What is a trickling filter used for?

United States Environmental Protection Agency Office of Water Washington, D.C. Trickling filters (TFs) are used to remove organic matter from wastewater. The TF is an aerobic treatment system that utilizes microorganisms attached to a medium to remove organic matter from wastewater.

How trickling water treatment works?

The fixed media in Trickling water treatments filter may be of rocks, plastic, metal, etc. In Trickling water filter there is no straining or filtering action involved. Passing of waste water after primary water treatment through the filter causes the development of a gelatinous coating of bacteria, protozoa and other organisms on the media.

What is the difference between activated sludge treatment and trickling filter?

Unlike activated sludge treatment, the trickling filter follows an attached growth system inspite of suspended growth system. In this article, we will highlight the design or construction, operation, types, advantages and disadvantages of the trickling filter.

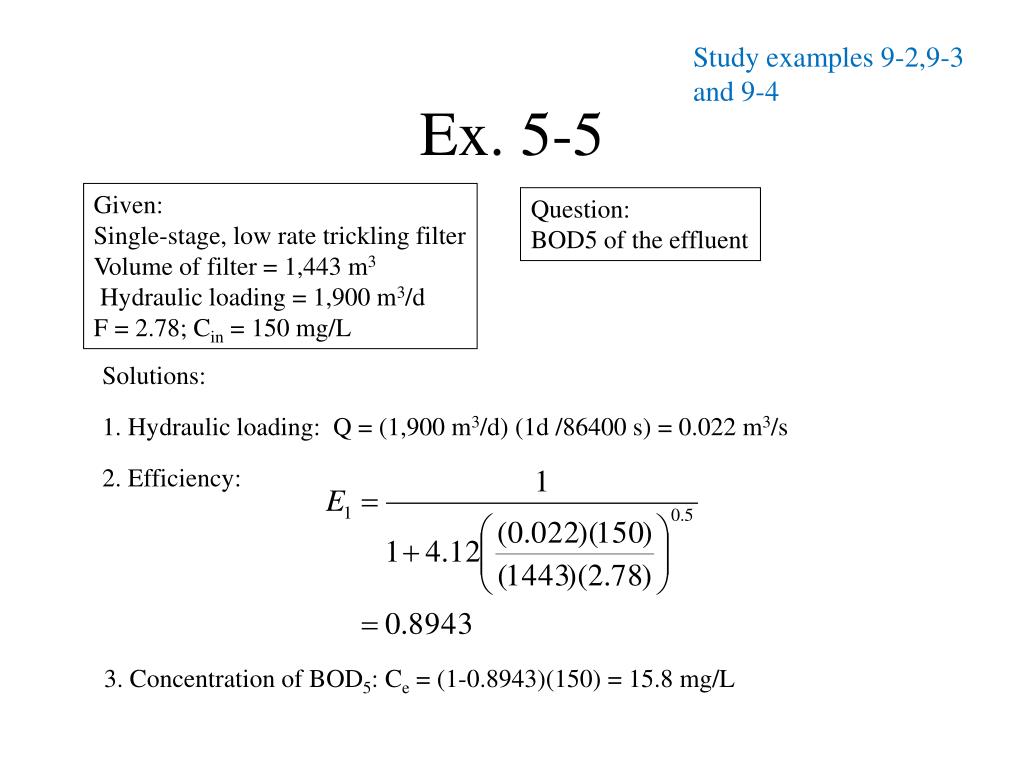

What is the effluent flow rate of a trickling filter?

A trickling filter that is 80 ft in diameter is operated with a primary effluent of 0.588 MGD and a recirculated effluent flow rate of 0.660 MGD. Calculate the hydraulic loading rate on the filter (in gpd/sq ft).

How does a trickling filter work wastewater treatment?

A trickling filter uses filtration, adsorption, and assimilation for removal of contaminants from wastewater. Wastewater should flow in a thin film over the media to allow time for treatment. The media serves as a substrate where a biological film grows and is fed by the nutrients contained in the wastewater.

What type of treatment process followed in trickling filters?

primary treatmentIn most wastewater treatment systems, the trickling filter follows primary treatment and includes secondary settling tank or clarifier as shown below. The process is a fixed film biological treatment method designed to remove BOD and suspended solids.

