Can bioreactors be used for biological wastewater treatment?

Various processes that have been successfully developed for wastewater treatment (treatment of industrial wastes/effluents) have been surveyed with special reference to biological treatment including design of bioreactors.

How do bioreactor landfills work?

Aerobic - In an aerobic bioreactor landfill, leachate is removed from the bottom layer, piped to liquids storage tanks, and re-circulated into the landfill in a controlled manner. Air is injected into the waste mass, using vertical or horizontal wells, to promote aerobic activity and accelerate waste stabilization.

What type of bioreactor is used for phenolic wastewater?

Sokol W, Korpal W. Phenolic wastewater treatment in a three-phase fluidised bed bioreactor containing low density particles. J Chem Technol Biot. 2005;80:884–91.

What are the bioreactor projects currently underway within EPA?

Bioreactor Projects within EPA The following is a list of the bioreactor research studies, demonstrations, and guidance projects currently underway within EPA. Project XL (eXcellence and Leadership) is an EPA initiative begun in 1995.

What is a wastewater bioreactor?

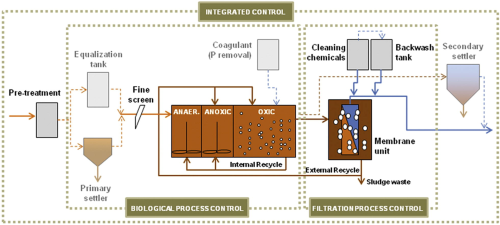

Membrane bioreactors for wastewater treatment is a combination of a suspended growth biological treatment method, usually activated sludge, with membrane filtration equipment, typically low-pressure microfiltration (MF) or ultrafiltration (UF) membranes.

How do bioreactors work?

How Bioreactors Work. Bioreactors consist of a of buried trench with woodchips through which the tile water flows before entering a surface water body. Microorganisms from the soil colonize the woodchips. These microorganisms "eat" the carbon from the woodchips and "breathe" the nitrate from the water.

What are the reactors used in wastewater treatment?

Types of Reactors in Wastewater TreatmentThe Activated Sludge Process. ... The Membrane Bioreactor (MBR) Process. ... The Biodiscs Sewage Treatment. ... Wastewater Treatment Biofilters. ... Trickling Filters in Wastewater Treatment. ... Moving Bed Biofilm Reactor (MBBR)

What is the advantage of MBR?

The MBR technology provides the following advantages over ASP: High-quality effluent, higher volumetric loading rates, shorter hydraulic retention times (HRT), longer solid retention times (SRT), less sludge production, and potential for simultaneous nitrification/denitrification in long SRTs [2,5,13,14,15,16].

What are the advantages of bioreactor?

Advantages and disadvantages of bioreactorsContinuous operation.Good temperature control.Easily adapts to two phase runs.Good control.Simplicity of construction.Low operating (labor) cost.Easy to clean.

What is bioreactor and its applications?

A bioreactor is a device that consists of various features such as an agitator system, an oxygen delivery system, a foam control system, and a variety of other systems such as temperature & pH control system, sampling ports, cleaning, and sterilization system, and lines for charging & emptying the reactor.

What do you mean by bioreactor?

Definition of bioreactor : a device or apparatus in which living organisms and especially bacteria synthesize useful substances (such as interferon) or break down harmful ones (as in sewage)

What are the types of bioreactors?

The major types are:(1) Continuous Stirred Tank Bioreactors.(2) Bubble Column Bioreactors.(3) Airlift Bioreactors.(4) Fluidized Bed Bioreactors.(5) Packed Bed Bioreactors.

What are the components of a bioreactor?

A fully functional bioreactor requires perfect integration of several components to ensure that cultures will finish at the desired productivity. These components include a jacketed stainless steel vessel, temperature control, agitation, sparge gas control, head sweep gas control, pH and dissolved oxygen control.

How does MBR wastewater treatment work?

