Can plasma treatment improve the bonding of PDMS to glass?

PLASMA TREATMENT OF PDMS RESULTS. Contact angle measurements indicate whether a surface is hydrophobic (over 90°) or hydrophilic (under 90°) by... X-RAY PHOTOELECTRON SPECTROSCOPY (XPS). XPS is a widely used technique to analyze the functional groups present on the... CONCLUSIONS. Bonding of PDMS to ...

How long does it take for PDMS to recover after plasma treatment?

Jun 30, 2013 · Clean a glass slide using deionised water, ethanol and isopropanol. Dry with nitrogen. Place glass slides and devices in the oxygen plasma. After treatment, press them gently together, making sure that the entire device is softly pressed down. 1 hr @ 80°C; Place your bonded devices in the oven for 1 hour. Additional PDMS leak-proofing

How does plasma treatment work?

Plasma Surface Modification of PDMS After patterning a PDMS substrate by replica molding from a master mold, the PDMS is oxidized in air or oxygen (O2) plasma. An air or O2 plasma removes organic, hydrocarbon material by chemical reaction with highly reactive oxygen radicals and ablation by energetic oxygen ions.

How long does it take for PDMS bonding to occur?

Plasma Treatment of PDMS Removal of hydrocarbon groups Exposure of hydrophilic -OH groups Improved bonding to PDMS and glass substrates Improve analyte flow Possibility of patterned surfaces with alternating hydrophilic/hydrophobic regions

What does plasma treatment do to PDMS?

Oxygen plasma treatment has been used extensively by many in the fabrication of PDMS microfluidic devices. The treatment of oxygen plasma on PDMS introduces polar functional groups12 which is mainly the silanol group (SiOH). This group changes the surface properties of PDMS from being hydrophobic to hydrophilic.Sep 30, 2010

How does plasma surface treatment work?

Plasma treatment is used to alter the top few molecular layers of surfaces. When plasma is applied to the surface, the energy applied to the surface “activates” the surface. This freshly energized surface improves the adhesion characteristics of paints, coatings, and adhesives.

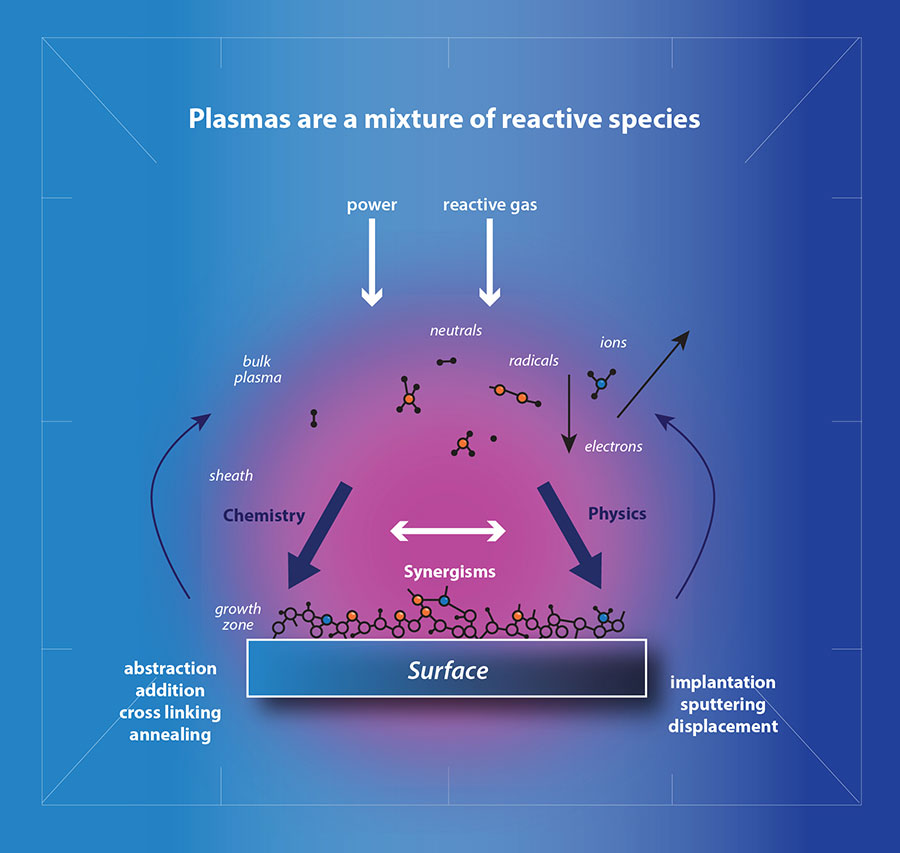

How does plasma process work?

