [2]. Hardening is often used in cast-irons and steels alloyed with metals such as nickel and magnesium.

What is heat treatment?

Heat treatment is a heating and then cooling process using predefined methods to achieve desired mechanical properties like hardness , ductility, toughness, strength, etc. It is the combination of thermal, industrial, and metalworking processes to alter the mechanical properties and chemical properties of metals.

What is the first step in heat treatment?

The first step in the heat treatment process is heating the metal. The temperature depends on the types of metal and the technique used. Sometimes you need to heat the outer surfaces of the metal, and sometimes you need to heat the whole body. That depends on what kind of alteration you want in the mechanical structure.

Why is heat treatment important?

Heat treatment is an essential process in the material science industry to improve metal properties for commercial purposes. It is one of the key processes that help gain the desired mechanical and chemical properties of metals.

How is annealing done?

Annealing is done by heating the metals at the above critical temperature , hold them there for some time and then cool it at a very slow rate in the furnace itself. Annealing is usually done on ferrous and non-ferrous metals to reduce hardness after the cold working process.

How does tampering work?

Tampering is a very common process for machine tools, knives, etc. Tampering is usually done by heating the metal at a relatively low temperature. The temperature depends on the required mechanical properties of metals.

What happens after holding a furnace?

After the holding process, cooling starts. The cooling must be done in a prescribed manner. During cooling, there are some structural changes occur. Different media such as water, oil, or forced air is used to aid in cooling. You can also use furnaces for cooling purposes as the control environments help inefficient cooling.

How does heat treatment help metals?

Heat treatment assist in improving the ductility of metal in the annealing process. Heat treatment helps in hardening metals. Case hardening helps in hardening only the outer surface of the metal piece keeping the rest of the portion soft and ductile. Machinability of metals gets improved.

What temperature is steel heated to?

Steel is heated to a temperature that is 10-20 degrees higher than that during quenching. After heat preservation, quenching is performed, and then tempered at a temperature of 400-720 degrees.

What gas is used to cool steel?

The flame incinerated with oxygen-acetylene mixed gas is sprayed onto the surface of the steel part, and the steel is heated rapidly. When it reaches the quenching temperature, to spray with water to cool the steel immediately.

What is normalizing steel?

Normalizing is usually used as a pre-treatment process for forgings, weldments and carburized parts. For low- and medium-carbon carbon layout steels and low-alloy steel parts with low functional requirements can be performed with the final heat treatment.

How long to keep steel in furnace?

Heat the steel to 80 – 200 degrees, keep it for 5 – 20 hours or longer , then take it out of the furnace and cool it in the air.

How to operate a steel inductor?

Operation method: Put the steel parts into the inductor, make the surface of the steel parts induce current, heat to the quenching temperature in a very short time, and then spray water to cool.

How hot should carburizing medium be?

Put the steel parts in the carburizing medium, heat it to 900-950 degrees and keep it warm, so that the surface of the steel parts can obtain a carburizing layer with a certain concentration and depth.

Why is stainless steel quenched?

Sometimes when high-alloy steel (such as stainless steel, wear-resistant steel) is quenched, it is to obtain a single uniform austenite arrangement to improve wear resistance and corrosion resistance.

What are the steps of heat treating?

Heat treating processes require three basic steps: Heating to a specified temperature.

What is heat treated parts?

Heat treated parts are essential to the operation of automobiles, aircraft, spacecraft, computers and heavy equipment of every kind. Saws, axes, cutting tools, bearings, gears, axles, fasteners, camshafts and crankshafts all depend on heat treating.

Why is hard surface important?

It can make parts harder, to improve strength. It can put a hard surface on relatively soft components, to increase abrasion resistance. It can create a corrosion-resistant skin, to protect parts that would otherwise corrode. And, it can toughen brittle products.

Why do we heat treat?

There are various reasons for carrying out heat treating. Some procedures make the metal soft, while others increase hardness. They may also affect the electrical and heat conductivity of these materials.

What metals are heat treated?

Although ferrous metals account for the majority of heat treated materials, alloys of copper, magnesium, aluminium, nickel, brass, and titanium may also be heat treated. About 80% of heat treated metals are different grades of steel.

What is each schedule?

Each schedule refers to a different rate of heating, holding and cooling the metal. These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties.

What is the role of microstructure in mechanical properties?

And microstructure plays an important role in the mechanical properties of a material. The final outcome depends on many different factors. These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. The parameters depend on the heat treatment method, ...

Is a solid solution a mixture?

A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. Different media such as brine, water, oil or forced air control the rate of cooling. The sequence of cooling media named above is in decreasing order of effective rate of cooling.

What are the properties of metal?

Among those properties are electrical resistance, magnetism, hardness, toughness, ductility, brittleness and corrosion resistance.

Is aluminium a heat treatment?

