Coagulation water treatment process

- Coagulants. Coagulants are the chemicals that are used to removes tiny particles in water. ...

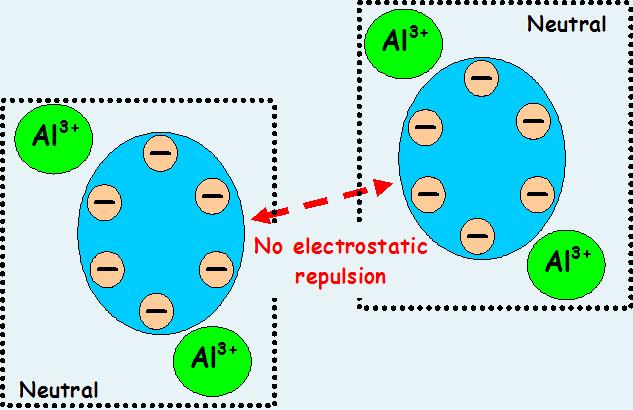

- Coagulation Mechanism. The colloidal particles carry electrical charges; normally negative charge. ...

- Factors affecting coagulation water treatment. ...

- Coagulation jar test. ...

- Conclusion. ...

What is coagulation normal values?

Oct 15, 2021 · During the process, a coagulant is added to water, and its positive charge neutralizes the negative charge of suspended contaminants. Neutralization causes suspended particles to bind together (hence the term). In clumps known as “flocs”, these particles sink to the bottom of the treatment tank. They can then be more easily filtered out of water.

What are flocculants and coagulants for wastewater treatment?

Jul 14, 2021 · The flocculation process follows coagulation in water treatment. Coagulation is the charge neutralisation of fine particles, and flocculants are the agents that then promote the clumping of these particles together. Flocculants are polymers, materials consisting of long, repeating chains of molecules. They are water-soluble, and will stabilise or enhance the …

What does a coagulation test determine?

What is coagulation in water treatment Coagulation is a chemical process in which a chemical compound, a “coagulant”, is added to the water, in order to destabilize the suspended particles and promote creation of flocs. A ‘Stable colloidal particle’ is a colloidal particle that remains as a separate entity in the water, i.e. in a dispersed state.

What is the purpose of a coagulation test?

Flocculation and coagulation treatment chemicals are used in effluent wastewater water treatment processes for solids removal, water clarification, lime softening, sludge thickening, and solids dewatering. Coagulants Coagulation treatment neutralizes the negative electrical charge on particles, which destabilizes the forces keeping colloids apart.

What is the purpose of coagulation in water treatment?

Coagulation is the chemical water treatment process used to remove solids from water, by manipulating electrostatic charges of particles suspended in water. This process introduces small, highly charged molecules into water to destabilize the charges on particles, colloids, or oily materials in suspension.7 days ago

What is the function of coagulant?

3 Coagulants. Coagulants and flocculation processes are used to remove colloidal impurities: suspended particles such as bacteria, clay, silts, and organic matter from the contaminated water. This produces large flock aggregates that can be removed from the water in subsequent clarification/filtration processes.

What are the advantages of using a coagulant in water treatment?

The primary purpose of using a coagulant besides removing vary fine particles from suspension is that this process results also in less turbidity of the water, i.e. clearer water. With coagulants' positive charge, the negatively charged particles in the water are neutralized.

What are advantages of using sodium aluminate as coagulant in the water treatment process?

Key benefitsGives high purity and quality of water.Excellent coagulation, flotation and sedimentation.Increases alkalinity – no need for lime and hydroxides.Excellent removal of phosphor.Minimal chemical sludge.Low transportation cost.

Why is coagulation and flocculation important?

Coagulation and flocculation are essential components of both drinking water and wastewater treatment. They provide a reliable process for treating water turbidity (the cloudiness or haziness of a fluid typically invisible to the naked eye), which is a key test of water quality.

What is the difference between coagulant and flocculant?

Coagulation involves the use of a coagulant which has the potential to de-stabilize the previously stabilized charged particles in the suspension. Whereas in flocculation, the de-stabilization is brought about by physical techniques such as mixing of the solution, and also sometimes by the addition of polymers.Dec 26, 2016

What are Coagulation and Flocculation in Water Treatment?

Coagulation and flocculation are two processes that go together in water treatment. They are separate, but they are used one after the other to remove particles in water.

How Coagulation Water Treatment Works

Coagulation water treatment prevents the suspended particles from repelling one another and encourages them to form into clumps, or flocs.

How Flocculation Works

The flocculation process follows coagulation in water treatment. Coagulation is the charge neutralisation of fine particles, and flocculants are the agents that then promote the clumping of these particles together.

How Does Temperature Affect Coagulation in Water Treatment?

Temperature can have a significant effect on coagulation and flocculation.

Is Coagulation Caused by Bacteria in Water Treatment?