Does trickling filter remove suspended solids?

Trickling filters are widely used for the treatment of domestic and industrial wastes. The process is a fixed-film biological treatment method designed to remove BOD5 and suspended solids.

What are the advantages of trickling filter?

4.2. 1 Trickling filtersAdvantagesDisadvantagesSimple and reliableNeed to additional treatmentLow power requirementVector and odor problemsNeed to moderate level of technical expertise for managing the systemNeed to regular operator attention

How many types of trickling filters are used in sewage treatment?

4. How many types of trickling filters are used in sewage treatment? Explanation: The trickling filters are divided into conventional and high rate trickling filters.

Which is better trickling filter or activated sludge?

Although trickling filters are more easily operated and consume less energy than activated sludge processes, they have a lower removal efficiency for solids and organic matter, they are more sensitive to low air temperatures, and can become infested with flies and mosquitoes (UNEP et al. 2004).

What is the difference between activated sludge process and trickling filter?

The key difference between activated sludge and trickling filter is that activated sludge is a suspended culture system in which biomass is mixed with the sewage while trickling filter is an attached culture system in which biomass is grown on media and the sewage is passed over its surface.

Which type of bacteria are used in trickling filter?

Explanation: Facultative bacteria are used in trickling filters. Pseudomonas and Alcaligenes are some of the strains used in these filters. Also, Flavobacterium and Achromobacter are also used in this type of treatment.

What is a trickling filter?

Trickling filter process is one of the types of aerobic wastewater treatment. It is a fixed-bed bioreactor that is the part of secondary wastewater treatment, which eliminates the coarse particles, suspended organic and inorganic waste, small colloids etc. out of the primary effluent. A trickling filter is also called biological filter, as it makes the use of active microbial mass as a bioweapon to degrade the waste out of primary sewage.

What is the hydraulic load of a trickling filter?

The hydraulic loading rate can define as the sewage flow ( Q) per unit volume ( V) of filter bed in a day, while the organic loading rate can define as the kilograms of BOD ( Y5) introduced into the per unit volume ( V) in a day.

What is the BOD removal efficiency of a standard and high rate trickling filter?

The BOD removal efficiency of both standard and high rate trickling filter is about 75 to 90%. The nitrification of the primary effluent is relatively higher in low rate filters, whereas high rate trickling filters produce partially nitrified effluent.

What is the role of microorganisms in wastewater filter media?

Thus, the microorganisms in the filter media play a pivotal role in degrading the organic matter in the sewage, thereby minimizes BOD and COD from the sewage.

How deep is a sewage filter bed?

Filter bed: It is a bed chiefly containing crushed rock or other coarse media. The construction of a filter bed is roughly 6 feet deep and 200 feet in thickness. Settled sewage is flushed evenly over the filter bed containing organic and inorganic waste via continuously rotating distributor’s arm. Holes within the rotary distributor arm facilitates the trickling of primary influent and settled sewage throughout the filter bed.

How does a filter bed work?

It works under the aerobic conditions and makes the use of aerobic microbes so that they can exploit or oxidize the organic matter into a simpler form. The filter bed is placed below the pebble filled media, which aids the separation of secondary effluent out of waste activated sludge.

What is the purpose of a filter bed?

The microorganisms attached to the filter bed utilize organic waste as a food material. The pollutants like organic and inorganic waste in the sewage suspension go through the absorption and adsorption into and over the filter bed by the microbial slime layer.

What is a trickling filter?

Originally built using rock or stone media, Trickling Filters have proved simple to run, reliable, energy e˙cient and able to achieve successful treatment. The modern version of Trickling Filters uses the structured plastic cross-˝ow media.

Why are trickling filters important?

While management and monitoring is essential, Trickling Filters are designed to minimize the necessity for operator involvement in the simpler filtration processes.

How much carbon is in a trickling filter?

Sustainability Studies show that a gravity fed Trickling Filter has a carbon footprint (including construction and 25-year operation) which is around 10% of an Activated Sludge Plant. If the system were pumped, this would equate to around 30% of a similar sized activated sludge plant.

