Selecting the Appropriate Wastewater Treatment

Sewage treatment

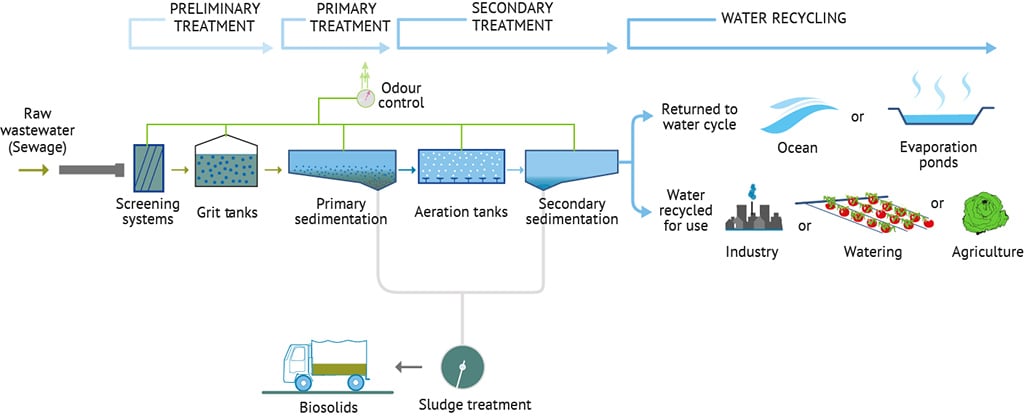

Sewage treatment is the process of removing contaminants from wastewater, primarily from household sewage. It includes physical, chemical, and biological processes to remove these contaminants and produce environmentally safe treated wastewater (or treated effluent).

- What are the wastewater characterizations of the production facility?

- What are the regulatory requirements for discharge from the plant?

- What are the outcomes of a thorough wastewater treatability study and pilot test?

How to choose the right wastewater treatment system?

There are three main factors that will help you choose the ideal wastewater treatment system: What are the wastewater characterizations of the production facility? What are the regulatory requirements for discharge from the plant? What are the outcomes of a thorough wastewater treatability study and pilot test?

What is the process of wastewater treatment?

The physical process of wastewater treatment begins with screening out large items that have found their way into the sewer system, and if not removed, can damage pumps and impede water flow. A bar screen is usually used to remove large items from the influent and ultimately taken to a landfill. Water Quality and the Clean Water Rule

Should a wastewater treatment plant have a different name?

No one wants to have his or her home near a wastewater treatment plant, regardless of how well the plant is designed and is aesthetically acceptable. But calling it by a different name could mitigate that concern. Consider naming it a water reclamation plant, water conservation plant, water recycling plant or water factory instead.

How is sewage treated in a sewage treatment plant?

As sewage enters a plant for treatment, it flows through a screen, which removes large floating objects such as rags and sticks that might clog pipes or damage equipment. After sewage has been screened, it passes into a grit chamber, where cinders, sand, and small stones settle to the bottom.

What happens after a wastewater treatment plant meets all permit specifications?

What is the process of removing large items from the influent?

Why is wastewater pumped into a secondary clarifier?

What is activated sludge?

What happens if water flows too slow?

What is the function of an aeration tank?

What is a bar screen in wastewater treatment?

See more

About this website

What are the factors that influence the decision in choosing a suitable wastewater treatment method?

Chemical and microbiological stability of water leaving the treatment plant. Prevention of internal corrosion and deposition. Microbiological control in the distribution system. Compatibility of the quality with water from other sources.

What is the best method for a wastewater treatment plant?

Chemical. Chlorine is the chemical most often used in treating sewage and other types of wastewater. The process is called chlorination. This is the most effective means of destroying a variety of viruses and bacteria.

What are the factors to be considered while selecting the site for the water treatment plant?

Most recent answerAt a distance from the place which people live.Large enough at the future.the source of water and the best location at deep point far from the soil.study the degree of contamination at the point.

What are the four major processes in wastewater treatment?

Four common ways to treat wastewater include physical water treatment, biological water treatment, chemical treatment, and sludge treatment. Let us learn about these processes in detail. In this stage, physical methods are used for cleaning the wastewater.