During MBR wastewater treatment, solid–liquid separation is achieved by Microfiltration (MF) or Ultrafiltration (UF) membranes. A membrane is simply a two-dimensional material used to separate components of fluids usually on the basis of their relative size or electrical charge.

What is MBR in wastewater treatment?

A Membrane bioreactor (MBR) processes are mainly used for wastewater treatment (WWT) by using microfiltration (MF) or ultrafiltration (UF) and integrating them with a biological process like a suspended growth bioreactor.

What are the advantages and disadvantages of MBR?

Specific advantages and disadvantagesAdvantagesDisadvantagesHigh effluent qualityStress on sludge in external MBRHigh volumetric load possibleMembrane pollutionHigh rate of degradationCost pricePossible to convert from existing conventional active sludge purification1 more row

Abstract and Figures

The article touches upon the efficiency of small capacity wastewater treatment plant for industrial sewage. Current operation scheme fails to meet existing regulation requirements due to several drawbacks. The article describes a technology for wastewater treatment and the construction of bioreactor to implement the scheme above.

References (7)

To maintain a comfortable life it is necessary to pay special attention to environmental aspects. This issue is as relevant for small towns as it is for big cities. The most important tasks are studies of wastewater treatment based on the principles of energy efficiency.

What is biological wastewater treatment?

Biological wastewater treatment is a biochemical process that is centuries old. Even today, as the quantity of industrial effluents discharged is on the increase and the types of pollutants present in the effluent streams are getting diversified, wastewater treatment processes are being investigated and experimented exorbitantly all over the globe. It is always desirable to couple wastewater treatment with waste utilization. In such a situation, it becomes invariable to propose and develop renovations in effluent handling and treatment processes to improve their overall economy as well as their energy efficiency. This paper surveys the developments in biological wastewater treatment processes and in the design of bioreactors associated with.

What is stirred tank bioreactor?

As in the case of aerobic treatment of wastes, stirred tank bioreactors are the earliest and still one among the popular ones employed for anaerobic treatment of industrial, domestic and municipal wastes .

What is a UASB bioreactor?

They are sludge bed reactors and they employ sludge granules, which are minute colonies of several classes of microbes that take part in the bioconversion. No support particles are used, the microbial cells collect together and form the sludge granules (the discrete phase). The reactor column consists of a sludge bed at the bottom and a sludge blanket of larger height above it, which is composed of gas bubbles (formed during the anaerobic process) which carry a part of the sludge granules with them as a wake or tail, apart from the substrate solution containing suspended sludge granules. The sludge bed is, in fact, a partially expanded bed. The major share of bioconversion occurs in the sludge blanket.

What is biofilm reactor?

Biofilm reactors employ attached growth of microbes. They are multiphase reactors dealing with heterogeneous systems. These bioreactors employ support particles (with an exception of down-flow stationary fixed film (DSFF) bioreactors, discussed subsequently) such as silica granules, polymer beads, activated carbon particles, etc. Each particle is surrounded by microbial cells forming a thin biofilm. These particle-biofilm aggregates form the discrete phase in these bioreactors. If dP is the diameter of the support particle and δ is the thickness of the biofilm surrounding it, then the diameter of each aggregate ( dPm) shall be

How many bioreactors are there in a series?

The conventional scheme involves two bioreactors (stirred tanks) in series, the first one being the aerobic tank in which carbon removal (organic matter destruction) and nitrification occur, while in the second denitrification is performed anoxically.

What is moving bed biofilm?

The terminology “moving bed biofilm reactors”, commonly employed in association with wastewater treatment, is, in fact, a misnomer. It is not a column reactor (like a circulating fluidized bed or a column reactor in which the particles and the fluid move counter-currently) and it does not contain a particle bed. It is a stirred tank bioreactor which is fed with the particle-biofilm aggregates and these aggregates remain suspended in the substrate solution (wastewater) present in the stirred tank. In the aerobic process, the compressed air that is sparged under pressure from below keeps these aggregates in suspension. Due to the agitation provided by the air stream, these aggregates tend to move within the liquid bulk and that is why the term moving bed biofilm reactors has been assigned to these systems. However, it would be more appropriate to call them as “biofilm slurry reactors”.