Suspended solids in water can be the result of natural causes, arising from organic materials such as algae, or inorganic materials such as sediment or silt.

How to Maximise the Effects of Water Treatment

Coagulation is a long-established water treatment, but it doesn’t remove all bacteria from water systems.

What is coagulation in water treatment?

Water and wastewater may contain suspended and dissolved impurities that must be removed in order to meet certain water quality criteria. These impurities include:

What is the purpose of coagulation?

Coagulation is a chemical process in which a chemical compound, a “coagulant”, is added to the water, in order to destabilize the suspended particles and promote creation of flocs. A ‘Stable colloidal particle’ is a colloidal particle that remains as a separate entity in the water, i.e. in a dispersed state.

What are coagulants made of?

Organic coagulants include polyamines, polyDADMACS, dicyandiamide and melamine formaldehyde. Inorganic coagulants are mostly based on metallic salts, such as iron sulfate and aluminum sulfate. When they are introduced to the water, they react with the alkalinity of the water and hydrate to form a metal hydroxide.

What are the different types of coagulants used in wastewater treatment?

Types of coagulants used in water and wastewater treatment: Coagulants can be classified as organic coagulants and inorganic coagulants. Organic coagulants are cationic polymers with high molecular weight.

What are the advantages of organic coagulants?

The major advantage of organic coagulants is that produce much less sludge than inorganic coagulants, due to their higher efficiency . Another advantage is that they do not affect the pH of the treated water. Organic coagulants include polyamines, polyDADMACS, dicyandiamide and melamine formaldehyde.

What is the pH of a coagulant?

Therefore, each coagulant has an optimal pH range in which it works best. For example, Alum works best at a pH of 5.8-6.5, Aluminium chlorohydrate (ACH) works at a pH range of 6.5-7.5.

What is the term for the adsorption and bridging of electrolytes?

Adsorption and bridging. Precipitation, or sweep-coagulation. Compression of the double layer – when electrolytes are introduced. Higher concentration of electrolytes neutralizes more charges, and as a result the thickness of the double electrical layer is reduced, and particles get closer to each other.

What is a coagulant in water treatment?

Water treatment coagulants are comprised of positively charged molecules that, when added to the water and mixed, accomplish this charge neutralization. Inorganic, organic, or a combination of both coagulant types are typically used to treat water for suspended solids removal. When an inorganic coagulant is added to water containing ...

When to use organic coagulant?

Organic coagulant is generally used when a reduction in sludge generation is desired. Furthermore, blended organic and inorganic chemicals are often more effective than either organic or inorganic chemicals alone. The correct blend can often combine the advantages of using the inorganic coagulant sweep-floc mechanism with ...

What polymers act similarly to inorganic coagulant products?

Melamine Formaldehydes and Tannins. These all-organic polymers act similarly to the inorganic coagulant products in that they not only coagulate the colloidal material in the water, but also contribute their own precipitated floc. This sweep-floc precipitate readily adsorbs organic materials such as oil and grease.

What is the most widely used class of organic coagulation chemicals?

Polyamine and PolyDADMAC. These are the most widely used classes of organic coagulation chemicals. They function by charge neutralization alone, so there is no advantage to the sweep-floc mechanism. Polyamines will generally treat higher turbidity raw water (approximately >20 NTU) effectively.

Is sludge hazardous to water?

For influent or raw water applications where the sludge is generally non-hazardous, the penalty for creating more sludge with higher water content is small. For wastewater applications with hazardous sludge, the economic penalty can be significant.

Is ferric chloride a coagulant?

Ferric chloride is generally the least expensive inorganic coagulant, because it is generated as a waste material from steel-making operations (waste “pickle liquor”). However, it is by far the most corrosive and hazardous inorganic coagulant, and its use is limited to facilities equipped to handle it safely.

Is coagulation effective in water?

Inorganic coagulation is both cost-effective and applicable for a broad variety of water and wastewater. Inorganic coagulant treatment is particularly effective on raw water with low turbidity (total suspended solids concentration) and will often treat this type of water when organic coagulants cannot.

Why is coagulant added to water?

A coagulant, together with other chemicals, are added in water to aggregate dissolved contaminants and tiny particles into larger particles so that filtration, clarification, or any other solid removal process may be used to remove them.

What is a coagulant in water?

A coagulant is used in colored, low pH or alkaline and low turbidity water. The optimum pH it generates helps in water purification. The coagulate dose used in purification produces a hydrolysis process that generates a pH suitable for coagulation.

Can coagulant cause corrosion?

An inappropriate coagulant dose might lead to corrosion due to acidity, hence one must follow guidelines by the governing authority. To improve on filtration, certain guidelines are placed to govern the change of coagulant in any filtration process.

How is coagulation affected by pretreatments?

Coagulation is affected by the type of coagulant used, its dose and mass; pH and initial turbidity of the water that is being treated; and properties of the pollutants present. The effectiveness of the coagulation process is also affected by pretreatments like oxidation.