How long does a trickling filter last?

During the 25-year lifetime of a Trickling Filter, over 90% of the carbon (CO2) footprint results from day to day operations, such as pumping the feed up to the ˚lter and recycling water, either by separate pump or by feeding back into the feed pump chamber. If the feed-to-˚lter is driven by gravity, only the recycling pump will be required.

Why use a nitrifying tricking filter?

For extremely low ammonia discharge contents, Nitrifying Tricking Filters can be con˜gured in their operation to ensure that healthy nitrifying biomass is maintained throughout the media to maintain a robust process .

Where is the Thames Water plant?

Since going live in 2017, a purpose-built BIOdek trickling ˚lter solution has continued to exceed expectations by ensuring Thames Water’s SWT plant in Wheatley, Oxfordshire: • hits the company’s 100% compliance target by removing over 75% BOD and achieving ammonia levels of 1mg/l in the ˚nal e˝uent • meets Thames Water’s commitment to safeguarding the local water environment • has a resilient, sustainable future

Do trickling filters produce sludge?

Trickling Filters produce less sludge than suspended growth systems. The sludge that is produced generally settles e˛ciently and results in low turbidity in the clari˜ed water.

What is a trickling water filter?

A Trickling water treatment filter (TF), an attached growth system , consists of a fixed bed of highly permeable media on whose surface a mixed population of microorganisms is developed as a slime layer. The fixed media in Trickling water treatments filter may be of rocks, plastic, metal, etc. In Trickling water filter there is no straining or filtering action involved. Passing of waste water after primary water treatment through the filter causes the development of a gelatinous coating of bacteria, protozoa and other organisms on the media. The waste water sprayed through a bed of coarse stones or plastic material packed in a circular tank. A rotating distributor (a rotating pipe with several holes across it) evenly distributes the waste water from the top of the bed. The waste water trickles down and collected by an under drain system. The microorganisms in the waste water attach themselves to the filter media in the bed and break down the organic matter and remove them from the wastewater.

What happens when you filter water with a trickling filter?

In Trickling water filter there is no straining or filtering action involved. Passing of waste water after primary water treatment through the filter causes the development of a gelatinous coating of bacteria, protozoa and other organisms on the media. The waste water sprayed through a bed of coarse stones or plastic material packed in ...

How does a rotary distributor work?

The rotary distributor is used for spraying the waste water over the filter media of the Trickling Filters because of its reliability and ease of maintenance. The rotary distributor consists of a hollow vertical central column carrying two or more radial pipes or arms, each of which contains a number of nozzles or orifices for discharging the waste water onto the filter media. All of these nozzles point in the same direction at right angles to the arms. The force of the water causes the spray heads to rotate above the media, acting like a sprinkler and evenly distributing waste water across the media. The rotary reaction is furnished by a head of 450 to 600 mm. The speed of revolution will vary with the flow rate, but it should be in the range of one revolution in 10 minutes or less for a two-arm distributor.

Why do trickling filters need secondary settling tanks?

For this reason, trickling filters should be followed by secondary settling tanks (SST) to remove these sloughed solids by settling and to produce a relatively clear effluent. This sloughing cycle is continuously repeated throughout the operation of a trickling filter.

What is the ratio of the volume of treated wastewater to the volume of raw sewage called?

The volume of filter will not be affected by recirculation. The ratio of the volume of sewage recirculated (R) to the volume of raw sewage (I) is called recirculation ratio . Recirculation factor (F) is given by

Why is recirculation important?

Recirculation also helps to minimize problems with responding and restriction of ventilation. Recirculation can be continuous or intermittent at constant or variable rate. Recirculating effluent to the trickling filter dilutes the in fluent waste water entering the trickling filter.

What is the recirculation rate?

The recirculation is generally expressed as a decimal. Typical recirculation rates range from 0.2 to 2.0.

How TFs work

A rotary or stationary distribution system distributes wastewater from the top of the filter, percolating it through the interstices of the medium (see Fig. 4.6).

Advantages and disadvantages

There are advantages and disadvantages of TFs associated with biological treatment of food and agricultural wastewater; their importance depends on the needs of the end user and characteristics of wastewater.