What are the 5 stages of water treatment?

Public water systems often use a series of water treatment steps that include coagulation, flocculation, sedimentation, filtration, and disinfection.

What are the 3 stages of wastewater treatment?

There are three main stages of the wastewater treatment process, aptly known as primary, secondary and tertiary water treatment. In some applications, more advanced treatment is required, known as quaternary water treatment.

What are the five principles of site selection?

Site Selection PrinciplesSeparation or Buffer Distances. ... Site Suitability. ... Proximity to Waste Source. ... Zoning. ... Protection and Enhancement of Conservation Values.

What are three critical things you would need to consider when designing a water treatment facility?

Major factors to be considered are: (1) type of the water source, (2) desired finished water quality, (3) skill of facility operators, and (4) the relative size of available funds.

What are points that should be kept in mind while selecting a water source?

What are the main factors to be considered while selecting a particular source of water? The quantity and quality of water available, the distance and elevation of the source, and the topography of the surrounding area are to be considered while selecting a particular source of water.

What are the 7 steps in wastewater treatment?

The Wastewater Treatment ProcessStage One — Bar Screening. ... Stage Two — Screening. ... Stage Three — Primary Clarifier. ... Stage Four — Aeration. ... Stage Five — Secondary Clarifier. ... Stage Six — Chlorination (Disinfection) ... Stage Seven — Water Analysis & Testing. ... Stage Eight — Effluent Disposal.

What are the 3 stages of wastewater treatment PDF?

Wastewater is treated in 3 phases: primary (solid removal), secondary (bacterial decomposition), and tertiary (extra filtration).

What is the difference between water treatment and wastewater treatment?

Water treatment is done to water before it is sent to a community, while wastewater treatment is done to water that has been used by the community. Water treatment has higher standards for pollution control because it is assumed that any drop of distributed water could be consumed by a person.

Processes of Waste Water Treatment: 4 Process (With Diagram)

ADVERTISEMENTS: This article throws light upon the four processes of waste water treatment. The four processes are: (1) Preliminary Treatment (2) Primary Treatment (3) Secondary or Biological Treatment and (4) Tertiary or Advanced Treatment. 1. Preliminary Treatment: As already stated, preliminary treatment involves the removal of floating materials (leaves, papers, rags) and settleable ...

Waste and Waste Water Treatment (With Diagram)

ADVERTISEMENTS: Brewery and Distillery Effluents: Breweries and distilleries produce huge quantity of liquid effluents originated from different sections of the industrial processing. These effluents are highly pollutants bearing in terms of BOD and COD loadings. ADVERTISEMENTS: 1. Origin of wastes: The malting process produces two major wastes: those arising from the steep tank after grain […]

Step-By-Step Wastewater Treatment

BUTLER AREA SEWER AUTHORITY 100 LITMAN ROAD BUTLER, PA 16001-3256 (724) 282-1978 www.basapa.org Step-By-Step Wastewater Treatment Step 1: Raw Sewage enters the plant from public and private customers. Step 2: The Sewage first passes through mechanical bar screens. This combs out any large

What are the considerations for biological wastewater treatment?

The general considerations include : Occupied area or how much land the system will occupy on site; Construction costs, how much money will be required to build the system;

What are secondary stages in wastewater treatment?

Secondary stages typically consist of biological wastewater treatment systems, and those, in particular, have several different options. Careful considerations of multiple aspects need to be made to choose the most optimal solution for a particular application. At the core of the biological wastewater treatment process, ...

What is a return activated sludge?

A suspended solids system that aerates a loose biological media and is then pumped to a clarifying tank to settle. Sludge from the clarifier is recirculated back into the reactor, called return activated sludge. A version of an ASP that does not have a separate clarifying tank.

Why is wastewater treated?

To protect the environment, these wastewaters typically must be treated to minimize pollutant concentrations before discharging to the environment, or to municipal wastewater-treatment plants for further treatment. Compared to chemical and physical treatment methods, biological treatment processes are very economical and efficient options when the wastewaters contain biodegradable pollutants.