What is the difference between coagulation and flocculation?

Coagulation (water treatment) In water treatment, coagulation flocculation involves the addition of compounds that promote the clumping of fines into larger floc so that they can be more easily separated from the water. Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process ...

What is the SCD for coagulant dose?

The SCD measures the net surface charge of the particles and shows a streaming current value of 0 when the charges are neutralized ( cationic coagulants neutralize the anionic colloids ). At this value (0), the coagulant dose can be said to be optimum.

Is coagulation a physical process?

Coagulation is a chemical process that involves neutralization of charge whereas flocculation is a physical process and does not involve neutralization of charge. The coagulation-flocculation process can be used as a preliminary or intermediary step between other water or wastewater treatment processes like filtration and sedimentation.

The role of coagulation in wastewater treatment

In the wastewater treatment process, coagulants play a critical role in dealing with sludge. Often used in combination with other mechanical filtering processes and treatment chemicals, using coagulants helps to thicken the sludge into a form which allows the solids and other particles which are contaminating the water to be easily removed.

The history behind coagulation in the treatment of wastewater

The idea of using coagulation as a way to clean up dirty water is nothing new. There is evidence that the Ancient Egyptians were adding almonds to water in rivers as an attempt to clean it up as early as 2,000 BC. The Romans even added a chemical called alum to water as a coagulant as early as the 8 th century.

How does coagulation work?

In simple terms, coagulation describes a chemical reaction. It involves adding a special chemical product called a coagulant, something like iron or aluminium salts to the wastewater, which then affect the electrostatic charge associated with the small particles suspended in the water.

Where can coagulation be used?

Coagulation can be used in a range of different situations, to deal with specific pollutants affecting your water and causing it to become contaminated. Coagulation is particularly effective against:

How coagulation aids mechanical filtration

The main idea behind using coagulation as a treatment for wastewater is to create a state in the water that allows effective mechanical filtration of the effluent. This involves the formation of flocs or clumps of solid material.

What are the different types of wastewater coagulants?

Coagulation doesn’t happen by itself, and in order to kick-start the process you have to add special coagulant chemicals into the wastewater treatment system. The exact combination of chemicals you’ll use will typically depend on the type and concentration of contaminants that are affecting your effluent streams, and the chemical composition.

Organic coagulants

For solid-liquid separation, one of the best options to think about first is the use of organic coagulation. Organic coagulants are also effective when trying to reduce the total volume of sludge which is created as part of the treatment process.

What happens when you add coagulants to water?

When metal coagulants are added to water the metal ions (Al and Fe) hydrolyze rapidly but in a somewhat uncontrolled manner, forming a series of metal hydrolysis species. The efficiency of rapid mixing, the pH, and the coagulant dosage determine which hydrolysis species is effective for treatment.

Why is coagulation important?

Coagulation is also important in several wastewater treatment operations. A common example is chemical phosphorus removal and another, in overloaded wastewatertreatment plants, is the practice of chemically enhancing primary treatment to reduce suspended solids and organic loads from primary clarifiers.

What is the best coagulant for organics removal?

Organics removal and enhanced coagulation are effective with traditional coagulants like aluminum sulfate, ferric chloride and ferric sulfate, as well as formulations like polyaluminum chloride (PACl) and acid alum. Acid alum formulations are aluminum sulfate with 1 to 15-percent free sulfuric acid.

What are the variables in coagulation?

The efficiency of the coagulation-flocculation process is dependent on many variables. For a particular water these may include: 1 Type of coagulant used 2 Coagulant dosage 3 Final pH 4 Coagulant feed concentration 5 Type and dosage of chemical additives other than primary coagulant (e.g. polymers) 6 Sequence of chemical addition and time lag between dosing points 7 Intensity and duration of mixing at rapid mix stage 8 Type of rapid mix device 9 Velocity gradients applied during flocculation stage 10 Flocculator retention time 11 Type of stirring device used 12 Flocculator geometry.

How does orthokinetic flocculation work?

Orthokinetic flocculation arises from induced velocity gradients in the liquid. It is here that primary particles are induced to approach close enough together, make contact and progressively form larger agglomerates, or flocs. The principal parameter governing the rate of orthokinetic flocculation is the velocity gradient applied. The degree or extent of flocculation is governed by both applied velocity gradients and time of flocculation. These two parameters influence the rate and extent of particle aggregation and the rate and extent of breakup of these aggregates.

What are some examples of coagulation operations?

Coagulation operations can be useful in some cases for the removal of inorganics. Examples of successful applications are copper and mercury reductions from wastewaterplant effluents. Two applications discussed in more detail below are arsenic and fluoride removals in potable water treatment:

Why are synthetic polymers more effective than flocculants?

They are, in general, more effective as flocculants because of the level of control made possible during manufacture. Important mechanisms relating to polymers during treatment include electrostatic and bridging effects.