There are 5 important steps in treating municipal water: chemical addition, coagulation and flocculation, sedimentation and clarification, filtration, and disinfection. Let’s look at this process in further detail. Steps in the Municipal Water Treatment Process

...

The sewage treatment plants typically adhere to four stages of treatment namely;

- Primary treatment.

- Secondary treatment.

- Tertiary treatment.

- Sludge treatment.

How do municipal water treatment systems really work?

In most cases of domestic wastewater treatment in developed urban areas, carbon (usually indicated by biochemical oxygen demand [BOD]) and nitrogen (NH4 -N and total nitrogen (TN)) removal are achieved using biological aerobic (BOD oxidation and nitrification) and anoxic treatment (denitrification) as part of the ASP.

What is the best method for wastewater treatment?

There are 5 important steps in treating municipal water: chemical addition, coagulation and flocculation, sedimentation and clarification, filtration, and …

Why is municipal wastewater treatment important?

Municipal Wastewater and Sludge Treatment 49 Secondary municipal wastewater treatment is almost always accomplished by using a biological treatment process. Microorganisms in suspension (in the "activated sludge" process), attached to media (in a "trickling filter" or one of its variations), or in ponds or other processes are used to remove

What is municipal water treatment process?

Sep 14, 2020 · Gravitation sludge dewatering – This is one of the simplest ways to separate sludge from wastewater produced by municipal and industrial sources. This involves storing sludge in a dewatering container and let it drain the water using gravity. At times, vacuum could be used to expedite the dewatering process.

What are the main steps of treatment of municipal wastewater?

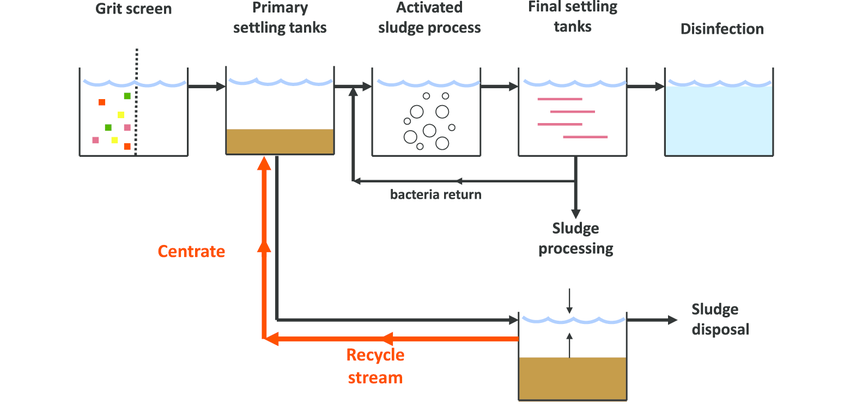

- Step 1: Screening and Pumping. ...

- Step 2: Grit Removal. ...

- Step 3: Primary Settling. ...

- Step 4: Aeration / Activated Sludge. ...

- Step 5: Secondary Settling. ...

- Step 6: Filtration. ...

- Step 7: Disinfection. ...

- Step 8: Oxygen Uptake.

What are the steps of municipal water treatment?

What are the 4 stages of wastewater treatment?

What are the 3 steps to wastewater treatment?

- Primary Treatment. Before wastewater even gets to primary treatment, it is funneled through collection systems and treated with odor-neutralizing chemicals. ...

- Secondary Treatment. In secondary treatment, the goal is to break down wastewater even further. ...

- Tertiary Treatment.

What are the 5 steps of water treatment?

- Coagulation. Coagulation is often the first step in water treatment. ...

- Flocculation. Flocculation follows the coagulation step. ...

- Sedimentation. Sedimentation is one of the steps water treatment plants use to separate out solids from the water. ...

- Filtration. ...

- Disinfection.

What are the 5 stages of water treatment?

Which of the following is a step of wastewater treatment?

What is the first stage of sewage treatment?

Primary wastewater treatment involves sedimentation. This is when wastewater is temporarily held in large sedimentation tanks to remove settleable solids. With gravity, heavier solids sink to the bottom while lighter solids rise to the top.Mar 7, 2021

What is the first stage in sewage treatment process?

How many steps are there in wastewater treatment?

What is primary treatment in wastewater?

Primary treatment will typically remove 60% of the raw sewage suspended solids and 35% of the BOD 5. Soluble pollutants are not removed in this process.

What is sludge in wastewater treatment?

Sewage sludge is a residue of a municipal wastewater treatment plant . Mechanically dewatered sludge contains 12%–25% solid (LHV=12.0 MJ kg−1) with an organic fraction of 56% of dry solids rich in carbon (50%), hydrogen (7%), and oxygen (31%) [44]. This may lead energy recovery by producing biofuels as well as bioproducts beside the incineration commonly used. One way for energy recovery is the gasification of the sludge and conversion of syngas produced into MeOH as well as other chemicals. In the low-pressure MeOH process catalytic synthesis takes place at 77 bar and 200 o C using the cleaned syngas. This will help minimize waste as well as recover energy.

