At present, the refining treatment methods of aluminum alloy melt mainly include: Foreign countries often use vacuum smelting and rotary spraying of inert gas to complete the purification and alloying treatment of aluminum alloy melt to achieve the purpose of refining aluminum alloy melt.

What are the effects of accelerators on the phosphating process of aluminum?

The effects of accelerators, fluorides, Mn2+, Ni2+, Zn2+, PO4; and Fe2+ on the phosphating process of aluminum have been studied in detail by using SEM, XRD, potential-time curve, film weight change and other methods. Studies have shown that guanidine nitrate has the characteristics of good water solubility, low dosage, and rapid film formation.

Why does the material need to be surface treated?

The material needs to be surface treated before application to improve its corrosion resistance and form a surface layer that is easy to combine with the organic coating to facilitate the subsequent surface.

What is the role of nitric acid in chemical polishing of aluminum?

For this reason, it is necessary to analyze the three-acid chemical polishing process of aluminum, especially the role of nitric acid. The main function of nitric acid in aluminum chemical polishing is to inhibit pitting corrosion and improve polishing brightness.

What is a common surface treatment of aluminum alloys?

Typical aluminum surface treatment methods include anodic oxide coating, coloration, coating, mechanical surface treatment, chemical film coating, bright anodic oxide coating (gloss treatment), enamel coating, and plating.

What is the most common surface treatment of aluminum alloy surfaces?

Anodizing is the most common surface treatment of nonclad aluminum alloy surfaces.

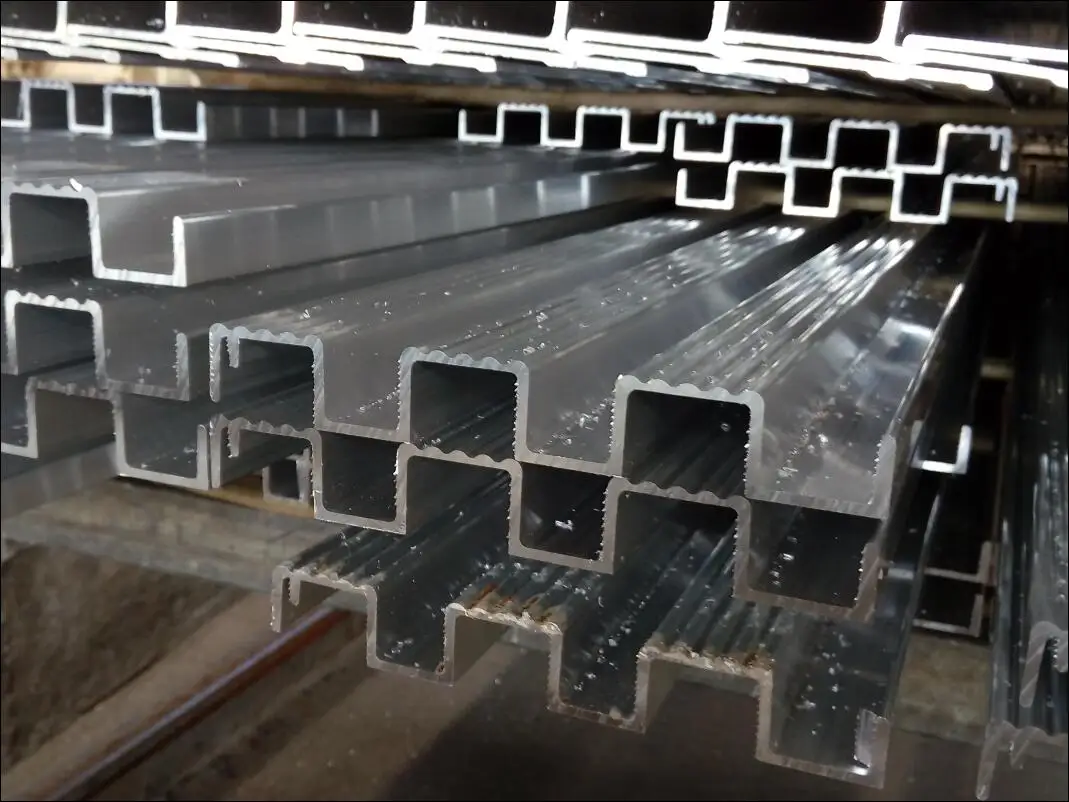

How are aluminum alloys processed?

Common aluminium alloy hot processing methods include hot extrusion, hot rolling, hot forging, hot upsetting, liquid forging, semi-solid forming, continuous casting and rolling, continuous casting and rolling, continuous casting and continuous extrusion.

What is the best strengthening method for aluminum?

All aluminum alloys can be strengthened by cold working. During the cold working, the strength of a metal increases due to the increase in the number of dislocations in the metal compared to its pre-cold-worked condition.

How do you treat aluminum?

The typical aluminum heat treatments are annealing, homogenizing, solution heat treatment, natural aging, and artificial aging (also known as precipitation hardening). Depending on the exact process being used, furnace temperatures can range from 240 to 1000°F.

What is surface treatment of alloys?

Surface treatment is an additional process applied to the surface of a material for the purpose of adding functions such as rust and wear resistance or improving the decorative properties to enhance its appearance.

What is the process of alloying?

The Alloying Process To create an alloy, the metals (or a metal and a nonmetallic element) are heated until they are molten. The two elements are mixed and the solution is poured into metal or sand molds to solidify. The resulting alloy is a combination of the two elements.

Which process is applied for production of aluminium from bauxite?

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer.

What is the forming method used for aluminium to make it into the I section?

Answer: ELECTROSYASIS. Explanation: Highly electropositive elements like Na, K, Al, Mg, Ca, Al can't be reduced by Carbon at moderate temperature.

How are metal alloys strengthened?

Thus a higher stress is required to move dislocations thereby increasing the strength. The principal strengthening mechanisms in metals/alloys include: strain hardening, solid-solution strengthening, grain-boundary strengthening, precipitation strengthening, and dispersion strengthening.

How do you strengthen wrought aluminum alloys?

Heat-treatable alloys can be strengthened by heat treatment. Alloys of 2xxx, 6xxx and 7xxx series are heat-treatable. The initial strength of these alloys is achieved due to the hardening effect of the alloying elements: copper (Cu), silicon (Si), magnesium (Mg) and zinc(Zn).

How do you make aluminum alloys?

The alloy is made by mixing together the elements when aluminum is molten (liquid), which cools to form a homogeneous solid solution. The other elements may make up as much as 15 percent of the alloy by mass. Added elements include iron, copper, magnesium, silicon, and zinc.

2. Alkaline electrolytic polishing process of aluminum

Conducted research on alkaline polishing solution system, compared the effects of corrosion inhibitors, viscosity agents, etc.

3. Environmentally-friendly chemical polishing of aluminum and aluminum alloys

It is determined to develop a new environmentally-friendly chemical polishing technology based on phosphoric acid-sulfuric acid as the base fluid. This technology must achieve zero emission of NOx and overcome the quality defects of similar technologies in the past.

4. Electrochemical surface strengthening treatment of aluminum and its alloys

The process, properties, morphology, composition and structure of the ceramic-like amorphous composite conversion coating formed by anodic oxidation and deposition of aluminum and its alloys in a neutral system were preliminarily discussed.

5. YL112 aluminum alloy surface treatment technology

YL112 aluminum alloy is widely used in structural parts of automobiles and motorcycles. The material needs to be surface treated before application to improve its corrosion resistance and form a surface layer that is easy to combine with the organic coating to facilitate the subsequent surface.