What is coagulation and flocculation in wastewater treatment?

What is coagulation and how is it used in water treatment?

- Works to treat particles that are suspended in the water — not just those which have already formed non-suspended solids.

- Forms clumps or flocs that can be removed from the water relatively simply.

- Cost-effective, as the chemicals required in coagulation are not difficult or expensive to obtain.

What is conventional water treatment process?

conventional treatment processes in detail. 1. Raw water basins slow the water’s velocity after it passes through the intake structure, allowing heavy sediment and grit to settle to the bottom of the basins before the water enters the treatment plant. 2. Chemical coagulants are added to react with the remaining small particles in the water to form particles large enough to settle out.

What is coagulation process?

Coagulation, also known as clotting, is the process by which blood changes from a liquid to a gel, forming a blood clot.It potentially results in hemostasis, the cessation of blood loss from a damaged vessel, followed by repair.

What are flocculants and coagulants for wastewater treatment?

Removal of Inorganics

- Arsenic removal. Arsenic is a commonly occurring toxic element and long term exposure to arsenic is injurious to health.

- Fluoride removal. In 1975, the EPA named fluoride as a contaminant in the National Interim Primary Drinking Water Regulations.

- Chemical Phosphorus Removal. ...

What is used in coagulation in water treatment?

Aluminum sulfate (alum) is the most common coagulant used for water purification. Other chemicals, such as ferric sulfate or sodium aluminate, may also be used. Coagulation is usually accomplished in two stages: rapid mixing and slow mixing.

What does the coagulation and flocculation stage of water treatment involve?

Coagulation-flocculation: The use of chemical reagents to destabilise and increase the size of the particles; mixing; increasing of flog size, A physical separation of the solids from the liquid phase. This separation is usually achieved by sedimentation (decantation), flotation or filtration.

How does coagulation filtration work?

A coagulant (typically either iron or aluminum salts with polymeric materials) is added and mixed with the influent water. The larger particles formed by coagulation are then removed from the water by filtration (typically sand, anthracite coal, or a combination of the two).

What is coagulation in water treatment PDF?

Coagulation is the destabilization and aggregation of a colloidal dispersion to permit particle removal by sedimentation and for filtration. The physical chemistry of coagulation may be considered as: 1.

What kind of process is coagulation filtration?

precipitative processCoagulation/filtration is a precipitative process. The most widely used coagulants for water treatment are aluminum and ferric salts, which hydrolyze to form aluminum and iron hydroxide particulates, respectively.

Is coagulation used in wastewater treatment?

Coagulation plays a vital role in the wastewater treatment process, allowing for solids removal and dewatering, water clarification, lime softening, and sludge thickening.

What are the coagulation process?

Coagulation, also known as clotting, is the process by which blood changes from a liquid to a gel, forming a blood clot. It potentially results in hemostasis, the cessation of blood loss from a damaged vessel, followed by repair.

What is the function of coagulation in water treatment quizlet?

The purpose of coagulation and flocculation is to remove particulate impurities and color from the water being treated.

What is the purpose of coagulation water treatment?

The purpose of coagulation water treatment process is to removes the colloidal particles from water. The water may contain suspended matter, small or large solid particles. Sedimentation and filtration processes can removes most of the solid particles but the small particles that are remains in colloidal suspension cannot removes.

What is the process of coagulation?

The process of consolidation of colloidal particles by neutralizing the charges with a coagulant, so that they can remove from the treated water by sedimentation or filtration is called coagulation. It is a vital part for drinking water and wastewater treatment.

What is a coagulant?

Coagulants. Coagulants are the chemicals that are used to removes tiny particles in water. We used different types of coagulants in coagulation water treatment process. Generally, we can categories the common type of coagulant into two groups, aluminium base and iron base.

What is the name of the chemical that neutralizes the negative charges on colloidal particles?

This chemical is known as coagulant. The positive charges of the coagulant neutralize the negative charges on the colloidal particles. As a result the particles are able to coagulate into coarse formations which are easily removable. The process of consolidation of colloidal particles by neutralizing the charges with a coagulant, ...

What are the factors that affect the coagulation of water?

