What is a headworks in a wastewater treatment plant?

A plant’s headworks plays a crucial role in the pretreatment influent for any wastewater treatment facility. It protects the operation of downstream equipment and enhances the efficiency of the overall wastewater treatment process.

How do headworks clean wastewater in Camden County?

Headworks accomplish this wastewater cleaning in Camden County, MO through a variety of methods. The first step in the cleaning process is to simply get the water from an influent well (i.e., the place it ends up after its journey through the public waterworks) into the headworks themselves.

What is the purpose of a headworks?

In fact, the purpose of the headworks is to remove large inorganic materials from the wastewater. The goal is to make sure the wastewater is free of toxins and debris when it reaches downstream equipment.

How do you get water into headworks?

This is accomplished with the help of a pump. Engineers can employ one of a variety of pumps to get the water into your headworks. The choice will depend on the size of your operation, the size of the influent well, the contamination levels of the water and several other factors.

What is removed during wastewater treatment?

As sewage enters a plant for treatment, it flows through a screen, which removes large floating objects such as rags and sticks that might clog pipes or damage equipment. After sewage has been screened, it passes into a grit chamber, where cinders, sand, and small stones settle to the bottom.

What is removed from the wastewater by the grit chamber Why?

0:297:24Wastewater Treatment | Grit Removal - YouTubeYouTubeStart of suggested clipEnd of suggested clipSince it removes debris that can cause damage to downstream equipment such as pumps as well asMoreSince it removes debris that can cause damage to downstream equipment such as pumps as well as preventing the clogging of pipes.

What is removed in the aeration basin from the wastewater?

Aeration brings water and air in close contact in order to remove dissolved gases and to oxidize dissolved metals, including iron, hydrogen sulfide, and volatile organic chemicals (VOCs).

What does wastewater treatment not remove?

Biological stages in wastewater treatment plants are not able to remove substances such as drugs, found in the wastewater of medical centers, or halogenated compounds and cyanides from industrial wastewater.

What is removed during the grit chamber from the bottom of the water?

What is Grit Removal? Grit removal is the process used to remove sand, silt and grit from water. Grit (and sand) removal is often found in the headworks of wastewater treatment plants (WWTP).

What do grit chambers do?

Grit chambers are long narrow tanks that are designed to slow down the flow so that solids such as sand, coffee grounds, and eggshells will settle out of the water. Grit causes excessive wear and tear on pumps and other plant equipment. Its removal is…

Which pollutants Cannot be removed or reduced by aeration?

The complete removal of hydrogen sulfide must be combined with pH reduction or chemical oxidation. Nonvolatile organic compounds cannot be removed by air stripping. For example, phenols and creosols are unaffected by the aeration process alone.

What do aeration basins do?

An aeration basin (also called an aeration lagoon) is a holding and/or treatment pond provided with artificial aeration to promote the biochemical oxidation of wastewaters.

How does aeration clean water?

How aeration works. Aeration treatment consists of passing large amounts of air through water and then venting the air outside. The air causes the dissolved gases or volatile compounds to release from the water. The air and the contaminants released from the water are vented.

Which 3 elements are commonly removed from wastewater during the treatment process?

The Three Most Difficult Items to Remove From Wastewater#1 – Pharmaceuticals and Personal Care Products (PPCPs) Both prescription and over-the-counter medications and supplements are wreaking havoc on wastewater. ... #2 – Nitrites and Nitrates. ... #3 – Polyethylene and Polypropylene Microbeads.

Does wastewater treatment remove chemicals?

New research shows that wastewater treatment plants that employ a combination of purifying techniques followed by reverse osmosis – a process by which water is forced through a barrier that only water can pass – do a good job of removing chemicals that may elicit health effects.

How is nitrogen and phosphorus removed from water?

Wetlands are able to remove nitrogen and phosphorus through a combination of physical, chemical, and biological processes. These naturally occurring processes adsorb/absorb, transform, sequester, and remove the nutrients and other chemicals as water slowly flows through the wetland.

What is headworks in wastewater treatment?

