What is a filter press and how does it work?

Steps on How the Filter Press Works

- The press has a control box that acts as a brain of the waste water plant. ...

- Secondly, the sludge is pumps from the bottom of the clarifier into a sludge homogenizing tank. ...

- Then a high-pressure pump sends the uniform sludge into the plates of the filter press. ...

- After that, once full, the high-pressure pump stops, and the plates open. ...

How much water does a filter press clean?

When used in combination with each other, a clarifier and filter press can recover 90-95 percent of your water as clean water. The remaining water will discharge with the solids from the filter press. Total Water Treatment with ChemREADY

What is a filter press used for?

A filter press is one of the oldest and most trusted pieces of dewatering equipment. It’s used for wastewater treatment across a variety of industries and applications. A filter press works by separating out solids from liquids, removing impurities, and suspended solids from industrial wastewater. This allows plant managers to easily handle and dispose of waste while returning clean water to their systems.

What is the best emergency water filter?

- Filter is not compatible with other systems

- Struggles with heavy sediment

- Short filter life of 1,000L

Why do we use filter press?

A filter press works by separating out solids from liquids, removing impurities, and suspended solids from industrial wastewater. This allows plant managers to easily handle and dispose of waste while returning clean water to their systems. Filter presses separate liquids and solids.

What is filter press sludge?

A filter press (FP) provides sludge dewatering by pressing the sludge between a series of porous plates. The process forces water from the sludge by applying high pressures to sludge layers held between a series of 20−80 rectangular plates.

What is a membrane filter press?

A membrane filter press is fed in the same way as a chamber filter press, however the filling level of the chambers can be controlled manually. The increasing feed pressure ensures pre-compression and dewatering of the filter cake in the chamber.

How many types of filter press are there?

There are four main basic types of filter presses: plate and frame filter presses, recessed plate and frame filter presses, membrane filter presses and (fully) automatic filter presses.

What are the advantages and disadvantages of filter press?

Filter Press AdvantagesFewer parts for easy maintenance.Captures a high amount of solids.In some areas, it is the only device capable of producing a cake that is dry enough to meet landfill requirements.Large processing capacity.Long service life.Low energy consumption.

How is filter press capacity calculated?

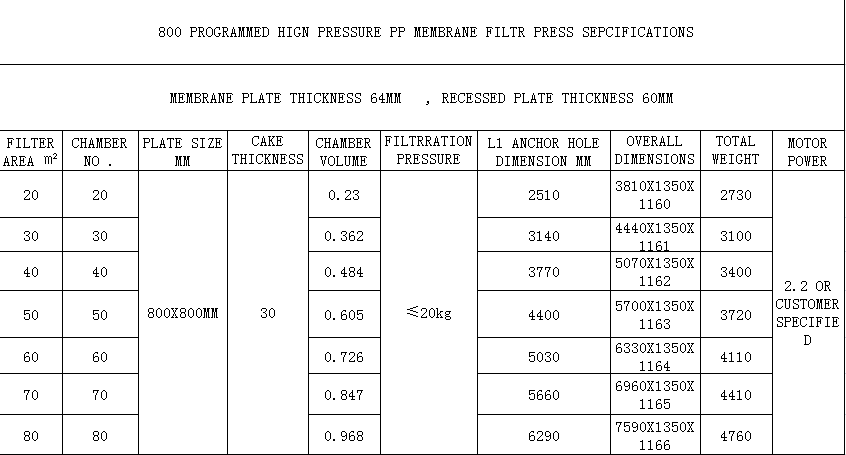

The sizing of a filter press is determined by the volume (in litre) of cakes in the chambers formed between the plates.

How do you know when filter press is full?

1. How do I know when the filter press is full? The diaphragm pump will get to 30 second to one minute intervals between thrusts, indicating that pressure has increased due to solids building up inside the press cavities. This is your signal that the press is full.

How much is a filter press?

These small and automated filter press can cost only between $30,000 and 60,000 typically! This cost is extremely affordable, saving not only money in the press itself, but also labor costs which could be a close equivalent to the same cost of someone operating a manual press for an entire year.

How does a hydraulic filter press work?

1:533:54Process of Filter Press - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere are small holes in each plates to drain out the slurry liquid. This holes are located in theMoreThere are small holes in each plates to drain out the slurry liquid. This holes are located in the bottom of. Plates. The pressurized air enters from the top end flanges this start pressing the slurry

How do I select filter press?

Choosing a Filter PressPlate Size. ... Plate Construction. ... Plate Style. ... Optional Backing Plate. ... Plate and Press Pressure Rating. ... Cake Thickness. ... Cloth Type. ... Frame Design.More items...

What is filter plate?

Filtration plates are used in their simplest form to remove particulate matter from liquid. Either the particulate matter or the filtrate is needed for further study. Porvair Sciences has a range of filter plates to suit most filtration applications.

