Blower is used to transport water, wet sludge and flocculant liquid in sewage treatment because of its variable transportation, strong self-priming ability, reversibility and ability to transport liquid containing solid particles.

What is the purpose of a wastewater blower?

Wastewater Treatment: Design Consideration for Blowers Blowers are mostly used in the secondary phase of treatment to create air bubbles which serve two main processes: aeration and agitation.

How do you choose a blower for wastewater treatment?

Blowers for Wastewater Treatment. Proper aeration and blower selection are two of the most important considerations at a wastewater plant. Aeration energy consumption at wastewater treatment plants typically consumes 60% of all electrical usage. Blowers can offset some of the energy requirements.

Can compressed air be used in wastewater treatment plants?

If the answer is yes, then you might be familiar with using compressed air in wastewater treatment plants. Check out what Airtech Vacuum Incorporated has in store for our customers when it comes to blowers for waste water treatment. Waste water is defined as water that is no longer suitable for use or no longer needed.

Do I need a separate blower for each depth of aeration?

For wastewater treatment plants that use different submersion depths, it may be more beneficial to use separate blowers for the various depths of aeration. Mooers provides custom aeration blowers and blower controls for optimizing water treatment and waste water treatment systems in the USA. What type of blower is best for you?

What are the 3 stages of water treatment?

There are three main stages of the wastewater treatment process, aptly known as primary, secondary and tertiary water treatment.

Why is a vent required on a system with a treatment plant?

Proper ventilation is required for the following purposes: Purging emitted pollutants from plant spaces to protect the structures & equipment. Managing the air introduced and expelled from plant spaces to ensure a clean environment in and around the plant.

How does a water treatment plant operate?

The wastewater enters an aeration tank, where it is mixed with sludge. Air is then pumped into the aeration tank to facilitate the growth of bacteria and other small organisms within the sludge. The bacteria and other microorganisms break down the organic matter in the water into harmless byproducts.

How do treatment plants clean water?

Disinfection. After the water has been filtered, water treatment plants may add one or more chemical disinfectants (such as chlorine, chloramine, or chlorine dioxide) to kill any remaining parasites, bacteria, or viruses.

Do you need to vent every drain?

Without getting too far into building science, a general plumbing rule of thumb is that every drain needs a trap, and every trap needs a vent. All those traps and drains are designed to prevent sewer gas from entering your home.

What does a stink pipe do?

Stink pipes (or stench pipes) are Victorian era stack vents placed above drain waste vents (or DWVs). Their purpose is to provide ventilation for pipe networks that handle sewage and greywater.

What are the 4 steps of water treatment?

4 Steps of Community Water TreatmentCoagulation and Flocculation. ... Sedimentation. ... Filtration. ... Disinfection.

What is the final step of water treatment?

They typically consist of several steps in the treatment process. These include: (1) Collection ; (2) Screening and Straining ; (3) Chemical Addition ; (4) Coagulation and Flocculation ; (5) Sedimentation and Clarification ; (6) Filtration ; (7) Disinfection ; (8) Storage ; (9) and finally Distribution.

What is first step of raw water treatment?

The first step is coagulation, which involves adding chemicals to the water. That causes small particles to adhere to one another, or coagulate. The second step is called flocculation, in which larger particles called flocc form after coagulation.

What are the 5 stages of water treatment?

The 5 major unit processes include chemical coagulation, flocculation, sedimentation, filtration, and disinfection (described below). There are chemicals added to the water as it enters the various treatment processes.

Where does human waste go after a sewage treatment plant?

The treated wastewater is released into local waterways where it's used again for any number of purposes, such as supplying drinking water, irrigating crops, and sustaining aquatic life.

How a treatment plant works?

4:3910:03How Do Wastewater Treatment Plants Work? - YouTubeYouTubeStart of suggested clipEnd of suggested clipInjected from the bubblers creates an environment. Perfect for the process of aerobic digestionMoreInjected from the bubblers creates an environment. Perfect for the process of aerobic digestion summarized. Simply it's the breakdown of organic matter along with the use of excess oxygen.

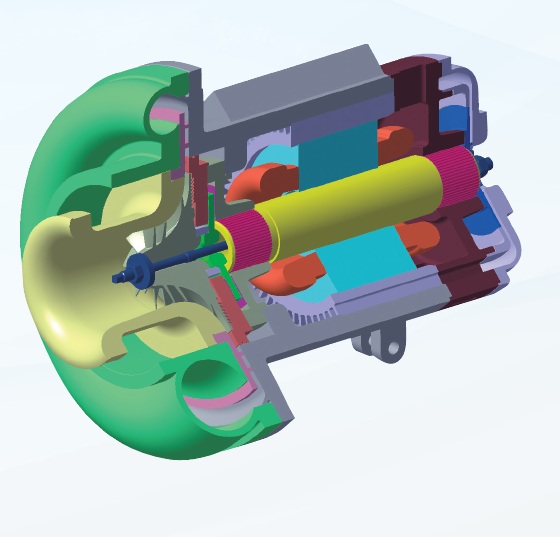

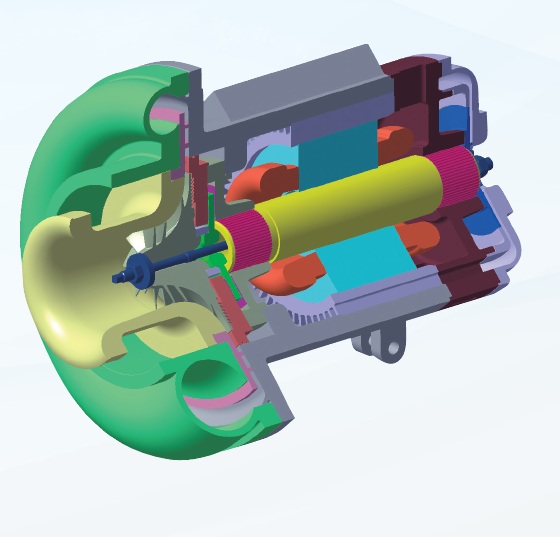

What type of blower is used in aeration tanks?