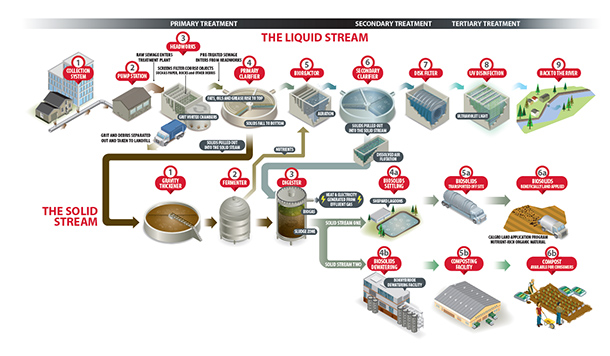

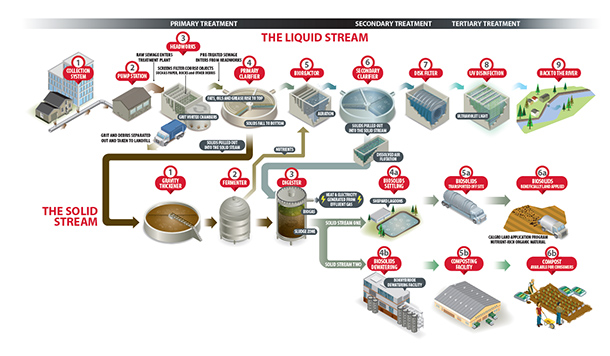

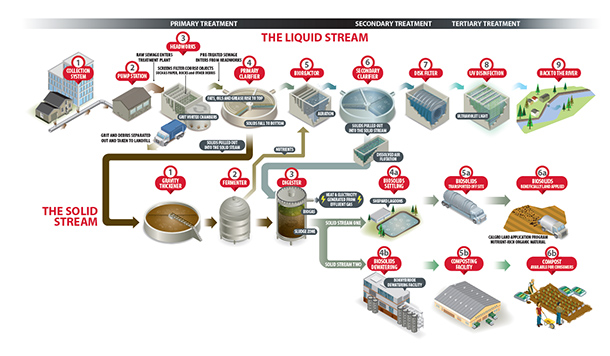

The " headworks " of a wastewater treatment plant is the initial stage of a complex process. This process reduces the level of pollutants in the incoming domestic and industrial wastewater to a level that will allow the treated wastewater or effluent to be discharged into a stream, river or lake. This treated effluent also may be sprayed onto dedicated land areas where it is used for the irrigation of crops and even golf courses. The complete process includes preliminary treatment, primary treatment, secondary treatment and often tertiary treatment.

What is the complete process of wastewater treatment?

The complete process includes preliminary treatment, primary treatment, secondary treatment and often tertiary treatment. The treatment processes of a wastewater plant have become more and more sophisticated and the performance of the headworks is more important than ever. The function of them is to remove inorganics such as sticks, stones, ...

Why is a vortex pump not used?

This pump is used primarily for clean water, or treated effluent, and should not be used for raw wastewater or sludge applications because large solids and stringy material can easily cause plugging. The vortex, or torque flow, pump has an impeller completely recessed from the volute area.

What is the vortex action in a pump?

The vortex action created directs the flow of both the fluid and entrained solids entering the pump into the volute area, where centrifugal force pushes the flow out. The fluid and entrained solids do not enter the impeller, but pass from the suction line through the volute into the discharge line.

Why is grit washed?

After removing the collected grit from the grit chamber, the grit normally is washed to ease handling. In most cases, a reduction in grit volume by removing the water contained in grit saves transportation costs and eases transport and handling during disposal.

Is washing and dewatering of screenings critical?

Therefore, washing and dewatering of the screenings is critical to maintaining a good screening process. Screens can be classified as coarse, fine and micro. Increasingly, treatment plants use a combination of coarse screens and fine screens.

What happens if you choose the wrong headworks system?

The wrong choice can result in headworks systems that do not meet the required level of protection of downstream treatment processes, or a system that is too costly for the plant’s requirements.

What is water treatment?

Water treatment facilities in smaller towns and villages, as well as treatment works supporting institutions, prisons, resorts or remote facilities, have difficult choices to make when selecting their headworks systems. All require a solids-control strategy, but lower flows and smaller budgets limit the available equipment options. The necessary equipment is called upon to effectively screen out the solids and prepare them for disposal while meeting the financial constraints of the smaller facilities.

Who is the manager of the Bridgewater Correctional Complex?

In the more than 62 years Leo DuBois has served as the manager of the wastewater treatment plant at the Bridgewater Correctional Complex in rural Massachusetts, he’s observed a curious stream of flushed debris. Dealing with the prison’s wastewater is a unique challenge, as inmates treat their toilets like trashcans. Everything from cigarette butts to jumpsuits and plastic baggies get sent down into the pumps to be weeded out at DuBois’ headworks facility.

Can a small plant have a screening washer?

Often a smaller plant will not have the capital for a screening washer and they must contend with smelly, wet screenings that attract both vermin and odor complaints from the community. By washing and compacting the solids, the handling and transport of the screenings is simplified and odor-free.

Do automated bar screens eliminate manual raking?

While the automated screens do eliminate the manual raking, they do not remove other challenging operating problems. The installation of automated bar screens typically calls for civil work to modify channels, and can also require additional headroom in the headworks building to account for the automated raking system.

Practical Considerations for Odor Control with Hydrogen Peroxide

The most frequent obstacle to implementing H2O2 for headworks odor control involves providing sufficient reaction time. Although a minimum of 5 minutes is recommended, there are certain instances (where iron levels are > 2-3 mg/L) where 60-70% completion is achieved within two minutes.

Evaluation Process for Headworks Odor Control with Hydrogen Peroxide

The evaluation process for headworks odor control is straightforward and reasonably accurate estimates can be made before progressing to a field study.