Where was the first Kubota wastewater treatment plant installed?

The first Kubota municipal wastewater treatment works installed outside Japan was at Porlock in the United Kingdom in 1997 (Section 5.3.1.1 ), following successful trials at Kingston Seymour by Wessex Water in the mid-1990s. The first Zenon membrane-based plant of similar size installed outside of the USA was the Veolia (then Vivendi) Biosep ® plant at Perthes en Gatinais in France in 1999 ( Section 5.3.1.1 ). Both these plants have a peak flow capacity just below 2 MLD, and represent landmark plants in the development and implementation of immersed MBR technology.

What is MBR technology?

A simple definition for the MBR technology is a wastewater treatment process that integrates membrane filtration with a biological process 6. In an MBR, membrane filtration replaces the clarifier used in conventional activated sludge processes. The membrane provides a physical barrier that retains the biomass and other suspended solids in the tank, producing an effluent stream with typically less than 0.1 NTU Turbidity. In addition to removing virtually all suspended solids, the membrane can remove emulsified oils and other soluble organics that may not have been degraded by the microorganisms 6,14,15. In terms of commercial applications, the hollow fiber configuration dominates the larger scale municipal & industrial MBR markets. MBR is now considered a mature technology with several units treating volumes greater than 100 MLD. The MBR technology has been implemented in more than 200 countries with a growth in the last decade of around 10% per year 6.

Can MBR be used to treat PW?

Although MBRs are a proven technology for both municipal and industrial wastewater treatment and has had growing acceptance to treat wastewaters from refineries and petrochemical industries, there are no reports of an MBR being used to treat PW from an oil or gas field. However, several field works carried out demonstrated that PW can in fact be biologically degraded. For instance, a field work 16 with PW generated from a Southwestern US oilfield (TDS = 35,000 mg/l; Oil & Grease (O&G) = 147 mg/l; COD = 431 mg/l) concluded that removal efficiencies of 99 % (after clarification stage) could be achieved for O&G and 97% for COD, with a conventional activated sludge process. Another recent work has even shown that some microorganisms can achieve high levels of organic removal in hypersaline media containing 20% NaCl 17. If the MBR technology is proven successful in treating PW at a full scale, the opportunities for this technology in the oil and gas industry are tremendous.

How does MFC produce electricity?

In the MFC, bacteria fed with organic matter produce electrons via oxidation of wastewater on the anode, and thus produce electricity.

What is activated sludge?

Activated sludge is a by-product of municipal wastewater treatment processes. Sludge disposal is a critical issue with environmental perspectives and have 50% of the operational cost of total wastewater treatment. MFCs can meet the necessity of sludge degradation along with energy production. There were various reports which successfully demonstrated the use of activated sludge as a substrate for MFCs [70,71]. Moreover, hydrogen production is also possible, and the yield is two- to threefold higher using microbial electrolysis cells as opposed to fermentative hydrogen production using sludge as the substrate [72].

What are the steps of municipal water treatment?

There are 5 important steps in treating municipal water: chemical addition, coagulation and flocculation, sedimentation and clarification, filtration, and disinfection. Let’s look at this process in further detail.

What is the first step in wastewater treatment?

For treatment of contaminated wastewater, particle filtration is commonly one of the first steps. Particle filtration takes place early in the treatment process because it is designed to remove solids measuring larger than one Micron. Cartridge filtration, bag filtration, and self-cleaning filters are the three common filter types ...

What is the process of adding a chemical to a precipitate?

Chemical addition is the process in which a chemical is added that reacts along with the natural alkalinity to form an insoluble precipitate. The chemicals help make the suspended particles floating in the water clump together to form a gelatinous particle called a floc, which is usually larger and heavier than a single particulate.

What is the process of coagulation and flocculation?

Particles bind with these chemicals, forming floc, similar to the process in the chemical addition step. The treatment unit where coagulation and flocculation are performed is called the “flocculator.”

Where is clarified water collected?

During the filtration process, clarified water enters the filters from above then is collected in a drain system at the bottom of the filter unit. Filters are made up different materials or media, such as sand or gravel.

What is a granular carbon filter?

Granular activated carbon is becoming the media of choice in many conventional plants because it provides mechanical filtration of particulate matter and it removes organic compounds which are often associated with taste and odor problems.

What happens after filtration?

After the filtration process, the water is clear and as clean as it can get but there may still be bacteria and viruses present. To destroy the viruses and bacteria, the disinfection process begins. In the United States, chlorination is commonly used for disinfection.

Does wastewater have to be treated?