Design criteria

A TF consists of permeable medium made of a bed of rock, slag, or plastic over which wastewater is distributed to trickle through, as shown in Fig. 4.6. Rock or slag beds can be up to 60.96 m (200 ft) in diameter and 0.9-2.4 m (3 to 8 ft) deep, with rock size varying from 2.5-10.2 cm (1 to 4 in).

What chapter is Trickling Filters?

Along with the online lesson, read Chapter 6: Trickling Filters in your textbook Operation of Wastewater Treatment Plants Volume I.

Where does the trickling filter effluent go?

The trickling filter effluent collects in the underdrain system , then travels to a sedimentation tank called asecondary clarifier. Secondary clarifier (or final clarifier as it is sometimes called) construction is similar in most respects to the primary clarifier, although differences occur in operation that can include detention time, surface settling rate, hydraulic loading, sludge pumping, overflow rate, weir loading, and other details.

What is recirculation in a filter?

Recirculation: The return of filter effluent back to the head of the trickling filter. It can level flow variations and assist in solving operational problems, such as ponding, filter flies, and odors.

How deep is a trickling filter?

The primary consideration for media selection is that it be capable of providing the desired film locations for biomass development. Media may be 3 to 20 or more feet in depth, depending on the type of media used and the filter classification. Trickling filters that use ordinary rock are usually only about 3 meters deep. The weight of the rocks causes structural problems, and also requires wide bed construction - in may cases up to 60 feet in diameter. Ligher weight synthetic media allows much greater bed depths.

How does a zoogleal slime work?

The organisms aerobically decompose the solids producing more organisms and stable wastes, which either become part of the zoogleal slime or are discharged back into the wastewater flowing over the media . The wastewater continues through the filter to the underdrain system where it is collected and carried out of the filter. At the same time air flows through the filter (bottom to the top or top to bommtom depending on temperature). Oxygen is transferred from the air to the wastewater and slime to maintain the aerobic conditions. Periodically the slime on the media becomes too heavy and portions will be released. This material known as sloughingsis carried out of the filter with the wastewater flow and is removed in the settling tank following the filter.

What is a biological tower?

Biological Towers: A type of trickling filter that is very deep (10 to 20 ft). Filled with lightweightsynthetic media, these towers are also known as oxidation or roughing towers or, because of their extremely high hydraulic loading, super-rate trickling filters.

What is the moving force in primary treatment?

Gravity is the moving force in primary treatment whereas biological activity is the moving force behind secondary treatment. Secondary treatment includes methods that use biological processes to convert dissolved, suspended, and colloidal organic wastes to more stable solids, which can be either removed by settling or harmlessly discharged to the environment. Biological treatment, sometimes called secondary treatment, provides biochemical oxygen demand (BOD) removal well beyond the levels that primary treatment can achieve, producing an effluent with not more than 30 mg/L BOD5and 30 mg/L total suspended solids to meet Clean Water Act requirements. Trickling filters were the most widely used form of wastewater treatment in the first half of the twentieth century and are still considered a viable treatment alternative due to their low energy and maintenance requirements and their ability to treat variable organic loads and toxic substances.

What is a trickling filter?

Trickling filters are used to remove organic matter and its components from the wastewater. The trickling filter is an aerobic treatment system that utilizes microorganisms attached to a medium for the removal of organic matter from wastewater. This type of system is commonly usedin The effluent quality achieved with the new activated sludge systems is often better than the ones achieved from trickling filters. The inventionof lightweight and synthetic media increased the treatment capability of trickling filters to an extent.The low energy and maintenance requirements make Trickling filters a viable alternative for treatment of varying

Can polypropylene be used as a filter?

It can be concluded that poly-propylene pall rings can be used as the prime filter media in the purification of dairy wastewater. Although both pall rings and sponge media give appropriate results, the pall rings have been chosen over sponge media based on certain challenges that could occur in future by using sponge and also by studying a comparison between the filter media. By adopting acclimatisation for development of biofilm on the plastic filter media an overall efficiency of about 80% can be obtained by testingfor parameters like BOD, Chlorides, PH, total solids etc.