Plasma treatment occurs when gas is exposed to an energy source such as electricity or microwave, and becomes a mixture of ions, radicals, free electrons and other types of molecular fragments. The resultant plasma treatment is the means by which all traces of organic contamination are removed.Jun 28, 2016

How is plasma treatment performed?

A plasma treatment is usually performed in a chamber or enclosure that's evacuated (Vacuum plasma). The air within the chamber or enclosure is pumped out prior to letting gas in. The gas then flows in the enclosure at a low pressure. This is done before any energy (electrical power) is applied.

How long does plasma treatment last?

It will also take several days for the tiny scabs to disappear from the pinpoint wounds on the skin's surface. During this time you will begin to see the results of your treatment, and your skin will continue to improve over the next six months. After that, results generally last about three years.Aug 25, 2020

How long does plasma cleaning last?

Most plasma treatments last approximately 48 hours if the treated surface remains clean and dry. This time can vary depending on the treatment performed and the conditions parts are stored in.

How many times can the patient treat with plasmapheresis?

A: There is no set number of plasma exchanges performed, although typically patients receive between three and seven exchanges, each of which takes 2-4 hours. The number of treatments can be guided by the clinical recovery, or sometimes a preset number of exchanges are performed.

What is plasma treatment for plastics?

Plasma Treatment of Plastic Plasma treatment of plastics to improve adhesion is a two-fold surface activation and cleaning process. In the first instance, the plasma treating the plastic cleans away volatile organic compounds that otherwise impede bonding, painting and gluing.

What is plasma treatment material?

Plasma surface treatment is a process that raises the surface energy of many materials so as to improve the bonding characteristics. One form of plasma treatment is also commonly known as a corona treatment, which was invented by Danish engineer Verner Eisby in the 1950s.

What does PRP do for the face?

PRP is a facial rejuvenation treatment that uses your own plasma to stimulate collagen production and cell migration, allowing for the elimination of lines, folds, and wrinkles. Results from PRP therapy are natural looking and subtle, and they can last for as long as two years.

What is plasma exchange?

Plasma exchange, also known as plasmapheresis, is a way to "clean" your blood. It works sort of like kidney dialysis. During the treatment, plasma -- the liquid part of your blood -- gets replaced with plasma from a donor or with a plasma substitute.May 20, 2021

What is plasma skin treatment?

Plasma skin regeneration is a non-laser treatment that uses a device to deliver energy in the form of plasma to rejuvenate skin by improving facial lines and wrinkles (rhytides) and skin pigmentation associated with photoageing.

How to cure PDMS?

The idea is to partially cure the PDMS, so it’s solid but still somewhat sticky. Let the PDMS cool for about an hour afterwards; this will facilitate the next step. Cut out devices. Cut out each device from the wafer. Be careful to avoid cutting near master features, as it will be reused for future devices.

What is the best treatment for PDMS?

To assure a strong bond between PDMS layers, oxygen plasma treatment is necessary. This surface treatment is known to have a very short duration, that is to say that both surfaces must quickly be brought into contact after exposure.

How long to cook PDMS block in oven?

Place your bonded devices in the oven for 1 hour. Additional PDMS leak-proofing. An additional step that has helped prevent leaks between the glass and PDMS is the addition of a PDMS seal at the perimeter of the PDMS block. You prepare a 11g mixture of 10:1 PDMS as before, but without the degassing step.

How long to degas tridecafluoro-1,1,2,2-tetrahydrooct

Full name: (tridecafluoro-1,1,2,2-tetrahydrooctyl)trichlorosilane. 30 min degass. Fill the dish with PDMS. Place the dish in the vacuum chamber, and allow it to degass for 30 minutes, or until it stops bubbling. To prevent overflow, you may have to periodically break vacuum and allow some bubbles to escape.

Can ethanol be used in plasma bonders?