Aluminium is suitable for heat treatment methods such as annealing, solution heat treating, natural and artificial ageing. Heat treatment for aluminium is a precision process. Process scope must be established and it should be controlled carefully at each stage for the desired characteristics.

Why is heat treatment done?

The heat treatment is done to improve the machinability. To improve magnetic and electrical properties. To increase resistance to wear, heat and corrosion, ...

What are the different types of heat treatment?

Types of Heat Treatment. 1. Annealing. Annealing is one of the most important processes of heat treatment. It is one of the most widely used operations in the heat treatment of iron and steel and is defined as the softening process.

How is steel heated?

The steel is heated above its critical temperature range. It is held at that temperature for a definite period of time. The steel is then rapidly cooled in a medium of quenching.

What is the purpose of normalizing steel?

Normalizing. Normalizing: The main aim of normalizing is to remove the internal stresses developed after the cold working process. In this, steel is heated 30 – 50°C above its upper critical temperature and cooling it in the air. It improves mechanical and electrical properties, machinability & tensile strength.

What temperature is steel heated to?

The steel is heated to a temperature of about 40° to 50°C above its upper critical temperature. It is held at this temperature for a short duration. The steel is then allowed cool in still air at room temperature, which is known as air quenching.

What is tempered steel?

It is an operation used to modify the properties of steel hardened by quenching for the purpose of increasing its usefulness. Tempering or draw results in a reduction of brittleness and removal of internal strains caused during hardening. Steel must be tempered after the hardening process.

What is the process of hardening a metal?

Nitriding. Nitriding is the process of the case or surface hardening in which nitrogen gas is employed to obtain hard skin of the metal. In this process, steel is heated in the presence of ammonia environment. Due to this, a nitrogen atom is deposited and makes material hard.

What is heat treatment?

Heat treatment is a general process of the usage of heating and cooling operations at various staged levels to alter the physical properties of metals (microstructure) such as steel, aluminum, and many more. The major purpose of such treatment is to improve the physical and structural properties for some specific use or future work of the metal. ...

Why is heat treatment important?

Heat treatment helps to improves a metal’s manufacturability. This is done by the removal of internal stress from previous fabrication processes such as hot work, cold work, machining, welding, and stamping. For example, if a metal is highly hard to bend or machine, it can be subjected to annealing or stress relieving.

What are the different types of furnaces?