What is biological wastewater treatment?

Biological wastewater-treatment processes are widely adapted to remove soluble, colloidal and suspended organic substances. Biological treatment is also used for nitrogen and phosphorus removal. The two categories of biological treatment are suspended-growth and attached-growth processes. In the suspended-growth category, ...

What is activated sludge?

Activated sludge is a widely used biological treatment process. It produces a good-quality effluent, but is more sensitive than an MBBR to shock loads and toxic matter. The system is associated with biomass instability issues, such as sludge bulking.

What are the components of activated sludge?

There are three basic components in the activated sludge process: (1) a biological reactor in which the microorganisms responsible for treatment are kept in suspension and aerated; (2) a clarifier for liquid-solids separation; and (3) a recycle system for returning solids removed from the liquid-solids separation unit back to the reactor.

What industries produce large amounts of wastewater?

Chemical, pharmaceutical and related industries produce large amounts of wastewater in their production and cleaning processes. The wastewater characteristics are often diverse, and may include minimally biodegradable or toxic substances, or both.

What is QuicktoCuv?

QuickTOCuv (photo) is a measuring device for continuous online determination…

How often does Chemical Engineering publish free emails?

Chemical Engineering publishes FREE eletters that bring our original content to our readers in an easily accessible email format about once a week.

What is the purpose of WWTP?

Generally the main goal in the design of a WWTP process is to minimise the volume and toxicity and the final treatment residue, since final disposal can incur significant cost and liability. If you understand the purpose and goal of the project before selecting the preferred wastewater treatment technology and provider, it will make your life a lot easier in the long run.

Is recycling water good for you?

Recycling water has many benefits but the most obvious one is that it saves potable water which means that you have the potential to save on costs both procuring potable water and disposing of the treated water. In selecting a new WWTP it would be wise to consider this as an option.

What happens after a wastewater treatment plant meets all permit specifications?

After meeting all permit specifications, clean water is reintroduced into the environment. Although testing is continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications.

What is the process of removing large items from the influent?

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment .#N#The process of treating and reclaiming water from wastewater (any water that has been used in homes, such as flushing toilets, washing dishes, or bathing, and some water from industrial use and storm sewers) starts with the expectation that after it is treated it will be clean enough to reenter the environment.#N#The quality of the water is dictated by the Environmental Protection Agency (EPA) and the Clean Water Act, and wastewater facilities operate to specified permits by National Pollutant Discharge Elimination System (NPDES). According to the EPA, The Clean Water Act (CWA) establishes the basic structure for regulating discharges of pollutants into the waters of the United States and regulating quality standards for surface waters. Under the CWA, EPA sets wastewater standards for industry. The EPA has also developed national water quality criteria recommendations for pollutants in surface waters. EPA's National Pollutant Discharge Elimination System (NPDES) permit program controls discharges.#N#As an example of expected standards, the Biochemical Oxygen Demand (BOD) of average wastewater effluent is 200 mg/L and the effluent after treatment is expected to be >30 mg/L. It is crucial a wastewater facility meets these expectations or risk stiff penalty.#N#The physical process of wastewater treatment begins with screening out large items that have found their way into the sewer system, and if not removed, can damage pumps and impede water flow. A bar screen is usually used to remove large items from the influent and ultimately taken to a landfill.

Why is wastewater pumped into a secondary clarifier?

Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow. As the influent exits the aeration process, it flows into a secondary clarifier where, like the primary clarifier, any very small solids (or fines) sink to the bottom of the tank.

What is activated sludge?

These small solids are called activated sludge and consist mostly of active bacteria. Part of this activated sludge is returned to the aeration tank to increase the bacterial concentration, help in propagation, and accelerate the breakdown of organic material. The excess is discarded.

What happens if water flows too slow?

If the water flow is too slow, it impacts the process up stream. The solids that fall to the bottom of the clarifier are know as sludge and pumped out regularly to ensure it doesn’t impact the process of separation. The sludge is then discarded after any water is removed and commonly used as fertilizer.

What is the function of an aeration tank?