Though ethanol has been known to extend the effects, it caused a partial collapse in the valve area of the main channels, and as such is not recommended .

How long does it take for PDMS to recover from plasma?

It is recommended that PDMS bonding and other subsequent processing steps be performed within 15 minutes to an hour of plasma treatment.

What are plasma treatments?

Plasma treatment has been used to facilitate the fabrication of microfluidic devices for applications such as: 1 Study of chemical reactions and fluid flow on micron scale 2 Detection of biological organism or chemical species 3 Clinical diagnostics and drug screening for medical research 4 Manipulation of fluid on cellular length scale 5 Cell Culture, Tissue Culture, Organoid Studies

How is PDMS oxidized?

After patterning a PDMS substrate by replica molding from a master mold, the PDMS is oxidized in air or oxygen (O2) plasma. An air or O2 plasma removes organic, hydrocarbon material by chemical reaction with highly reactive oxygen radicals and ablation by energetic oxygen ions. This leaves silanol (SiOH) groups on the surface, rendering the surface more hydrophilic and increasing surface wettability. Following plasma activation, the PDMS is immediately placed in contact with another oxidized PDMS or glass surface to form bridging Si-O-Si bond at the interface, creating an irreversible seal. This water-tight covalent bond is ideal for microchannel formation and function.

Why is high temperature important for PDMS?

The high temperature provides activation energy for additional bond formation. Cleanliness: the presence of particulates or oil can block bonds from forming. Avoid touching the surfaces to be bonded when removing PDMS from the plasma chamber.

Who is Harrick Plasma?

Harrick Plasma is a leading supplier of plasma equipment to the research community. We have been providing quality tabletop plasma devices specifically designed for laboratory and R&D use for over 30 years.

How to treat PDMS?

Plasma Treatment of PDMS 1 Removal of hydrocarbon groups 2 Exposure of hydrophilic -OH groups 3 Improved bonding to PDMS and glass substrates 4 Improve analyte flow 5 Possibility of patterned surfaces with alternating hydrophilic/hydrophobic regions

Why do you need a surface treatment step for PDMS?

PDMS, however, requires a surface treatment step in order to produce strong, conformal bonds between surfaces. Plasma treatment of PDMS increases hydophilic (-OH) groups on the PDMS surface which subsequently form strong covalent bonds (Si– O–Si) when brought together with glass.

How is motility assay used?

In vitro motility assays are readily used to simplify the complex environments within the cell and in muscle tissue. These assays have afforded considerable insight into the fundamentals of their underlying biophysics, interactions with cargo, intracellular regulation, and motor cooperation/competition. Extension of the standard in vitro motility assay into a more automated and cost-effective fluidic design while providing availability to the scientific community without expertise in lithographic fabrication is critical for the continued advancement of the field. In this work, we utilized a standard plasma cleaner to oxidize the widely prevalent material polydimethylsiloxane (PDMS) to create flow cells that could be used for in vitro motility assays. Our analysis indicated that a 40 min pre-treatment of the PDMS with plasma exposure resulted in optimal bundle motility. This finding was attributed to the condition at which the least amount of oxygen permeates the PDMS slab, enters the motility buffer, and oxidizes the motor proteins. Based on these findings, we developed a method for constructing microfluidic devices from glass and plasma-treated PDMS molds in which motility could be observed.

Can PDMS be used for motility?

In this study, we found that PDMS can be used as a material to fabricate flow cells for motility experiments if its surface is first oxidized to SiO x to prevent oxygen diffusion . Based on these findings, we developed a method for constructing microfluidic devices from glass and plasma-treated PDMS molds in which motility could be observed.

What is Plasma and Plasma treatment?

Plasma is matter that exists in the form of ions and electrons. Basically, it is a gas that’s been electrified charged with freely moving electrons in both the negative and positive state.

How Plasma treatment is performed

A plasma treatment is usually performed in a chamber or enclosure that’s evacuated (Vacuum plasma). The air within the chamber or enclosure is pumped out prior to letting gas in.

Useful for pretreatment of surfaces

On an industrial level, plasma treatments are used for treating surfaces of various materials prior to any coating, printing or adhesion. Therefore, it can also be referred to as a kind of pretreatment of surfaces.