An Introduction to Cryogenic Hardening of Metal

- 3 Beneficial Effects. Greater durability: Cryogenic treatment helps to promote the transformation of retained austenite present in heat-treated steels into harder martensite steel.

- Process. The process of cryogenically treating a metal part involves very slowly cooling the metal using gaseous liquid nitrogen.

- Applications

How can cryoheat metal treatment help me?

Jan 01, 2018 · When metal is cryotreated the crystal defects are reduced, resulting in crystal homogeneity due to the reduction of vacancies inside crystal lattice. Residual stresses are balanced. Cryogenic treatment favors more transmutation of retained austenite into martensite and precipitation of fine secondary carbides [1-20].

What are the benefits of cryogenic treatment of metals?

Jul 16, 2019 · Cryogenic hardening is a metal treatment process that’s characterized by the use of liquid nitrogen to freeze metal. While temperatures vary, it’s not uncommon for metal to reach -301 degrees Fahrenheit during this process.

What is deep cryogenic treatment (cryo heat)?

Cryogenic Treatment, which is also known as Cryogenic Processing, modifies the micro-structure of metals by subjecting them to ultra-cold temperatures (down to –300ºF). Cryogenic Treatment as a whole, promotes three transformations in heat-treated steels, cast irons and other metals:

Does deep cryogenic treatment change the color of the metal?

CryoHeat Metal Treatment performs cryogenic processing by simply allowing the molecules to realign in a uniform like fashion. This releases any stored energy that may be trapped in the object. ... Deep Cryogenic Treatment done in a controlled environment with a CryoHeat processor and special proprietary formula is a very viable stress reliever ...

What is cryogenic treatment of alloys?

A cryogenic treatment is the process of treating workpieces to cryogenic temperatures (i.e. below −190 °C (−310 °F)) in order to remove residual stresses and improve wear resistance in steels and other metal alloys, such as aluminum.

What is Cryo treated?

In short, cryo treatment is a process by which metal is subjected to extremely cold temperatures as low as minus 301 degrees Fahrenheit. The process works on anything made of metal. The time it takes to treat a part relates directly to its mass.May 1, 2007

What is Cryo treated knife?

Cryogenic treatment is a common process designed to enhance the performance of metal blades. Extreme deep freezing increases the service life of knives by improving their resistance to wear. As a one-time treatment, freezing knife blades makes them more durable and less prone to chipping and fracturing under stress.

Why cryogenic treating is done?

The cryogenic treatment improves mechanical such as hardness, toughness and tribological properties such as wear resistance, coefficient of friction, surface finish, dimensional stability and stress relief. The deep cryogenic treatment is the most beneficial treatment applied on cutting tools.

How do you treat Cryo gears?

0:131:53Cryogenically Treating Gear At Music Direct - YouTubeYouTubeStart of suggested clipEnd of suggested clipAfter you seal the tank. And turn the machine on the metals inside are slowly cooled to extremelyMoreAfter you seal the tank. And turn the machine on the metals inside are slowly cooled to extremely sub-zero temperatures the machine keeps the metals inside at these extreme temperatures for several.

What is cryogenic processing transmission?

Cryogenic treatment of transmissions increases the life of all internal parts as well as the casing. Gear failure and wear are reduced. There have been reports that smoother shifting and better clutch performance have resulted from transmission treatment. NitroFreeze can treat both automatic and manual transmissions.

What is D2 steel good for?

The D2 steel has a high wear resistance, hardness, and good toughness, which make it an excellent choice for knife makers, and if you do a little search on the market (example: go to baldehq.com) you 'll find out how cheap are the knives compared to their high quality, but it doesn't mean that the D2 is better than the ...

Can you quench steel in liquid nitrogen?

Quenching is a very common technique used in the heat-treating process for steel. The quenching process helps to prevent low-temperature processes like phase transformation by shortening the thermodynamic and kinetic windows for these reactions.Mar 10, 2020

What is SOG Cryo D2?

CRYO D2 STEEL BLADE A versatile high-carbon tool steel that is cryogenically heat-treated to SOG's unique performance specifications. D2 provides the ideal combination of edge retention and durability for long term use with ease of maintenance.

What is Cryo temperature?

cryogenics, production and application of low-temperature phenomena. The cryogenic temperature range has been defined as from −150 °C (−238 °F) to absolute zero (−273 °C or −460 °F), the temperature at which molecular motion comes as close as theoretically possible to ceasing completely.

Can liquid nitrogen damage metal?

Metals can also become brittle when they are cooled in liquid nitrogen. The first two, copper and aluminum, flex easily but the tin strip breaks with almost no force.

How do you cold harden steel?

Cold rolling is the most common method of work hardening. This involves the metal being passed through pairs of rollers to reduce its thickness or to make the thickness uniform. As it moves through the rollers and is compressed, the metal grains are deformed.Nov 13, 2019

Why is cryogenic treatment beneficial?