Depending on the depth of the aeration tank, low or high pressure blowers are used. Low pressure blowers are used in aeration tanks of average depth.

What is the biological approach to wastewater treatment?

This method is based on the destruction of organic compounds by bacteria in aerobic conditions. The bacteria are nurtured in aeration tanks (usually rectangular). In this reservoir, air is pumped into the wastewater. Air-saturated sewage is the ideal environment for ...

What is the purpose of air saturation in aeration tank?

In this reservoir, air is pumped into the wastewater. Air-saturated sewage is the ideal environment for the development of specific aerobic bacteria. There are various means of sewage air saturation in the aeration tank. For this purpose, Bioxica uses different types of blowers such as: vortex,

Do vortex blowers wear?

In these blowers, there are no wearable parts except bearings. Vortex blowers are able to work in compression and vacuum modes. The rotor of BL series blowers is mounted directly on the motor shaft for noncontact compression. As there are no friction pairs in the working area, there is no wear.

Why do industrial plants use waste water treatment plants?

Industrial plants, manufacturing firms, and factories often used physical waste water treatment plants as they need to deal with chemicals and toxins that can harm the environment. Business premises and households are usually matched with biological treatment systems.

Why is wastewater treated?

One of the reasons why it needs to be treated is because it is full of contaminants including chemicals, bacteria, and other nasty toxins, which can be a result of rainwater runoff, ...

What are the two types of waste water treatment plants?

Today, the two main types of waste water treatment plants are biological waste water treatment plant and physical or chemical treatment plants . The first treatment plant type utilizes biological matter and bacteria to break down waste matter.

Is wastewater treatment illegal?

Here is a quick look at the steps and processes of how wastewater is treated: Disposing untreated waste water into oceans, lakes, rivers, and into the environment are illegal acts. If one is found culpable, he or she can be prosecuted. As you can see, waste water treatment is one of the most important environmental conservation processes ...

What are the requirements for a wastewater treatment plant?

Kaeser understands the important requirements wastewater treatment plant designers and operators consider when evaluating and selecting blowers and compressed air equipment. You can reduce life cycle costs of your equipment with components that offer: 1 best possible equipment reliability 2 simplicity and ease of maintenance 3 superior energy efficiency 4 small footprint and ease of installation 5 low-noise operation 6 easy integration into SCADA control systems

What is a Kaeser blower?

To fulfill these needs and more, Kaeser offers fully packaged blower systems for applications including aeration, agitation, membrane scouring, filter backwashing, and bio-gas recovery. Kaeser can also provide complete compressed air systems for controls, instrumentation, and shop air.

What is HR blower?

HR Blowers can offer dissolved oxygen control boxes. The control box will regulate the blower and adjust its set point to reach the desired level of oxygen in the water. It can be configured with multiple blowers and multiple probes connected.

What is the process of aerating water?

Aeration. Aeration is a key process in water treatment , and at its heart the blower is required, Large volumes of are pumped through the water. this process reduces the levels of volatile organic compounds and removes dissolved gasses.

Can HR blowers be used in multiple setups?

HR Blowers can supply a full range of blowers to suit the aeration process, these can be arranged in multiple setups with turndown of up to 50% this allows multiple set points to be covered.

Can you use multiple blowers in parallel?

Load balancing – Multiple blowers can be used in parallel this allows the setpoint to be shared, this reduces the loading of all the blowers and increases the life span of the blowers.

3. Coagulation

Even if the water appears relatively clear and free from large pieces of organic material, looking at a drop under a microscope would probably reveal a world of floating particles and microorganisms. To remove the tiny floaters and swimmers, technicians add chemicals such as aluminum and iron compounds that make them coagulate into small clumps.

4. Flocculation

Flocculation is similar to coagulation but with more dramatic results. In this step, turbines or paddles stir the water for 20 to 30 minutes to increase the frequency with which the smaller pieces bump into each other. This slow agitation causes clumped particles to form larger pieces called flocs.

5. Sedimentation

The flocculated water then rests in a sedimentation basin for 2 to 4 hours. During this time, the flocs gradually sink to the bottom, leaving behind water free from particulate matter. To ensure the sedimentation process removed all impurities, the product flows through a deep layer of sand or anthracite on its way to the final step.

6. Disinfection

The deadliest pathogens in drinking water are invisible to the naked eye. For this reason, the final step is to kill any microorganisms remaining in the otherwise clean drinking water by the addition of disinfectant chemicals. Chlorine is a common substance many plants use, but some also use ozone, chlorine dioxide, or chloramines.

How a drinking water treatment plant works

Water has always been indispensable. We drink it, wash with it, give it to our animals, plants and garden, and use increasing amounts in a range of industries. A water treatment plant puts natural processes to work to remove harmful or unhealthy materials to make water safe to use and drink.

Primary treatment stage

Most water treatment plants have two stages: primary and secondary. The primary stage removes large solid objects from the water. A screen keeps large floating objects from getting into the water supply: logs and sticks, rags, garbage or other debris that can be floating or suspended in the water.