What is the EPA doing with bioreactors?

EPA and its state and industry partners are studying and conducting research and demonstrations on bioreactor landfills and other landfills, such as those that re-circulate leachate. EPA hopes to learn more about the possible effects of bioreactor operations and the costs that may be associated with them. EPA's Offices of Solid Waste; Air and Radiation; Policy, Economics, and Innovation; and Research and Development are examining various aspects of bioreactor landfills in order to:

How does a bioreactor landfill work?

A bioreactor landfill operates to rapidly transform and degrade organic waste. The increase in waste degradation and stabilization is accomplished through the addition of liquid and air to enhance microbial processes. This bioreactor concept differs from the traditional “dry tomb” municipal landfill approach.

What is the purpose of the EPA study?

The purpose of this study is to compare data from bioreactor landfills with that from traditional dry landfills.

What data does the EPA need to collect?

In order for EPA to make a determination regarding the benefits of bioreactors, as well as to understand the concerns associated with them, EPA will need to collect data on: Alternative liner design/materials for leachate re-circulation and bioreactor landfills.

What are the considerations of a bioreactor landfill?

Bioreactor landfills generally are engineered systems that have higher initial capital costs and require additional monitoring and control during their operating life, but are expected to involve less monitoring over the duration of the post-closure period than conventional “dry tomb” landfills. Issues that need to be addressed during both design and operation of a bioreactor landfill include:

What is the effect of a bioreactor?

A side effect of the bioreactor is that it produces landfill gas (LFG) such as methane in an anaerobic unit at an earlier stage in the landfill’s life and at an overall much higher rate of generation than traditional landfills. Top of Page. 3. Potential Advantages of Bioreactor Landfills.

What is the type of landfill in a bioreactor?

There are three different general types of bioreactor landfill configurations: Aerobic - In an aerobic bioreactor landfill, leachate is removed from the bottom layer, piped to liquids storage tanks, and re-circulated into the landfill in a controlled manner.

The aeration plant

In 1999, HDR was retained by a southern California gaming facility to evaluate the operation of its extended aeration wastewater treatment plant, which was unable to meet strict effluent water quality standards mandated by the local regulatory agency.

Activated sludge plant

Early this year, HDR was retained by a southern California agency responsible for wastewater treatment and disposal facilities that serve a community of 30,000 people. The existing facility, rated for an average flow of 4.5 mgd, is a conventional activated sludge plant using irrigation fields and percolation ponds for effluent disposal.

Why MBR?

For the most part, municipalities that need to increase treatment capacity, improve effluent quality or consider a water recycling program will be confronted with challenges similar to those illustrated by the above examples. The following facts about MBR can help municipalities make an informed decision.

What is the largest wastewater treatment facility in Maryland?

This WWTP receives domestic wastewater from the Washington County sewer system and pretreatment effluent from the Conococheague Industrial Pretreatment Facility (CIPF), the county’s designated facility for treating wastewater from septic tanks, holding tanks, and chemical toilets.

Where does treated effluent flow?

Treated effluent flows from the Conococheague WWTP into the Conococheague Creek, which is discharged into the Upper Potomac River and the Chesapeake Bay.

What is ENR upgrade?

The ENR upgrade, in conjunction with the addition of the BioMag system, has allowed the WWTP to achieve stringent effluent limits—without the need for effluent filters or tertiary treatment . It offers stable operation across a wide range of flows.

How is biological floc separated?

This is where the biological floc is sheared apart and the magnetite is separated by imparting mechanical energy. The biological floc WAS then flows to the mag drum, which separates magnetite from biological solids. This process is accomplished by permanent magnets mounted inside the rotating mag drum.