The primary function of the aeration tank is to pump oxygen into the tank to encourage the breakdown of any organic material (and the growth of the bacteria), as well as ensure there is enough time for the organic material to be broken down.

What is a bar screen in wastewater treatment?

A bar screen is usually used to remove large items from ...

Stage 1: mechanical water treatment

In the first stage, the still completely untreated wastewater is mechanically treated; this removes about 20 - 30% of the contained solids. To achieve this, the wastewater is guided into a screening plant, where a screen or sieve drum filters out coarse impurities such as leaves, paper or textiles.

Stage 2: biological cleaning

In most wastewater treatment plants, the water pre-purified in the mechanical treatment stage now reaches what are known as aeration tanks, which are often designed as circulation tanks. This is where the biological cleaning takes place.

Stage 3: chemical wastewater treatment

In this stage of wastewater treatment, chemical processes are used for wastewater treatment. To this end, chemical compounds are used to achieve legally prescribed water standard values.

1. Screening

At this step, screening equipment is used to remove any large objects such as plastics, cotton buds, rags, broken bottles, and whatever else is lurking in there. This can be done as simply as using a single screen or as sophistically as using multiple screens of different types in combination with grinders.

2. Grit Removal

Particles of heavy materials like sand and silt are referred to as grit. At the second step of primary treatment, grit is removed from the wastewater using grit chambers. If you’re looking for something affordable, you should look into a vortex-type grit chamber.

3. Primary Settling

While grit settles quite fast, there are other materials called the primary sludge which take a longer time to settle at the bottom of the tank. This step is all about removing that primary sludge using scrappers and then pumping the water out for further treatment, ultimately removing any macrobiotic solid matters.

How Percentage of Solids in Wastewater is Measured

Most plants use a microwave moisture analyzer to measure the percentage of solids due to their exceptional accuracy and speed. One such device is the Reconditioned CEM Smart System 5 we have in stock at an affordable price ($12,500 as of this writing). Using this advanced system, you can get a result within just a few minutes.

4. Aeration

This is the step where most of the treatment takes place. Activated sludge is mixed with wastewater by pumping air into aeration tanks, thus creating a thriving environment for microorganisms to biologically degrade the remaining organic matter. However, the oxygen gas levels must be above 2 ppm for it to be effective.

5. Secondary Settling

As the particles from the aeration process settle down, treated wastewater is separated using secondary clarifiers. By the end of this step, which takes around 3-6 hours, about 90% of the treatment is already achieved. In the end, a solid counting test is performed again.

6. Disinfection

At this step, the treated wastewater is disinfected using a mixture of chlorine and sodium hypochlorite to eliminate any harmful organisms still remaining. This is achieved using a chlorinator.

What to call a wastewater treatment plant?

No one wants to have his or her home near a wastewater treatment plant, regardless of how well the plant is designed and is aesthetically acceptable. But calling it by a different name could mitigate that concern. Consider naming it a water reclamation plant, water conservation plant, water recycling plant or water factory instead. This could mitigate, if not eliminate, that concern. Sometimes, it could simply be a perception issue, which can be addressed by giving the facility a different catchy name. Most plants in the U.S. today are renaming their facilities with those listed earlier. A plant in Orange County, California, for instance named its plant Water Factory 21.

Where is Tillman Water Reclamation Plant located?

A plant located in the Los Angeles area, owned and operated by the city of Los Angeles—the Tillman Water Reclamation Plant—houses a beautiful Japanese Garden on its property (below), which is regularly visited by tourists and has become a sought-after place for holding wedding ceremonies and receptions.

What is a scrubber for plants?

Most modern plants are opting for biological scrubbers due to the facts that no chemicals are required thus reducing the carbon foot print of their plant; they are not as tall, thus have lesser visual and obtrusive impact; and they can scrub nearly all odor-causing compounds—whatever their origin—if properly designed with adequate residence time unique to the nature of odorants to be removed. In fact, these scrubbers can be designed to be aesthetically pleasing—even underground or sticking a couple of feet above ground and mildly landscaped at the top. The media can be compost, wood chips, bark, peat, lava rock, or any combination of the above materials. For sensitive neighborhoods, these scrubbers can be followed by an adsorption scrubber using activated carbon as the adsorption media for final polishing.

