Full Answer

How to maintain the screening water treatment system?

Check and clean the bar screen at frequent intervals. Ensure no large gaps are formed due to the breakage of the screening water treatment. Replace breakage bar screen immediately. Mechanically cleaned screening system to remove larger materials because they reduce labor cost and they improve flow conditions and screening capture.

What type of screens are used in wastewater treatment plants?

Depending on your specific situation, static wedgewire, rotary drum, or step fine screens may be used. Static wedgewire screens are typically used in industrial wastewater treatment facilities and small municipal plants.

What are the steps in the screening of water?

There are few steps in the screening of water. Practically all intakes are screened, even though the screens may be of the simplest type of bar grille. The bars must be quite substantial in size (of about 25 mm diameter) and are normally spaced at 75-100 mm centres.

How does a water intake screen work?

Water passes through the water intake screen while debris and aquatic life remain in the water. Screens may be placed far from the shore for better water quality and lower concentrations of marine life and debris. With no moving parts, passive screens are reliable and easy to maintain.

How do you check a water filtration system?

1:163:47Yes bacteria can be present you fill it up you shake it and you leave it for 48 hours if it changesMoreYes bacteria can be present you fill it up you shake it and you leave it for 48 hours if it changes colors.

What are the 7 stages of water treatment?

They typically consist of several steps in the treatment process. These include: (1) Collection ; (2) Screening and Straining ; (3) Chemical Addition ; (4) Coagulation and Flocculation ; (5) Sedimentation and Clarification ; (6) Filtration ; (7) Disinfection ; (8) Storage ; (9) and finally Distribution.

Can you filter rainwater for drinking?

Rainwater can be filtered for drinking as long as you have a clean catchment surface and you use a proper filter. Water for the whole house can be filtered using a uv filter or quantum filtration system or you can use a gravity filter such as a Berkey Water Filter just for your drinking water.

What are the 4 most common types of household water treatment systems?

Four Common Water Treatment Methods:Reverse Osmosis Water Filtration. Reverse Osmosis is a process where water pressure is employed to force water through a semi-permeable membrane. ... Ultraviolet Water Sterilization and Filtration. ... Filtration. ... Distillation.

What are the 4 main steps to water treatment?

4 Steps of Community Water TreatmentCoagulation and Flocculation. ... Sedimentation. ... Filtration. ... Disinfection.

What are the 5 steps of water treatment?

Public water systems often use a series of water treatment steps that include coagulation, flocculation, sedimentation, filtration, and disinfection.

What is the easiest way to filter rainwater?

How to Filter Rainwater from a RoofStep 1 - Filter the water before it enters the storage tank. ... Step 2 - Oxygenate the water. ... Step 3 - Siphon off any floating particles. ... Step 4 - Fit a moving fine mesh filter before the pump. ... Rainwater Harvesting System Kits. ... Rainwater Harvesting Water Quality Questions.

How do you decontaminate rain water?

Two key steps you can take to improve the quality of rainwater are to boil it and filter it. 1 Boiling the water will kill off pathogens. Filtration, such as through a home water filtration pitcher, will remove chemicals, dust, pollen, mold, and other contaminants.

What is the best way to filter rain water?

To remove the smell and the taste of chlorine in the drinking water, you can use an activated carbon filter or charcoal filter. This system is made of coconut shells, carbon, and other eco-friendly solution. The last method of filtering rainwater is through solar pasteurization.

What is screening in water purification?

Screening is a wastewater pre-treatment, which aims to prevent coarse solids, such as plastics, rags and other trash, from entering a sewage system or treatment plant. Solids get trapped by inclined screens or bar racks.

Which water filter removes the most contaminants?

Reverse osmosis systemsReverse osmosis systems are the most effective filters for drinking water. Many of them feature seven or more filtration stages along with the osmosis process that makes them effective at moving 99 percent of contaminants from water, including chemicals such as chlorine, heavy metals, pesticides, and herbicides.

What water treatment system is best?

The best option for well water is the iSpring 3-Stage Filtration System (model WGB32BM). It uses robust carbon and sediment filters to eliminate organic particles often found in underground wells, like dirt, sand, and rust.

What is bar screen water treatment?

Bar screen and screening water treatment is the first process unit operation used at wastewater treatment plants. Screening removes objects such as rags, paper, plastics and metals to prevent damage and clogging of downstream equipment and piping.Cleaning frequency depends on the characteristics of the wastewater entering a plant.