How do filters work?

filtration, the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that permits the fluid to pass through but retains the solid particles. Either the clarified fluid or the solid particles removed from the fluid may be the desired product.

WHAT IS A FILTER PRESS?

A filter press is a batch operation, fixed volume machine that separates liquids and solids using pressure filtration. A slurry is pumped into the filter press and dewatered under pressure. It is used for water and wastewater treatment in a variety of different applications ranging from industrial to municipal.

HOW DOES A FILTER PRESS WORK?

Slurry is pumped into the filter press. The solids are distributed evenly during the feed (fill) cycle.

HOW LONG DOES A FILL CYCLE TAKE?

The Fill Cycle is dependent on many parameters. The most important parameter is the nature of material to be dewatered. A sand slurry releases its water readily and dewaters quickly. On the other hand, an Aluminum Hydroxide waste slurry from beverage can manufacture does not readily release its water and dewaters slowly.

CAN YOU GIVE SOME EXAMPLES OF FILL CYCLES?

With 32mm (1.25”) cake chamber thickness, 100 psi max feed to the press and a 3-5 SCFM filter cloth, a 5% sand slurry would be expected to dewater in 20-30 minutes and a 10% sand slurry in 10-15 minutes.

WILL A SMALL PRESS FILL FASTER THAN A LARGER PRESS?

The Fill Cycle times for a 1 cubic foot, 10 cubic foot and 100 cubic foot press are approximately the same. Press volume is the ability to remove solids. Associated with this volume is the square feet of surface area in the press.

WHAT TYPE OF PUMP SHOULD I USE TO FEED MY PRESS?

For press capacities of 125 cubic feet or less, the double Air Operated Diaphragm pump (A OD) is uniquely suited for filter press operations. The filter press is not a constant flow device. As the solids build up within the press, the resistance to flow increases and the flow rate through the press decreases. At a given air pressure supply, the time between pump strokes for an AOD pump, then, constantly increases with no harm done to the pump.

IS THERE ANY WAY TO QUICKLY RELATE THIS RULE OF THUMB INFORMATION TO PRESS CAPACITY?

The vast majority of filter presses sold are 125 cubic feet in capacity and below. The table below gives quick guidelines. However, there are always overlaps at the ends of the range. A 15 (or 16) cubic foot press can be fed with a 1.5” or 2” pump.

What is a Filter Press?

A filter press is a piece of equipment used in liquid/solid separation. Specifically, the filter press separates the liquids and solids using pressure filtration, wherein a slurry is pumped into the filter press and is dewatered under pressure. Basically, each filter press is designed based on the volume and type of slurry that needs to be dewatered. Micronics, Inc. is a trusted expert in liquid/solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering. These include configurations such as sidebar automatic, manual overhead, automatic dual overhead beam, stainless steel clad, explosion-proof filter presses, vacuum filter presses, and hand filter presses.

What are the factors that determine the design of a filter press?

Design of a filter press depends on a host of factors such as filtration cycle time, cake dryness required, cloth life, whether manual or automated plate shifting is desired, and many other factors.

What is a micronics filter press?

Micronics is the world-wide authority on filter presses and advanced liquid filtration technology. Here, we’ll explore the question – how does a filter press work? We will also examine the applications where they are most frequently utilized, and some of Micronics’ standard and custom filter press solutions.

What size filter plate is used for a filter press?

Filter presses can be built in a wide range of sizes, from small, lab-scale 150 mm presses, to those with much larger capacities, such as those with 1500 and 2000 mm filter plates. Filter presses are used for liquid/solid separation in an extensive range of industries and applications including:

Can you add videos to your watch history?

Videos you watch may be added to the TV's watch history and influence TV recommendations. To avoid this, cancel and sign in to YouTube on your computer.

What is a Filter Press?

A filter press is a piece of dewatering equipment that is used to separate liquid and solids. Filter presses achieve this by using high-pressure filtration to separate the liquid and solids, as slurry is pumped into the filter press.

How Does it Work?

Filter presses are designed to hold a specific volume of material and separate the liquids and solids through pressure filtration. A slurry is pushed into the filter press and subjected to high pressure for dewatering. As the pressure builds, solids begin to build within the chambers.

Filter Press Advantages

The filter press has many advantages that other dewatering methods cannot provide. These include:

Is a Filter Press Right for My Sludge Dewatering Project?

The filter press is generally used when sludge characteristics are poor and require more than 35% cake dryness. If sludge characteristics are expected to change, or if minimal conditioning is needed, the filter press can also be helpful.

About Handex

Handex is a provider of Pumping, Dredging, Sludge Dewatering, and Treatment of industrial and process wastes. Our staff includes experienced Project Managers, Engineers, Operators, Technicians, Fabricators, Scientists, Mechanics, and Health and Safety Professionals.