How to build a plant?

A good layout can often be helpful in public acceptance of the project. Consider the following: 1 Locate the plant downwind of residences and other concerned neighbors. 2 Keep some buffer between residences and the nearest plant facility (say 500 ft.). 3 Build odorous facilities farthest from residences (i.e. headworks). 4 Cover and/or house the odor causing facilities, provide necessary ventilation and air scrubbing.

How far away should a plant buffer be?

Keep some buffer between residences and the nearest plant facility (say 500 ft.).

What equipment should be used for low decibels?

This is another concern that the plant design must address. Equipment with low decibel ratings should be selected (e.g. high speed turbo bowers instead of positive displacement or multi-stage centrifugal blowers). The buildings which house such equipment (blowers, pumps etc.) can have acoustic treatment done to the walls. In addition, many of these equipment come with their own acoustically designed enclosures which could be used on the project if possible.

Why should citizens be given tours of plants?

Concerned citizens should be given tours of these plants by members of the PR team so that they are comfortable with the technologies being proposed. Their comments should be heard and addressed in the design and layout of the plant. In other words, these citizens should become a part of the selling team that promotes the need, location, design and other elements of the plant to other citizens, interested groups or skeptics in the community, who were not able to attend tours.

What happens after a wastewater treatment plant meets all permit specifications?

After meeting all permit specifications, clean water is reintroduced into the environment. Although testing is continuous throughout the wastewater treatment process to ensure optimal water flow, clarification and aeration, final testing is done to make sure the effluent leaving the plant meets permit specifications.

What is the process of removing large items from the influent?

Removal of large items from the influent to prevent damage to the facility’s pumps, valves and other equipment .#N#The process of treating and reclaiming water from wastewater (any water that has been used in homes, such as flushing toilets, washing dishes, or bathing, and some water from industrial use and storm sewers) starts with the expectation that after it is treated it will be clean enough to reenter the environment.#N#The quality of the water is dictated by the Environmental Protection Agency (EPA) and the Clean Water Act, and wastewater facilities operate to specified permits by National Pollutant Discharge Elimination System (NPDES). According to the EPA, The Clean Water Act (CWA) establishes the basic structure for regulating discharges of pollutants into the waters of the United States and regulating quality standards for surface waters. Under the CWA, EPA sets wastewater standards for industry. The EPA has also developed national water quality criteria recommendations for pollutants in surface waters. EPA's National Pollutant Discharge Elimination System (NPDES) permit program controls discharges.#N#As an example of expected standards, the Biochemical Oxygen Demand (BOD) of average wastewater effluent is 200 mg/L and the effluent after treatment is expected to be >30 mg/L. It is crucial a wastewater facility meets these expectations or risk stiff penalty.#N#The physical process of wastewater treatment begins with screening out large items that have found their way into the sewer system, and if not removed, can damage pumps and impede water flow. A bar screen is usually used to remove large items from the influent and ultimately taken to a landfill.

Why is wastewater pumped into a secondary clarifier?

Treated wastewater is pumped into a secondary clarifier to allow any remaining organic sediment to settle out of treated water flow. As the influent exits the aeration process, it flows into a secondary clarifier where, like the primary clarifier, any very small solids (or fines) sink to the bottom of the tank.

What is activated sludge?

These small solids are called activated sludge and consist mostly of active bacteria. Part of this activated sludge is returned to the aeration tank to increase the bacterial concentration, help in propagation, and accelerate the breakdown of organic material. The excess is discarded.

What happens if water flows too slow?

If the water flow is too slow, it impacts the process up stream. The solids that fall to the bottom of the clarifier are know as sludge and pumped out regularly to ensure it doesn’t impact the process of separation. The sludge is then discarded after any water is removed and commonly used as fertilizer.

What is the function of an aeration tank?

The primary function of the aeration tank is to pump oxygen into the tank to encourage the breakdown of any organic material (and the growth of the bacteria), as well as ensure there is enough time for the organic material to be broken down.

What is a bar screen in wastewater treatment?

A bar screen is usually used to remove large items from ...