Wastewater has the natural ability to treat itself with time. But with increasing population and industrial activity, increased levels of treatment before discharging municipal and industrial wastewater is needed.

Is wastewater treated as simple as it used to be?

Treating wastewater is not as simple a process as it used to be half a century ago. Increasing population, CWA guidelines, changing EPA regulations with a focus on health and safety, throw newer challenges to segregate and process the wastewater.

What are the challenges of water management?

Common Wastewater Management Challenges and Solutions 1 High Biochemical Oxygen Demand (BOD) & Chemical Oxygen Demand (COD) – Aerating the waste can encourage biological oxidation and produce solid waste that can be easily removed via filtration and clarification. 2 High Total Suspended of Dissolved Solids – CWA regulations put a limitation on Total Suspended Solids (TSS) and Total Dissolved Solids (TDS) in wastewater. TSS is often filtered with sand carbon filtration method. TDS require chemical treatment, demineralization, or evaporation. 3 High Nitrate and Phosphate Levels – Nitrates and phosphates enter wastewater streams through human and animal waste. It can be treated with IX, RO, clarification, or biological treatment. 4 Oil and Grease – In addition to environmental damage, oil and grease can clog the waterways and drainage systems. They are often treated with Dissolved Air Floatation (DAF), Ultra-Filtration (UF), and carbon filtration methods. 5 Large Discharge Volume – Some industrial and municipal facilities generate large volumes of wastewater which may demand the implementation of zero liquid discharge systems. This allows chemical volume readjustments, recovers most of the liquid waste for reuse, treats valuable byproducts, and produces dry/ solid cake for disposal.

What is TDS treatment?

TDS require chemical treatment, demineralization, or evaporation. High Nitrate and Phosphate Levels – Nitrates and phosphates enter wastewater streams through human and animal waste. It can be treated with IX, RO, clarification, or biological treatment.

What is secondary wastewater treatment?

Secondary Wastewater Treatment. At this stage, biological organisms are used to naturally separate pollutants from wastewater. The solid waste thus produced settles at the bottom of the tank and can be easily removed. The waste produced is called secondary waste or biological sludge.

What are the sources of waterborne diseases?

Pathogens – Infectious micro-organisms or pathogens are the source of water-borne diseases. They may percolate into the groundwater via industrial activity such as tanning and food processing, or via animal feces from pets and livestock.

What is inorganic waste?

Inorganic waste – Human and industrial activity releases large amounts of inorganic waste into the drainage system which includes detergents, household cleaning liquids, heavy metals, pharmaceuticals, and pesticides.

What is primary treatment in sewage treatment?

Primary treatment is aimed at the removal of fine suspended organic solids that cannot be removed in the preliminary treatment. Primary treatment basically involves the process of sedimentation or settling. In the normal process of sewage treatment, sedimentation is usually carried out twice-once before the secondary treatment, referred to as primary sedimentation, and then after the secondary treatment is complete, a process known as secondary sedimentation. It is sometimes necessary to use chemical coagulants to facilitate or aid sedimentation, and this process is referred to as chemical precipitation or coagulation-aided sedimentation.

What is the biological treatment of sewage?

Biological treatment of sewage is required for the removal of dissolved and fine colloidal organic matter. This process involves the use of microorganisms (bacteria, algae, fungi, protozoa, rotifers, nematodes) that decompose the unstable organic matter to stable inorganic forms.

What is the treatment of sewage in a facultative pond?

In facultative ponds, the treatment of sewage is carried out by a combination of both aerobic and anaerobic processes. Three types of microorganisms aerobic, anaerobic and facultative (both aerobic and anaerobic) are employed in facultative ponds.

What is tertiary treatment?

Tertiary treatment or advanced treatment is sometimes needed for the removal of suspended and dissolved substances, after the conventional primary and secondary treatments. In general, the effluent of the sewage obtained after secondary treatment can be conveniently disposed without causing any nuisance.

What is skimming tank?

Skimming Tanks: Several greasy and oily materials (fats, oils, waxes, soaps etc.) from the domestic or industrial outlets find their entry into the sewage. They can be removed by using a skimming tank which is fitted with baffle walls that divide the tank (Fig. 57.2B).

Why do solid particles settle down in sewage?

The solid particle of the sewage tend to settle down due to gravity. However, most of the solid particles of organic compounds remain in a suspended state in a flowing sewage. If the flow of the sewage is stopped and if it is stored in a tank referred to as sedimentation tank, the solid particles can settle down at the bottom. The process of sedimentation is influenced by several factors. These include the size, shape and specific gravity of particles, besides viscosity and flow velocity of sewage.

What are the different types of settling?

There are four major types of settling—discrete settling, flocculent settling, hindered or zone settling and compression. This categorization is mainly based on the tendency of the particles to interact and form solids.