The process of coagulation of water depends on various factors like pH of the medium, temperature of water, coagulant feed concentration, coagulant dosage, type of coagulant, mass and initial turbidity. Moreover it is also depends on pre-treatment and type of pollutants present.

What is the pH of alum coagulant?

pH affects on the activities of coagulants. The optimum pH for alum coagulation is 6 to 7.5 whereas 5.0 to 8.0 are for iron. If the alkalinity is lower or higher, then the floc does not form properly. As a result, more coagulant is consumed. In this case, it is beneficial to correct the pH by adding acid or base.

Why is alum added to water?

Usually a metallic salt like alum is added as a coagulant to create positively charged ions. Normally 5-10% solution of coagulant is used.

What is a Coagulant for Water Treatment?

Ferric sulfate, aluminum sulfate, or ferric chloride, classed as aluminum or iron salts, are common coagulants for water treatment.

How Does Coagulation Treatment Work?

Coagulation treatment is usually carried out before sedimentation and filtration. During the process, a coagulant is added to water, and its positive charge neutralizes the negative charge of suspended contaminants.

What Is Removed During Coagulation?

Coagulation is most effective at removing suspended solids and natural organic matter like gravel, sand, algae, clay, iron, protozoa, and even bacteria. Many of these contaminants can give water an unpleasant taste when present in large quantities, and can also give water a brown or orange color.

What Are the Most Common Types of Coagulants?

The most commonly used chemical for coagulation is aluminum sulfate. Ferric sulfate, ferric chloride, or sodium aluminate are also popular types of coagulants.

How to Choose a Coagulant for Water Treatment

The type of coagulant used by your local water treatment facility will usually depend on availability and affordability. With aluminium sulfate being available, affordable and highly effective, it is the preferred choice for public water treatment around the world.

About the author

Brian Campbell is the founder of WaterFilterGuru.com, where he blogs about all things water quality. His passion for helping people get access to clean, safe water flows through the expert industry coverage he provides. Follow him on twitter @WF_Guru or contact him by email [email protected]

Why is coagulation important in water treatment?

It is, however, an important primary step in the water treatment process, because coagulation removes many of the particles, such as dissolved organic carbon, that make water difficult to disinfect. Because coagulation removes some of the dissolved substances, less chlorine must be added to disinfect the water.

Why are pathogens removed from water?

Usually, the pathogens that are removed from the water are removed because they are attached to the dissolved substances that are removed by coagulation. In the picture below, the coagulants have been added to the water, and the particles are starting to bind together and settle to the bottom.

What is the most widely used water treatment technology?

Many water treatment plants use a combination of coagulation, sedimentation, filtration and disinfection to provide clean, safe drinking water to the public. Worldwide, a combination of coagulation, sedimentation and filtration is the most widely applied water treatment technology, and has been used since the early 20th century.

What is added to ferric chloride?

If ferric chloride is used, iron and chloride are added. And if aluminum sulphate is used, aluminum and sulphate are added. The majority of municipal water treatment plants use aluminum sulphate as the coagulation chemical. Generally, water treatment facilities have the coagulation process set up so that the coagulant chemicals are removed with ...

What is residual water?

Residuals are the by-products that remain in the water after substances are added and reactions occur within the water. The particular residuals depend on the coagulant that is used. If ferric sulphate is used, iron and sulphate are added to the water. If ferric chloride is used, iron and chloride are added.

What is slow sand filtration?

that are used. Slow sand filtration removes bacteria, protozoa and viruses, and produces. essentially clean water, though it is still advisable to use a disinfectant as a precautionary. measure.

How is fine sand removed from water?

Particles with a diameter greater than 100 microns (or 0.1 millimetre), such as fine sand, are removed through sand filtration. As the pore size decreases, a greater proportion of material is retained as the water passes through the filter.

How is coagulation affected by pretreatments?

Coagulation is affected by the type of coagulant used, its dose and mass; pH and initial turbidity of the water that is being treated; and properties of the pollutants present. The effectiveness of the coagulation process is also affected by pretreatments like oxidation.