Cryogenic treatment has been proven beneficial to increase the mechanical properties of the material and improved productivity due to the increase in life and functional performance of the mechanical component. 1.1.

When did cryogenic treatment start?

Since 1965 commercial deep cryogenic treatment became available in the United States [8]. In 1966, Ed Busch established Cryotech in the USA. He started to make the use of dry steam Liquid Nitrogen. This enabled them to manage the temperature the process as per type and cross section of the material [7].

How long does it take to soak a cryo?

For shallow cryogenic treatment soaking period varies from a few minutes to 6 hours, whereas in deep cryogenic treatment there is a soaking period of 8 to 72 hours.

What is cryogenic processing?

Cryogenic processing (CP) is used in the fields like aerospace, automotive, cutting tool and manufacturing industries, sports and music instruments etc . for performance enhancement of various components.

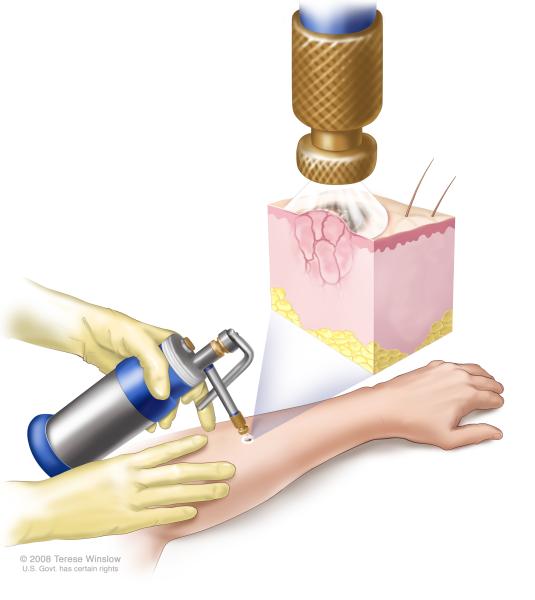

How to cryogenic harden metal?

To perform cryogenic hardening, metal is first exposed to heat using a conventional heat treatment process. Next, the metal is slowly cooled using liquid nitrogen. Once the metal is submerged or otherwise exposed to liquid nitrogen, its temperature begins to drop. The metal is held at a stable, cool temperature for up to 24 hours, ...

What is cryogenic hardening?

Cryogenic hardening, however, is a unique metal treatment process in which metal is intentionally exposed to extremely cold temperatures.

Why is aluminum heat treated?

July 16, 2019. Metals like steel, iron, copper and aluminum are often heat treated to improve their physical properties. When metal is exposed to heat, it undergoes a chemical reaction in which its atoms expand. Normally, heat treatment is performed in conjunction with cooling. After the metal has been heated, it’s rapidly cooled ...

Does cryogenic hardening help metals?

Cryogenic hardening, however, can eliminate these stresses to achieve a uniform composition. It’s also worth mentioning that cryogenic hardening supports a variety of metals.

What is cryogenic treatment?

Cryogenic Treatment greatly reduces or eliminates fatigue failures, as well as the propagation of cracks in the metal components.

What happens when molten metal freezes?

Molten metal freezes – or transforms from its liquid phase to its solid phase – like water. As heat is extracted through cooling, dendrites (or crystals) form from the coolest areas first. Typically, these are at the surfaces and edges.

What is cryo heat?

CryoHeat Metal Treatment provides huge performance gains to metal objects by completely stress reliving the metal . This promotes stronger metal that is more wear resistant, holding greater dimensional stability and capable of dissipating thermal temperatures much easier. CryoHeat has a proprietary process for all different types of metals and they are custom tailored for each application.

What happens to the metals during cryoheat?

During the CryoHeat process there is also a precipitation of fine extra carbides throughout the metal, this is in addition to the larger carbides already present in the ferrous metals. These fine carbides increase the bond within the molecular structure of the metals; which in turn increases wear resistance again.

How many increments does cryoheat work?

The Cryogenic process must be strict and deliberate with slow changes in temperatures occurring. CryoHeat is able to perform this within 1° increments. The post temp process must be just as absolute. That is why you need to use CryoHeat Metal treatment.

How much does cryoheat save?

2 to 4 times the service life and 20 – 50% stronger metal. CryoHeat guarantees about 50% savings or more after the treatment; saving in service, repair and replacement of metal parts.

Does cryogenic treatment change the color of metal?

A properly done Deep Cryogenic Treatment will ensure stress relief. The CryoHeat process will never change the color of the metal in any way, as it will change with a heat treatment. CryoHeat Metal Treatment performs cryogenic processing by simply allowing the molecules to realign in a uniform like fashion.

Why is cryogenic machining important?

Cryogenic machining is useful in rough machining operations, in order to increase the tool life. It can also be useful to preserve the integrity and quality of the machined surfaces in finish machining operations.

What is cryogenic hardening?

