Is Alodine bad for your skin?

Although alodine is generally safe and doesn’t pollute the environment, it can be quite toxic to the skin. Therefore, it must be very carefully handled and disposed of after use.

What are the challenges of Alodine surface treatment?

So the challenge is that in specifying an “Alodine” surface in a structural application, it may not provide a stand-alone surface treatment to withstand the exposure of the natural environment for an application that is intended to last several decades – at minimum!

How do you clean your Alodine?

Then dip in cool water and spray with hot water then back to cool for 3 min. Alodine for 3 to 6 min. let hang 30 sec dip in cool water 10 to 15 sec. Dry with air heater. I recently installed a heater in the Alodine to bring it to 70 °F. Since then the parts have come out lighter gold and the 2024 parts don't seem to plate at all.

How to prepare an anodizing surface for Alodine treatment?

In preparation, Alodine treated metals need to be etched with acid first and foremost. Hence, to prepare an Anodizing surface, it must be placed in a saltwater tank and clean of debris.

How do you clean alodine?

Synopsis: Very fresh chem-film (Alodine, Iridite, chromate conversion coating) can be softened with 50% nitric acid, then wiped from aluminum [credit Max Stein & Brian Terry].

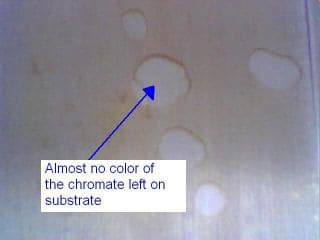

Does alodine rub off?

Yes, in that it is not uncommon to see, but no, in that it's not supposed to come off significantly. Alodine needs some time to cure after processing, a couple days is plenty, before you start handling it normally.

How long do you leave alodine on aluminum?

Allow the Brush Alodine 600 to act on the surface until an iridescent golden to golden yellow coating is obtained. This will take 3-6 minutes depending on the activity and temperature of the surface.

Is alodine corrosive?

In addition to protecting the part, alodine does not add any noticeable weight to an assembly. It does not alter any dimensions on the parts, and it can also be used as a primer for paint. If a part is scratched after it's been treated with alodine, it will still retain its anti-corrosive properties.

How long should alodine sit?

Normally, 1-5 minutes is required for coating formation.

How is alodine applied?

Apply ALODINE 1201: Buildup: For brush application, ALODINE 1201 is applied to a chemically cleaned surface using the solution undiluted. For immersion application, ALODINE 1201 is diluted by mixing 33 parts of ALODINE 1201 and 67 parts of water for each 100 parts of bath volume required.

Does alodine add thickness?

Chem film is applied by dipping, brushing or spraying, and the chromate conversion coating thickness does not change the dimensions of the part.

Is alodine toxic?

Yes, alodine is a dangerous compound and should be handled carefully. Here are some of the effects of this chemical compound. Can cause burns to the skin, eyes and mucous membranes and even blindness. Inhalation may cause ulceration of nasal membranes.

Does alodine contain hexavalent chromium?

Alodine 5200 is a substitute pretreatment for aluminum substrates. It does not contain hexavalent chromium, which has become an issue as of late.

What is the purpose of alodine on aluminum?

Chem film or Alodine is a chemical conversion coating that's mostly used to protect aluminum from corrosion. It's primarily used to passivate aluminum as it protects this metal and serves as a base for paint coatings. It leaves aluminum unaffected, so it's easier to put paint over it without changing anything.

How do you protect aluminum from oxidation?

How to Protect Aluminum From Fading, Oxidation and CorrosionFor architectural , painted or anodized aluminum, use Everbrite Coating.For automotive, marine, and highly polished aluminum, use ProtectaClear.For aluminum that needs antimicrobial protection like railings, use CrobialCoat.

How thick is alodine coating?

0.00001-0.00004 inchesAluminum chromate conversion coating/alodine produces a thin coating in the range of 0.00001-0.00004 inches (0.25-1.0 µm) in thickness. Chemical conversion coatings on aluminum are amorphous in structure with a gel-like composition hydrated with water.

What is Alodine?

Also known as chem film, Alodine is a chromate conversion coating that protects aluminum and other metals from corrosion. In chromate conversion co...

What is Alodine Used For?

Aerospace - Aluminum corrosion protection is critical to aerospace metal finishing applications to prevent surface exposure. Marine - Watercraft, l...

What is a chromate conversion coating?

A chromate conversion coating protects the underlying aluminum against corrosion, serves as a base for paint adhesion, and can allow for electrical...