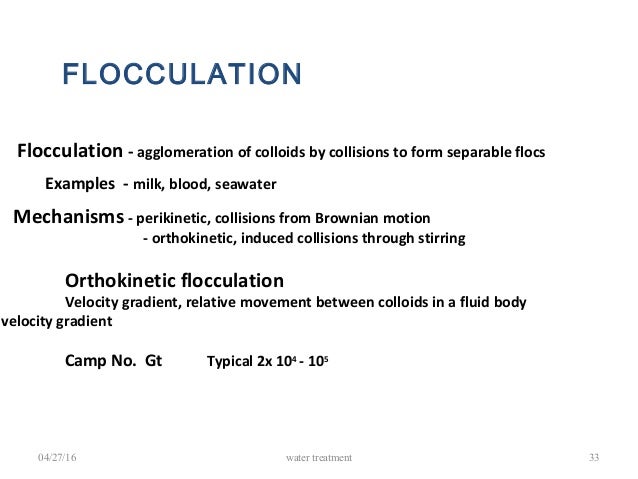

What is the difference between coagulation and flocculation?

Coagulation (water treatment) In water treatment, coagulation flocculation involves the addition of compounds that promote the clumping of fines into larger floc so that they can be more easily separated from the water. Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process ...

What is the SCD for coagulant dose?

The SCD measures the net surface charge of the particles and shows a streaming current value of 0 when the charges are neutralized ( cationic coagulants neutralize the anionic colloids ). At this value (0), the coagulant dose can be said to be optimum.

What force causes colloidal particles to cling together?

Once the repulsive charges have been neutralized (since opposite charges attract), van der Waals force will cause the particles to cling together (agglomerate) and form micro floc.

Why do colloidal particles settle slowly?

In a colloidal suspension, particles will settle very slowly or not at all because the colloidal particles carry surface electrical charges that mutually repel each other. This surface charge is most commonly evaluated in terms of zeta potential, the electrical potential at the slipping plane. To induce coagulation, a coagulant (typically a metallic salt) with the opposite charge is added to the water to overcome the repulsive charge and "destabilize" the suspension. For example, the colloidal particles are negatively charged and alum is added as a coagulant to create positively charged ions. Once the repulsive charges have been neutralized (since opposite charges attract), van der Waals force will cause the particles to cling together (agglomerate) and form micro floc.

Is coagulation a physical process?

Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process and does not involve neutralization of charge. The coagulation-flocculation process can be used as a preliminary or intermediary step between other water or wastewater treatment processes like filtration and sedimentation.

What Coagulants Are Used In Water Treatment?

In order to use coagulation in your water treatment, you have to apply coagulants to chemically initiate the process. These specialty chemicals should be formulated to meet your specific water quality application based on a particle analysis of your dissolved/suspended solids.

Organic Coagulants

Organic coagulants are best used for solid-liquid separation. They are also good options to use when trying to reduce sludge generation. Being organic in nature, these coagulants offer the added benefits of working at lower doses and having no effect on the pH of your water.

Inorganic Coagulants

Inorganic coagulants are typically cheaper than their organic counterparts, making them a cost-effective solution for a broad range of water treatment applications. They are especially effective when used on raw water with low turbidity.

ChemREADY: Your Water Treatment Experts

With our chemical expertise and mechanical filtration knowledge, ChemREADY offers total water treatment assistance for industrial processes of any kind.

What types of coagulants are there?

Metal coagulants fall into two categories: those based on aluminium and those based on iron. The aluminium coagulants include aluminium sulphate and aluminium chloride and iron coagulants ferric sulphate, ferrous sulphate, and ferric chloride. Along with these, other chemicals also used as coagulants include hydrated lime.

Coagulation for Removal of Natural Organic Matter

Natural organic material is usually humid substances arising from the aqueous extraction of living woody substances. This includes the degradation of products in decaying wood and the solution of soil organic matter.

Coagulation for Removal of Inorganics & Arsenic

Coagulation can be used for the removal of inorganics such as and mercury reductions from wastewater plant effluents. There are various ways of removing arsenic from wastewater, however, the removal of arsenic by coagulation can be more economical than other treatments.

Coagulation for Wastewater Treatment

Adding coagulant chemicals to primary clarifiers and physical separation processes is an effective way of reducing the load to downstream biological processes.