Cryogenic hardening is a cryogenic treatment process where the material is slowly cooled to very low temperatures . By using liquid nitrogen, the temperature can go as low as −196 °C. It can have a profound effect on the mechanical properties of certain materials, such as steels or tungsten carbide. In tungsten carbide (WC-Co), the crystal structure of cobalt is transformed from softer FCC to harder HCP phase whereas the hard tungsten carbide particle is unaffected by the treatment.

How is nanostructured material produced?

It can be defined as rolling that is carried out at cryogenic temperatures. Nanostructured materials are produced chiefly by severe plastic deformation processes. The majority of these methods require large plastic deformations ( strains much larger than unity). In case of cryorolling, the deformation in the strain hardened metals is preserved as a result of the suppression of the dynamic recovery. Hence large strains can be maintained and after subsequent annealing, ultra- fine-grained structure can be produced.

What is cryogenic treatment?

Cryogenic treatment is a common process designed to enhance the performance of metal blades. Extreme deep freezing increases the service life of knives by improving their resistance to wear. As a one-time treatment, freezing knife blades makes them more durable and less prone to chipping and fracturing under stress.

What temperature is cryogenic treatment?

Cryogenic treatment goes by many other names, including cryogenic tempering, cryogenic hardening and deep cryogenic treatment (DCT), which usually indicates that the process uses temperatures below 300 degrees Fahrenheit.

How do metal tools harden?

Most manufactured metal tools undergo a hardening treatment process, conventionally done through heat treatment. Cryogenic treatment is an extension of this usual process, following similar steps but adding in the controlled application of a cryogenic fluid, like liquid nitrogen. The cryogenic treatment process can vary depending on a few factors:

What metals are prone to oxidation?

Ferrous metals, like cast iron, stainless steel or steel alloys, and non-ferrous metals, like aluminum or copper, are both prone to oxidation, which increases wear. Oxidation is a chemical reaction that takes place on the metal’s surface when oxygen is present. Over time, oxidation corrodes the metal.

Why do knives need cryogenic process?

Knives and blades need to undergo and repeated use, often under high-impact and severe conditions. They need to maintain their shape, sharpness or strength. Metal becomes harder through the cryogenic process and can then stand up to significant and repetitive use for much longer .

How to improve hardness of metals?

During the manufacturing process , a standard way to improve the hardness of metals, like iron, steel, aluminum or copper, is to expose the material to extreme temperatures. Exposure to extreme heat, also called heat treatment, fundamentally alters the material at its atomic level.

Why cryogenically freezing knife blades?

1. Increases Resistance to Wear and Tear. The primary benefit of cryogenically freezing knife blades is that it increases the blades’ resistance to wear and tear. In industrial settings, maintaining and improving productivity are the primary goals.

What is cryogenic processing?

Industrial Manufacturing. BY using cryogenic processing, Industrial manufacturing operations are able to run longer with fewer changes to gears, dies, and tooling. Production lines require tight specifications, recalls and downtime can eat into profits. That’s why they turn to us.

What is heat treatment?

The heat treatment of metals is commonly understood as the addition of heat to metals, thereby increasing the temperature in a controlled manner, to bring about desirable changes in the crystal structure. The final step in heat treatment procedures is cooling to room temperature.

What is the final step in heat treatment?

The final step in heat treatment procedures is cooling to room temperature. Cryogenic Processing, in contrast, takes advantage of desirable changes to crystal structure if cooling is extended to very low, sub atmospheric temperatures.

What is cryogenic process?

Cryogenic processing involves lowering the temperature of metal engine components to more than -300° F.

What happens when you heat treat metal?

When heat treating, the temperature is increased to the proper “high” temperature for the type of metal being treated. At the correct time, the parts being heat-treated are put in “the quench,” at which time the temperature begins to decrease. It is during the quench that the improvement actually takes place.

What is the uniformity of a metal?

The uniformity of the crystalline or micrograin structure of the metal is at an atomic level. When a piece of steel or cast iron is hardened, it is heated up into a range where the atoms of iron and the atoms of carbon form a particular type of crystal called austenite.

How long does subfreezing last?

The subfreezing condition is maintained for several hours ; then the temperature is carefully and slowly raised again. Many materials then require a heat tempering cycle, so the temperature is raised even higher and then returned to ambient. These cycles may be repeated as needed.

What happens to metal after it is cooled?

As the cooling process takes place, natural stress fractures occur. In addition, even after the metal is formed, cooled and then heat treated, it will usually undergo manufacturing processes such as grinding, cutting, machining, and forging where other stresses and fatigue are introduced.

Does cryogenics work in cold?

But while cryogenics works with severe cold, the truth is, it’s actually an extension of the heat-treating process. A key component of the heat treating process is, of course, the cooling stage. As parts return to room temperature they develop their desired microstructure.

Is cryogenic treatment a coating?

Cryogenic treatment is not a coating, nor is it a simple surface finish that can simply be “machined out.”. The computerized treatment process ensures that the thickest cross-section of the metal is treated – in other words, the entire volume of the metal is structurally changed throughout.