Why is a mechanically cleaned screening system important?

Mechanically cleaned screening system to remove larger materials because they reduce labor cost and they improve flow conditions and screening capture.

What is electrocoagulation treatment?

The treatment plant is based on Electro-coagulation Treatment. Electrocoagulation system has distinct advantages for the treatment of Textiles industrial wastewater. EC Systems present high efficiency, easy operation and environmental compatibility this process involves generation of coagulants by electrolytic oxidation of a sacrificial anode (iron) by applying a direct current. The most widely used electrode materials in electrocoagulation process are iron. The hydrolyzed iron ions can form long chains of Fe-O-Fe-OH which may chemically adsorb a large amount of contaminants. Screening water treatment with bar screen is very essential for etp.

What is the most widely used electrode material in electrocoagulation?

The most widely used electrode materials in electrocoagulation process are iron. The hydrolyzed iron ions can form long chains of Fe-O-Fe-OH which may chemically adsorb a large amount of contaminants. Screening water treatment with bar screen is very essential for etp.

Why do treatment facilities use automated bar screens?

With that said, the majority of treatment facilities are gravitating towards automated, mechanically cleaned bar screens for the following reasons: They produce a higher screening capture rate. Provide improved flow conditions through the screen. Because they automatically remove solids, manual cleaning is not required.

What is a fine screen?

Fine screens are used to remove particles that may cause maintenance issues for process equipment and/or operational problems to the treatment process. Typically in smaller treatment facilities, fine screens can be used in place of primary clarification. Fine screen openings typically range from 0.06 to 0.25 inches.

What is a static wedgewire screen?

Static wedgewire screens are typically used in industrial wastewater treatment facilities and small municipal plants. Compared to static wedgewire screens, drum screens can handle a large flow rate in a smaller footprint.

Can a rotary screen be externally fed?

Rotary drum screens can either be internally or externally fed. Internally fed drum screens are capable of handling higher flow rates compared to an externally fed drum screen. Step screens (or stair screens) are comparatively a newer technology. Debris is lifted up the screen by means of fixed and movable plates.

Do bar screens need maintenance?

Manually cleaned bar screens require little to no mechanical maintenance, but do require routine cleaning by an operator. If you speak with a wastewater operator who works at a facility with a manually cleaned bar screen, I bet he'll tell you that one of his least favorite job duties is cleaning out the bar screen.

Screen Maintenance Improves Water and Wastewater Treatment Plant Performance

Advances in screening technologies have been driven by the need to protect increasingly sophisticated downstream equipment by capturing and removing floating debris. Routine maintenance can dramatically improve water and wastewater treatment plant system processes.

ISO 9001:2015 Certified

Copyright ©2021 Hydro-Dyne Engineering. All Rights Reserved. | Privacy Policy | Terms of Use

What are the different types of wastewater screens?

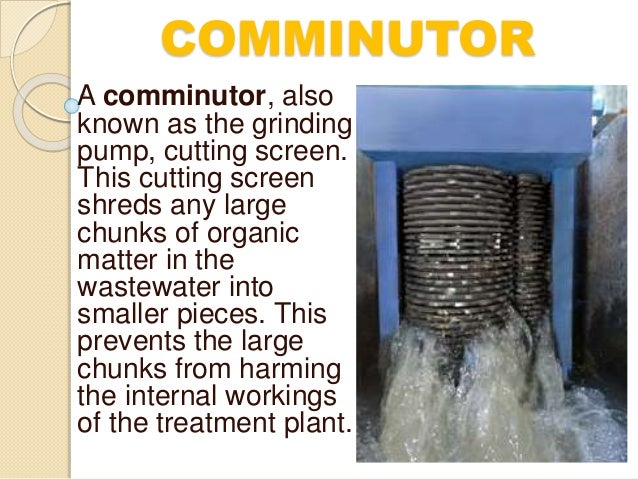

There are different types of wastewater screens which include coarse screens, fine screens, and communitors and grinders (which are typically used at a smaller treatment facility). Screens can be made of a simple trash rack, or can be as complex as a mechanical bar system. There are also hydrocyclone systems which are devices used ...

What are the design elements of wastewater screening?

