There are three traditional ways to check heat-treatment quality:

- Monitor heat-treatment manufacturing processes

- Sample (batch) testing

- Continuous (in-line) testing

- X-ray diffraction. The X-ray diffraction method enables measuring the absolute residual stress value and retained austenite content. ...

- Barkhausen noise analysis. ...

- Stresstech provides turnkey solutions for heat treatment verification and retained austenite measurements.

What is heat treatment testing?

Laboratory Testing Inc. offers a wide-variety of heat treatment testing and inspection services to evaluate materials following treatments. Heat treat testing is performed to assess a material’s response to a treatment process in order to certify the material to specified requirements.

What is a successful heat process validation?

A successful heat process validation consists of four steps; determining the target pathogen; pathogen reduction; verifying pathogen reduction; and identifying the controls and critical limits to include in the HACCP plan to ensure a consistently safe product. We’ll go through each of these and show how they

What should you look for in a heat treatment specification?

Heat treatment specifications should also identify the case tolerance, or the range of depths the prescribed hardness should reach. For example, a good spec for the heat treatment of a theoretical gear might state the effective case depth should be between 0.007 and 0.012 inches at the prescribed hardness.

Where can heat treatment verification and retained austenite measurement be done?

With Stresstech products, heat treatment verification and retained austenite measurement can be done effortlessly in production lines, laboratories, and even in the field. Need help with heat treatment verification?

What is the requirement of heat treatment?

Proper heat treating requires precise control over temperature, time held at a certain temperature and cooling rate. With the exception of stress-relieving, tempering, and aging, most heat treatments begin by heating an alloy beyond a certain transformation, or arrest (A), temperature.

How do you classify the different heat treatment processes?

Various heat treatment processes can be classified as follows:Annealing.Normalizing.Hardening.Tempering.Case hardening.Surface hardening.Diffusion coating.

What are the 3 stages of heat treatment process?

The stages of the heat treatment process include heating, soaking, and cooling.Heating: Heating is the first stage in a heat-treating process. ... Soaking: Soaking is the stage at which the complete part of the heated metal completely changes in its structure. ... Cooling: The third stage of heat treatment is cooling.

What are the properties of heat treatment?

The heat treatment develops hardness, softness, and improves the mechanical properties such as tensile strength, yield strength, ductility, corrosion resistance and creep rupture. These processes also help to improve machining effect, and make them versatile.

How many types of heat treatment are there?

4 TypesWhat are the 4 Types of Heat Treating Processes? Common types of heat treating methods include annealing, hardening, quenching, and stress relieving, each of which has its own unique process to produce different results.

Is heat treatment a code?

IS 13417: Code of practice for heat treatment of steels.

Why quenching is done?

quenching, rapid cooling, as by immersion in oil or water, of a metal object from the high temperature at which it has been shaped. This usually is undertaken to maintain mechanical properties associated with a crystalline structure or phase distribution that would be lost upon slow cooling.

What is hardening in heat treatment?

Hardening heat treatments invariably involve heating to a sufficiently high temperature to dissolve solute-rich precipitates. The metal is then rapidly cooled to avoid reprecipitation; often this is done by quenching in water or oil.

Why hardening is done?

Metal Hardening Hardened materials are usually tempered or stress relieved to improve their dimensional stability and toughness. Steel parts often require a heat treatment to obtain improved mechanical properties, such as increasing increase hardness or strength.

What is RC in heat treatment?

Rockwell Hardness (RC) Values of Heat Treated Mild Steel Springs.

Why is heat treatment used?

Heat treatment is commonly used to alter or strengthen materials' structure through a heating and cooling process. It can be applied to both ferrous and non-ferrous metals, and there are a number of different methods of heat treatment.

What is annealing in heat treatment?

annealing, treatment of a metal or alloy by heating to a predetermined temperature, holding for a certain time, and then cooling to room temperature to improve ductility and reduce brittleness.

Verifying How Materials Respond to Treatments

Steel, iron, and other metals are hard and strong by nature, but some applications require more durable or corrosion-resistant metals that can be attained by industrial heat treating processes. Laboratory Testing Inc. offers a wide-variety of heat treatment testing and inspection services to evaluate materials following treatments.

One-stop for Temperature Calibration Too

The field technicians at LTI Metrology, our calibration division, provide pyrometry services to let you know if your furnaces, controllers and other temperature equipment are operating efficiently and accurately.

Inspection Mistakes That Cost

Rockwell hardness testing requires adherence to strict procedures for accurate results. Try this exercise to prove the importance of proper test procedures.

CQI-9 Best Practices

Whether you need to meet rigid CQI-9 standards or not, what are the top 3, nay 4 best practices that nearly every in-house heat treat department ought to follow to make sure their pyrometer stuff is together?

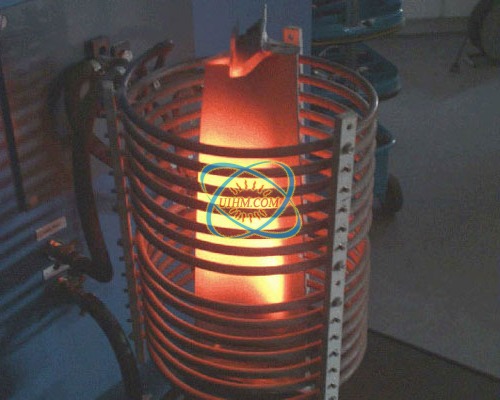

Control of Back Tempering With Induction Heat Treating

Induction heat treating is a selective hardening process. When hardening an induction path close to an area that had previously hardened, the heat from the hardening the second path tempers back the area that was previously hardened. This is a particularly common issue when tooth by tooth hardening of small gear teeth.

What is heat treatment?

Heat treatment is an invaluable process that allows manufacturers to optimize the mechanical and physical properties of their metallic components. This helps provide a desired level of performance and life expectancy of a product. The end results are tailored by parameters such as heating method, temperatures, cycle times, atmospheres, quench media and tempering.

Why is eddy current testing important?

Eddy current testing is a good way to ensure that all components on a production line are validated for proper heat treatment. This technology also helps save time and money by reducing both scrap and warranty costs associated with improperly heat-treated components.

Why do metalurgists need accurate specifications?

Metallurgists need accurate specifications in order to correctly perform the necessary heat treatment of parts. This helpful guide, written by William Rassieur, Sales Leader at Paulo Heat Treating, is a useful tool to identify what details ought to be communicated to the heat treating expert.

Is it enough to state on a spec that a piece is steel?

It’s not enough to state on the spec that a piece is steel alloy. Consult materials standards and use the correct material designation on the spec. For example, if you want to treat a carbon steel or an engineering alloy, using those terms (or known trade names for a specific material) isn’t adequate.

Can too much specificity lead to trouble?

Avoid too much information. Sometimes, though, too much specificity can lead to trouble. Specs that include too much process information can paint metallurgists into a corner, forcing them to abide by strict requirements that can end up thwarting their efforts to deliver improved parts.