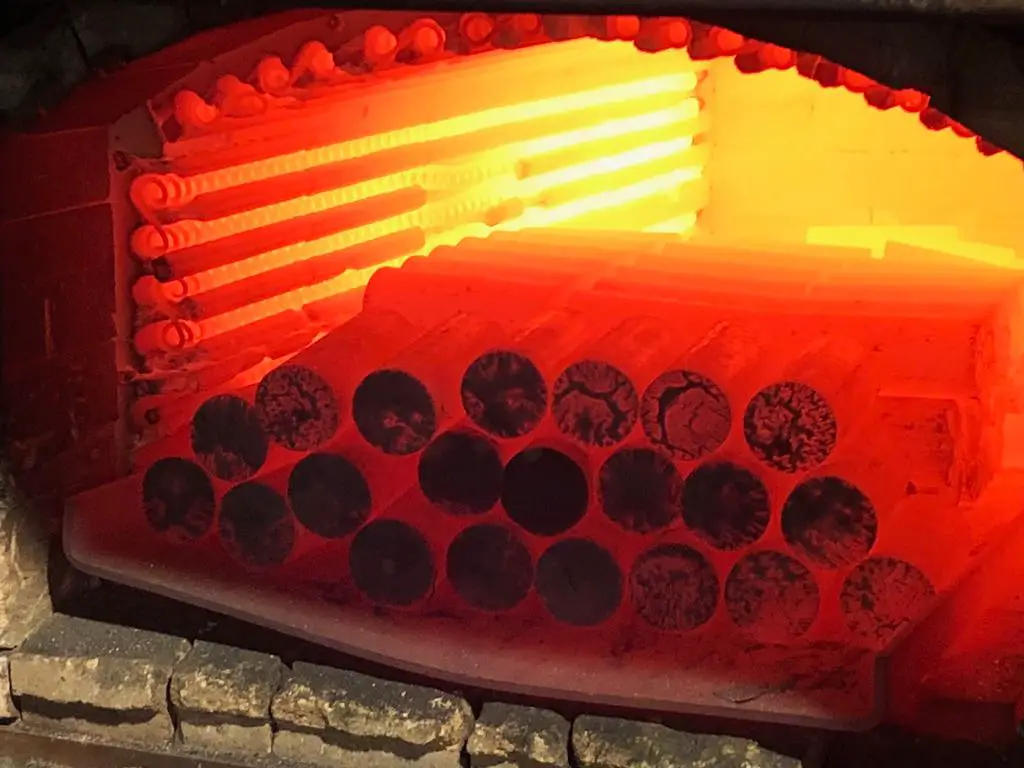

Also, the atmospheric condition within the furnace can affect the condition of parts to be heat treated. Furthermore, the quenching medium and quenching equipment must be elected to fit the material being used and the heat-treating process. Lastly, there must be provision for equipment for parts and materials handling, straightening parts, and cleaning metals. The following are the different types of furnaces required for the heat treatment process: 1 Batch Furnace: made up of insulated chambers featuring a heating system, a steel shell, and access to the chamber. 2 Bell-type furnace: made up of removable covers named bells which can be lowered over the load and hearth by crane 3 Box-type furnace: most has been upgraded to a semi-continuous batch furnace with feature including slow-cool chambers and integrated quench tanks. 4 Car-type furnace: also regarded as bogie hearth which is an extremely large batch furnace with a movable insulated car that can be moved in and out of the furnace. 5 Elevator -type furnace: the hearth and the car are rolled into position under the furnace unlike the car furnace 6 Fluidized bed furnace: made up of cylindrical retort produce from high-temperature alloy. 7 Pit Furnace: furnace is constructed in a pit and extended to floor level or slightly above 8 Salt bath furnace: uses a variety of salt for heat treatment

How does quenching work?

The returning to room temperature is done by placing the hot metal in the oil, brine, a polymer dissolved in water, or another suitable liquid to harden the structure fully. This process is carried out in a rapid state. Quenching is done for both ferrous alloys and non-ferrous alloys. While non-ferrous metal produces softer than normal parts, ferrous alloys produce a harder part.

What are the advantages of heat treatment?

In the world of manufacturing, heat treatment of metals is generally used and it is a precisely controlled process of heating and cooling. Heat treatment does not only make the metal harder, but it also makes it softer too.

How does carbon affect hardness?

The carbon content of metal influences the metal’s hardness. During the decarburization process, the carbon diffuses from the surface of the metal, thus leading to the weakening of the metal.

What is the most heat treated ferrous metal?

As mentioned earlier, the most heat-treated ferrous metal is steel. The adjustment of the carbon content of steel is the simplest heat treatment of steel. This helps to change the mechanical properties of steel. Additional changes are done by heat treating – for example by accelerating the rate of the cooling through the austenite-to-ferrite transformation point. Also, increasing the rate of cooling of pearlitic steel (0.77% carbon) to about 200 o C per minute generates a DPH of about 300, and cooling at 400 o C per minute rases the DPH to about 400. The increasing hardness is attributed to the formation of a finer pearlite and ferrite microstructure that can be obtained during slow cooling under ambient air.

What happens when steel is heated?

High temperatures used for annealing send steel into its austenite phase. During this phase, the grain quality of the steel changes. When hot steel is cooled and solid again, it cannot be used as is.

What is the process of annealing steel?

Annealing - Heating and then slowly cool steel to refine it and make it softer. Carburizing - Adding carbon to the surface with heat and carbon-rich substances. Case hardening - Carburizing and quickly cooling steel to keep the center soft while the rest hardens.

What are the elements that make steel?

For quality assurance purposes, all the following have to be present in order for an alloy to be called steel: 1 Aluminum 2 Carbon 3 Manganese 4 Nitrogen 5 Oxygen 6 Phosphorus 7 Silicon 8 Sulfur

What is steel made of?

Put simply, steel is an alloy made from a combination of iron and other elements . There are different types of steel depending on what other elements are used alongside iron. For quality assurance purposes, all the following have to be present in order for an alloy to be called steel: Aluminum. Carbon. Manganese.

Is steel an alloy?

Looks like you're ready to build your own skyscraper. (Just kidding.) To recap: All steel is an alloy of iron and a variety of other elements. All steel has to be treated in order to be used in commercial products. The heat treatment of steel generally always involves annealing, quenching, and tempering.

What is tempering steel?

Tempering steel is a way to make hardened steel less brittle and change its durability to suit your needs. Each steel project may require a different heat level for tempering, but tempering never pushes steel back into the austenite phase.

Is cast iron the same as steel?

For example, cast iron is an alloy much like steel that contains more than 2.1 percent carbon. Wrought iron is a similar alloy to cast iron but contains very little carbon in comparison, making it easier to twist and bend. Steel is engineered for its final purpose starting with the elements used to make it.

What Is Heat Treatment?

Heat Treatment Methods

- Heat treatment generally consists of controlled heating, soaking and cooling steps. There are five techniques used for the heat treatment of materials. Here is an overview of these principal heat treatment processes and how they affect the material.

Heat Treatment Applications

- The most common application of heat treatment is in metallurgy. The following are some examples of the applications for heat-treated parts : 1. Automobiles 2. Aerospace 3. Computers 4. Metalworking 5. Machinery 6. Construction 7. Others The globalautomotiveindustry has been a large player in the market of heat-treated metals recently. In terms of materials, steel dominates …