Coagulation Treatment Mixers

Coagulation Treatment Mixer systems are designed for several applications, including:

Continuous Flow 3 Stage Tanks

These tanks are split into 3 stages, one for each process distinctive processes – coagulation, flash mixing, flocculation, and clarification. These tanks are sized to give sufficient time and velocity are necessary to maximise the effectiveness of the flocculent.

Polymer Mixing Tanks

Polymer Mixing Tanks are manual preparation systems for powder polymers. These provide an economical and effective solution for effluent treatment in process and industrial applications. Part of an essential part water treatment are a complement to any chemical dosing system.

What is Coagulation in Wastewater Treatment?

Coagulation is a somewhat simple chemical process that involves bringing insoluble materials together by manipulating the charges of particles, by adding iron or aluminum salts, such as aluminum sulfate or ferric sulfate, to a wastewater stream.

What Coagulants Are Used In Water Treatment?

In order to use coagulation in your water treatment, you have to apply coagulants to chemically initiate the process. These specialty chemicals should be formulated to meet your specific water quality application based on a particle analysis of your dissolved/suspended solids.

What Are The Common Coagulation In Wastewater Treatment?

Organic coagulants are best used for solid-liquid separation. They are also good options to use when trying to reduce sludge generation. Being organic in nature, these coagulants offer the added benefits of working at lower doses and having no effect on the pH of your water.

ChemREADY: Your Water Treatment Experts

With our chemical expertise and mechanical filtration knowledge, ChemREADY offers total water treatment assistance for industrial processes of any kind.

What is the process of coagulation?

The coagulation process uses coagulant chemicals to destabilize negatively charged particles in the water, such as dirt, clay, soil, and other organic particles. Since the negative charge is what keeps these dispersed particles from coalescing, neutralizing that charge allows those solids to stick together, creating submicroscopic clumps of particles known as microflocs.

Why is coagulation important in filtration?

While coag ulation helps to encourage particles to combine into larger, more easily filtered clumps, the resultant microflocs are still far too small for standard filtration systems to clear. Flocculation takes the coagulation process a step further by gently agitating the microfloc-containing water at varying speeds to encourage more particle adhesion.

What is the purpose of coagulation and flocculation?

Coagulation and flocculation are two methods used to increase particle size and enhance filtration efficiency. Regardless of the size of the system, coagulation and flocculation are typically the initial steps in water and wastewater treatment.

How does flocculation work?

The flocculation process takes treated water from the coagulation stage and mixes it slowly to increase the collision rate between suspended microfloc particles. As they collide, the microflocs bond further to create larger flocs, which are visible to the naked eye.

Overview

In water treatment, coagulation and flocculation involve the addition of compounds that promote the clumping of fine floc into larger floc so that they can be more easily separated from the water. Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process and does not involve neutralization of charge. The coagulation-flocculation pr…

Factors

Coagulation is affected by the type of coagulant used, its dose and mass; pH and initial turbidity of the water that is being treated; and properties of the pollutants present. The effectiveness of the coagulation process is also affected by pretreatments like oxidation.

Mechanism

In a colloidal suspension, particles will settle very slowly or not at all because the colloidal particles carry surface electrical charges that mutually repel each other. This surface charge is most commonly evaluated in terms of zeta potential, the electrical potential at the slipping plane. To induce coagulation, a coagulant (typically a metallic salt) with the opposite charge is added to the water to overcome the repulsive charge and "destabilize" the suspension. For example, the c…

Determining coagulant dose

The dose of the coagulant to be used can be determined via the jar test. The jar test involves exposing same volume samples of the water to be treated to different doses of the coagulant and then simultaneously mixing the samples at a constant rapid mixing time. The microfloc formed after coagulation further undergoes flocculation and is allowed to settle. Then the turbidity of the sampl…

Limitations

Coagulation itself results in the formation of floc but flocculation is required to help the floc further aggregate and settle. The coagulation-flocculation process itself removes only about 60%-70% of Natural Organic Matter (NOM) and thus, other processes like oxidation, filtration and sedimentation are necessary for complete raw water or wastewater treatment. Coagulant aids (polymers that bridge the colloids together) are also often used to increase the efficiency of the …

See also

• Electrocoagulation

• Industrial wastewater treatment

• Industrial water treatment