The design elements that classify screening equipment are size, depth, width, the screen’s angle, approach velocity of the channel, the discharge height, wind and other aesthetic considerations.

What is wastewater treatment equipment?

Our wastewater treatment equipment is efficient in that it screens, washes, compacts and dewaters in one smooth, seamless operation. This equipment is designed to handle wastewater, septage, sludge, scum, and grease. Our equipment offers: 1 Compact design with screening and grit removal in one unit 2 Security control station allows access for authorized haulers 3 All stainless steel construction resists corrosion 4 Available for indoor or outdoor environments 5 Multiple sized units to suit your application 6 Unload up to two (2) waste haulers at the same time

What is hydrocyclone system?

Hydrocyclone Systems – This is a system that separates liquids from solids directly from the wastewater. Heavier grit and suspended solids collect on the sides and bottom of the cyclone, while scum and lighter solids are removed from the center through the top of the cyclone.

What is a bar screen?

A bar screen is essentially a heavy duty screen that uses a reciprocating rake which cleans the wastewater bar screen by pulling out debris. In general, manually cleaned screens will require frequent raking to avoid them getting clogged up.

What is the most important component of a water treatment system?

One of the most important components of a water treatment system is the screen . As discussed, screens come in different sizes, depths, widths, and different designs according to the technology available in the area as well as for your budget. Overall, mechanical screens are commonly used in larger treatment facilities and require lower labor costs.

Can a mechanical screen cause waste?

The time that is taken to clean the screen manually will also detract from the time it is serving its purpose, which can also cause overflow of waste solids. Mechanical screens, on the other hand, aren’t subject to the same concerns, but they do require higher maintenance costs.

OUR QUALITY LEADS TO GREATER PERFORMANCE

You don’t have time to spend repairing, replacing or cleaning your screens. That’s why you need screens that are built to exact specifications and can withstand the rigors of a particular application for a long, long time. When you choose Delta Screens, that’s exactly what you get.

WE KNOW RISK. WE ALSO KNOW HOW TO MINIMIZE IT

By any consideration, be it quality, engineered design, efficiency – whatever your measuring stick of choice, one company stands apart: Delta Screens. Our state-of-the-art manufacturing technologies lead to best-in-class screen performance that you can depend on to perform.

What is passive water intake screen?

Passive Water Intake Screens. Passive screening admits water through the intake point at a low, uniform velocity. Water passes through the water intake screen while debris and aquatic life remain in the water. Screens may be placed far from the shore for better water quality and lower concentrations of marine life and debris.

Why are passive screens placed far from shore?

Screens may be placed far from the shore for better water quality and lower concentrations of marine life and debris. With no moving parts, passive screens are reliable and easy to maintain.

What is a Hendrick intake screen?

Hendrick manufactures T-intake screens with flexible, cost-effective designs. Flow modifiers maximize flow equalization, reduce head loss and minimize costs. For shallow-water applications, we offer a patented* half-barrel intake screen. This screen has the same flow characteristics as the T-intake screens, but it’s designed for shallow creeks and rivers where the full-size version won’t work.

Can a drum screen be installed vertically?

They are also the best solution for installations where there are space restrictions that won’t allow a T-intake style screen to be utilized. Drum screens can be installed vertically or horizontally and can be customized based on a specific project’s intake requirements.

Is Hendrick Screen 316 B compliant?

Hendrick Screen offers various options — such as T-intakes, half intakes, drum screens and flat panels — all designed to be 316 (b) compliant. Additionally, we have an engineering group dedicated to water intake and water treatment screens, thus ensuring you have the right screen for your particular application.

How Does Screening Work?

What Happens After Screening?

- One thing screens cannot capture is the fine sand and grit that finds its way into wastewater. Sand from winter road maintenance, silt from rivers, and other fine materials pass the screens and settle into the bottom of the grit chamber where it can be removed. At this point, there can still be tiny particles. They are processed in a sedimentation tank where they’ll combine to form …

How Big Or Small Are These Water Treatment screens?

- Lakeside Equipment sells Raptor Screening products. Rotary Strainer Screens are in a cylinder that sits horizontally. The wire openings start at 1/10th of an inch down to 1/100thof an inch for fine screening. The Fine Screen can capture solids and organic materials in a cylindrical basket. There’s a Rotating Drum Screen that ranges from 1/4th inch to 1/50thinch in size. We also have t…